In any septic tank (with the exception of simple storage tanks), biological processes are used in the process of wastewater treatment. The decomposition of organic matter occurs as a result of the activity of various microorganisms. However, in different septic tank models, the conditions for the reproduction and development of bacteria may differ. To improve the quality of cleaning, you can make a biofilter for a septic tank with your own hands. Let's look at how you can make and install a homemade biofilter for a septic tank.

Natural processes are usually used to treat domestic wastewater. Including biological decomposition of organic matter. The use of biological filters in septic tanks can significantly increase the degree of wastewater treatment.

Such a septic tank is especially recommended for small areas where it is not possible to arrange extensive filtration fields. And if the area of the filtration fields is not large enough, the drainage layer will quickly become clogged, and the wastewater will not be able to be properly cleaned.

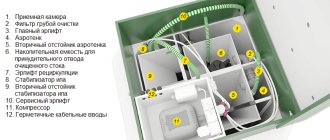

Design of a septic tank with a biofilter

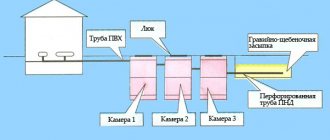

A septic tank with a biofilter usually consists of three compartments:

- Septic chamber. This compartment serves as a receiving chamber; in addition, large inclusions settle to the bottom here;

- Secondary settling tank. This is an intermediate chamber in which secondary settling and removal of smaller inclusions occurs;

- A biological filter is installed in the third chamber. This is a load with a large specific area used for the propagation of bacterial colonies.

When passing through a biological filter, wastewater is, firstly, mechanically purified, and, secondly, aerobic and anaerobic purification processes occur. As a result, practically pure water is sold for output, which can be sent for disposal without fear for preserving the ecology of the site.

Advice! A septic tank with a biofilter is always a horizontal installation. For objective reasons, it is impossible to make a vertical septic tank with a biological filter.

Principle of operation

To make a biofilter, an inert material is used, most often expanded clay, granular polymer, plastic three-dimensional mesh or brushes with polymer bristles. This material is used to “disperse” microorganisms – bacteria, protozoa, yeast.

In addition to bulk loading made of expanded clay, other options can be used:

- granules made of polymeric materials;

- volumetric mesh made of plastic or eraser brushes with a large amount of fibers.

As a result of the activity of microorganisms, sludge is formed, which gradually accumulates in the biological filter chamber. Therefore, for normal operation of the septic tank, it is necessary to periodically pump out the sludge and wash the load. If washing is not done on time, the filtration rate will decrease over time and the quality of cleaning will decrease.

Advice! To reduce the need for major rinsing of the biofilter, it is recommended to regularly use special biological products for septic tanks.

In essence, a biofilter is a filtration field, only it has compact dimensions, since in conventional filter fields bacteria are located only in the upper (soil) layer, but in a biological one they are located throughout the entire volume.

crazy hands

The price of a finished deep biological treatment station for a family of two or three people is no less than 60 - 70 thousand rubles. At the same time, a septic tank of sufficient productivity, made by yourself, will cost 3-5 times less; however, it will provide a much worse degree of purification.

At high groundwater levels, soil purification becomes problematic; dumping sewage onto the terrain or using it for irrigation is also not an option: the smell of sewage knows no mercy and is overwhelming. What to do?

The obvious solution is to attach a biofilter to a one- or two-chamber septic tank.

General principles

- The most effective scheme is a biofilter with aerobic bacterial cultures and forced aeration. With a minimum volume, it provides the maximum degree of purification of septic tank wastewater.

This is the most effective, but not the only solution. Here is a diagram of a septic tank with an irrigated anaerobic filter.

- Efficiency will require costs. Forget about cheap aquarium compressors: their performance will not be enough. Our choice is special compressor stations for septic tanks with a capacity of 60-120 liters per minute.

The compressor in the photo has a capacity of 60 l/min.

