SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

A mandatory accessory of any comfortable home is a cistern and the toilet flush mechanism included in its kit. The latter most often fails, which leads to the creation of uncomfortable conditions when visiting the bathroom. In order to encounter this problem less often, you should correctly select, install and configure the drainage mechanism. This article will help you deal with this issue.

In order for the drain mechanism to perform its functions efficiently, it must be installed and configured correctly.

How the toilet cistern works: the internal filling of the device

The normal operation of the drainage system is ensured through the interaction of its individual components. The water supply to the container is carried out thanks to the fill or inlet valve for the toilet. It is represented by a threaded pipe that is inserted into a hole in the side wall or bottom of the tank. The presence of a thread allows you to press the element to the tank wall using nuts, which will ensure a tight connection. Control over the opening and closing of the hole through which water enters is carried out by a locking mechanism connected to the rocker arm.

The principle of operation of the flush mechanism in the toilet cistern

The rocker arm is the lever that moves the exhaust valve. The free end of the element is attached to a float or control valve. A float is a plastic sealed container with air inside. At the moment when the float floats up or the shut-off device is activated, the rocker arm rises, which helps to close the gap in the filling valve or vice versa.

In normal condition, the drain hole is closed by the drain valve. This is a flat or hemispherical elastic gasket that connects the load-bearing part to the hinge mount.

The operation of the drain mechanism for the tank is controlled by a push-button or lever mechanism, which is located in the upper part of the tank. When exposed to it, its load-bearing part rises, opening a hole for water to flow at high speed into the toilet bowl.

All components of the mechanism can be arranged in different ways. In older models of tanks, the flushing and water overflow control mechanisms were mounted separately. In modern models, shut-off valves are presented as a single complex, which facilitates easy installation and configuration, while at the same time complicating repairs.

Water is supplied to the tank capacity through a fill or inlet valve

What are the drainage mechanisms?

All you need to do to flush the toilet after visiting the toilet is to press the button on the tank. Then the entire mechanism works independently: the water drain valve opens via the drain valve. After this, the contents of the tank flow into the bowl, washing away all feces and sewage with its flow.

The toilet flush mechanism can be activated in several ways:

- By pressing a button.

- Focus on the lever.

- We pull the chain.

The configuration and design of the cistern varies. Typical containers have a standard volume of 6 and 4 liters, equipped with holes for water inlet of standard diameters. Siphon mechanisms for toilet cisterns are available in several varieties. They are installed quite simply, so if the indoor unit breaks down, it can be replaced without any problems.

How a toilet flush mechanism should work

The flush mechanism for the toilet is located inside the tank. It does not have a complex design, but it performs important functions. The drain mechanism is responsible for draining water from the tank, filling the container with water, and controlling the water level, which eliminates the possibility of the tank overflowing when the liquid reaches a certain level.

The principle of operation of the drain tank is as follows. Water enters the container through a fill valve, which may be located in the wall or bottom of the tank. As the container fills, a shut-off device in the form of a float or valve is activated, which shuts off the supply of liquid when it reaches a certain level, blocking the filling valve.

When it becomes necessary to flush the water, the button or lever is pressed, which opens the shut-off valve of the toilet cistern. As a result, liquid enters the toilet bowl. Double button systems work similarly. When the small button is pressed, part of the water is poured out of the tank, when the large button is pressed, a complete drain is performed.

Important! The flush mechanism of the toilet tank with a button for two modes ensures water saving.

Water can enter the tank through a valve located in the bottom or wall

Draining the water entails a decrease in the liquid level in the container. This helps activate the control devices, as a result of which the outlet valve opens and the tank fills with water.

What is included?

Any toilet tank includes a set of several components:

- Drain mechanism. It is a closed siphon connected to a pipe using a sealing rubber gasket.

- Float that regulates the water level. It is connected using a spoke to the main mechanism.

- Lever responsible for water supply. The structure is connected to the water supply using a ball valve.

The principle of operation depends on the type of fittings installed for the tanks. The most common among them are flush cisterns, which are installed on the toilet itself, although noisy hanging structures have recently been common. Let's look at the types of cistern fittings and the most important differences in more detail.

Types of drain fitting design for toilet cistern

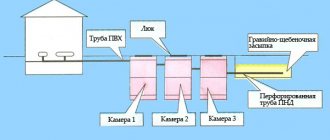

There are several options for the drainage system. The filling valve can be bottom or side mounted. In the first case, the pipe is located in the bottom of the drain container. This system includes a vertical rod float, a rod and a buoy. The last two elements are connected into a common structure, which acts as a water limiter.

