Plastic pipes have long been an excellent alternative to metal products. This popularity is explained by the strength and durability of polymer materials. In addition, polypropylene pipes have a composite structure, which allows the material to withstand high temperatures and pressure (without deformation), not be subject to corrosion, and not react to aggressive components.

In addition, the installation of such pipelines is much simpler: the plastic is easily processed and heat welded. In this article we will look at the key parameters that will be useful to both the home handyman and the professional plumber.

Scope of application of pipes made of polymer material

Considering that polypropylene pipes are able to function in almost any conditions, the products have a wide range of applications. In particular:

- Hot and cold water supply in multi-storey and private buildings.

- Sewerage.

- Installation of a “warm floor” system in the house.

- Disposal of groundwater and wastewater.

- Creation of drainage, irrigation and reclamation systems.

- Ventilation.

- Pneumatic systems.

- Pipelines for transporting chemically active substances.

It should be noted that depending on the application, different types of pipes are used. Subject to operating conditions, these products can last about 50 years without loss of functionality.

What determines the service life

The main quality parameter of composite pressure pipes is their service life, which depends on the characteristics of the source material and the conditions of use - operating temperature and pressure.

Under standard operating requirements, the operating cycle of water pipelines for cold and hot water supply is 25-50 years, respectively.

Standard conditions provide for the use of water supply systems within the boundaries of the recommendations provided by the manufacturer. Exceeding the permissible temperature and pressure leads to softening and rupture of the material structure, which affects the service life of the product.

Physico-mechanical characteristics

- Melting point: +149C (GOST 21553).

- Density: 0.9 g/cu.m. cm (GOST 15139).

- Yield strength (tension): from 24 to 25 N/kV. mm (GOST 11262).

- Tensile strength: from 34 to 35 N/kV. mm (GOST 11262).

- Elongation at yield point: 50%.

- Expansion coefficient: 0.15 mm/mmS (GOST 15173).

- Thermal conductivity (at +20C): 0.24 W/mS (DIN 52612).

- Specific heat capacity (+20C): 2 kJ/kgC (GOST 23630).

Advantages and disadvantages of plastic pipes

Polypropylene has a number of undeniable advantages over metal pipelines. The strengths of the material include the following:

- Long service life . Manufacturers claim that pipes used in cold water supply can last at least 100 years .

- Low weight . Polypropylene is a lightweight material. If we compare products of similar length and diameter made of plastic and metal, the former will be about 9 times .

- Easy installation . A person who does not have special skills and knowledge can handle the installation of such a water supply system.

- Increased level of sound insulation . Pipes in residential buildings do not allow noise to pass through.

- Corrosion resistance . The inner surface of the pipe is processed using a special technology, which eliminates the appearance of solid formations that reduce the throughput of the pipeline.

In addition, one can note high resistance to low temperatures and dynamic loads. Such pipes do not require special maintenance and are sold in an affordable price segment.

The material also has some disadvantages. In particular:

- There remains a high probability of linear expansion, which requires the installation of special compensators .

- Accelerated aging of the material under the influence of direct sunlight .

- Low thermal stability , which implies the mandatory use of insulation.

In addition, wall mounting pipelines are not allowed to sag, so the number of fastening elements increases significantly.

Properties of polypropylene

Although polypropylene is the least dense of all plastics, it is more resistant to abrasion, tolerates heat better, begins to soften only at 140°C, is chemically resistant, and almost does not crack as a result of corrosion. The material is plastic. Under loads not exceeding the maximum, it stretches and then returns to its previous shape without any changes in properties and characteristics. So it's a really good and safe option. Pipelines in food factories are made from polypropylene pipes.

An additional plus is that polypropylene pipes are easy to connect - they are welded. In general, not only water pipes and heating are made from polypropylene. This material can be used as a frame for greenhouses, country furniture and a bunch of other useful things.

As you can see, the diameters of polypropylene pipes are different. And that's not all. There is also up to 1600 mm

Polypropylene has two disadvantages: high thermal expansion and reaction to oxygen and ultraviolet radiation. We learned to deal with both. In order for polypropylene to tolerate UV rays and light, stabilizers are added. To reduce thermal expansion, reinforced pipes are made. But even with reinforcement, the increase remains large and compensators must be installed in pipelines.

Another disadvantage of polypropylene pipes is that they become brittle at low temperatures. Some types begin to crumble at -5°C, others at -15°C. So external pipelines made of polypropylene require UV protection and insulation. That's why they probably prefer to bury them.

Symbols - markings

By marking polypropylene pipes you can learn about the raw materials used for production and the technical features of the material. The symbols given above indicate the ability of pipes to withstand a certain pressure inside the pipeline.

Now let's look at the markings, which indicate some properties of the material. In the construction market, you can find pipes of the following categories:

- PPB are products with high resistance to mechanical damage and water hammer, used in underfloor heating and cold water supply systems.

