The uninterrupted operation of the sewer system depends on the competent selection of components and correct installation of the network. Often home craftsmen install engineering systems on their own and are faced with the primary question: which sewer pipes in the house are better technically and financially.

We will help you sort out this difficult issue. The article we have proposed describes all types of pipes used, listing their positive and negative sides. The material is systematized to make it easier to compare product characteristics, service life, cost and application practice.

No. 1. What are PVC sewer pipes?

PVC pipes are often called simply plastic, which is not entirely true. Plastic pipes are a whole group of products, which can also include polypropylene pipes, cross-linked polyethylene pipes and, in fact, polyvinyl chloride (PVC) pipes. The latter are made from polyvinyl chloride thermoplastic, which also includes special additives that provide additional strength to the product. Pipes from the prepared mass are created using extrusion and retain their shape well.

Depending on the specifics of production, there are two types of PVC pipes:

- pipes made of plasticized PVC (PVC) are characterized by their low price, good elasticity, but cannot boast of high strength. Such pipes for organizing separate sections of sewerage;

- pipes made of unplasticized PVC (PVC-U) are more expensive, but also more rigid, resistant to various external influences, excellent for arranging internal and external sewage systems, and provide sufficient durability of the system. Such pipes can even be used in pressure sewer systems.

PVC pipes are actively used in the construction of internal and external sewerage; they are also used for installing a cold water supply system, for creating drainage systems, and for laying Internet and telephony cables. Such a wide distribution area is a consequence of the huge number of advantages of this type of product.

No. 2. PVC pipes: advantages and disadvantages

Before choosing anything, every sane person weighs the pros and cons. Sewer pipes will be no exception.

Advantages of PVC sewer pipes:

- affordable price . Installing a sewer system using PVC pipes will cost several times less than organizing the same pipeline from cast iron;

- corrosion resistance . Plastic does not rust, unlike cast iron, which means that PVC will allow you to create a more durable sewer system;

- resistance of both external and internal surfaces to aggressive environments;

- high tightness . Since the material is not afraid of corrosion and other negative factors, there is no need to be afraid that the underground pipe will lose its integrity and wastewater will get into the ground;

- the smooth internal surface minimizes the likelihood of pipes becoming overgrown and clogged with fecal fractions;

- resistance to low temperatures . Polyvinyl chloride pipes do not deform even with prolonged exposure to negative temperatures;

- light weight , which greatly facilitates the transportation and installation of PVC pipes;

- sufficiently high strength and environmental safety;

- durability _ Manufacturers talk about a service life of up to 50 years ;

- plastic does not conduct stray currents, and this is another plus in terms of your safety;

- huge selection of pipes of different diameters and length, there are also a sufficient number of adapters and mounting elements, so installing a sewer system from PVC pipes is a relatively simple task.

Not without its drawbacks:

- sensitivity to high temperatures . The maximum operating temperature for PVC pipes is +400C. The products can withstand heating up to +800C, but such effects should be rare and short-term. With prolonged contact with hot liquids, the material loses a number of useful performance qualities and quickly fails;

- PVC pipes behave better than cast iron pipes, but over time, even on their smooth walls, plaque . With regular, albeit short-term, exposure to high temperatures, the pipe begins to turn from round into elliptical. All this together can lead to a decrease in throughput or even the formation of a leak, so it is important to follow the rules during the installation and operation of pipes;

- low fire resistance;

- Despite the fact that manufacturers say that PVC is completely inert to aggressive substances, individual compounds can still gradually corrode the walls of the pipes. To be fair, we note that such connections are not usually found in home sewer systems.

Details

Rules for installing plastic sewerage with your own hands

After the sewerage system is connected, the water supply should be connected. To do this, it is worth drawing a diagram for connecting the elements, and for hot water supply you should leave a technological gap of 1 cm, because plastic expands when heated. Then, when calculating the total length of the line, it is worth calculating how many fastening and locking elements are required. For further addition of new devices, it is recommended to leave several outlets with plugs.

When planning a water supply, you should know that plastic pipes are always gray. They have different markings:

РN25 – heating.- РN20 – hot water and heating.

- РN16 – cold and hot.

- РN10 – only for cold water.

Where the water temperature is less than +600 degrees, PN10 and PN16 are suitable, and if higher, then the rest, since they are reinforced. To save time and also ensure control over the condition of the water supply network, it is better to use an open connection method. Pipes should be installed at floor level, in the corners of the rooms.

The typical (and most simple option) option is a consistent water supply to all consumers. To carry out repairs without shutting them all down, you need to install a shut-off valve in front of each one. When the elements have been purchased and the tools have been prepared, all that remains is to decide on the installation of plastic sewerage with your own hands. According to the diagram, it is worth cutting sections of the pipe with special scissors.

