The American is a universal and indispensable device that is used in domestic and industrial construction of pipelines of various configurations. Almost all craftsmen have to face the need to create a quick-release connection on a line to replace a section of it, insert an insert, or clean it. Thanks to this useful invention, plumbers have at their disposal a variety of practical fittings for American plumbing, allowing them to do the job quickly and efficiently.

Fitting purpose

This coupling was developed in the USA, so the name is appropriate - American. Many beginners are interested in how suitable American is for plumbing and what kind of connection it is. It is intended, first of all, for connecting pipes of different materials and cross-sections. Although American thread standards differ from European and Asian ones, American threads are excellent for installing plumbing fixtures and devices of various manufacturers. For this, American developers came up with a technology for universal and high-quality joining of pipes made of copper, steel and even plastic.

The main tasks that are performed using an American coupling:

- installation of pipelines into tees, taps and other devices;

- eliminating damage to the pipe section;

- installation without the use of electric and gas welding.

The American connection has spread greatly in Russia, thanks to its design features and versatility.

Coupling according to American standards Source uspehidelo.ru

Typical sizes

An American connection or a combined detachable coupling (technical name) is usually sold in retail chains in the form of two units. The first is a coupling with a union nut and a sealing gasket; the mating part is equipped with a double-sided thread - for the nut and for connection to threaded pipes of various sizes.

Sometimes the gasket is placed in the mating part; in many designs it is made in the form of a ring and fits into the groove.

Based on the fact that the combined coupling is supplied as a ready-made joined unit, its characteristics indicate the internal size of the passage channel on both sides. Its standard values for connecting PP pipes in water supply and heating communications are: 20, 25, 32, 40, 50, 63 mm.

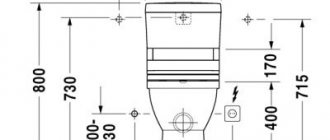

Rice. 6 Standard American sizes

American types used

When installing plumbing and pipes for different purposes, you have to deal with many ramifications. An American connection has been developed specifically for this purpose. What kind of device this is and what type it is can be understood based on its purpose. For example, to connect radiator or toilet pipes, corner and combination couplings are used. Many types of fittings are used for different purposes, since the fastening must not only be of high quality and tight, but also have an acceptable appearance.

Corner type

Before the introduction of connector fittings, welding of adapters was mainly used for corner joints. Now this is not necessary - it is much more convenient to install the coupling. American women are available in various sizes and degrees of bending. On sale you can find corner joints from 45º to 135º.

With such a variety of fittings, joints can be connected smoothly and without additional intervention. The union nut on the American one will ensure a tight fit and sufficient pressure on the internal gaskets. This connection is convenient both during installation and disassembly of the line.

Angle fitting Source vseinstrumenti.ru

Combined type

It is common when connecting straight sections and allows you to install various PVC metal pipes. The quality and tightness of the joints is ensured throughout the entire operation of the pipeline.

Ball Valves

This type of coupling has replaced drives, which are inferior in quality, although they are cheaper. The ball valve is made of stainless steel with brass inserts and is resistant to most types of corrosion. Installation is simple and reliable; the absence of internal gaskets eliminates breakage and rapid abrasion of the fitting. Basically, taps according to the American standard are installed when installing flush tanks and at the junction of the main line at the entrance to the building.

See also: Catalog of companies that specialize in the design and installation of water supply and sewerage systems

How to install correctly

Depending on what material you have to work with, different methods of installing fittings are chosen.

At the joints of metal pipes

Steel lines are used to transport hot liquids under high pressure. Threaded connections are used to connect their sections.

First you need to take a die of the required size and make 7 turns of thread at each joint. After this, the fitting is inserted between the joints, and the union nuts are screwed onto the threads until the required degree of pressure on the gasket is achieved.

In plastic joints

Threads are not made on polypropylene pipes, since they are not intended for this. Adapters with metal fragments with internal or external threads pressed into them are welded or glued to the ends of the pipes (this depends on the operating conditions). And American women are already attaching themselves to these elements.

Dear reader, if you have experience in this field, share it with those who are taking their first steps in the repair business. We will be very grateful to you.

( 1 ratings, average: 5.00 out of 5)

Differences in carving

Novice professionals are often interested in the question of what an American is in plumbing, and what shape and cross-section are suitable for different types of connections. Quite a lot of them have been developed, let’s focus on the main ones.

Fitting disassembled Source prom.st

Cone and flat

The most well-known and used type of connection when joining a pipeline is a cone connection. Due to the absence of a gasket, contact during docking becomes reliable and tight. Thermal resistance allows the American cone to be installed in heating systems.

The flat American is slightly inferior to it due to the reduction in gasket during operation. This causes leaks. It is best to install it on an accessible section of the pipeline for timely maintenance.

With internal thread

To connect steel and brass pipes, use a strong and reliable American coupling with internal threads. Before joining, a thread is made to match the American type used, so plastic is not well suited for these purposes. It is not necessary to completely dismantle or remove sections of the highway. After installation, the connection is secured using a union nut screwed onto the pipe.

Internal thread connection Source prom.st

Scope of application

“American” is used for quick fixation/disconnection of pipes and control elements of heating and water supply systems. Most often it is used in the following cases:

- for connecting metering equipment (meters) to hot and cold water supply pipelines;

- for connecting two threaded sections if their rotation is impossible or unacceptable, for example when connecting a pipe to a shut-off valve.

Coupling materials

The strength and stability of the connection under the influence of different temperatures depends on the material of the fitting. The material must be free from rust and other types of corrosion. For each type of pipeline, separate American pipes made of different metal or plastic are selected.

