Polypropylene pipes are used to equip water supply systems in residential, industrial and administrative buildings. The material used for the production of plastic water conduits belongs to the group of polyolefins and, like all substances in this category, is an environmentally friendly product. The products are distinguished by impact strength, chemical resistance and mechanical strength in different temperature conditions.

Polypropylene pipes for cold and hot water supply have become popular and widely used due to their advantages.

Polypropylene pipes for cold and hot water supply: scope of application

Plastic composite water supply systems are used as a distribution mechanism in public and residential buildings, and are widely used in the agricultural sector to supply the industry with process and drinking water. In addition, polypropylene pipelines can be used to transport chemically active liquids and compressed air.

The technical characteristics of polymers allow them to be used in almost any industry that requires transportation of air and liquids:

- for cold water and hot water supply;

- for organizing heating systems;

- to ensure the workflow of hydraulic and compressor equipment;

- as ventilation and climate control equipment;

- for the purpose of heating surfaces;

- for organizing sewerage;

- in land reclamation, artificial irrigation, drainage, etc.

The effectiveness of welded joints of plastic pipelines is close in strength to the quality of welding of metal products. This allows us to consider polypropylene one of the most advantageous building materials for the production and use of pipelines.

What about areas of application?

There are other designations as well. Some of them are able to show where and how to install a pipeline from a particular material.

Typically this designation takes the form of a schematic drawing. Marking of reinforced polypropylene pipes is no exception.

The following is a complete list of areas of application.

- For systems providing fire protection.

- In shipbuilding

- For sports facilities.

- To irrigate farmland.

- For use in industrial infrastructure.

- For heating, warm floors and walls.

- In water supply systems.

- With heating pipelines.

- For drinking water pipelines.

Polymers have become especially widespread and have become an integral part of our lives. Labeling of plastic pipes for water supply also cannot be done without them.

Advantages and disadvantages of polypropylene pipes

The reliability and durability of polypropylene pipes for cold and hot water supply largely depends on the quality and performance characteristics of the source material, which is characterized by high strength, elasticity and durability.

The main advantages of polymer pipelines:

- When in contact with water, they do not form salt or alkaline deposits that promote corrosion.

- The diameter of plastic pipes remains unchanged throughout the entire service life.

- The product is environmentally friendly, which especially affects the quality of the transported water.

- The material is chemically inert and non-toxic.

- The composite withstands pressure and short-term temperature changes well.

- Eliminates pressure drop due to friction in the pipes (low roughness).

- Low thermal conductivity.

- In operating mode, no condensation forms on the surface of the pipes.

- High sound insulation properties.

- Composite products are made from an opaque material, which inhibits the formation of algae and light-sensitive bacteria during the transportation of liquids.

- When water freezes in polymer pipelines, their structure is not destroyed, but stretches and is restored when defrosted.

- Installation of polypropylene fittings does not require special skills. The use of sleeve welding allows you to create a tight and durable connection in a few minutes.

- Polymer pipes are 9 times lighter than steel water pipelines.

- Low cost and easy to maintain. Plastic does not require additional heat and waterproofing.

Polypropylene pipes are characterized by increased durability and high operating temperature.

Among the disadvantages of polymer pipes, several positions can be distinguished, these are:

- high linear expansion rates;

- impossibility of installation and operation in low temperature conditions;

- low resistance of the material to ultraviolet radiation;

- The use of plastic products in fire extinguishing systems is not permitted.

The deformation and strength characteristics of plastic pipelines largely depend on the temperature of the transported medium. Therefore, the design of pressure polymer networks must be carried out taking into account the operating temperature, technical conditions for performing the work and the planned service life of the structure.

Popular manufacturers

On the domestic PPR market, water pipes are represented by products of Russian and foreign manufacturers. There is no particular difference between them; the plastic production technology is used in all cases. However, it is extremely important to look at the numbers written on the product label. Manufacturers often add various plasticizers to their plastic to enhance certain characteristics.

