The process of installing plumbing is the same in a house, apartment or bathhouse. Once you figure out how to connect the toilet to the sewer, you can do it in any necessary place. Agree, in the end you will be able to save a lot of money, especially if you have to install more than one plumbing unit.

We will help you understand the issue. Below are basic diagrams and step-by-step instructions for connecting a toilet to a sewer system, which it is advisable to study before purchasing plumbing fixtures.

Visual photo instructions and explanatory videos will help you better understand the intricacies of the process and determine the sequence of actions in a given situation.

Installation tool kit

The process of connecting a toilet to a sewer requires a preliminary assessment of the necessary materials. The choice of plumbing and connecting fittings depends on the type of sewer riser supply, the intended installation location of the toilet and its type.

In addition to the equipment itself, when installing a toilet yourself, you may need:

- Sewer corrugation.

- Plastic corners and adapters.

- Eccentric cuff.

- Silicone.

- Rubber seals and adapters.

- A saw for plastic pipes or a regular hacksaw for metal.

- Tape measure, pencil, hammer.

- Tools for dismantling old sewerage elements and fixing the toilet to the floor.

To remove old cast iron pipes, you may need a professional hammer drill and grinder, but in such advanced cases it is better to invite specialists with their own tools for dismantling.

Is it possible to vent the ventilation into the attic?

In a one-story or two-story private house, most owners install and replace toilet pipes with their own hands. In some cases, you can get by with one hood, but in large buildings where there are 2 or more bathrooms, it is necessary to install 2 ventilation risers. But each option has one thing in common - a ventilation outlet. Is it best to install the exhaust riser on the roof or in the attic?

Output to the roof

First things first. If the house is two-story, and the toilets on each floor are placed one above the other, then the design itself predicts that you can get by with one common riser. Although it is not recommended to take it out into the attic. Even with the optimal diameter, sewer “odors” will be heard throughout the space. After some time, unpleasant odors can be felt in the attic. Plus, a lot of warm, moist air will be released from the riser, which will easily turn into condensation during contact with the roof.

Over time, fungus will begin to appear in the wood, and moisture in winter will turn into icicles. That is why it is necessary to carry out the drain pipe to the roof.

This option has its own characteristics:

- it is enough for the riser to rise 25-35 cm above the roof. A hood that is too high will contribute to the appearance of ice plugs, since warm air escapes through it. It is not recommended to cover the end with deflectors or weather vanes, as they help trap warm air;

- You cannot install the outlet very close to windows or ventilation hoods, because the smell will be everywhere after a while. When the riser is removed to the opposite end of the roof, away from ventilation, the sewer “odors” will not be drawn back into the room. An option with a non-return air valve for waste pipes is possible if there is only one bath.

Important! When constructing multi-story buildings, the sewer riser has an outlet to the roof. This is ventilation. In this case, it serves as a funnel pipe.

Multi-angle roof outlets

A vertical riser can enter the atmosphere in three ways: at a slope of 90 degrees, 45 degrees, and without a slope - immediately vertically upward through the roof.

Dismantling cast iron elements

To dismantle cast iron elements and cement left over from old plumbing, you will need a hammer, a pry bar and a flat-head screwdriver. The outlet of older toilets is often cemented into a cast iron elbow.

Often the only way to dismantle is to break the ceramic pipe with a hammer.

When breaking a toilet cemented into a cast iron elbow, you must wear special glasses to protect against splinters.

After removing the toilet, you need to tap the cast iron pipe on all sides and begin removing cement and deposits from its internal surface. To do this, use a hammer and a screwdriver, and large pieces are removed with a pry bar.

Old cast iron pipes cannot be hit too hard with a hammer, because they may split, and you will have to break the floor all the way to the sewer riser and insert a new outlet into it

To completely clean the pipes of rust and deposits, you can moisten them with toilet cleaner and then scrape them off with a wire brush.

Complete cleaning with a rag. These manipulations must be done wearing special protective gloves. It is important that the first 5 cm of the internal space of the cast iron pipe are smooth, as they will ensure the tightness of the future connection.

Types of fan products

Fan pipes are classified according to the construction material used in the manufacture of the product.

The classification divides fan pipes into 2 types:

- metal;

- plastic.

The metal (cast iron) version can be installed in a sewer system made of a similar material. Plastic products can be installed in both plastic and cast iron pipelines.

When repairing fan pipes, it is recommended to replace cast iron elements with plastic analogues. This material is much more durable than cast iron

When installing a plastic element, you get a flexible sewer pipe, a monolithic elbow or a compact adapter. Cast iron products are not flexible and do not have a variety of shapes.

Instructions for connecting a toilet with corrugation

The basic steps for connecting a toilet to a sewer will be discussed using the common option using a corrugated pipe. Installation of corrugation is the basic and most common type of connection between a toilet and a sewer system.

