Here you will learn:

- Depth limits for placing an electric pump in a well

- Technical properties of well pumps

- Choosing a pump for a well

- Preparation of materials

- Preparing to install the pump

- Rules for installing a surface pump

- How to properly lower a submersible pump

- How to connect with your own hands

- Dismantling the deep-well pump

- Some important recommendations

Installing a pump in a well is an important and responsible stage of work. Before installation, you need to select the pump model, prepare the installation site and necessary materials, and think over the connection diagram.

Depth limits for placing an electric pump in a well

Determining the depth of lowering of the electric pump is always associated with the dynamic and static level of the source. The static level is understood as the distance between the soil surface and the water horizon of the source in the absence of water intake; when drawing up a well passport, it is determined an hour after pumping.

The dynamic level of wells and boreholes is recorded when the electric pump is turned on at full power, which draws water from a given source; it is also equal to the distance between the surfaces of the earth and water. The dynamic threshold is fixed at the equilibrium point of the staying and pumped flow, when the water surface is at a constant level.

Rice. 3 Water level indicators

It is clear that when determining the depth of descent, it is necessary to take into account the dynamic characteristics of the well, that is, the electric pump must be located below the dynamic threshold by at least 1 - 3 m - this is the first indisputable condition.

If the pump is installed in a well on sand, then one should take into account the fact that in the bottom area of the filter there is an increased concentration of suspended particles of sand and clay - their absorption by the electric pump will lead not only to its breakdown, but also to rapid clogging of the filters and subsequent failure of the entire water supply system. .

In addition, such water will become unsuitable not only for drinking, but also for household needs. Therefore, a correctly calculated lowering depth should take this factor into account; the distance to the bottom should not fall lower than 0.5 - 1 m; for powerful electric pumps, the highest limit is chosen and this distance is even increased.

Checking the work done

Before you start lowering all elements into the well, you must carefully check:

- Check valve;

- Tightening fittings;

- Cable connection tightness;

- Cable fastener;

- Fixing the cable and cable to the pipe;

- Fastening the opposite end of the cable to the surface of the ground;

- Reciprocal fitting.

This is necessary in order to eliminate all problems and obtain a successful result after a test run of the equipment.

Otherwise, if the element check was not performed properly or was missing altogether. And after lowering the system into the well and starting it up, it turned out that there were problems. It will be difficult to lift the entire structure back, since it will be additionally filled with water. In this case, the mass can increase two or more times.

It is advisable to carry out a test run before lowering the system into the well, and if problems are detected, fix them immediately while the structure is within reach of your hands.

Technical properties of well pumps

The main characteristic properties of submersible pumping equipment are the following:

- the ability to create water pressure at a level that ensures its optimal extraction from the well and supply to the water supply system;

- high duration of uninterrupted operation;

- cylindrical body shape, which provides a certain convenience during installation;

- Some models are capable of pumping from a well that contains impurities in the form of sand and clay; such devices are made of materials that have high wear resistance.

Types of pumps for wells.

Deep-well pumping equipment is characterized by good workmanship and a high degree of reliability. These qualities allowed these devices to gain high popularity and become in demand among owners of country houses and summer cottages.

The use of these pumping systems has become a popular way to organize autonomous water supply for country cottages and private houses.

The main advantages of submersible pumps:

- large depth of water intake;

- low technical complexity of installation;

- absence of rubbing elements, which increases the overall service life and increases wear resistance;

- low noise level;

- long service life.

Due to the reliability of this equipment, maintenance and replacement of a submersible pump in a well is carried out very rarely.

Basic selection parameters

Before connecting a circulation pump to the heating system, professionals select a device taking into account the features of the existing heating circuit of the house. During this process, they must pay attention to the following parameters of the device:

- The operating voltage should be 220 V. This characteristic allows you to connect the electric pump to a household power line. Therefore, there is no need to install separate wiring.

- Power – the optimal value is the minimum value. It is recommended to choose a device with power consumption class A. This device is the most economical. As the class decreases, power consumption increases.

Manufacturers produce modern pumping units with two or even three operating modes. They allow you to change the pressure of the pumped liquid. At the same time, the power of the device will change. These parameters are usually marked on the body of the electric pump.

