Gone are the days when heavy and clumsy cast iron pipes were used to connect plumbing to the sewer system. Today they are being replaced by lightweight, convenient and, what is also important, cheap plastic.

Using plastic corrugation, installing or replacing a toilet becomes accessible even to novice craftsmen. It is enough to have the necessary set of tools and strictly follow the recommended sequence of actions.

Types of corrugation

In essence, the corrugation is a wide and flexible sleeve with a cuff that drains waste from the toilet outlet to the sewer pipe. Such an adapter is manufactured industrially from a special thermoplastic that can be bent at any angle, stretched and compressed without loss of strength.

The standard product has the following dimensions:

- length – 231-500 mm;

- diameter at the end approaching the sewer riser – 110 mm;

- the diameter on the side connected directly to the toilet outlet is 134 mm.

Modern industry offers consumers various types of corrugated pipes for connecting a household toilet:

- Soft plastic corrugation. Due to its ease of installation and versatility, it is most popular.

- Hard corrugation. More durable and reliable. Installation of such corrugation is somewhat more complicated.

According to the presence of reinforcing elements:

- Unreinforced. Does not have additional elements in the design. Inexpensive, but also less durable.

- Reinforced. Additional rigidity is given to the product by a thin wire running in a spiral along the walls of the corrugation. It has excellent reliability and durability, although it costs a little more.

In addition, the corrugation can vary in length. The length is always selected individually, depending on the location of the toilet.

Important rule! The length must be calculated with some margin. The corrugation should not connect the plumbing fixtures to the sewer pipe under tension. In this case, there will be a high risk of leaks.

Selection of quality products

A wide price range should not confuse the buyer when choosing the necessary plumbing elements. When choosing corrugation, you need to pay attention to the highest quality product. The cost of connecting plastic products for plumbing equipment is low. Having gained an insignificant amount on the price, the buyer risks purchasing a low-quality product, which will complicate the operation of the sanitary facility and reduce its time.

Note!

When choosing a manufacturer, you must take into account that domestic components for plumbing are inferior to foreign analogues.

The option of corrugation reinforced with metal wire should be preferred. A product with wire rings or mesh retains its strength longer. To ensure that the elastic partition does not sag or stretch excessively, you need to know the distance from the toilet outlet to the entrance to the sewer system. The durability of the product is also affected by the thickness and rigidity of the pipe walls. Understanding how to choose the right corrugation for a toilet bowl, the master will be able to choose the best products for repair.

This is interesting: How to choose a toilet seat: types, materials and additional options

Pros and cons of corrugated pipes for toilets

The popularity of corrugation can easily be explained by its numerous advantages in comparison with other methods of connecting plumbing fixtures to the sewer system:

- The most cost-effective installation method.

- Simple installation technology that any homeowner can easily handle.

- There is no need to use special tools.

- An ideal option for temporary installation of a toilet, for example, during renovations in a bathroom.

- A good solution for cases where the overall dimensions of the toilet outlet and the sewer outlet do not match.

We recommend that you read: Making a greenhouse from a profile pipe and polycarbonate with your own hands

Despite its versatility, the use of corrugation is not always justified. This is primarily due to the low strength characteristics (especially of standard, soft and unreinforced varieties) of the plastic from which it is made. Besides:

- Corrugated pipe is not intended for installation in thick walls and should be used exclusively in open areas.

- At large rotation angles, the corrugation tends to form blockages.

- Over time, extended sections of corrugated pipe will begin to sag under the influence of gravity.

- When large waste, glass fragments or tiles pass through the corrugation, it runs the risk of being damaged and becoming unsuitable for further use.

When should you install a corrugated connector?

Before purchasing, study the technical specifications.

It is permissible to install such a pipe when other options cannot be used:

- corrugation is used as a temporary measure, during the construction phase or in case of leakage of an existing pipe, and it takes more time to select, purchase and deliver a new one;

- changing the existing layout of plumbing fixtures in the bathroom: the toilet is shifted relative to the sewer riser, the floor level becomes higher;

- discrepancy between the diameters of the toilet flush and the pipe connection of the sewerage system;

- The plumbing fixture was replaced, and when purchasing a new one, the type of outlet was not taken into account: straight or oblique.

The reason may be due to repairs. In this case, the cladding is often mounted on top of the old coating. The bathroom also contains household appliances, such as a washing machine. Often problems during the installation of communications arise when you need to install a new plumbing fixture in a bathroom where the pipes have not been changed for a long time.

How to choose corrugation

Before you start buying a corrugated pipe for a toilet, you should clearly understand which product is best suited for our bathroom. It is imperative to check the diameters of the toilet outlet and sewer pipe. Most often these sizes are standard, but there are exceptions.

Another important point is the length of the corrugation. If the toilet is installed in close proximity to the sewer hole, the corrugation can be replaced with a special rubber cuff. And, on the contrary, for large combined bathrooms, you can consider the option of corrugation with an additional outlet, which will allow you to simultaneously connect not only the toilet, but also another element (bathtub, sink, etc.) to the drain.

It is not recommended to save on purchasing corrugated pipes. Even the most expensive products from leading imported manufacturers will not create a serious gap in the construction budget, but they can last much longer. In addition, the risk of receiving a low-quality fake in this case will be much lower.

Dismantling the old structure

If the corrugation is being installed on an already installed toilet, the previous connection of which has become unusable or is no longer suitable for the owner, you will first have to dismantle it:

- Before starting work, shut off the water supply and completely drain the water from the toilet tank.