Popular manufacturers of polypropylene pipes

Among the popular manufacturers of the pipes in question are:

- Banninger and Rehau (Germany);

- Valtec (Italy);

- Ecoplastic FIBER (Netherlands);

- TEBO and Vesbo (Türkiye);

- BLUE OCEAN (China);

- ProAqua and Politek (Russia)

The quality of these manufacturers is almost the same. But for German pipes you will have to pay a little more due to the brand, and for Chinese ones, on the contrary, a little less. At the same time, Russian analogues also maintain their brand, having a very affordable cost per linear meter.

Types of polypropylene pipes

When laying out pipelines for water supply and heating, one of the main factors is the choice of components. Based on their structure and technical characteristics, polymeric materials are divided into several types:

- Single-layer pressure pipe for cold water with an operating temperature of +20°C and an allowed pressure of up to 10 bar.

- Single-layer for hot and cold water supply with maximum pressure up to 20 bar and operating temperature up to +75°C.

- Multilayer, reinforced with perforated aluminum foil, temperature up to +90°C, pressure - 20 bar.

- Multilayer, fiberglass reinforced - up to +90°C, 20-25 bar.

According to the material of manufacture

In accordance with the international standard EN ISO 15874-2013 and Russian GOST 32415-2013, pressure pipes and connecting fittings are made from the following materials:

- PP-N (Type 1 PP-G) - homopolymers;

- PP-V (Type 2 PP-B) - block copolymers;

- PP-R (Type 3 PP-R) - random copolymers;

- PP-RCT (Type 4 PP) are random copolymers with modified crystallinity and high heat resistance.

Fittings of classes 1-4 must be suitable for transporting hot and cold water for 50 years.

By type of reinforcement

The pipe, whose structure is improved by perforated aluminum foil, consists of three layers. During the manufacturing process, the inside of the pipe is connected to evenly spaced perforated foil and covered with a layer of polymer on top.

Reinforcement reduces the coefficient of thermal expansion of structures.

The outer contour is needed to protect the aluminum perforated layer from damage. The middle part of the foil forms an intra-diffusion barrier to protect against air penetration into closed heating systems.

The low value of thermal linear expansion (less than that of single-layer pipes) makes the product more rigid, which reduces its sagging and allows for a reduction in the volume of fasteners and expansion joints.

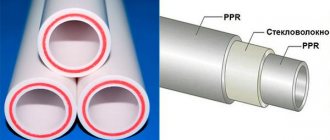

Pipes reinforced with fiberglass have the same properties as those with an aluminum layer. The presence of a middle layer gives such reinforcement additional strength and reduces the linear elongation.

“Reading” the information

If you pick up a polypropylene pipe, you will see a long row of symbols, abbreviations and numbers on it. Let's figure out what they mean. A detailed transcript is in the image below.

- The first place is usually the name of the manufacturer.

- Next comes the designation of the type of material from which the product is made: PPH, PPR, PPB.

- The working pressure must be indicated on pipe products, which is designated by two letters - PN - and numbers - 10, 16, 20, 25.

- Several numbers indicate the diameter of the product and the wall thickness in millimeters.

- On domestic modifications, the operating class may be indicated according to GOST.

- Maximum permissible operating pressure.

Additionally indicated:

- Regulatory documents in accordance with which pipe products are manufactured, international regulations.

- Quality mark.

- Information about the technology used to make the product and MRS classification (minimum long-term strength).

- 15 digits containing information about the production date, batch number, etc. (the last 2 are the year of manufacture).

Now let’s take a closer look at the most important characteristics of polypropylene pipes indicated in the labeling.

Main technical characteristics

Polypropylene is an artificial material with high physical and chemical characteristics, obtained by the polymerization of synthetic substances. Pipes made from such a composite have the following properties:

- density - 0.92 kg/cm³;

- resistance to chemically active liquids;

- bending and tensile-compressive strength;

- high levels of electrical and thermal insulation;

- wear resistance;

- permissible temperature range - -15...+120°С;

- plastic deformation to the conditional yield strength - 50%;

- low linear elongation when heated;

- heat capacity 2.0 kJ/(kg.°C);

- low thermal conductivity.