When deciding to choose a corrugated pipe, you need to be aware of the positive and negative features of this design. The remaining installation options follow the same scheme, but with some differences.

The positive properties of corrugation include:

- Low cost.

- Ability to lengthen and bend.

- No problems with hole alignment.

- Can be used as a temporary connection.

Among the disadvantages of corrugated pipes are the following:

- The walls are easily damaged during installation.

- Periodic cleaning is required on low slopes.

- Sagging during long-term use.

- Difficulty in cleaning the external surface from dust.

The final decision on the installation of corrugation is made after taking into account all the above-described features.

Corrugated connections are installed on toilets with oblique and horizontal flushes. Before purchasing a product, you must measure the approximate distance between the toilet and the sewer hole. The length of the corrugation must be at least 1/3 longer than this value.

Step one: fitting

At the beginning of the procedure for connecting the toilet to the sewer, it is necessary to try out the compatibility of the design. To do this, take a rubber seal and insert it into the sewer hole, having previously lubricated the joint with a thick layer of silicone. Then push the rubber tip of the corrugation into the sewer drain.

It is necessary to insert the tip of the corrugation into the seal until the last rubber ring is level with the cast iron pipe

After inserting the corrugated pipe, at subsequent stages of installation, it is not advisable to twist it until the silicone has completely dried.

The next step is to take the toilet and install it in its planned permanent place. Sit on it, checking that it is stable and does not rock. If the toilet is unstable, you will need to level the floor or install expansion stands to correct the unevenness of the tiles.

If the toilet is stable, then it is necessary to connect a corrugated pipe to its pipe without lubricating it with silicone. After this, you need to pour three buckets of water into the toilet and, after waiting a minute, check both holes of the corrugation for leaks.

Horizontal toilet pipes may leak a few drops at the junction with the corrugation. The leak is subsequently repaired using sealant

If there are leaks, it is necessary to remove the corrugation, check the correct location of the rubber seals and once again connect the parts along their axes.

If there are no leaks, then you need to mark with a marker where the toilet is attached to the floor.

Before determining the location for the toilet, it is recommended to let all residents sit on it to determine the optimal location of the equipment

After the measurements, it is necessary to disconnect the corrugation from the toilet and secure it so that there is no distortion at the junction with the sewer hole. Move the toilet aside.

Step two: fixing the toilet

In the designated places, we drill holes in the floor with a drill, insert dowels into them and place the toilet in a permanent place.

It is recommended to make holes in the tiles using a special spear-shaped drill, which reduces the likelihood of chipping and speeds up the drilling process

After installing the toilet, we fix it to the floor. Then you need to sit on the toilet and move your center of gravity in different directions for a minute. After this, tighten the fixing screws again and put decorative caps on them.

Before installation, most installers advise treating the joint between the toilet and the tiles with waterproof silicone. But they do not take into account the complexity of subsequent cleaning of the premises. After a few months of cleaning the floor, the silicone sealant will peel off from the joint and a gap will form.

Therefore, before installing the toilet in place, you need to turn it over and lubricate the perimeter that will come into contact with the tiles with silicone. After this, you should put the toilet and screw it on, and seal the gap between it and the floor with a sealant on a waterproof cement base, which will not be destroyed when the bathroom is wet cleaned.

The features of installing a toilet on a wooden floor are described in this article.

Step three: sewer connection

After installing the toilet, you need to lubricate the inner surface of the rubber corrugation with silicone and pull it onto the toilet pipe.

It is necessary to stretch the corrugation evenly along its entire length so that the slope is maximum and there is no sagging anywhere

After installing the corrugation, you must wait 2 hours until the silicone hardens and only then proceed to the next step.

Step Four: Testing

After the sealant has dried, you can test the toilet by sitting on it and performing 2-3 full flushes. If after 5 minutes nothing has leaked, then you can screw on the tank with the toilet seat and use the plumbing.

In case of a small drop-shaped leak, you should completely remove the water from the toilet bowl and remove the corrugation from it. After this, re-lubricate the rubber band of the corrugated pipe with silicone and pull it onto the toilet pipe. You can also additionally lubricate the joint with sealant from the outside.

At this point, connecting the toilet to the sewer using a corrugated pipe can be considered complete.

Niche for installation

A niche is made in the wall for installation if the installation depth of the frame, materials and wall thickness allow such work to be performed. And in addition to the niche in the wall, they also cut channels for water and sewer pipes, which, like the installation, must be installed secretly.

Important. This method is not suitable for load-bearing walls made of bricks (for walls made of reinforced concrete, it is technically impossible to make a niche with your own hands). And if the arch of a niche can be reinforced with an insert made of a metal profile (standard practice for an opening), then this option is not suitable for hidden pipe laying - cutting horizontal channels in a load-bearing wall is prohibited at the regulatory level.