They are fastened together by welding or fittings, and the technology is simple:

- Cleaning is carried out, and then the ends need to be degreased.

- It is worth choosing nozzles of the required diameter for the soldering iron, and also heating it.

- Insert the elements for connection and wait (the time is determined by the cross section of the products).

- After the welding process, the elements should be fixed until they cool completely.

Structural elements are fixed to the walls with clips. The risers are secured with a rubber gasket and a clamp. Additional elements, such as meters and valves, have a metal threaded connection, and it is also sealed with tow. Professional craftsmen prefer to use fluoroplastic sealing material. With a little experimentation, each master will be able to independently connect a plumbing system that will work like a clock.

Process Features

There is a relatively new device that was able to combine the properties of polymer and metal pipes. In some ways it resembles a layer cake - glue, polyethylene, aluminum, more glue and polyethylene. The performance properties are excellent - at a pressure of 9.8 atm they can withstand temperatures of +960 degrees, and with short-term overheating up to +1350 degrees. Such pipes are resistant to frost, easily retain their given shapes and can even be bent by hand. They are used in the transportation system of gases, liquids, heating systems, as well as in heated floors and air conditioning systems. The connection diagram is the same as for polypropylene pipes. But due to the fact that they are more susceptible to mechanical stress and the influence of ultraviolet radiation, it is important to install them inside special boxes, floors and walls. Special fittings are produced for fastening:

- Compression (for clamping).

- Detachable.

- Press fittings (for press jaws).

Installation does not require expensive equipment or special education. When assembling the water supply system with your own hands, you should know that the connection with press fittings is permanent, and it can also be “packed” inside the walls or floor. The first two types can be placed in special boxes so that there is access in the event of an emergency.

Installation of heating pipes

The main problem that the master solves when installing a new heating system is connecting plastic pipes to metal ones.

Industry makes it possible to do this:

- Section up to 4 cm (fittings with threaded connections are available).

- From 4 to 30 cm (flange).

The working instructions are similar to connecting polypropylene pipes.

No. 3. Main types of PVC sewer pipes

Polyvinyl chloride pipes are used for laying internal and external sewage systems and are used under various conditions, so manufacturers offer us several types of products that differ not only in performance, but even in appearance.

The following types of pipes are used for sewerage installation:

- hard gray pipes used for laying internal sewerage. The wall thickness varies from 1 to 3.2 mm, the diameter - from 32 to 160 mm, and the length of the segments - from 0.3 to 3 m;

- hard orange pipes Designed for laying the outer part of the sewer system. The diameter of such products ranges from 110 to 500 mm, length - from 1.2 to 3 m, and the walls have a thickness of 3 mm. These pipes are strong enough to withstand the load of soil. They have a small coefficient of expansion, so they are not able to deform greatly even with a significant temperature difference. The individual sections are connected to each other using a socket method;

- corrugated sewer pipes gray in color and small in diameter, used to connect washing machines and dishwashers to the sewer system. Two- and three-layer orange pipes are used for arranging external sewage systems. They are quite strong and elastic, can withstand decent loads, and can be mounted to a depth of up to 15 m. Such strength qualities are achieved due to the presence of numerous stiffening ribs. Corrugated pipes are also used for laying storm sewer systems and arranging drainage pipelines.

Calculation of wastewater volume

In order for the water drainage system to operate as efficiently as possible, it is necessary to accurately calculate the average amount of precipitation falling in a particular area during the month.

To do this, you can use the formula taken from SNiP 2.04.03-85: Q = q20 x F x Ψ

Here the indicators are the following data:

- Q - average volume of rain or melt water that will need to be drained from the site;

- q20 is the intensity of rain or snow precipitation in a specific region of Russia. The data is recorded in SNiP tables for each specific area;

- F is the total area of all roofs and platforms from which storm or snow wastewater will be drained;

- Ψ is the correction factor, which allows you to achieve the most accurate calculations of the average volume of water for disposal. This indicator completely depends on the type of coating from which the liquid will be drained.

The coefficient indicators are also specified in the tables of SNiP 2.04.03-85 and have the following wording:

- Roofs of any type - coefficient is 1;

- Asphalt platforms and paths - coefficient 0.95;

- For sites and objects made of concrete - the coefficient is 0.85;

- For crushed stone with bitumen admixture - coefficient 0.6;

- And for simple crushed stone in its pure form - 0.4.

Thanks to the use of this formula, it is possible to calculate as accurately as possible the volumes of rain or melted snow water that will “attack” the object in each season.