- Simply supplying air to the bottom of the biofilter tank is not enough. One vertical chain of bubbles will aerate a small portion of the effluent volume. The simplest aerator is a sewer pipe with a diameter of 40-50 mm, plugged at one end, with frequent perforations made with a drill with a diameter of 4-5 millimeters.

Tip: if the pump performance is sufficient, you can use tees to assemble a simple comb that will saturate the entire volume of the biofilter container with air.

Capacities

We have already found out that a container with an aerated biofilter is only one of the chambers of the septic tank, the last one on the path of wastewater.

What materials can it be made of?

- The ideal solution is a polyethylene water container. As a rule, in its lower part there is a pipe for a relief valve; in our case it will be useful for connecting the compressor. Of course, through a check valve: getting septic tank wastewater into the electric air pump is clearly not in our interests.

A horizontal polyethylene container is a ready-made section for a septic tank.

- In a brick or concrete septic tank, it is possible to fence off a small section in the secondary sump and provide it with two overflows - inlet and outlet.

- Finally, an old steel barrel can serve as a container. A simple instruction will help protect it from rust: the outer and inner surfaces are covered with two layers of bitumen mastic.

Filling

Actually, we have already mentioned the most affordable options.

- Expanded clay is the cheapest filling possible. The large surface area is provided by its porous structure.

Expanded clay is used as filling.

- Somewhat more expensive (but also somewhat more effective)... yes, plastic dish scourers. They are placed in a container without compaction, filling its entire volume.

What types of biofilters are there?

All biological filters can be divided into groups according to two criteria:

- Based on the type of microorganisms used, aerobic and anaerobic biofilters are distinguished. When installing the first, good ventilation is necessary. Filters with anaerobic loading are installed in sealed containers;

- Depending on the type of loading performed, filters with dry or wet loading are distinguished. In the first case, the filter is periodically supplied with purified liquid. With the wet loading type, the chamber with the biofilter is completely filled with the liquid being purified.

Installation of soil treatment systems

Let's consider the stages of earthworks that are necessary to organize a filtration field for a septic tank and infiltrator.

The soil cleanup area must be impressive. Typically, a system of 2-5 pipes is installed, the length of which usually does not exceed 25 meters. The distance between the pipes is at least 1.5 meters, and the laying depth must exceed the freezing level of the soil. A layer of crushed stone is laid at the bottom of the trench; a drainage collector will pass here. The pipe should be laid at an angle of 2 cm per meter to ensure adequate gravity flow of the liquid. A layer of fine sand is poured over the drainage. Distribution channels are placed at the top, which come out of the well. They are also filled with crushed stone, and geotextiles are laid on top of the ditches. The topmost layer can be made of finished lawn; it is permissible to fill the system with soil. The filtration field for a septic tank must have gas outlet pipes that rise at least 50 cm above the ground. They are equipped with visors. The location of the soil treatment zone is at least 5 meters from the house, at least 30 meters to open water intake sources for clay soils and 50 meters for sandy soils. There should be no bushes or trees in the filtration zone, and vehicle traffic is prohibited. The soil in the fields is replaced every 5-10 years.

The system uses 110 mm perforated pipes.

The infiltrator is placed in series with the septic tank. It is a plastic case that does not contain a bottom. Stiffening ribs protect it from deformation. The distance from the well to the infiltrator tank should be about 1 meter.

When choosing a device, the volume and number of containers are taken into account. The capacity of the infiltrator must exceed the salvo release from the well by three times. It is also important to consider the absorbency of the soil (it is higher in sand).

At the excavation stage, the groundwater level is taken into account. The depth of the hole must be above this level, otherwise your system will float in the spring and fall. For installation, a small trench is dug, 50 cm larger than the dimensions of the container. Next, we proceed to laying the filtration layer. We put geotextiles on the bottom, pour sand and crushed stone of the middle fraction. The thickness of the pillow is 40 cm.

It is not recommended to exceed this value, as the filtration rate will drop sharply.

An infiltrator is placed on top of the pillow. Its dimensions allow you to carry out this stage independently, without the help of equipment. Pipes are connected to the container: the outlet from the well, the overflow for the second device (if there is one) and the gas outlet to the soil surface. After checking the tightness of the system, cover it with geotextiles and fill it with soil.