And without horizontal grooves, it is extremely difficult to make hidden wiring - only if the pipes approach the niche from below, and before it are laid in a screed or between the joists of a wooden floor.

For a niche in the wall, there is only one option provided by the manufacturer - for a block installation with an attached toilet.

In addition to this option, they also use a bathroom niche in which the water supply and sewer risers pass. In this case, a frame made of a metal profile is installed in a niche, and a frame installation for a wall-mounted toilet is attached to it.

Connecting the toilet with plastic elbows

Unlike corrugated pipe, plastic elbows do not have flexibility. But if the sewer line was originally planned for a specific toilet model, then rigid outlets are more preferable because of their durability and problem-free nature.

When connecting the toilet to the sewer with plastic elbows, they dictate the location of the plumbing fixtures, because the slightest displacement threatens leakage

The main steps for connecting a toilet to a sewer with plastic elbows are similar to those for installation using corrugation.

Basic rules for using rigid connection elements:

- All connecting pipes are lubricated with silicone before installation in the holes.

- Excessively long pipes can be cut with a hacksaw.

- It is necessary to exclude any distortions.

- Horizontal 90 degree bends should be avoided due to the possibility of clogging.

The disadvantage of budget plastic outlets is their gray color, which does not at all harmonize with the snow-white toilet. White models are much more expensive, but their appearance is worth it.

How to choose?

According to technical characteristics and design, several types of toilet corrugation can be distinguished:

- in terms of rigidity - hard and soft. The soft one is made of thinner plastic, more elastic, suitable for a toilet with any outlet - vertical, horizontal, oblique. It is easier to install, as it is more elastic and bends easier. Rigid corrugation has thicker walls and is more wear-resistant;

- according to reliability - reinforced or unreinforced. Reinforced corrugation has greater rigidity, greater strength, wear resistance, and, as a result, greater durability. Reinforced, reinforced with thin wire cast into the walls. Reinforced products are usually imported and cost slightly more than non-reinforced ones, but this is the case when “the miser pays twice”;

- long or short. The length is chosen according to the distance from the plumbing to the sewer, but it should be borne in mind that the corrugation should not be greatly stretched - this negatively affects the service life and appearance. A stretched product is more likely to cause sagging and leaks.

For difficult cases, there are models with a curved bell with a bend angle of 45° and 90°.

For compact placement of other plumbing fixtures in small bathrooms, there are models with an outlet to which you can connect a bathtub or sink drain.

Sizes and prices

Products found on the market have standardized sizes.

- Length of products: short corrugation in a compressed state has a length of 212 mm, in an extended state - 320 mm; long - 285 and 500 mm, respectively. If a short model will have to be stretched greatly, then it is better to choose a longer model.

- Diameters: the socket that fits onto the sanitary fixture has a diameter of 134 mm; the hole in the seal in the socket has an internal diameter of 75 mm; the cuff for connection to the sewer has an outer diameter of 110 mm.

Direct connection of the toilet to the sewer

If the toilet pipes fit perfectly into the sewer pipe, or it was installed from scratch specifically for the existing plumbing, then there is no better option than to insert the outlet pipe directly into the sewer riser.

#1: Stand-up toilets

Toilets with a vertical pipe can be installed in your own home or in new buildings in which the sewer line runs under the floor, and not in wall niches. This design eliminates clogging and minimizes the likelihood of water leakage when draining.

The advantage of a vertical flush is that it saves space, because due to the lack of connecting elements, the toilet can be placed close to the wall

Installation of a toilet with a vertical outlet begins with attaching a special flange to the sewer pipe. To do this, it is first measured against the floor, holes for the dowels are marked and drilled. After this, the flange is mounted in place and screwed.

When attaching the flange, remember that the axis of the fixing bolts must be strictly perpendicular to the axis of the toilet bowl

The sealing ring can be lubricated with silicone to prevent unpleasant odors from the sewer from entering the bathroom. Then the toilet is placed on top of the flange and secured with nuts, onto which decorative caps are placed on top. Installation is complete.

The process of connecting a toilet with a vertical flush is clearly demonstrated in the video:

#2: Connecting a toilet with a horizontal pipe

Installation of a toilet with a horizontal pipe is similar to that using corrugation, and it can be installed almost flush against the wall.

The difference is that initially a rigid system is installed that will connect the toilet to the sewer riser. The structural elements should not move when the toilet pipe is inserted into it.

The easiest way to connect a toilet is with a horizontal type of pipe. The connection uses both rigid pipes without corner joints and all types of corrugations

Before installation, you need to try on the toilet and mark the locations for drilling holes for fastenings. After this, remove the plumbing, drill holes, insert dowels and put the toilet back in place, putting the pipe into the sewer hole greased with silicone.