- PPH are large diameter pipes, which are usually used when installing ventilation systems.

- PPR is a universal product, equally effective in hot and cold water supply.

Regardless of the marking, polypropylene pipes are made of plastic. However, manufacturers usually add active additives to the raw materials that increase the elasticity and heat resistance of the material.

Types and classification

There are 4 classification groups, which are divided according to operating pressure parameters. It looks like this:

- PN 10 . They are used for transporting liquids at low temperatures – up to +45 degrees.

- PN 16 . Suitable for arranging a gas or liquid transport system, provided that the coolant temperature does not exceed +60 degrees.

- PN 20 . Widely used pipes that can withstand temperatures up to +95 degrees.

- PN 25 . Products for supplying hot water and steam, with coolant temperatures up to +100 degrees.

The numerical designation of each group indicates the pressure value in atmospheres inside the line. Design pressure depending on service life and temperature:

| Temperature (°C) | Service life (years) | Pipe type | |||

| PN 10 | PN 16 | PN 20 | PN 25 | ||

| Permissible excess pressure, kgf/cm2 | |||||

| 20 | 10 | 13,5 | 21,7 | 21,7 | 33,9 |

| 25 | 13,2 | 21,1 | 26,4 | 33,0 | |

| 50 | 12,9 | 20,7 | 25,9 | 32,3 | |

| 30 | 10 | 11,7 | 18,8 | 23,5 | 9,3 |

| 25 | 11,3 | 18,1 | 22,7 | 28,3 | |

| 50 | 11,1 | 17,7 | 22,1 | 27,7 | |

| 40 | 10 | 10,1 | 16,2 | 20,3 | 25,3 |

| 25 | 9,7 | 15,6 | 19,5 | 24,3 | |

| 50 | 9,2 | 14,7 | 18,4 | 23,0 | |

| 50 | 8,7 | 13,9 | 17,3 | 23,5 | 21,7 |

| 25 | 8,0 | 12,8 | 16,0 | 20,0 | |

| 50 | 7,3 | 11,7 | 14,7 | 18,3 | |

| 60 | 10 | 7,2 | 11,5 | 14,4 | 18,0 |

| 25 | 6,1 | 9,8 | 12,3 | 15,3 | |

| 50 | 5,5 | 8,7 | 10,9 | 13,7 | |

| 70 | 10 | 5,3 | 8,5 | 10,7 | 13,3 |

| 25 | 4,5 | 7,3 | 9,1 | 11,9 | |

| 30 | 4,4 | 7,0 | 8,8 | 11,0 | |

| 50 | 4,3 | 6,8 | 8,5 | 10,7 | |

| 80 | 5 | 4,3 | 6,9 | 8,7 | 10,8 |

| 10 | 3,9 | 6,3 | 7,9 | 9,8 | |

| 25 | 3,7 | 5,9 | 7,5 | 9,2 | |

| 95 | 1 | 3,9 | 6,7 | 7,6 | 8,5 |

| 5 | 2,8 | 4,4 | 5,4 | 6,1 | |

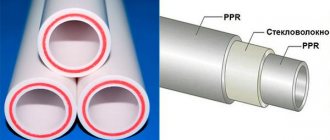

By type, products are divided into reinforced and non-reinforced. For the second group, reinforcement with the following materials is allowed:

- Fiberglass.

- Internal reinforcement with perforated foil.

- External - a layer of aluminum.

- Composite: internal layers made of glass or fiberglass.

For the installation of hot water supply or heating systems, only reinforced pipes are used.

Use of reinforcement

Reinforcement is one of the ways to give pipes special mechanical properties.

Reinforcement is as follows:

- Aluminum foil layer. It can be either external or located internally.

- Fiberglass layer. As a rule, it has an internal location.

Thanks to the reinforcement, the pipes are more durable, and the amount of their thermal expansion becomes smaller.

Experts recommend paying attention first of all to the fiberglass reinforcement layer. This type of pipe never loses its mechanical strength and does not delaminate, and its installation does not require stripping

This type of pipe never loses its mechanical strength and does not delaminate, and its installation does not require stripping.

Standard Size Charts

Considering that pipes of this type are used almost everywhere, manufacturers produce products in a wide size range. Product sizes vary within the following limits:

- Diameter – from 5 to 400 mm . Small pipes are usually used when laying pneumatic systems, medium pipes are used for private and multi-storey construction, large pipes are used for the improvement of buildings where high throughput of engineering communications is required.

- Length - the standard value is 4 meters , however this is not a standard characteristic and remains at the discretion of the manufacturer.

- Wall thickness – 1.9-15.1 mm .