Choosing a pump for a well

Installing a pump in a well often begins with choosing a good pump. The choice can be influenced by many factors, including reviews from users, acquaintances, relatives, personal experience, advertising, and the like. In this regard, when choosing pumping equipment, consider the following points:

- choose exclusively from downhole-type centrifugal units, since other types, in particular vibration, are intended for other operating conditions. The price of such devices is the lowest on the market, and the quality is correspondingly the same;

- One of the most important characteristics is the performance of the pump, which, first of all, must meet your needs. By performance we mean the number of liters of water that the device can pump in one hour. You need to rely on a level of productivity that will ensure an uninterrupted supply of water to the target locations;

- Also, the diameter of the pump housing is considered important. This value must correspond to the internal diameter of the casing pipes, which are the walls of the well. Here it is necessary to take into account that the closer to the bottom of the well, the smaller its diameter.

Preparation of materials

Before starting work, you need to purchase the necessary materials. A special moment of installation is lowering the pump into the casing. To do this you will need the original rope. The factory equipment of some models of submersible units includes a polymer cord. If it is not available, you should purchase a device for lowering the mechanism into the pipe separately.

The following requirements apply to the cable:

- reliability and strength, expressed by the ability to withstand loads 5 times greater than the weight of the suspended equipment;

- resistance to the destructive effects of dampness, since certain areas of the product are under water.

When installing a pump in a well with your own hands at a depth of less than 10 m from the surface, you will need to take measures to additionally cushion the device during operation.

It is allowed to use available materials to dampen vibrations. A piece of medical tourniquet or elastic hose will do. You should not hang the mechanism on a metal cable or wire because of the likelihood of damage to the fastening.

The next element that allows you to correctly install a deep-well pump in a well is a cable for supplying power to the equipment. It is better to take a wire with a small margin in length.

Water is supplied from an autonomous source to consumption points in the house through a water main. The best option is polymer pipes with a cross-section of 32 mm or larger. With a smaller diameter it is impossible to provide sufficient pressure.

It is allowed to use a metal pipeline when installing a well pump. In this case, threaded connections must be sealed with FUM tape, flax fiber or a special Tangit product. To further strengthen the linen winding, silicone-based sealant is used.

Depending on the operating conditions, the characteristics of the water main are selected. The determining factor is the depth of the local source. HDPE pipes designed to operate under a pressure of 10 atm are installed up to 50 m. For 50-80 m, a pipeline capable of withstanding 12.5 atm is suitable. Water supply from deeper mines is carried out by polymer hollow products designed for 16 atm.

In addition, before installing the pump on the well, you need to prepare the following materials:

- pressure gauge;

- fastening unit made of durable steel;

- fittings for fixing the electrical cable on the pipe line (clamps can be used);

- check valve;

- shut-off valve that shuts off the water supply, etc.

A nipple adapter is installed at the outlet pipe of the pump. If the pump unit is not included in the factory configuration, this device is purchased separately.

During the initial pumping of a well, a large volume of heavily contaminated liquid is removed from it. For this procedure, it is recommended to use powerful models capable of pumping dirty water. After this, you can begin installing a standard well pump for further operation.

Preparing to install the pump

Also, the choice of pump will depend on what performance you need. After all, if this is a residential country house, then you need constant water pressure, without interruptions.

If this is just a dacha in which you live infrequently, then a lower power will suit you. In order for the well pump to serve you for a long time, be sure to use it according to the technical specifications, i.e. buy for the depth at which it will be used.

If the soil quality is not good, then it is better to protect the well with concrete rings, creating a so-called “corridor” that will prevent soil destruction. The casing pipe is selected according to the diameter of the pump.

Also consider how the pump will be connected to the electrical network. The cable should be in a relaxed state, not stretched.

Water from the pump rises through pipes, most often plastic. It is plastic that is more durable: it has a good service life, it does not rot and is not susceptible to corrosion.

In addition to all of the above, you will need clamps with which to secure the electrical cable through the pipe, a pressure gauge, a check valve and a shut-off valve.

Before installing a pump for permanent use, first pump the dirty water from the well using a cheap pump.

The deep-well pump is installed directly in the well, thereby not requiring a separate space.

First you need to assemble the entire structure, which will subsequently be immersed in the well.

The pump is connected to: water supply pipe, electrical cable, safety cable.

Lowering

Photo taken from the site https://kolodec.guru/

The well pump is lowered directly into the well itself with a pipe and cable.

When lowering the entire structure, it is necessary to seek help from another person who will provide insurance support. It may be needed when the well depth is more than 50 meters. Then the mass of the entire assembled structure may be too much for one person to handle.