When the tank is empty, the float lowers. At this moment, draft begins to act on the toilet valve, opening it. When the float reaches a certain level, the valve closes. Sealing of the system is ensured by a pair of gaskets.

When placed on the side, the pipe with the valve is inserted into the tank through a side hole, which is located in the wall of the container under the lid. This gap is made conditionally sealed, since water does not reach it. In this design, the control mechanism of the flush tank is placed horizontally. It consists of a shut-off device, a float, a lever and a filling tube. When the tank is emptied, the float lowers, which moves a rod that opens the shut-off valve. When the tank is filled with water, the control mechanism gradually rises.

In a side-valve design, the mechanism is located horizontally

From the point of view of efficient and comfortable operation of the drainage device, it is better to choose models with a bottom connection, which are more reliable and make less noise when the container is filled with water. Systems with side connections are characterized by ease of installation and ease of adjustment and repair work.

Important! Tanks with bottom connections require close attention to the tightness of the connection.

The flush mechanism is activated by a trigger, which can be a lever, a rod or a toilet button. Older models were equipped with a lever to which a cord with a handle or a chain was attached. The drain system with a rod was activated by lifting the handle up. This option has also lost popularity and is rarely found in modern tanks.

Bottom-mounted designs are more reliable

Currently, models are most often controlled by pressing a button located in the tank lid. The push system, in turn, can be one-button or two-button. In the first case, the tank is completely emptied when you press the button. The second option involves two modes of operation of the tank drain mechanism with a button. The first ensures that half the volume of the container is drained, and the second ensures that the tank is completely emptied.

Types of toilet flush valve as a system overflow control mechanism

The toilet cistern flush valve can be a float or membrane shut-off device. Models of the first option may differ in structure and principle of operation. Old tanks were equipped with Croydon valves, which consisted of a body, piston, axle, seat and float lever. When the float lever was acted upon, the mechanism began to function. In this case, the piston moved vertically.

Most modern drain mechanisms are equipped with a piston valve, which moves horizontally when the lever is pressed. The water supply is regulated by the contact of the piston and the seat. When the container is filled, the inlet hole is closed using a gasket located at the end of the piston.

The diaphragm valve is not equipped with a piston gasket, but with a rubber or silicone membrane. When a lever acts on it, the plastic piston begins to displace the membrane, which closes the water supply.

The drain valve can be equipped with a membrane or float mechanism

Important! The diaphragm valve facilitates quick and silent filling of the tank.

The disadvantage of this element is the greater sensitivity of the product to dirt and the presence of impurities in water. The diaphragm valve will quickly lose its operational properties due to poor quality water in the system. A mechanical cleaning filter will help avoid problems.

There are floatless options for the drain system. The water supply to them is stopped due to the presence of a special chamber shaped like an inverted glass.

Material for making toilet flush valves

Expensive models of toilet flush systems are made of bronze or brass. These materials are characterized by strength, reliability, corrosion resistance, and the ability to withstand mechanical and chemical loads. The design can be either simple or complex. Metal filling is found in expensive collectible models, which are produced with a certain stylization.

Most drain valves are made from polymers

In other cases, bronze and brass can be used in the manufacture of only the fill valve, which makes the shut-off and drain system universal, easy to install, configure, repair, and allows you to replace each unit individually.

Many valve models are made from polymers. The quality of plastic and precision of production affect the cost of the product. The more expensive the fittings, the more reliable and durable the drainage system will be. However, there are high-quality models that have an affordable price.

How to choose the right toilet parts

If elements of the drain system fail, it is important to choose the correct option that will correspond to the factory configuration. The units may differ in the material they are made of. Products made of bronze and brass are considered the highest quality and most durable. However, they are characterized by high cost.

The repair kit for the toilet is selected based on the model of the tank. Important parameters are the location of the inlet, its size, the diameter of the drain opening and the overall dimensions of the device, which must fit freely into the tank. The flush mechanism for a toilet can be represented by a single design or consist of separate (drain and fill) devices. The second option significantly facilitates and simplifies the process of replacing products.

If elements of the drain mechanism break down, the repair kit is selected based on the model of the tank

When choosing a valve, you should pay attention to the quality of the product. The mechanism must operate under its own weight. It is necessary that all its components are movable, move smoothly and unhindered. There should be no jamming of any kind.