Product color

There are PPR pipes on the market made from materials of different colors. Is there a difference when choosing? Can we say that a gray pipe is better than a white one?

Experts are divided over this indicator: some believe that shades do not affect anything and that this is just a marketing ploy. However, there are many descriptions of products that differ in color, which present different operational, performance and economic characteristics.

For convenience, the estimates are tabulated:

| Pipe color | Performance properties |

| White | Long service life. The maximum pressure withstand is twenty-five bar. Low cost. Not subject to corrosion. |

| Grey | Ability to withstand elevated temperatures Ability to withstand aggressive environments: acidic and alkaline. Long period of operation. Environmentally friendly. High level of tightness. |

| Black | Immunity to ultraviolet rays. Ability to withstand aggressive environments. Resistance to drying out. Increased strength |

| Green | Cheap option, low operating pressure. Suitable, perhaps, for a country shower and watering the garden. |

Technical requirements according to GOST

According to established norms and standard requirements for the manufacture and use of polypropylene products for plumbing, heating and hot water supply, materials must meet the following characteristics:

- Pipe used to transport liquids must have smooth internal and external surfaces.

- Small longitudinal defects are allowed on the polymer profile: waviness, stripes that do not protrude beyond the limits of permissible deviations.

- The presence of cracks, swelling, chips, cavities, and foreign inclusions on the internal, end and external surfaces is not allowed.

- Changes in yield strength from the original - no more than 20%.

- Vicat creep temperature ≤ +80…+115°С.

- The height of the profile after removing the sprues should be within the range of 0.3-0.5 mm.

- Fitting joints must ensure tightness for 5000-10000 cycles.

The water pipe used must have smooth internal and external surfaces.

Service class

When choosing domestically produced polypropylene products, the purpose of the pipe will indicate the service class according to GOST.

- Class 1 – the product is intended for hot water supply at a temperature of 60 °C.

- Class 2 – DHW at 70 °C.

- Class 3 – for underfloor heating using low temperatures up to 60 °C.

- Class 4 – for floor and radiator heating systems that use water up to 70 °C.

- Class 5 – for radiator heating with high temperatures – up to 90 °C.

- CW - cold water supply.

USEFUL INFORMATION: Polypropylene hot water pipes are an excellent alternative to metal pipes.

Marking of polypropylene pipes

Technical marking of materials for the consumer is necessary for the correct calculation and selection of the required range of plastic pipes, which depends on the purpose and operating conditions of the product. There is a basic article and several types of additional designations.

The standard designation of a polymer product is as follows:

- the word "pipe";

- abbreviated name of the material;

- SDR is the dimensional ratio of the optimal outer diameter to the wall thickness;

- external profile size;

- wall thickness;

- operating class;

- maximum working pressure;

- standard number.

For example, polypropylene random copolymer SDR 11, external size 20 mm, wall thickness 1.9 mm, class 1, optimal pressure 1.0 MPa:

Pipe PP-R SDR 11-20´ 1.9 class 1/1.0 MPa GOST R 52134-2003.

Marking can also be done indicating the structure of the product, type of material, nominal pressure, category and area of application.

Product structure:

- S—single-layer pipe;

- M - multilayer;

- TI - with thermal insulation;

- PP - standard polypropylene;

- PP-RP - products that can withstand high pressure.

Material type:

- PPB - increased mechanical strength, for hot water in underfloor heating systems;

- PPH - with increased internal diameter (ventilation and cold water supply);

- PPR is a universal pipe with elevated operating temperatures.

Pressure indicator:

- PN 10 - operating pressure 1.0 MPa, temperature - +20...+45°C;

- PN 16 - up to +60°C, 1.6 MPa;

- PN 20 - pressure 2 MPa, temperature - +95°C;

- PN 25 - for heating and hot water supply - 2.5 MPa, +95°C.

Pipe class:

- class 1 - up to 60°C - water supply;

- class 2 - pipelines up to 70°C;

- class 3 - up to 60°C - “warm floor”;

- class 4 - heating, up to 70°C;

- class 5 - up to 90°C, heating;

- class XB - cold water.