After all, it is possible that there will not be enough strength, and there will be no one to support you, and you will have to let everything go into the well. To avoid this, you need an assistant.

Rules for installing a surface pump

It is not practical to install surface pumps on deep hydraulic structures. When diving below 8 m, such devices fail. In small wells, their installation is justified due to their lower price than submersible options.

The installation procedure consists of the following sequential steps:

- A separate room is prepared to house the equipment. You can allocate space in the caisson for a surface pump.

- A rubber sleeve is placed on the suction pipe. Its length should be sufficient to connect to the aquifer.

- A check valve is fixed on the opposite side of the hose. It performs the function of stopping the drainage of liquid when the mechanism is turned off.

- A strainer is mounted on top of the valve device. It sifts out silt fragments and sand granules.

- The end of the elastic sleeve is lowered into the water.

The process ends with a trial run.

How to properly lower a submersible pump

Do-it-yourself installation of a pump in a well is carried out after studying the instructions with drawings for installing the pump and gaining practical experience using the videos below.

In accordance with the passport data for the excavation and the immersion depth, the downhole unit and materials are selected. When assembling the structure and installation work, two or three people are involved, sequentially, step by step, performing the following operations:

- We check the project package and lay out the submersible pump, pressure hose, control cable, cable and fasteners for assembly.

- We begin assembly by installing the check valve into the outlet on the pump using an adapter fitting. In this case, we take into account the direction of movement of the liquid, indicated by the arrow on the body.

- We cut the end of the pressure pipe at an angle of 90 degrees to the axis, put a plastic coupling with an O-ring on the hose and insert it into the body of the adapter fitting screwed into the valve. Tighten the coupling nut to secure the connection.

- Using a heat-shrinkable sleeve, we connect the control cable to the engine, and fill the entry point of the wires into the unit body with waterproofing glue.

- We insert a safety rope into the eyes on the device body, bend the threaded end into a loop and, using a special lock and a pressure washer, connect it to the main part of the rope.

- To prevent the cable and cable from touching the column when lowered into the shaft, we connect it together with the hose into a single strand using plastic clamps. A meter from the pump, we fix the ties every 20 cm, and then every meter to the top of the casing.

- Using a grinder, we cut off the casing pipe to the bottom of the caisson and install the head on the end. The cover serves to protect the well from debris, and it has holes for a pressure hose, cable and safety rope.

- We thread the hose, cable and cable into the holes on the head. We cut off the pressure pipe at the level of the lid and insert an angle fitting into it to connect to the water main laid in the trench to the house. We attach the safety cable to the casing carabiner. We lay the cable in a trench and lead it into the technical room.

- If the well is drilled no further than 5–7 meters from the house, the connection is simplified and a caisson is not installed. The pressure pipe is cut off at ground level and, together with the cable, is led through the head into the technical room in an insulated tray. To prevent the water from freezing in winter, a heating wire is inserted into the main hose, and a check valve is not installed on the pump. After injection, the liquid flows back, and the HDPE pipe remains dry.

When installing a water pipeline into a house below the freezing point of the ground, a trench is dug to this level. A hole is drilled in the casing pipe, at the bottom of the ditch, into which the adapter is fixed. Through an adapter, a pressure hose and control cable are inserted into the house through the trench.

Determining the pump operating point

Correct installation of a deep-well pump requires clarification of its characteristics during operation in standard mode. To do this, you will need to determine the water consumption for a single period of time.

The pressure is measured with a pressure gauge, and the current strength during operation of the mechanism is measured with conductive forceps. How deep should the pump be lowered into the well?

After measurements are taken, the indicators are compared with information from the technical documentation. If the actual data exceeds those recommended by the manufacturer, the unit valve should be slightly moved. Due to additional resistance, the parameters are normalized.

Connecting the pipe to the electric pump and correctly securing the cable

After preparing the electric pump, they begin to install it in the well shaft; operations are carried out in the following order:

- Before work, you need to know the depth of lowering the electric pump, which determines the main dimensions. First, the HDPE water pipe and cable of the required length are cut off; the length of the power cable is calculated in advance at the stage of preparing the unit for lowering.

- Screw an adapter coupling into the outlet fitting of the electric pump for connection to the HDPE pipe; if the device does not have a check valve, it must have an adapter.

- Using a compression fitting, the HDPE pipe is connected to the electric pump; if a head is used, the pipe and electrical power cord are first pulled through it.