When choosing a drain mechanism, you should carefully inspect the elements. They must have a solid body, free from chips and cracks, and the correct geometric shape, which will contribute to efficient and uninterrupted operation. Spare parts for toilets made from high-quality material have a high cost.

Seals and gaskets should be purchased from silicone. Such products, unlike rubber ones, are characterized by strength, reliability and durability. Elements are checked for compression and bending. They should not be deformed or cracked.

Helpful advice! The best performance and strength properties are provided by sealing elements, in the manufacture of which rubber is added to enhance elasticity.

New mechanism parts must be of high quality, without chips or cracks.

Additional recommendations for choosing a toilet

Having decided on the main parameters for choosing a toilet, you should not forget about secondary, but at the same time important factors.

Firstly, the material from which the toilet is made. The most common are earthenware and porcelain. Both materials are based on clay. Earthenware is not durable: over time, cracks appear in the bowl and the surface becomes stained. Porcelain surfaces are stronger, denser and smoother. Dirt practically does not accumulate on them. You can also select toilets made of ceramics. They are attractive in appearance, but the level of strength and durability leaves much to be desired.

Toilet bowl made of sanitary porcelain

Secondly, the degree of comfort. When choosing, it is recommended to “try on” the toilet and trust your feelings. Staying on the toilet should not be constrained; the abdominal and pelvic muscles should be completely relaxed.

Thirdly, the shape and color of the toilet. These parameters do not in any way affect the functionality of the plumbing fixtures, but they play a very important role when choosing. The market offers many shapes and colors of toilets: from traditional to exclusive and unusual. Here you should be guided only by your own preferences and the general concept of the bathroom.

Plumbing in unusual colors

A person spends a total of about five years of his life in the toilet, so choosing the right toilet is very important. A comfortable toilet with a good flush without splashing will make visiting the toilet not only comfortable, but also hygienic.

Tornado flush system: video

Choosing a toilet: photo

Dismantling and installation of the flush mechanism for the toilet cistern

If the drain mechanism fails, you can replace it with a new repair kit yourself. Replacing the flush mechanism in the toilet cistern is carried out according to the following algorithm.

Related article:

How to choose a toilet: main criteria and features of various models

Review of the 5 most popular manufacturers and models. Common breakdowns and ways to fix them.

The first step is to turn off the water supply. Next, press the drain button to empty the tank. It is carefully removed, which makes it possible to remove the tank lid. Then the water supply hose is disconnected. The nut that secures the filler pipe is unscrewed. You need to remove the part itself from the hole.

Helpful advice! Before changing the flush mechanism in a toilet cistern with bottom water supply, it is recommended to install a small container under the plumbing fixture into which the water that does not go down the drain will drain.

The internal fittings are removed from the tank and unscrewed from the fasteners. Next, unscrew the bolts securing the tank to the toilet bowl. The container is removed. After this, the lower part of the drain system is dismantled and the sealing gaskets are removed. After disassembly is completed, it is necessary to clean the inner surface of the tank and all its openings, remove plaque, debris and lime deposits.

After removing the internal fittings, it is necessary to unscrew the bolts securing the tank and toilet

Installation of the drain mechanism involves the reverse sequence of work. The lower part of the drain system is inserted into the hole, and sealing gaskets are attached. Next, install the flush cistern on the toilet and secure it with fastening bolts.

Important! If corrosion has formed on the old bolts, the elements should be replaced with new ones.

The internal part of the flush mechanism is installed in the toilet siphon. The fill valve should be inserted into the gap in the bottom or side wall of the tank, securing it with a nut and sealing gaskets. A water supply hose must be connected to the outlet pipe. The water is turned on and the system is checked for functionality.

If all elements are installed correctly and the joints are securely sealed, then there will be no leaks.

The filling valve is inserted into the side wall of the tank or into the bottom

Toilet design features - which is best?

The quality of the flush is determined not only by the nature of the water movement, but also by how much the bowl gets dirty during use. And here a lot depends on its shape. Let's discuss the existing options.

Visor bowls

For a long time, this form of toilet was considered classic. From the inside, the bowl looks like a sloping slide with a convex surface, the drain hole (siphon) is located in the front part. Sewage falls right on that very slide, so such a bowl usually gets very dirty and the user has to clean it up with a brush.

Toilet bowl shapes

Funnel bowl

Wanting to make life easier for the user, manufacturers moved the drain hole directly under it, that is, almost to the center of the bowl. Now the impurities fall directly into the water and the cup remains unstained.