Marking of polymer pipes for water supply allows the buyer to quickly determine whether this product is suitable for him or not.

The area of application of the composite is indicated by the color of the product:

- white - water pipes;

- gray - heating system, hot and cold water;

- black - sewerage, drainage systems;

- green - individual water supply within the boundaries of a personal plot.

As additional parameters, depending on the supplier of materials, the pipes may indicate the manufacturer’s trademark, the presence of a certificate, the date of manufacture and the serial number of the batch.

General information

Where are polypropylene pipes used?

Pipes made of high-quality plastic are used when laying water pipes in apartments, private houses, cottages and industrial enterprises. With their help, they organize the supply of cold and hot water, and they are also capable of transporting aggressive chemical solutions and air.

Important! Welding joints of polypropylene pipes are considered as strong as metal ones. This quality makes the material beneficial for the construction of various water supply systems.

Pros and cons of plastic pipes. Positive characteristics of polypropylene pipes:

- 1. They are not susceptible to corrosive changes or the deposition of limescale from water.

- 2.Polypropylene is absolutely non-toxic, does not emit chemicals and odors during its entire service life.

- 3.The diameter of the products does not change under any circumstances.

- 4.The product is made from environmentally friendly raw materials, which has a positive effect on the water passing through the pipes.

- 5.pipes are able to withstand high pressure and sudden changes in temperature conditions.

- 6.The smooth surface helps maintain the water pressure at the outlet.

- 7.Low level of thermal conductivity.

- 8.pipes do not form condensation on the surface.

- 9.Increased sound insulation.

- 10.Polypropylene products are opaque, so during system operation they resist the formation of algae and bacteria that are sensitive to sunlight.

- 11. At low temperatures, the structure of the pipes is not damaged; they are able to stretch if the water in them freezes. When heated, the pipes restore their size.

- 12.Installation of polypropylene elements is easy and quick.

- 13. The weight of products made from polypropylene is nine times less than similar ones made from metals.

- 14.Considered to be an economical option for plumbing. Pipes do not require additional thermal or waterproofing.

Negative characteristics of polypropylene:

- 1.high linear expansion under temperature changes.

- 2.Cannot be installed or used at very low temperatures.

- 3.unresistant to UV rays.

- 4.Easily flammable, cannot be used in highly flammable systems.

Reference! The strength and resistance to deformation of polypropylene water pipes depends on the temperature level of the liquid in the system. When creating a water pipeline project, it is necessary to take into account the temperature regime of the water for which the outlet is being laid; it is also necessary to calculate the technical conditions of installation work and the approximate service life of the pipes.

Types of polypropylene products

Pipes of three classifications are considered widely used:

- PPH from homopolymer.

- Block copolymer PPB.

- PPR from random copolymer.

Pipes marked PP are practically never found, since they are of very low quality for this product. Common options for pipes are PPH, PPR markings, which are excellent for water pipes.

Polypropylene pipes are also marked PP-S or PP-PURE, which withstand the aggressive effects of liquids well and are suitable for use for industrial purposes.

Pipes made of PPH, PPB materials

PPH material is suitable for cold water supply and does not tolerate direct sunlight and frost.

PPB material is considered more durable and can withstand temperatures in the zone from twenty degrees below zero to 800 degrees above Celsius. Pipes are in a higher price segment.

The products are used when laying heated floors using hot water.

PPR material has the highest level of temperature resistance, does not undergo changes at temperatures of 900 degrees, and is not affected by ultraviolet rays. Pipes are widely used for all types of water supply and heating. The pipes must be installed in a warm room; their use outside is prohibited.

Reinforced pipes

The materials discussed above are used for single-layer pipes; along with them, there are reinforced products made of polypropylene, in which hard material is laid between layers of plastic.

Reinforcement methods:

- PPR-AL-PPR marking means reinforced with foil.

- PPR-FB-PPR stands for Fiber Fiber Reinforcement.

- PPR-GF-PPR stands for glass fiber reinforced.

- Reinforcement using composite materials.

Reinforced pipes are characterized by increased strength and surface rigidity, as well as heat resistance and thermal conductivity. Laying a water supply system using such elements will be very expensive. They are good for use in heating applications.

