The construction of an autonomous sewer system at a summer cottage begins with the selection of a system suitable for the price and quality of wastewater treatment.

The optimal solution is to tie into the centralized sewerage mainline, but suburban areas in the Leningrad region are for the most part deprived of this opportunity. Therefore, the only possible way to organize the processing and disposal of wastewater remains the arrangement of a private septic tank.

You just need to understand the principles of operation of different types of autonomous sewage systems and choose the appropriate option, taking into account the characteristics of the site, preferences and needs.

All existing types are divided into three groups:

- drainage pits made of different materials;

- septic tanks;

- local treatment plants.

Autonomous sewerage: how the drainage pit works

The most primitive way to dispose of wastewater is a drainage pit. The principle of operation is simple: liquid masses are transported from the house through the drain pipe into the tank. If the container is sealed, household waste accumulates until it is filled, after which it is pumped out using sewer equipment. The procedure is repeated every 2–4 weeks. The frequency of pumping depends on the intensity of sewer use.

There is a type of cesspool in the form of a filtration tank. Concrete rings or a tank without a bottom are installed in the pit, and the lower part is covered with crushed stone and sand. Such autonomous sewerage devices are permitted by law only to serve the minimum number of points of water use in the house - showers and toilets. It is prohibited to install cesspools in the city, near neighboring buildings and water intake sources (wells and boreholes).

Disadvantages of a drain pit:

- Persistent unpleasant odor.

- Cluster of insects

- Costs for regular pumping of wastewater.

Making a septic tank using reinforced concrete rings

Now let’s return to the question that we raised at the beginning of the article - is it possible to make a septic tank yourself? You can, but we will consider the option with reinforced concrete rings, which are convenient, first of all, because they are produced on an industrial scale, so you just have to assemble them correctly.

To work you need to prepare:

- 1 bottom;

- 2 or 3 rings;

- 1 cover equipped with a hatch;

- bitumen;

- cement;

- gravel;

- sand.

Now let’s get straight to the workflow, which consists of several important steps. Let's get to know them.

Step one . First you need to dig a hole in accordance with the dimensions of the well. The septic tank must have a volume corresponding to at least three times the daily volume of wastewater. Four people, for example, produce about 1.8 cubic meters of this “good” per day, so do the math yourself.

Step two . Place a concrete “pillow” with added gravel at the bottom of the hole. Wait a week for the concrete to harden and strengthen sufficiently. Water it with a little water every day.

Step three . Now you can bring reinforced concrete structures to your site. It is advisable that they be transported along with the manipulator in order to be immediately installed in a pre-prepared hole. First you need to install the bottom, then the rings, and finally the lid. Particular attention should be paid to the quality of the joints.

Step four . To seal joints you need to use a solution. The inner surface of the well is covered with bitumen, preferably in two layers. This way the structure will be as airtight as possible.

Step five . After this, the entrance of the sewer pipe into the septic tank is sealed, as well as the exit from it. At the end, the structure is covered with a lid.

Note! It is recommended to equip a special jumper inside, as shown in the image below. This will separate the foam from the clarified liquid.

That's it, your septic tank can be considered ready. That's all, good luck with your work and don't forget to watch the feature video below!

How does an autonomous sewage system work in the form of a septic tank?

For country houses inhabited by 3–4 people, an autonomous sewage system such as a septic tank is suitable. The design is a factory-made container of several chambers. The wastewater coming from the house undergoes at least double purification:

- Mechanical. Inside the chamber, the waste settles and separates, after which the insoluble solid substance settles to the bottom, and the liquid moves to the next compartment.

- Biological. Filtration takes about three days. Organic compounds are processed by anaerobic bacteria in a crust on the surface of the liquid. Microorganisms do not require oxygen. During cleaning, methane is released, so the septic tank is equipped with ventilation.

Multi-chamber septic tanks are becoming the best choice for seasonal homes, for areas without an electrical connection or with intermittent power supply. The non-volatile system requires only regular filter cleaning (every 1-2 months).

Filtration systems

Any autonomous sewer system of a private house with septic tanks, in which mechanical purification of black water is carried out using the sedimentation method, requires additional filtration structures. They are needed in order to reduce the degree of contamination of soils or underground water basins when wastewater is sent into the ground.

For this, two main technologies are used - filtration using fields or drainage wells.