- First of all, we disconnect the edge of the structure that is attached to the toilet. This will make it easy to drain the remaining liquid from the pipe into the sewer.

- If the old corrugation was fixed in the most compressed state, you may need to move the toilet to disconnect it. Most often, the toilet is attached to the floor with bolts that will need to be unscrewed.

- If the toilet is fixed to the floor with cement, dismantling it can cause much more problems. Here, most likely, you won’t be able to do without a hammer and chisel. You must act extremely carefully so as not to damage the toilet itself or the sewer pipe. Replacing these elements will be much more expensive than replacing a corrugated pipe.

- After disconnecting, it is necessary to thoroughly clean the toilet outlet (elements of the old structure, traces of sealant, cement, organic matter may remain here) and the sewer hole.

Note! As soon as the sewer bell is freed and cleaned of the remnants of the old structure, it is recommended to plug it with a thick fabric plug or a special plug. This will help avoid the spread of unpleasant sewer odors throughout the apartment.

Corrugated pipe installation

After dismantling the old connecting element, it is necessary to carefully inspect the new corrugation again for possible damage. In addition, you should once again make sure that the length of the product will be suitable.

We recommend that you read: Features of the production and use of ceramic sewer pipes

If the corrugated pipe is installed simultaneously with a new toilet, it will be more convenient to carry out installation in the following order:

- The corrugation is securely attached to the toilet outlet.

- The toilet is attached to the floor.

- Next, the structure is connected to the sewer system.

Despite the fact that the corrugation is attached to the standard outlet hole quite tightly and reliably, before installing it, it is advisable to treat the edge of the outlet with a special sanitary sealant. Such compositions based on silicone or acrylic are designed to work in conditions of constant high humidity, and their expansion upon drying will ensure the proper level of tightness.

Note! The corrugated pipe should be placed evenly and cover the outlet by 5-6 cm.

After this, the toilet with the corrugated pipe should be left until the sealant has completely dried (recommended periods are usually indicated in the instructions for the composition and may vary from one manufacturer to another).

Next, the toilet is installed in a permanent place, secured, and the free end of the corrugation is connected to the sewer pipe. The installation procedure is the same.

Flexible ribbed membranes at its end are responsible for reliable contact of the corrugated pipe with the inner surface of the drain.

When installed correctly, the contact is actually so strong that some craftsmen prefer to forego the use of sealants. Experience shows that such a solution reduces the service life of the corrugation and over time leads to the formation of leaks at the connection point.

Upon completion of all stages of work, the new design should be subjected to final tests. Water is supplied to the toilet and 2-3 flush cycles are carried out sequentially. The corrugated pipe and joints are carefully examined for leaks.

Single drops of water that appear will not require reworking the entire system; the problem area will simply need to be treated with sealant again.

Some useful installation tips

Despite all its advantages, plastic corrugation is not designed for heavy loads, so it cannot be mounted inside a wall. If the distance from the wall to the plumbing fixture is large, you should carefully select the length of the connector.

The corrugation stretches, but if this property is abused, the walls may become thinner and the strength of the structure will decrease. There is no need to stretch the corrugation before installing it - this will lead to sagging of the outlet.

Stretch it immediately before connecting to the sewer pipe. To avoid blockages, there is no need to allow sagging or counter-slope of the corrugation. When the sewer pipe and the outlet of the plumbing fixture are located relatively high, a support is built under the connector.

If the corrugation sag, a “pocket” will appear in it where deposits will accumulate. This may cause the connector walls to rupture. Stands or auxiliary clamps will help prevent this consequence.

When you decide to install a protective screen to mask communications, and use the fenced-off space as a place to store various small items, do not forget that a heavy object can damage the corrugation.

Before installing the plastic corrugation on the toilet, take into account that the product of standard sizes does not allow it to be installed flush against the wall. Here it is better to use an eccentric.

We must not forget about plumbing standards when choosing a slope. Do not turn the reinforced pipe at a right angle. If the device occupies a non-standard position, an offset connecting element is used.

Before you start work, you should make sure that the corrugation fits the parameters. You also need to check it for cracks. If, along with the corrugated pipe, it is also planned to replace the toilet, then it is put on before installing the plumbing

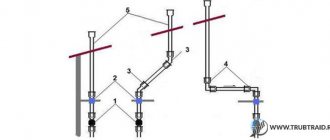

The corrugation can compensate for quite a significant displacement. Thanks to it, the device can be moved by a maximum of 200 mm. It can also be rotated to any angle you like. To do this, use an option such as a serial connection of two corrugated pipes.

You need to pay special attention to the angle at which the corrugation is bent. If the pressure is too high, draining cannot be carried out effectively. In addition to everything, the corrugation may crack at the point of pinching.

How can I replace corrugation?

Despite the numerous advantages of corrugation, not all owners choose such an element. Some are confused by the fragility of the ribbed plastic, others are not satisfied with the appearance of the finished structure.

We recommend that you read: Where to properly and safely hide heating pipes in a private house?

Fortunately, there are alternative options that will serve just as well. This could be a bright chrome pipe, which will definitely win in appearance.

A toilet with an oblique outlet type is conveniently connected to the sewer system using a piece of PVC or polyethylene pipe. To seal the joints, rubber cuffs of the appropriate diameter will be required. Also, the pipe can be preheated, which will make the material more pliable and facilitate the installation procedure.