No. 4. Strength class of PVC sewer pipes

The strength class of a PVC pipe tells you how much load a PVC pipe can withstand. This information is most necessary when it comes to pipes for arranging external sewerage. The strength and resistance of the pipe to external pressure show to what depth it can be buried without fear for its integrity.

There are three strength classes of sewer pipes:

- light pipes ( SN2) can withstand pressures up to 630 Pa and have a wall thickness of up to 2.3 mm. Such pipes are used inside an apartment, buried to a shallow depth (up to 2 m), and where large loads are not expected, for example, under a lawn, flower bed, pedestrian area and other places where there is no traffic load;

- medium-heavy pipes ( SN4) have walls 2.5-12.3 mm thick, withstand pressures of 600-800 Pa, can be safely used for laying under a road section with a light load, depth 2-6 m;

- heavy pipes ( SN8) with a wall thickness of 3.2-15.3 mm can withstand a load of 800-1000 Pa, designed for laying under roads with heavy traffic and buildings. Maximum depth – 8 m.

In the most difficult areas, it is naturally better to use unplasticized PVC pipes, which can withstand pressures of up to 1.6 MPa.

Procedure for replacement

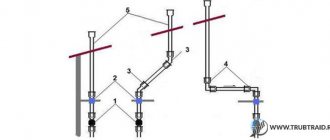

Let's look at how to replace a cast iron sewer with a plastic one. The main difficulty of the procedure is replacing the riser. Most often it is necessary to replace the vertical part of the system in one apartment. This is a rather complex and responsible procedure. It is necessary to carefully remove a section of the old riser, and then insert a vinyl fragment in its place. At the same time, it is important not to collapse the upper part of the old assembly, otherwise you will have to restore everything at your own expense.

If it is necessary to completely replace cast iron sewer pipes with plastic ones, remove all old parts of the system. Work begins from the top floor, gradually going down. This option is considered the simplest. Sequential dismantling is carried out, after which the assembly of system elements begins from below. The main labor costs come from disassembly, since the old elements were connected very reliably. Connecting PVC nodes is not difficult and is done very quickly. First, the riser is installed, and a tee is attached at the required height to drain the horizontal line. Assembly begins from the riser and continues until the very last plumbing fixture.

Sometimes the riser is not touched. All you need to do is replace the cast iron sewer tee with a plastic one. This is done in cases where the vertical part is still relatively new and can stand for a long time. Then only the tee (or crosspiece, if the system configuration is complex) is changed. To connect dissimilar elements, special rubber adapters are used.

All sizes are available for sale. Finding an adapter is not difficult, you just need to know the diameter of the metal pipeline.

No. 5. Pressure and non-pressure sewer system

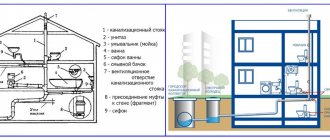

Pressure on pipes can be exerted not only from the outside, but also from the inside. Depending on how the drain is organized, the pressure will be different. There are non-pressure sewer systems , where wastewater moves by gravity. The sewage system in an apartment works in a similar way. Water drainage is also organized in a private house when the site is on a slope. Effluent moves through main sewer pipes under pressure. In a flat area, wastewater will also have to be forced to the septic tank. In this case, you cannot do without pressure equipment , the operation of which will subject the pipes to additional stress.

The type of sewer system affects the choice of PVC pipes:

- For non-pressure internal sewerage, pipes with a wall thickness of 1.8-3 mm are suitable; plasticized pipes are used. For non-pressure external sewerage, pipes with a wall thickness of 3.2 mm (for a diameter of 110 mm) to 12 mm (for a diameter of 500 mm) are taken;

- pipes for pressure sewerage made from unplasticized PVC. Such products, depending on the wall thickness, can withstand pressure of 0.8-1.6 MPa. Wall thickness varies from 2.2-6.6 mm for a pipe with a diameter of 90 mm to 12.3-23.9 mm for pipes with a diameter of 500 mm.

How to test

The wiring of the internal sewerage system is represented by different units that are subject to testing before launch:

- Outgoing pipe.

- Local sections on a horizontal pipeline with inflowing plumbing pipes.

- Sewer risers.

- Place where plumbing fixtures are connected to drain pipes.

- Plumbing fixtures.

Representatives of each party directly participating in the tests and signing the final verification report are responsible for inaccuracies and shortcomings. In accordance with current state standards, before launching, the pipe network is checked for strength, as well as fastenings are tested for 100% tightness. They also check the compliance of the placement of all installed devices and the outlet pipeline with the applicable design documentation, the correct installation of all plumbing fixtures and the presence of the required slope.