One could celebrate the victory, if not for an annoying circumstance: the user may be doused with a not-so-clean fountain.

If you decide to buy a funnel-shaped toilet, give preference to models with an anti-splash system. Here are their distinctive features:

- the vertical distance from the side to the water surface has been increased;

- The diameter of the drain hole is reduced.

The drain hole is equipped with a special rim.

The type of toilet outlet is selected depending on how the sewer pipe is laid. A toilet with a vertical outlet to the floor is not the most popular modification, but it has its advantages.

See instructions for assembling the toilet here. Materials and tools necessary for work.

Tiled flooring is the most common in bathrooms. Installing a toilet on tiles requires a careful approach. Using this link https://aquacomm.ru/cancliz/mnogokvartirnyie-doma/santehnika/montazh-na-kafel.html we will reveal all the nuances of installing a toilet on tiles.

Disc bowl

In such a toilet, instead of a sloping slide, there is a platform, which is also called a “shelf”, “step” or “springboard”, and the drain hole, as in the canopy structure, is moved forward. Devices of this type are especially popular in hospitals, as they allow visual monitoring of the condition of excrement or selecting it for analysis.

Most users consider this form outdated and extremely unsuccessful.

It is argued this way:

- while feces lie on the “step”, they manage to fill the room with an unpleasant odor;

- During flushing, the water, moving like a ski jumper, can splash the user.

Toilet with shelf

However, on the Internet you can find many positive reviews about toilets of this design. The authors of these messages draw the attention of readers to the following advantage: the bowl does not get dirty, since the sewage ends up in a small puddle on the “step”; in this case, no splashes are observed, as is the case with a funnel-shaped toilet.

As for splashes during flushing, to eliminate them you just need to adjust the drain. Fans of such toilets are extremely upset that they have become a rarity today, and refer everyone to the catalogs of the Russian sanitary ware manufacturer Santeri.

Testing the toilet flush system after installation

After installing or repairing the toilet cistern flush mechanism with a button, the system is tested. The first step is to check that there are no visible leaks. To do this, you need to run water through the plumbing fixture several times. Water should not flow into the toilet bowl unnecessarily, and you should also make sure that there are no leaks underneath. If they are detected, it is necessary to fix the fastenings as firmly as possible.

Next, it is checked whether the water level in the tank has reached the required level. If this does not happen, the toilet tank is adjusted. The filling valve should work normally and not stick. You can verify the quality of its operation by applying sharp downward or upward pressure to the mechanism.

Next, you need to evaluate the operation of the system by ear. If there is a hissing, whistling, or other sharp sound, this indicates that the flapper valve is closing. The problem is resolved by lowering or raising the element using a screw, which is driven by a screwdriver.

To ensure normal operation of the system, the water level in the tank is adjusted. The float, which is held in place by a thick wire, should be placed so that it is located 1-2 cm below the edge of the reinforcement. To gain more water, the metal lever needs to be bent in an arc downwards. To reduce the liquid level, the product is bent in the opposite direction.

After installing the drainage system, it must be tested

If the float lever is made of plastic, its adjustment is carried out by a special screw, which rotates until the float takes the desired position. The optimal level of liquid in the tank is considered to be at which the water will be 3 cm lower than the overflow hole.

The correct position of the buoy indicates that water does not overflow through the system and does not go into the toilet bowl unnecessarily. After adjustment, the lid is installed on the tank and secured with a button.

Installation and adjustment of the exhaust valve

The flush valve mechanism is designed to supply water to the toilet. Manufacturers produce many different device configurations.

For example, for the economical use of water, a two-level fitting has been developed in which the drainage can be complete or partial. Single-level devices are sometimes equipped with a “stop” system, which stops the draining process as soon as the button is released.

When purchasing a device, you need to pay attention to the material from which the locking gaskets are made.

If previously domestic manufacturers used only rubber, now they are increasingly made from silicone. This material has no mechanical memory and is not deformed.

Silicone and rubber gaskets and a conical lip on the valve seat provide multiple protection factors and prevent valve leakage

Installation of fittings step by step

If the flush mechanism is broken or outdated, there is no need to change the toilet tank - you just need to replace the faulty element.

Do you want to replace your toilet cistern with a new one? Detailed replacement instructions are provided in our other article.

Even if the toilet model is outdated, the manufacturer produces a new, but suitable device. It is better, of course, that the tank and shut-off valves belong to the same brand.