What marking indicates pipe pressure? In addition to the PP material, the pipes are marked with pressure that the pipes can withstand. According to GOST, pressure is designated by the letters PN with a value from ten to twenty-five.

PPR pipes have the following varieties:

1. PN 10 pipes with thin walls for cold drainage, also for heated floors with water temperatures up to four hundred and fifty degrees.

2. PN 16 pipes are considered universal for hot and cold water, withstand temperatures up to six hundred degrees.

3. PN 20 pipes with thick walls can withstand water temperatures up to nine hundred and fifty degrees.

4. PN 25 reinforced pipes for hot water disposal and heating systems, withstand temperatures up to nine hundred and fifty degrees.

Important! Pipes may experience a short-term excess of the maximum temperature, but long-term operation at the elevated temperature indicated on the marking will lead to destruction of the pipe. The service life will be greatly reduced compared to that declared by the manufacturer (up to 50 years).

Table of standard sizes of polypropylene pipes

Table of the main parameters of polymer pipes for cold and hot water supply.

| Diameter, mm | Conditional bore, mm | PN10 shell thickness, mm | PN20 shell thickness, mm | Weight of 1 m/p pipe, kg |

| 20 | 15 | 1,9 | 3,4 | 0,106-0,172 |

| 25 | 20 | 2,4 | 4,3 | 0,164-0,226 |

| 32 | 25 | 3,0 | 5,4 | 0,266-0,434 |

| 40 | 32 | 3,7 | 6,7 | 0,412-0,671 |

Chinese pipes - cheap fake or good quality?

Although products from China do not always have a positive reputation, good quality can be found among Chinese polypropylene pipes. We present to your attention well-known brands of pipes that can be found on the Russian market:

Blue Ocean

Blue Ocean. The Chinese company Blue Ocean produces high-quality fittings and pipes made of polyethylene. As practice has shown, pipes from the Blue Ocean manufacturer are excellent at soldering. For these pipes, it is customary to use soldering iron nozzles that have small curves that are located inside the nozzle. Thanks to this innovation, aluminum is better sealed with a layer of polypropylene. One of the disadvantages of pipes is the error in diameter, which can vary within small limits. Moreover, as installers say, Blue Ocean pipes are a bit difficult to insert into the soldering iron. You have to solder by eye, since the red line is drawn in a spiral.

Design. Dizayn pipes are produced reinforced. There is no need to strip the aluminum before soldering them. Thanks to this, their installation for both cold and hot water supply is accelerated and simplified. As a result, solder joints have an aesthetic appearance. Chinese Dizayn pipes occupy a worthy place on the Russian market. Even non-specialists can work with them. In some respects, they are not inferior to leading European brands of polypropylene pipes.

So, although China is famous for producing cheap building materials, you can find high-quality polypropylene pipes.

How to choose a diameter

When choosing pipes, in addition to quality characteristics, you need to take into account the outer and inner diameters of the product, the size of which affects the hydrodynamic properties of the system.

Pipeline capacity depends on many factors, including:

- number of sources;

- purpose of the water supply;

- pressure force;

- maximum load;

- number of branches (consumers);

- distance between the starting and ending connection points.

Connection to the central water supply for individual use is made using pipes Ø 32 mm. For internal networks, profiles with an outer diameter of 16-25 mm are used.

In everyday life, water pipes from 20 to 32 mm are considered the most used.

Additional data

In addition to the basic characteristics indicated, the marking of plastic pipes for hot water contains the following information:

- data on compliance with the requirements of international and domestic technical regulations;

- manufacturer – brand or trademark;

- name and number of the quality mark - this data confirms the product’s compliance with international standards;

- the type of production technology used and the minimum long-term strength (MRS) characteristic;

- production date, batch number and other information contained in the 15-digit code.

Which polypropylene pipes are better for water supply?

In order to find out which type of product is most suitable for hot and cold water, you must first choose the manufacturer of the material, read the recommendations and, based on this, make the right choice.