Before screwing in the plumbing, you should perform a test drain and check for leaks.

When inserting the pipe, it is advisable to hold the entrance of the sewer hole with your hand to prevent displacement of the sewer elements. Therefore, it is advisable to carry out this procedure together

If at the last moment a decision is made to move the toilet slightly to the side, then you can use an additional eccentric adapter, but its length will move the location of the toilet forward. This may require re-drilling the mounting holes.

In domestic apartments, toilets with a horizontal outlet are most often connected to the sewer system using a corrugated adapter, without the use of rigid structures.

A video guide on how to connect a toilet with a horizontal flush to a sewer system will help home craftsmen in their work:

#3: Installation of a toilet with an oblique pipe

Direct connection of a toilet with a straight pipe is not much different from that with a horizontal pipe and corrugation. The basic steps are described in more detail in the corresponding chapters above.

The plumbing design with an oblique pipe attracts the most problem-free flushing, but when connecting it, it is necessary to comply with technological requirements that ensure perfect tightness (+)

A slanted toilet outlet ensures a lower likelihood of the joint leaking when flushing water, therefore it is more preferable than a horizontal one. A plumbing structure with an oblique outlet is quite difficult to connect to the sewer using corrugations due to the small distance between the floor and the outlet of the pipe.

The installation instructions for a toilet with an oblique flush using corrugation will introduce you to the sequence of actions:

Before installing the sewer system, it is necessary to try on the toilet, mark the places for dowels for screwing the device, and check that the axes of the connected holes are not distorted.

It is better to connect a toilet with an oblique outlet to a plastic sewer together: one person holds the wiring, and the second person inserts the pipe of the raised toilet into the hole

After installing the dowels into the floor, the toilet pipe is placed on a sewer pipe pre-lubricated with silicone and fixed to the floor with screws.

In case of a slight leak, you can lubricate the outer joint with silicone and leave to dry for several hours. After this you can use the toilet.

Features of repair of fan systems

Installation of the internal sewerage system is carried out “in the socket”. This greatly simplifies the process of installing and dismantling all pipeline elements.

Repair work is necessary when there is physical damage to a drain or sewer pipe. Due to the excellent rigidity (pipe bending resistance is 80 MPa) and the long service life of the plastic (up to 60 years), there is a low probability of physical damage to the pipes.

When repairing sewer pipes, the technician must take into account the following rules:

- the end of the drain pipe is positioned in such a way as to ensure effective dispersion of unpleasant odors;

- the diameter of the pipe must be the same or larger than the riser on which the installation is being carried out;

- lay the pipe in warm rooms, and complete the installation in a cold zone, since the temperature difference provokes a pressure difference in different sections of the pipe.

Repair work involves connecting a waste pipe to a sewer riser. At the same time, vacuum valves are installed on other risers - rubber seals equipped with springs.

Replacement and repair of drain pipes must be carried out according to design documentation, taking into account the rules for installing risers in the sewer system

During operation, the sewer system creates a vacuum in the valve, as a result of which it opens and sucks air from the room. After stabilizing the pressure in the riser, a special spring automatically closes the check valve, preventing the unpleasant odor from escaping into the atmosphere.

Conclusions and useful video on the topic

To better understand the instructions described above, it is recommended that you watch the following video review:

It is not difficult to connect the toilet to the sewer system yourself. To do this, it is advisable to buy in advance a model of equipment that will fit most aesthetically into the interior of the bathroom.

With a minimum of tools, sealant and correctly selected connecting parts, you can install the toilet using the above instructions in a few minutes.

Do you have practical skills in installing and connecting a toilet to a sewer? Please share your knowledge, experience with our readers or ask questions. The comment form is located below.

What it is?

A corrugated toilet flush is a transitional element for connecting the toilet to the sewerage system; it is a wide pipe with corrugated walls, made of thermoplastic.

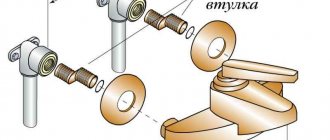

The faucet pipe has at one end a pipe with a funnel-shaped expansion with seals inside - this side of the pipe is put on the toilet. On the other side of the pipe there is a pipe with an attached rubber sealing coupling to facilitate connection to the sewer riser.

Thanks to the corrugation, such an adapter can easily be stretched to the desired length and makes it easier to install.

Hanging models

Recently, hanging varieties with installation have become increasingly popular, the connection methods of which involve hanging the bowl on a false wall and placing a cistern behind it. To do this, a strong metal vertical frame is mounted behind the wall, threaded studs with nuts are removed from it to hold the bowl, and a plastic drain tank is placed inside the frame; a button is placed on top of the wall to turn on the flush.

The advantages of a hanging design are space saving in a small toilet, aesthetic appearance, ease of cleaning (the floor is easier to clean under a hanging bowl).