The water flush valve kit includes a flush valve, a sealing gasket, an adapter ring, fastening the tank to the toilet, as well as detailed installation instructions

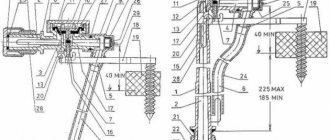

Next, the installation of a drain valve will be shown using the example of a device for a dual-mode drain with a cable. Install the tank on the toilet. To do this, put gasket 14 on the base of valve 12.

You may also be interested in information about choosing and replacing the gasket between the toilet and the tank.

Schematic representation of the valve components. Knowing the structure of this device, it is easier to configure and adjust it

The valve is installed in the hole of the tank and the nut 15 is tightened from the outside, onto which the gasket 16 is then put on. It will ensure the tightness of the connection.

Bolts 13 are installed in the mounting holes in a certain sequence.

It is important to maintain the sequence of fastening bolts 13 and do not forget to attach them intermediately to the tank

Install the cable mechanism. Its end is secured in the rocker arm 8 so that the plastic casing is wound in all the way.

Then lower the body of the drain valve 9 into the base 12 and secure it by turning it to the right. Check that the device does not touch the walls of the tank and the intake valve mechanism.

Before installing the cable mechanism, check that the cable is securely fastened in the holder. If it comes loose during transportation or installation, it must be secured.

Next, adjust the height of the overflow tube 7. To do this, you must first turn it clockwise to remove it from the lock. After setting the required height, it is locked again by turning it counterclockwise.

When the tube height is correctly adjusted, the water filling level should not rise closer than 20 mm to the edge of the overflow tube.

The edge of the overflow tube, in turn, if there is a side hole in the tank (for connecting to the water supply), should be 10 or more millimeters below it.

Next, attach the push button to the tank lid. A special holder is designed for this. Connect the button to the cable so that it does not twist and does not cling to the filling valve. In tanks with a non-standard opening, an adapter ring is used.

If necessary, you can adjust the water filling level in the toilet cistern using the inlet valve settings.

In a correctly installed device, the valve ring, when the button is pressed and released, should fall freely and tightly close the hole for draining the water. If this does not happen, then you need to adjust the length of the cable by rotating the regulator

Adjusting the water drain

You can change the volume of remaining water after complete drainage using regulator 10 on the toilet valve body.

To increase the balance, it is raised; to decrease, it is lowered. You can adjust the valve so that the water completely drains from the tank by lowering the regulator all the way down.

To adjust full or partial drainage, manufacturers provide an adjustment mechanism that allows you to set the required volume of flushed water

The small drain is regulated by a similar principle. But still, there are some differences. In some models, the adjustment lever is freely accessible; in others, the lever must be unlocked by turning to the right.

And then, when you raise the lever, the drain volume will decrease, and when you lower it, vice versa.

If the drain tank overflows, you need to adjust the overflow tube. To do this, just like during installation, you need to turn it clockwise and set the required height. Then it is fixed back by turning it in the opposite direction.

After installation and adjustment, the functionality of the system is checked - the small and large drain buttons should perform their functions.

When you press the small button, the small flush should be triggered, the large one should empty the tank almost completely, depending on the settings.

Different valve models can be configured differently, but the general meaning of the settings remains the same - it is based on the principle of operation of the system

You may also find useful information on how to properly disassemble the drain tank.

Possible system malfunctions and ways to eliminate them

Studying the principle of operation of the toilet will help identify possible malfunctions and eliminate them. If the overflow control does not work, you need to find the reasons that caused the damage to the system. The most common may lie in the misalignment of the lever or rocker arm that holds the float. It must be aligned, which will ensure the correct movement of the float and the restoration of the system.

For toilet flush systems with a membrane valve, when the element moves to the upper position, the hole may remain open. In this case, the position of the membrane is adjusted or replaced. The reason for the failure of the overflow control system may be perforation of the float with water ingress. This problem requires a complete replacement of the element. If the above operations do not resolve the malfunction, it is necessary to replace the inlet valve.

There are many reasons for a malfunctioning tank drain system.

A leak at the fill valve occurs primarily as a result of wear on the sealing gasket. In the early stages, the problem can be eliminated by tightening the fastening nut. In advanced cases, you will need to replace the gasket.

If the drain button does not work, the cause may be a misalignment of the lever that connects it to the drain valve. Such a malfunction may occur due to the breakdown of plastic elements of the internal fittings. In this case, replacement of the drain mechanism is required.