It is worth noting that before installing an autonomous sewer system in a private house with filtration structures, a geological survey of the soil should be carried out. If the soil has a clay structure, the surface groundwater level is very high, or water is drawn from well sources, the following problems may arise.

Clay and high groundwater with additional water load will contribute to swamping of the area. And a shallow well source for water intake can be contaminated with wastewater if a significant distance is not maintained between it and the underground filtration system.

Rice. 11 Filtration field - arrangement diagram

Filtration fields

If an autonomous sewage system with filtration fields is being installed, the following technology is used:

- A rectangular pit with a depth of at least 700 mm of a pre-calculated size is dug in the ground.

- Sand is poured onto its bottom, forming a cushion about 100 - 200 mm thick. Crushed stone is poured on top of the sand cushion in a layer of at least 400 mm.

- A pipeline is laid from the septic tank to the pit and branches are made with drainage pipes over the entire area, maintaining a distance between them of 1500 mm.

- Next, the entire site is covered with geotextile fabric, the surface is leveled with a sand cushion with a layer of 100 - 150 mm and sprinkled with fertile soil 100 - 150 mm thick.

In many fields, special polymer boxes called infiltrators are used to increase productivity. When using them, water from the septic tank is directed through a network of pipelines into each of the inverted boxes or a tunnel of several infiltrators.

Thanks to these products, the efficiency of water treatment systems increases due to the fact that the upper layers of soil do not exert pressure on the drainage pipeline, and the liquid is freely absorbed into the crushed stone under the boxes over a much larger area.

Also, with high volumes of discharges, some of the wastewater may be additionally mixed in the free space of the infiltrators without reaching the surface.

Like septic tanks, infiltration fields are equipped with a ventilation system, bringing a section of sewer pipe to the surface.

The disadvantages of filtration fields, in addition to taking up a significant area on the site, which cannot be used for a number of economic purposes, include the fact that the filter crushed stone backfill and sand bed need to be replaced every 3 - 5 years.

Rice. 12 Fields with drainage pipes and infiltrators

Drainage wells

Since infiltration fields occupy a fairly large area, one of the good alternatives is the use of drainage wells.

Most often they are made from concrete rings, digging a hole several meters deep in the ground until a layer of sand is discovered. After installing several well rings with locks and a standard diameter of 1 meter, a layer of crushed stone about 400 mm thick is poured onto the bottom.

A pipeline is brought from the septic tank into the well, using a perforator to punch a circle of the required size in its wall, and cover it with a lid on top, leaving a hole for ventilation.

Rice. 13 Diagram of a conical drainage well

Autonomous sewage system

To appreciate the benefits of local treatment plants, you should learn more about how autonomous sewers of this type work. The system provides maximum wastewater treatment (up to 98%).

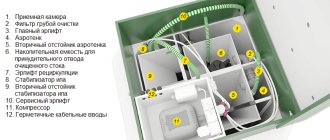

Volatile septic tanks are complex cleaning systems with compressors (Biodeka, Volgar, Unilos-Astra, Topas, Kolo Vesi, etc.). These factory-assembled complexes are equipped with equipment for multi-stage automatic filtration.

Principle of operation:

- Primary cleaning mechanically. The receiving compartment is equipped with mechanical filters that capture fats and large contaminants.

- Aerobic treatment (biofiltration). Aerobic bacteria process wastewater, breaking it down into sludge and water.

- Anaerobic filtration. Organic compounds are removed in a compartment with anaerobic microorganisms that do not require oxygen.

- Final cleaning, providing mechanical filtration.

VOCs do not require maintenance. About once a month, the site owner inspects the internal cameras. Mechanical filters are cleaned every 6 months, parts are replaced and serviced every few years (depending on the nature of use).

Self-production or ready-made design?

When the answer to the question - sewage septic tank for a private house, what is it - has already been received, the user is faced with the next task. Buy a ready-made tank, or make it yourself. The first option is simpler, but requires significant costs. The second method is more labor-intensive; it requires time and considerable effort. However, many users prefer homemade septic tanks, since the main part of the work - installation and installation - is necessary in any case. Therefore, if you have the skills and necessary materials, it is quite possible to independently assemble a system for cleaning household organic waste.