It should be clarified that polypropylene pipes can be made in the form of a monolayer or multilayer structure. The second option involves reinforcement: a five-layer structure, where there is an aluminum spacer between the layers of plastic. The thickness of the reinforcing layer usually varies between 0.1-0.5 mm .

| Outer diameter, mm | PN10 | PN20 | PN30 | |||

| Inner diameter | Wall thickness | Inner diameter | Wall thickness | Inner diameter | Wall thickness | |

| 16 | 10.6 | 2.7 | ||||

| 20 | 16.2 | 1.9 | 13.2 | 3.4 | 13.2 | 3.4 |

| 25 | 20.4 | 2.3 | 16.6 | 4.2 | 16.6 | 4.2 |

| 32 | 26.0 | 3.0 | 21.2 | 5.4 | 21.2 | 3.0 |

| 40 | 32.6 | 3.7 | 26.6 | 6.7 | 26.6 | 3.7 |

| 50 | 40.8 | 4.6 | 33.2 | 8.4 | 33.2 | 4.6 |

| 63 | 51.4 | 5.8 | 42 | 10.5 | 42 | 5.8 |

| 75 | 61.2 | 6.9 | 50 | 12.5 | 50 | 6.9 |

| 90 | 73.6 | 8.2 | 6 | 15 | ||

| 110 | 90 | 10 | 73.2 | 18.4 | ||

See size tables for water and gas steel pipes. Learn about nominal diameter and how to avoid confusion between inches and mm. Go to article >>>

| Equivalent passage, mm | Outer diameter, mm | ||

| Steel gas pipelines | Steel water pipes | Polymer | |

| 10 | 17 | 16 | 16 |

| 15 | 21.3 | 20 | 20 |

| 20 | 26.8 | 26 | 25 |

| 25 | 33.5 | 32 | 32 |

| 32 | 43.2 | 42 | 40 |

| 40 | 48 | 45 | 50 |

| 50 | 60 | 57 | 63 |

| 65 | 75.5 | 76 | 75 |

| 80 | 88.5 | 89 | 90 |

| 90 | 101.3 | ||

| 100 | 114 | 108 | 110 |

| 125 | 140 | 133 | 125 |

| 150 | 165 | 159 | 160 |

| 160 | 180 | 180 | |

| 200 | 219 | 225 | |

| 225 | 245 | 250 | |

| 250 | 273 | 280 | |

| 300 | 325 | 315 | |

| 400 | 426 | 400 | |

| 500 | 530 | 500 | |

| 600 | 630 | 630 | |

| 800 | 820 | 800 | |

| 1000 | 1020 | 1000 | |

| 1200 | 1220 | 1200 | |

How much heat should the pipeline supply?

Let's take a closer look at the example of how much heat is usually supplied through pipes, and select the optimal pipeline diameters.

There is a house with an area of 250 sq. m., which is well insulated (as required by the SNiP standard), so it loses heat in the winter by 1 kW per 10 sq. m. To heat the entire house, 25 kW of energy is required (maximum power). For the first floor - 15 kW. For the second floor - 10 kW.

Our heating scheme is two-pipe. One pipe supplies hot coolant, and the other pipe cools it to the boiler. Radiators are connected in parallel between the pipes.

On each floor, the pipes branch into two wings with the same thermal power, for the first floor - 7.5 kW, for the second floor - 5 kW.

So, 25 kW comes from the boiler to the interfloor branch. Therefore, we will need main pipes with an internal diameter of at least 26.6 mm so that the speed does not exceed 0.6 m/s. A 40mm polypropylene pipe is suitable.

From the interfloor branching - along the first floor to the branching on the wings - 15 kW is supplied. Here, according to the table, for a speed of less than 0.6 m/s, a diameter of 21.2 mm is suitable, therefore, we use a pipe with an outer diameter of 32 mm.

7.5 kW goes to the wing of the 1st floor - an internal diameter of 16.6 mm is suitable, - polypropylene with an outer diameter of 25 mm.

For each radiator, the power of which does not exceed 2 kW, you can make an outlet with a pipe with an outer diameter of 16 mm, but since this installation is not technologically advanced, the pipes are not popular; a 20 mm pipe with an inner diameter of 13.2 mm is more often installed.

Accordingly, we use a 32mm pipe on the second floor before branching, a 25mm pipe on the wing, and we also connect the radiators on the second floor with a 20mm pipe.

Some important installation nuances

The installation of plastic pipes is somewhat different from their metal counterparts. In particular, during installation the following conditions must be observed:

- Polypropylene pipes do not bend at right angles; tees and fittings are used here to change the direction of the line.

- Plastic does not collapse under the influence of temperature changes: the pipe increases in length. Therefore, if the length of the pipeline section exceeds 10 meters , temperature compensators must be installed.

- Under the influence of high temperatures, pipes are subject to linear expansion, so rigid fixation of the pipeline inside wall structures is not allowed: thermal gaps must be left.

- For hot water supply, only reinforced products are used, which are less susceptible to linear expansion.