No. 6. Size of PVC sewer pipes: diameter, thickness, length

Selecting the diameter of a sewer pipe is a matter of increased importance. If you take fewer pipes than required, they will not provide sufficient throughput. What this means is probably not worth explaining. At best, the wastewater will not drain well, at worst, it will begin to leak out in some places. In fear of facing similar consequences, many decide to play it safe and take pipes with a diameter significantly higher than required. Efficiency compared to pipes with the correct diameter will increase slightly, but the costs and area that needs to be allocated for these pipes will increase significantly.

Before you go shopping, you need to draw up a diagram of the sewer system and mark on it all the liquid drain points. The more drainage points there are, the larger the drain pipe should be. However, when choosing pipes, it is necessary to take into account not only their diameter, but also their length, as well as wall thickness .

To correctly select the diameter of a PVC sewer pipe , it is ideally necessary to calculate the expected volume of wastewater, but often this calculation is neglected, using parameters tested by millions:

- pipes from the shower cabin, bathtub, washbasin and bidet can have a diameter of 40-50 mm;

- for a kitchen sink – 32-50 mm;

- for a toilet – 110 mm;

- for dishwasher and washing machine – 25 mm;

- central riser – 110-160 mm;

- pool – 200-300 mm.

The diameter of the sewer pipe that leaves the apartment must be no less than the diameter of the common main. For houses up to 5 floors these are pipes with a diameter of 110 mm, for taller buildings - 160-200 mm. External sewerage cannot have a diameter of less than 110 mm, which must be remembered when arranging the sewerage system of a private house. As a rule, in summer cottages and country houses, pipes with a diameter of 110-200 mm are used to equip the external part of the sewer system. If a sewer system is being built to serve several houses, it is better to take a larger diameter - about 315 mm. Pipes with a diameter of 630 mm are suitable for arranging a main sewerage section to serve a small village.

The wall thickness depends on the loads on the pipes. For internal free-flow sewerage, pipes with walls of 1.2-2.2 mm are suitable. They have a diameter of up to 110 mm and belong to strength class SN2. SN4 pipes are most widely used. They are used for arranging both external and internal sewage systems. Such pipes with a diameter of 50 mm have walls of 2.6 mm, and with 110 mm – already 3.2 mm. Suitable for organizing a common house riser, as well as external non-pressure sewerage in a private house. If you need to equip a pressure sewer system, it is better to take pipes with the thickest walls possible (class SN8). With a diameter of 90 mm, the wall thickness is 3-6.6 mm.

The choice of length depends on the length of the pipeline. It is better to reduce all connections to a minimum, but you should not buy excessively long pipes - it is economically unprofitable and inconvenient. Usually PVC pipes are sold in lengths of 0.5 m, 1 m and 2 m , but you can find products 3 m and 0.3 m . Some manufacturers offer pipes with a length of 6 m and even 12 m; they are convenient for installing external sewage systems.

Remember that the junctions of individual sections are the most dangerous, so try to carry out the installation so that there are as few connections as possible. A competent preliminary calculation will help here. If necessary, the length of the pipe can be reduced using a hacksaw.

Using PVC pipes, you can assemble a sewer system of any complexity. Not only different pipe diameters come to the rescue, but also all kinds of adapters, rotary bends, tees, crosses, reductions, plugs, etc.

With your own hands

Let's look at how to replace a cast iron sewer with a plastic one with your own hands. The most difficult option is to dismantle part of the riser in an apartment building. A support structure will need to be installed. On which the upper part of the riser will be suspended after removing the defective fragment.

Procedure:

- using a grinder and a cutting disc, make two cuts in the metal pipeline at a distance of 10-15 cm from each other;

- A wedge or chisel is inserted into one of them. By hitting them with a hammer, they break out a section of the riser;

- a supporting structure is placed under the upper part. It can be an ordinary board, but it is better to make a clamp and hang the riser on the wall. This is an important point, since cast iron pipes are self-supporting and may not be fixed anywhere. If they are not supported with something, the entire riser may collapse;

- the lower part is dismantled, a tee is installed, and the remaining sections of the riser are assembled. It is recommended to insert a section with an audit in order to be able to clean the system from your apartment;

- After connecting the new section with the old one, begin assembling the horizontal section.

Before replacing a cast iron sewer with a plastic one, you need to notify your neighbors about the upcoming work. Otherwise, sewage from the apartments on the upper floors will flow into the toilet. Organizing such events is one of the most difficult aspects. Not everyone can be found at home, so you need to post a notice in the entrance in advance. It is necessary to soberly assess your capabilities. The riser belongs to the common property of the house. If difficulties arise during the work, restoration will be done at the expense of the person causing the problems.