The principle of operation of an autonomous sewage system in a private house: selection parameters

In order not to make a mistake when choosing an autonomous sewerage device, you need to consider the following parameters:

- average daily volume of wastewater (predicted system load);

- quality of power supply at the site;

- terrain features, groundwater level, the presence of nearby natural reservoirs and drinking wells.

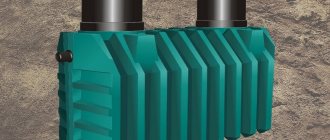

Factory septic tanks are made of polymers or metal. Sealed plastic containers are made using a seamless method and are not susceptible to corrosion or exposure to chemicals. Metal tanks are less reliable because they have welded seams, are susceptible to corrosion and cool quickly.

Autonomous sewerage: how VOCs work in a country house

Considering the range of local autonomous sewers, how this or that system works should be clarified with specialists before planning installation on the site. VOC is a complex system of several interconnected sealed chambers.

The first chamber is a settling tank. Here the wastewater is separated mechanically. The volume of the receiving chamber depends on the type of system and the required residence time of the waste in the receiving compartment. During the mechanical cleaning process, insoluble sediment sinks to the bottom, and water passes through a removable mesh filter basket. Large waste that ends up in the sewer system (vegetable peelings and other food debris) accumulates here.

In the second compartment, the liquid that has undergone primary purification undergoes biofiltration (the main stage of wastewater treatment). Depending on the model, this may be a chamber with an aerobic and anaerobic cleaning system or with combined processing. After this compartment, the wastewater is 80% purified. Next, the liquid enters the settling tank, where activated sludge is separated from process water. Water is removed from the installation, and the active one is stabilized in a special chamber.

deserves special attention . This is what distinguishes VOC from standard septic tanks. Most local stations are equipped with aeration tanks. This is the name for chambers with compressors that pump oxygen. The output is wastewater purified to 98%. Installation of such VOCs is possible in urban and suburban areas. There will be no problems obtaining permits.

Aerobic bacteria in the biofilter, which process waste, live inside the effluent. The colony population is regulated naturally. If the volume of wastewater has increased or it is necessary to speed up the cleaning, you only need to increase the volume of oxygen entering the chamber. The process is programmed, which reduces the hassle of the site owner to a minimum. Aerobic bacteria are not sensitive to the presence of chemicals in wastewater, so VOCs can be installed not only in residential buildings, but also in commercial facilities where detergents are intensively used.

Selecting a construction site

When choosing a location for a septic tank, it will be necessary to take into account the requirements of sanitary standards:

- The optimal distance from the site for the construction of a treatment plant to the house is 5-10 meters. It is impossible to place a septic tank closer, as this is fraught with erosion and premature destruction of the foundation. And when the septic tank is located at a considerable distance, the costs of pipeline construction increase. In addition, the farther the septic tank is located, the further it will have to be buried, since the pipes leading from the house must be laid with a slope;

- Particular care should be taken when choosing the location of the septic tank relative to the drinking water extraction points. Errors in this matter can lead to contamination of aquifers, and this is extremely dangerous for the health of people living in the area. The minimum distance separating the well from the septic tank should be 30-80 meters, depending on the degree of soil permeability.

- When choosing the most convenient place to build a septic tank, you need to take into account the fact that the septic tank will need to be cleaned periodically. Therefore, it is necessary to provide passage for sewer trucks.

The main differences between different types of autonomous sewers

Regardless of the operating principle of an autonomous sewer system, all its types accumulate household wastewater. The differences lie in what happens to the waste later. Each system has advantages and disadvantages. Some are attracted by price, others by environmental friendliness, and still others by the lack of need for constant maintenance.

Cesspools are the simplest and most cost-effective option, but due to a number of disadvantages they are practically not used in modern homes. The principle of operation is simple: wastewater from the house flows by gravity into a reservoir dug into the ground. The sealed container is regularly cleaned by vacuum trucks using special equipment. An improved option is a filtration pit, which instead of a bottom has a kind of filter made of crushed stone with sand. The wastewater is absorbed into the ground, partially purified by such a filter. The disadvantage of a pit is the constant unpleasant odor and the cost of pumping.

Septic tanks are structures made from a single container, divided into chambers that provide consistent wastewater treatment. In the receiving compartment, the mass is divided into heavy sediment, which sinks to the bottom, and liquid, which flows into the second tank. Here, anaerobic bacteria process organic matter, producing water purified to a certain quality.