- Slight bending of the pipe is allowed. This can be done by heating the surface with a hair dryer (temperature about 140 degrees ).

It should be noted that storing plastic pipes in open spaces is not recommended. To protect products from direct sunlight, which destroys the structure, canopies must be installed.

Connection method

As already mentioned, polypropylene is joined by welding. But despite the high level of plasticity, the minimum bending radius does not allow making turns even at an angle of 90°, not to mention steeper ones. All branches and turns are made using fittings. These are special elements for connecting plastic pipes. This is a whole range of different parts for each diameter.

Fittings for polypropylene pipes: types and varieties

The difference is that the marking indicates the diameter of the pipe for which these elements are intended. So you don't need any sizing. If you are using a pipe, say, with a diameter of 25 mm, then simply take fittings with the same marking. It is better to buy both from the same company. Then there will be no problems. If you had to take products from different companies, try them on to be sure. Take a piece of pipe to the store and check compatibility. It should fit in without any problems, but tightly, without gaps.

Key selection criteria

To buy high-quality pipes that will easily reach the service life declared by the manufacturer, you must follow the selection recommendations:

- Selection of components.

During installation, you will definitely need couplings, fittings, and wiring tees. The ideal option would be combined elements with threaded inserts or metal frames. Such products will provide a high-quality transition between plastic and metal pipes. - Manufacturer.

The products are in consistently high demand all over the world, so plastic pipes are produced by domestic, European and Asian companies. Pipes produced by German, Czech and Russian companies have proven themselves well. Products from Turkish and Chinese manufacturers should be treated with caution: low cost implies low quality.

- Marking.

Here you need to pay attention to the pipe capacity, resistance to water hammer and temperature changes. The best option is to choose a pipe whose characteristics slightly exceed the required values.

It should be noted that the durability of a plastic pipeline is affected not only by the characteristics of the product, but also by the correct installation.

Required data for calculation

The main task of heating pipes is to deliver heat to the heated elements (radiators) with minimal losses. We will build on this when choosing the correct pipe diameter for heating a house. But to calculate everything correctly, you need to know:

- pipe length;

- heat loss in the building;

- element power;

- what kind of pipe layout will be (natural, forced, single-pipe or two-pipe circulation).

The next point, after you have all the above data in your hands, will be necessary to sketch out a general diagram: how, what and where it will be located, what thermal load each heating element will carry.

Then you can begin to calculate the required cross-section of the diameter of the pipe for heating the house. You should also be careful when purchasing:

- metal-plastic and steel pipes are marked by the size of the internal diameter, there are no problems here;

- but polypropylene and copper - by outer diameter. Therefore, we need to either measure the internal diameter ourselves using a caliper, or subtract the wall thickness from the external diameter of the pipe for heating the house.

Don’t forget about this, because we need exactly the “inner diameter of the pipe for heating the house” in order to calculate everything correctly.

Rating of trusted manufacturers

Among companies engaged in the production of polypropylene pipes, the most popular brands are:

- WAWIN ECOPLASTIK . A Czech company that has managed to win a high rating among builders all over the world. The manufacturer's revolutionary solution is all-plastic FIBER pipes, which have minimal weight, but at the same time show high strength and resistance to linear expansion.

- FV-PLAST . Another Czech company presented on the market with reinforced pipes with perforated aluminum inserts. The products produced have a wide size range and are ideal for installing hot and cold water supplies.

- PRO AQUA . A Russian enterprise engaged in the production of multifunctional polypropylene pipes. The company's products are distinguished by high technical characteristics, while being sold in an affordable price range.

In addition, you can pay attention to the products of such companies: BANNINGER REISKIRCHEN (Germany) and VALTEC (Italy). Plastic pipes of these brands are in the high price segment, but have almost standard quality.

If you are setting up a house or apartment

When creating a project for a standard private house or apartment, there is no need to carry out precise calculations. The number of plumbing fixtures will be minimal, and the difference in price for pipes of different diameters will differ minimally, which will have virtually no effect on the budget.

If you look at the faucet hose, you can see what a small diameter they have, that is, through what minimal holes water flows into the sink. Taking into account the fact that the cross-section of the polypropylene pipe will be much larger, it will always be sufficient, since the bottleneck in this case will be precisely this hose. That is, the patency of the entire system will rest on its narrowest point.

That is why the owners of private houses and apartments do not carry out complex calculations, but simply purchase a polypropylene pipe with a cross-section of 20 mm, saving their precious time. In the vast majority of cases, with a standard number of washbasins, sinks, bathtubs and other plumbing fixtures, such a pipe will be sufficient with a large margin.

We hope everyone understands what diameter polypropylene pipes are measured by. Selecting them will not be difficult. As practice shows, you can often simply purchase the simplest and cheapest pipe - the result will be a high-quality and properly functioning water supply system.