- They pull a stainless steel cable, or a cheaper steel cable in plastic insulation, through the ears in the pump body, fix it with special clamps in two places, and cover the steel at the end with waterproof glue.

- Wrap all fasteners and ends of the cable with electrical tape.

- Connect the electrical cable, pipeline and cable together using ties or insulating tape in increments of 1 - 2 m.

- Hang the cable on a carabiner to the head and lower the electric pump into the well of the borehole channel, the protruding section of the pressure pipe is cut off and connected through compression fittings to the pipeline, after which the system is ready for operation.

When placing an electric pump in a well using an adapter, all preparatory procedures and its connection to the cable and pressure pipeline are performed in the above manner; the adapter is installed using a dovetail fitting, which is attached to the end of the plastic pipe using a compression clamp nut with a conical ring.

For lowering, a piece of pipe with an external thread is used, which is screwed to the mating part of the adapter; after it is lowered and connected to the second element located on the wall of the casing, the mounting pipe is unscrewed.

The top of the well is covered with a lid, to which it is possible to tie a cable and pull the power cord through the housing.

Rice. 8 Connecting the pump using an adapter

How to connect with your own hands

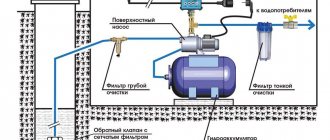

For trouble-free and long-term operation of an autonomous water supply, the installation of an automatic control system for equipment operation is mandatory.

The equipment installed in the technical room of the house includes:

- Hydraulic accumulator. A membrane tank is used to maintain pressure in the water supply system, which should be at 3.5 atmospheres. When the hydraulic tank is full, water is consumed within 3–4 hours, preventing the well pump from being turned on frequently. It protects the water supply system from water hammer, which can rupture pipes. In the body of the product there is a chamber made of hygienic rubber for water with a pressure valve, and the rest of the tank is filled with air, which creates pressure through a pneumatic valve using a compressor. A line from a submersible pump is connected to the hydraulic tank, through which water enters the water chamber. The operating principle is based on maintaining pressure in the water chamber using air. When water flows and the pressure in the system decreases, the well unit is turned on and water is supplied to the chamber.

- A cabinet with electronic and relay equipment control and protection devices, which control the operation of autonomous water supply through supplied sensors. Mini-blocks installed in the pump control the pump and, when the load increases, the low level of the aquifer and the heating of the single-phase motor turn off the unit through a relay. Sensors located in the pipeline monitor the nominal pressure of the liquid. When it decreases, the device turns on through the electronic system, filling the chamber with water. If the pressure is not set to the standard value, it is necessary to adjust the relay.

Connection technology

Before connecting the surface pump to the source, be sure to check the total length of the vertical and horizontal supply pipes. It should not be larger than the size specified in the accompanying documentation for the device.

The connection is made according to the following scheme:

- Connect the pump outlet to the water supply through a shut-off valve. You will also need a single elbow or a tee, it depends on the number of connections.

- Plug the plug into a 220 V/50 Hz power outlet.

- Fill the special hole on the station body, which is located near the pump, with water in accordance with the manufacturer’s recommendations.

- Perform a test run of the unit and wait until the automatic shutdown operates.

- Check the readings in the hydraulic tank using a pressure gauge and compare them with the data in the technical data sheet of the device. If the values do not match, adjust the pressure switch.

After filling the battery, you need to open the taps, check the pressure and general functioning of the water supply and plumbing fixtures.

Despite the fact that connecting surface pressure equipment has some difficulties, carefully reading the manufacturer’s instructions, as well as applying the advice of professionals, will make this task possible even for a beginner.

Dismantling the deep-well pump

The need for dismantling due to pump failure may arise for a number of reasons, the most common of which are:

- incorrect installation of a submersible pump in a well;

- incorrectly selected elements of automatic control of pumping equipment;

- incorrect choice of the hydraulic machine itself based on its power.

So, if a pump, initially designed to service wells with a depth of no more than 50 m, is used to lift water to a height of about 80 m, then repairs to such equipment may be required after just a few months of its operation. The automation of this pump, configured for a certain pressure of the pumped liquid medium, simply will not periodically turn off the device, as a result of which it will work with constant overloads and, accordingly, will quickly fail.

Deep pump removed from a well

When a broken deep-well pump requires dismantling, it is better to invite qualified specialists to carry out this procedure. If you have studied theoretical material on this topic and watched videos shared on the Internet by users of submersible pumping devices, you can dismantle it yourself.