Local treatment stations are more expensive, but are the most productive and modern solution. The wastewater goes through several stages of purification, and at the end the purity of the drain reaches 98%. The station is volatile and requires a reliable source of electricity. Automated operation of VOCs does not require human intervention. Only routine inspection is required, as well as maintenance approximately once a year.

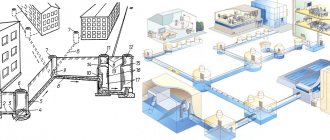

What does a modern sewer system of a private house consist of?

When choosing one of the modern treatment systems, you need to learn more about the design of an autonomous sewer system: how it works, how much space is needed for installation, what maintenance costs will be required, etc. The main elements of any system:

- A reservoir for storing wastewater (a cesspool, several septic tanks or a VOC tank) in relative proximity to the house.

- Internal communications (pipes laid in the house).

- External communications (a network of pipes laid with a slope underground to move wastewater into the sewer system).

- A filtration field (a bed of crushed stone with sand for post-treatment of wastewater), requiring regular maintenance.

Effluent from the house can move into the sewer system naturally (the pipe is laid with an inclination towards the septic tank).

To drain purified water, both forced and gravity options are used. The forced method is necessary for those users whose wastewater will be discharged onto the terrain, and gravity systems are suitable for those areas where a deep ditch has been dug, deeper than 80 cm, or there are well-draining soils (sand, sandy loam). In the latter case, a drainage well is installed.

Design elements

Many septic tanks have a mechanical filter to sediment sediment during the cleaning process. A mechanical filter involves sedimentation of particles without any chemical reaction or introduction of reagents. In septic tanks, wastewater is filtered through a layer of sand, expanded clay or gravel, and in some cases, after leaving the tank, additionally through a layer of soil.

Please note: If it is impossible to drain treated wastewater into the soil in septic tanks located in clay soils, pump pumping into an irrigation tank or drainage ditch.

An exception to the rule may be a single-chamber septic tank device, the operating principle of which does not allow for the gradual sedimentation of large and small fractions and filtering of wastewater. Such devices work only as storage devices. They compare favorably with cesspools in the impermeability of the walls and bottom, but have similar functionality. The single-chamber model is a completely waterproofed septic tank - the installation diagram does not provide for the presence of a filter bottom.

The main elements of all septic tanks are:

- chambers for settling water (in some models, sediment is processed in the chambers),

- pipelines at the inlet and outlet (the latter may be absent if treated wastewater is drained into the ground through the bottom),

- ventilation system,

- maintenance devices (hatches, inspection wells).

The photo shows a diagram of the installation of a septic tank from three chambers with soil post-treatment of wastewater on a filtration field.

The principle of operation of a septic tank is based on the flow of wastewater through communicating vessels (chambers) from one to another with a gradual decrease in the amount of impurities and clarification of the water.

Methods and stages of wastewater processing

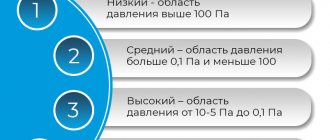

For a clearer understanding of how autonomous sewers work, there are two ways to process wastewater:

- anaerobic;

- aerobic.

Anaerobic treatment occurs due to bacteria that decompose wastewater into water and methane. Heavy waste settles to the bottom. In this case, processing is carried out as follows:

- Contaminated particles are separated by weight. The heavy ones precipitate, the light ones remain on the surface of the wastewater.

- Particles that settle to the bottom are processed by anaerobic bacteria. The heat generated allows the septic tank to be used all year round without the risk of freezing.

- Wastewater is filtered through a bed of sand and crushed stone and further purified by soil aerobic bacteria.

Aerobic cleaning is used in more modern systems. Thanks to the use of aerobic filters, there is no need to create a drainage layer. Stations that provide complete treatment allow you to reuse treated wastewater for household needs. A high level of purification is achieved through the use of both aerobic and anaerobic microorganisms in one system. Cleansing occurs in several stages:

- The wastewater settles in the receiving chamber, where mechanical filters filter out large contaminants.

- Large particles are processed by anaerobic bacteria, as in septic tanks.

- The environment is saturated with oxygen necessary for the life support of aerobic bacteria. The latter quickly and productively process organic matter.

- Repeated settling occurs with sludge settling to the bottom and clean process water moving out.