For hot water

When installing hot water supply, it must be taken into account that polypropylene pipes have a relatively high thermal expansion. Thus, with an increase in temperature by 10°C, the length of unreinforced products increases by 1.25 mm/m, and improved ones by an average of 0.32 mm/m.

In this regard, for the equipment of such systems it is necessary to use exclusively reinforced types of propylene pipes.

The temperature of supplied hot water for individual users is within +45…+75°C.

Therefore, to ensure uninterrupted supply, pipes designed for use in this temperature regime are suitable - these are grades PN 20 and PN 25 with an optimal pressure of 2.0-2.5 MPa.

For cold water

Unlike hot water, both single-layer and multi-layer pipes are suitable for cold supply. The main requirement for laying a water pipeline is the pressure of the liquid and the distance to the source.

In terms of price-quality ratio, more suitable materials are single-layer pipes with an operating temperature of up to 20°C and an allowed pressure of up to 10 bar. According to the designation, such pipes belong to service class 1, white or gray, grades PN 10 or PN 16.

Repair of PP pipes

For various reasons, polypropylene water pipes leak. To prevent accidents, you need to know the main causes of the leak, and most importantly, be able to eliminate them in a timely manner.

The causes of leaks are the same in pressure and non-pressure lines:

- The weak areas of the pipeline are the joints, so the majority of accidents occur due to their depressurization.

- Malfunctions in non-pressure pipelines are associated with improper operation, manufacturing defects and poor installation of water supply elements.

- A common cause of leaks is poor-quality welding of joints.

- Exceeding the permissible pressure.

- Often the influence of external forces violates the tightness and integrity of the polypropylene pipeline.

Repair of polypropylene pipes requires partial or complete replacement of a section of the main line.

To prevent depressurization of connections, during the installation of the water supply it is necessary to check whether the seals are in place; to do this, measure the depth in several places. If the ring is positioned properly, then the depth will be the same everywhere.

Carrying out repair work

Repairs begin with identifying the location of the leak; most often they appear in butt joints. Then the water is shut off in the section of the pipeline where repair work will be carried out.

Polypropylene water pipes for cold water in non-pressure mains are joined using a socket method and the joints are sealed with a rubber seal.

Accidents are more common in pressure mains, so the service life of the pipeline depends on the correct installation.

If the seals are worn, disassemble the joint and replace the rings. Joints in pressure pipelines are connected using soldering. To do this, use a special heating device (soldering iron), and only dry and clean pipes and fittings are used for welding to prevent depressurization in the future.

Features of the use of polypropylene pipes in the heating system

When determining which brand of pipe can be used for heating, it is necessary to take into account the supply temperature, which depends on the characteristics of the installed heating devices, their technical capabilities, the type of expansion tank and the method of recharging the system.

The higher the water temperature, the shorter the service life of propylene pipes for water supply and heating.

In an apartment, the cross-section of polypropylene water pipes should be equal to the internal diameter of the supply pipelines (risers). It should be taken into account that the wall thickness of polymer pipes is greater than that of steel reinforcement. In a private house, central wiring is carried out with a Ø 32 mm profile, connection to radiators is carried out using pipes with a cross-section of 20-25 mm.

For individual heating, multilayer reinforced products are used, but it must be remembered that for products with aluminum foil, the linear expansion is much greater than for products with a fiberglass layer.

When using a floor heating system in a private house, the pipes are calculated based on the design temperature of the structure, the type of room and the area of the heated area. The heat exchange limit is within the range of +35…+45°C.

Types of fittings for polypropylene pipelines

For the installation of polypropylene pipelines, manufacturers offer a full range of fittings necessary for the installation of engineering communications of all types: angles, couplings, reductions, plugs, valves and other connecting, regulating and shut-off elements of the pipeline. This eliminates the use of metal parts.

When deciding how to choose polypropylene pipes and fittings, they are guided by the purpose of the pipeline being installed and its design features. Thus, to connect the polypropylene section of the pipeline with the metal section, fittings with chrome-plated brass inserts are used. The same connecting elements are used when connecting polypropylene pipes to various plumbing fixtures.