So, the system with an infiltrator is easy to install and saves space on the site. In addition, it does not require excavation work to replace filter layers of soil.

Advantages and disadvantages

Like all other devices, biofilters have their pros and cons. Among the advantages it is worth highlighting:

- No restrictions when using biological filters;

- Compactness. Not every site has the opportunity to allocate an area for filtration fields, so in such conditions a biofilter is the best option;

- Easy installation and ease of use;

- Autonomy. Septic tanks with biofilters do not require a power connection;

- No odors.

The disadvantages of using a filter are:

- Higher cost compared to a conventional septic tank;

- Certain requirements for the composition of wastewater. When using biological filters, disinfectants must not be poured down the drain;

- In order for the biofilter to work effectively, you need to regularly add special biological products;

- When using septic tanks with biological filters, sewer system downtime must not be allowed. If the sewage system is not used for two weeks, the bacteria may die.

Features of gas connections

When connecting gas stoves, water heaters and other types of equipment, flexible hoses are also used. Unlike water models, they are yellow and are not tested for environmental safety. For fixation, end steel or aluminum reinforcement is used. There are the following types of devices for connecting gas appliances:

- PVC hoses reinforced with polyester thread;

- made of synthetic rubber with stainless steel braid;

- bellows, made in the form of a corrugated stainless steel tube.

The Santekhkomplekt holding offers engineering equipment, fittings, plumbing fixtures and devices for connecting them to communications. The assortment is represented by products and materials from well-known foreign and domestic manufacturers. Discounts apply for bulk purchases, and product quality is confirmed by standard certificates. For information support and assistance, each client is assigned a personal manager. The ability to arrange delivery within Moscow and to other regions of the Russian Federation allows you to quickly receive the purchased goods without unnecessary hassle.

How to make a biofilter?

If a conventional septic tank is installed on the site, then to improve the quality of its operation, you can additionally install a biofilter. You can purchase a structure that is ready for installation. This option is good because you can very quickly upgrade an already finished septic tank.

However, ready-made biofilters are not cheap, so many owners decide to make this part of the treatment plant themselves. The work on manufacturing a biological filter goes like this:

- A pit for a biological filter is being prepared next to the septic tank;

- If a ready-made plastic container is used, it must not only be lowered into the pit, but also secured to a reinforced concrete slab laid on the bottom. To create a container for installing a biofilter, you can use other options, for example, making a well from concrete rings or making a monolithic structure. In the latter case, you must first build the formwork and fill it with mortar. Filling is done in layers with compaction of each layer;

- The prepared pit is filled to two-thirds of its volume with backfill - expanded clay or other suitable material;

- The pit is backfilled. If the well body is plastic, then backfilling is done not with soil, but with a mixture prepared from dry sand and cement (ratio 5 to 1);

- A ceiling is installed on the well, and a ventilation system must be provided;

- The well cover must be insulated. The easiest way to use polystyrene foam for these purposes;

- The biofilter should be discharged into a storage well or ditch.

A biofilter is a device that allows you to improve the quality of wastewater treatment. Installing a biological filter avoids the need to install filtration fields.

Why us

Our company has been specializing in the sale and installation of cleaning equipment for more than 8 years. Our store offers a wide range of septic tanks of various brands and models from leading manufacturers. From us you can buy at competitive prices not only high-quality and reliable equipment, but also its components, as well as all the materials necessary for installation.

Residents of Moscow choose us as a partner due to the successes we have achieved, reliable reputation and comfortable conditions for cooperation:

- we install septic tanks in 1 day;

- We work throughout the Moscow region;

- We offer high quality work at affordable prices;

- We deliver equipment using our own fleet of vehicles;

- We provide additional discounts;

- We use different payment methods;

- We carry out repairs and maintenance of systems;

- We give our clients a three-year quality guarantee for all work.

Contact us by phone or post a message on the website, and we will offer you professional and the most optimal solutions to your problem.