A small amount of sludge accumulates in the off-grid system, so excess must be removed over time.

Conditions for good work

To get an effectively working septic tank, you need to pay attention to several necessary conditions.

Overflows, ventilation

Overflows should be located below the sewer pipe through which the waste flows directly into the receiver. The minimum difference is 100 mm. To ensure that the liquid is immediately directed to the lower part of the container, tees are installed at the ends of the overflows.

To ensure the flow of fresh air into the septic tank, high-quality ventilation is necessary. If there are several cameras, then it is mounted either in the first or in the last container. The minimum diameter of ventilation risers is 100 mm. The inflow must be positioned so that it is always above the surface of the wastewater. Gases are vented from the receiver through a sewer riser leading to the roof of the house. It is equipped with deflector caps.

Setup

To ensure the most efficient recycling of waste, it is necessary to provide the septic tank with microflora that will break down organic matter. The first way to find bacteria is to take sediment from an actively operating station. The optimal volume of the substance is 15% of the tank volume.

An alternative is special biological products containing aerobic, anaerobic bacteria, or bioactivators (universal, narrowly targeted), which include several types of microorganisms. The former need a good flow of fresh air, the latter can work in a closed environment.

Which septic tank is better? The answer to this question is clear: this is a factory product, durable, sealed, and maximally efficient. How to properly install a septic tank in a private house? Carry out all stages correctly. Since the efficiency of the treatment plant directly depends on the quality of installation, it is better to delegate such large-scale work to the shoulders of professionals. Or involve a friend who has already installed similar structures and therefore knows everything, or almost everything, about the process.

The following video will tell you how to choose a septic tank for your home:

Methods for regular drain cleaning

Having figured out how an autonomous sewage system works, you have to decide on the frequency and nature of maintenance of the selected system. The silt that accumulates at the bottom of the tanks and in the pipes transforms over time into a kind of clay and requires removal using special tools. To prevent the situation from getting worse, it is necessary to perform system maintenance in a timely manner.

- Manual cleaning involves emptying the tank using a drainage and fecal pump. The wastewater is pumped into another container, which is removed. Sludge deposits are removed from the bottom with a shovel, and the walls are washed under water pressure. Dirty water is pumped out into a mobile container.

- The sewer service uses a machine with a vacuum pump and a washing system to empty and clean the container.

- In complete treatment stations, sludge accumulations are removed in an aerobic stabilizer. The sludge is pumped to a compost heap, from where it can then be used as fertilizer. The container is cleaned with water pressure, the dirty liquid is pumped out of it and filled with clean water.

What about overflow wells?

If we talk about overflow wells, then systems of this type can be either industrially produced or made by hand. However, the operating principle will be the same in any case; let’s look at its key features.

First, the wastewater penetrates into the first container, which has a sealed bottom. They settle in it so that solid impurities precipitate. As a result, a silt layer forms at the bottom over time, and purified (relatively) water along with fat impurities is still on the surface.

Next, the slightly purified wastewater is moved to the second well through a special overflow pipe, which is located between both sections. In this well, the liquid is finally purified and then discharged into the soil.

A crushed stone or sand layer laid on the bottom can serve as an auxiliary filter. We also note that such treatment systems require that the bottom of the second well be at least 100 centimeters above the maximum groundwater level.

Important information! You should also prepare for the fact that you will still sometimes have to resort to the services of sewer trucks to regularly remove a layer of sludge (the frequency depends on the specific volumes of waste) from the first well. Although this will not be required often.

Video - What determines the cost of installation?

What you need to know about autonomous treatment plants: advantages and installation

Modern VOCs have a number of advantages. Before making a choice, it is worth learning more about what such an autonomous sewage system is: how it works, how it is installed and what advantages it has. Let's list the main ones:

- The design and operating principle of the system maintain environmental cleanliness on the site. No odors or environmental pollution.

- A minimum of maintenance is required, and the system itself will last more than 50 years.

- Autonomous systems are installed on any type of soil, regardless of the groundwater level.

- An important parameter to consider when choosing is the number of sewer users.

Our company’s specialists will help you choose the best option for autonomous sewerage:

- evaluate the characteristics of the site and soil;

- calculate the volume of the septic tank taking into account the number of residents in the house;

- will offer a cleaning system at an affordable price.

Call for more information.