If you use polypropylene pipes, it is advisable to determine how to choose their type and connecting elements in consultation with professionals. It should be remembered that communications and fittings are best purchased from one manufacturer.

To solve the problem - how to choose the right polypropylene pipes - you need to be guided by a set of indicators: the quality and cost of products, ease of installation, cost of work if you need to turn to the services of specialists.

Installation and wiring - what are the nuances?

The structures of polypropylene pipes are one-piece. They are mounted using diffusion welding. Special fittings are used to install internal outlets. When connecting plastic and metal parts (faucets, mixers), corner joints with pressed-in brass segments are used.

Polymer pipelines are suitable for all types of installation:

- in separate channels and shafts;

- exposed wiring on the surface of the walls;

- closed laying in a layer of cement-sand screed or plaster.

Work order:

- Plastic pipes are cut with special scissors included in the equipment assembly kit.

- Measure the distance with a tape measure and use a pencil or marker to transfer this value to the surface of the product.

- The junction area is thoroughly degreased. Pipe markings that fall within the installation area must also be removed.

- Nozzles are installed on the unit and plugged into the network. The heating temperature regulator is set to 260°C. The heating time of the material is controlled by a burning light bulb. When the operating temperature is reached, the indicator goes out.

- The prepared parts are put on welding attachments. Wait 7 seconds and remove the blanks.

- Quickly, without rotation, the pipe is joined to the fitting and pushed to the specified level.

- Before installation, the finished connection must cool and gain strength (2 minutes).

- It is better to pre-assemble complex components, such as a manifold, branches, and then install the entire set in place.

- When installing water pipelines on walls and ceilings, it is not recommended to use fixed supports.

Installation

Polypropylene pipe connections are permanent. They are performed by melting the polymer component using special soldering irons, which are equipped with various nozzles.

To ensure reliable installation of pipes with external metal reinforcement, before performing socket welding, the polymer surface layer and the aluminum layer are removed from an area equal to the insertion depth. The parts prepared for soldering are cleaned and degreased.

Polypropylene pipe connection

- The pipes are cut at a right angle (use a hacksaw or special scissors).

- Select a nozzle and heat the soldering iron to 250-270°C (it may take 15-20 minutes depending on the model).

- Both elements to be joined are heated simultaneously - one is inserted into the sleeve to the welding depth, the second is put on the mandrel of the apparatus.

- The heating time is determined by the diameter of the pipes. Underheated parts will not connect reliably, and if overheated, the product and the welding site will be deformed.

- It is important to connect the heated parts quickly and accurately, without displacement.

While the weld is cooling, do not bend the product or make turns (just wait a few seconds).

What determines the service life

The main quality parameter of composite pressure pipes is their service life, which depends on the characteristics of the source material and the conditions of use - operating temperature and pressure.

Under standard operating requirements, the operating cycle of water pipelines for cold and hot water supply is 25-50 years, respectively.

Standard conditions provide for the use of water supply systems within the boundaries of the recommendations provided by the manufacturer. Exceeding the permissible temperature and pressure leads to softening and rupture of the material structure, which affects the service life of the product.

Criterias of choice

The main recommendation when purchasing polypropylene pipes is to select products from one batch of one manufacturer. The composition of the substance may partially change and the quality of pipes in different deliveries will be different. This will affect the butt joints and the durability of the structure. Purchasing pipes from different manufacturers may result in the connecting elements being unsuitable due to size differences. Each manufacturer has its own recipe for the substance; a discrepancy can lead to failure of the entire plumbing system.

You should also pay attention to the following indicators:

- Estimated fluid temperature in the system. For hot water supply, it is better to select reinforced products.

- Estimated pressure. When heated, the material becomes less durable and may burst.

- The diameter must correspond to the area where the pipes are installed.

You should not save if short-term temperature or pressure surges occur in the system, which sometimes happens in centralized systems. In this case, it is better to buy reinforced, expensive polypropylene, which has a longer service life.

In home systems, where the pressure usually does not exceed 1 MPa, you can use ordinary pipes, but follow the manufacturer’s instructions regarding what kind of water the product is intended for - hot or cold.