During the initial operation of the tank, problems may arise as a result of incorrect adjustment of the system. To ensure its functionality, it is necessary to select the height of the drain cup corresponding to the height of the tank, fixing it in the correct position.

If weak pressure is observed while filling the tank at normal pressure in the general system, the water supply hose is dismantled, cleaned, and lime deposits that have blocked the lumen are removed. If cleaning cannot be done, the hose is replaced with a new one.

A misaligned lever may cause the button to not operate.

If the problem is not resolved, you need to inspect the intake valve and check its functionality. To do this, open it, clean the inner chamber and adjust the overflow system. If the problem persists, the valve must be replaced.

List of nodes

How does a toilet cistern work?

Regardless of its type and age of the structure, two main components can be distinguished.

- The fill valve is responsible for filling the container with tap water . The task of the unit is to measure the required amount and, when the desired level is reached, reliably cut off the tank from the water supply.

However: a toilet without a tank is also possible. The drainage system is a metering valve connected directly to the water supply. This scheme is workable if the diameter of the line and its permeability are large enough to provide an acceptable pressure during drainage and not cause a critical drop in pressure in the entire cottage or higher up the riser of an apartment building.

- The drainage system ensures that the entire volume of the tank or part of it is poured out in a short time . Preferably - in automatic mode (that is, the user does not need to hold the lever or button all the time while the water is pouring). As a rule, it is combined with an overflow - a pipe that allows you to dump excess water when the tank overflows into the sewer.

In this order, we will consider the schemes used previously and now.

Popular manufacturers of toilet cistern flush devices

One of the most famous manufacturers of plumbing products and spare parts for them is the Czech company Alka Plast. It produces high-quality, functional and durable products at an affordable price. A popular universal model is the AlkaPlast A2000 drain mechanism with a stop button function. The device is suitable for replacing the existing mechanism in ceramic tanks. Thanks to the special design, the height of the product can be adjusted within the range of 310-405 mm (depending on the height of the tank).

The device is equipped with a stop function button, which starts draining the water when pressed for the first time and stops it when pressed again. The mechanism is made of ABS plastic, which is resistant to abrasion and various types of loads. You can buy a drainage device for 850 rubles.

The Alka Plast A08A dual-flush drain mechanism has two modes of water release with a volume of 3 and 6 liters. The design of the device allows you to adjust the height of the drain mechanism within the range of 315-450 mm. The product is made of ABS plastic. The cost of the device is 1.1 thousand rubles.

The Czech company Alka Plast produces high-quality and durable drainage devices

Another equally popular manufacturer of toilet flush mechanisms is the Swiss company Geberit. The products of the global manufacturer are of high quality. The company is constantly improving its manufacturing methods for sanitary ware, introducing technological innovations.

Among the popular models of drainage systems, one can highlight the Geberit Impuls Basic 230 dual-flush mechanism, equipped with a chrome button. The device is made of durable high-pressure plastic, which increases its technical and operational properties. You can buy a flush mechanism for a Geberit toilet for 2.3 thousand rubles.

A high-quality model is the Geberit Impuls Type 290 drain mechanism, designed for two operating modes - drain for 3 and 6 liters. The device is intended for tanks with a height of 300-450 mm. The water supply can be carried out both from the side and from below. The cost of the Geberit drain mechanism is 2.8 thousand rubles.

The drain mechanism is a simple design. Having understood the principle of its operation and following the above tips, you can independently install, adjust and repair the device without completely replacing the toilet cistern.

General characteristics of shut-off valves

Drainage and water shut-off valves must withstand sudden pressure changes. On average, the operating rate ranges from 0.4 to 15 atm.

The water temperature at which the device will operate normally ranges from 2 to 45 °C. The working life is about 150-200 thousand cycles.

Almost every draining or filling device can be adjusted to suit the height of the cistern

The materials used to produce a toilet shut-off valve are:

- High pressure polyethylene. The denser this material is, the higher its strength. At the same time, an increase in density reduces its impact resistance at low temperatures.

- ABS plastic (a chemical compound of acrylonitrile-budadiene styrene). The material is resistant to mechanical stress, abrasion, aggressive chemicals, and insensitive to temperature changes.

For each valve model, the manufacturer indicates the permissible height of the tank; it can be from 295 to 500 mm.

It is also important to pay attention to the connecting size - if it does not match, use an adapter ring.