Stainless steel

Stainless steel fittings are durable and convenient, easy to install and have a long service life. The appearance and technical properties do not change throughout the entire service life. Due to this, stainless steel connections are considered the most popular.

Galvanized

They have a shorter service life and, due to their low cost, are used for large-scale construction work. The zinc leaves the iron body within a year, then corrosion destroys the black iron and causes the fitting to fail.

Galvanized coupling Source rodogerb.ru

Brass

The composition of such a fitting is resistant to heat and chemical compounds, which allows it to be used in various industries. Brass products meet all safety standards, the only drawback of which is the high price and change in the appearance of brass. The latter can be corrected by chrome plating or powder paints

Copper

High prices and poor demand resulted in limited production of American copper fittings. They are mainly used for installing copper pipes. Over time, copper develops a patina and begins to darken, which only makes it more difficult to maintain. In addition, copper is easily damaged by electrolytic corrosion, methods for combating which have not yet been developed.

Installation rules

Ball valves are easy to install. This is done using a special key in the following sequence:

- First, the integrity and cleanliness of the pipeline threads are checked.

- Then it is recommended to wrap it with FUM tape, which will ensure better tightness of the connection.

- Before installation, you should check whether the adjusting knob of the mechanism makes a full revolution.

- “American” is wound by 4-5 turns.

- It is checked that all the nuts are tightened well, after which the water supply is turned on.

- After a few minutes (if water begins to drip at the joints), the nut must be lightly tightened with a wrench.

Pros and cons of being American

Despite their widespread use, connections according to the American standard have not only advantages, but also disadvantages. Let's first look at the advantages:

- Maximum tightness due to the reliability and strength of the connection.

- American ones are installed without the use of welding tools. Just tighten a couple of nuts for installation.

- Reusable. The connection can be easily dismantled and assembled in another section of the highway.

- Versatility of docking. The American allows you to connect pipes of different materials.

- Reliability of fittings. Using American, all elements of the highway will be firmly connected and will last for a long time.

The only significant drawback is the high cost of the American coupling. This is due to the unsurpassed quality of the product.

Reliably connected plumbing pipes using an American Source moikolodets.ru

Design Features Differences

The standard threaded coupling is intended for the assembly of pipes and pipelines. The inability to create an effective water supply or heating system from a single pipe. Yes, it can be bent and connected to other, large branches, but this will significantly complicate the work without providing any serious advantages.

It is customary to assemble pipes using fittings. A coupling as a fitting - performs the simplest and most common task - fastens pipes together, forming straight or corner connections.

Threaded couplings are much more common than others, because they made it possible to assemble full-fledged branches from individual pipes, but at the same time leave them in a modifiable state. If a branch needs to be somehow modernized, improved, or simply disassembled, all you need to do is unscrew the coupling.

There are plenty of problems with standard threaded connections. This and:

- poor tightness;

- heavy weight, the need to cut a counter thread on the desired side of the pipe;

- the need to rotate pipes, etc.

The main problem lies in the design of standard type threaded connections. To disassemble the thread, you need to unscrew it. To do this, you need to rotate either the pipe or the fitting, which adds problems.

The American is like a coupling - it was conceived precisely in order to eliminate such shortcomings and give plumbers a convenient part.

Components of an American type coupling

The American turned out to be a truly universal example of plumbing. Its design, unlike a conventional threaded coupling, is completely dismountable and consists of at least three parts.

Two of them - counter ends with threaded threads - are screwed directly into the pipe cavity. They can have external or internal threads, it all depends on the specific design. The third part is a union nut, used to fasten the previous two.

The beauty of the whole design is its brevity. The detachable system allows you to connect fittings or ends on pipes by rotating the separate nut. There is no need to twist the pipes, the fitting itself, or the coupling body. Simply connect the coupling parts and tighten the nut until it stops.

Rubber gaskets are attached to the inner ends of the coupling parts. They are needed to improve the sealing of the connection.

Advantages and disadvantages

What specific advantages does the American-type coupling have and how is it useful for joining pipes?

Main advantages:

- American can be easily installed on any type of pipe;

- the ability to form transitions, corner connections, connect taps and any other plumbing fixtures;

- high level of tightness;

- availability on the market;

- good quality and performance;

- the design with a union nut simplifies installation and dismantling;

- a large selection of a wide variety of products to suit every taste and budget.

High-quality American steel

The advantages are traditionally considered to be ease of use and tightness. As we noted above, the standard connecting thread on a conventional coupling cannot boast of tightness or ease of installation. The American one saves us from such problems when assembling pipes into a single structure.

As for the minuses, the only thing that can somehow influence your decision is the price. The American one costs an order of magnitude more than a conventional threaded coupling. However, compression connections also cost their customers more, so there is nothing unusual here.

Joining of metal components

Metal pipelines for various purposes are still widely used in plumbing. Therefore, the installation of metal pipes is widely used in a wide variety of options.

For simple joining, you need to cut threads at the ends of the assembled elements using a standard thread-cutting tool. The American thread is screwed onto the prepared ends, and the threads need to be sealed by winding FUM tape or strands of flax fiber.

The final connection is made by tightening the nut and installing the gasket. When reusing the connecting assembly, the gasket must be replaced. The joint turns out to be reliable and repairable. What are the American types for metal components:

- direct connection of metal pipes;

- installation is carried out at right angles, as well as at angles of 30 and 45 degrees;

- installation of cantilever elements of a water supply system with a pipe, such as taps, mixers, air vents;

- threaded connection for changing to another diameter;