Narrative plan:

- Introduction;

- The need for ventilation;

- Design features;

- Types of ventilated systems for septic tanks: Supply;

- Forced;

Properly organized ventilation of a septic tank in a private house is a key component of its successful operation. Without air access, the decomposition processes of organic substances inside the tank proceed more slowly. Gaseous substances accumulate inside the drainage system, which can harm human health if handled incorrectly.

The need for ventilation

Autonomous sewer systems in suburban housing are gradually replacing the usual primitive cesspools as a type of engineering structure. But the very principle of operation of a septic tank requires a completely different attitude to their maintenance. For chemical filtration processes to occur, air flow is required.

When substances enter the autonomous sewer system, they are separated into heavy and light components. The former settle, the latter remain on the surface. Special bacteria located inside the container trigger the process of decomposition of organic substances, during which an active release of gases occurs.

A septic tank with forced ventilation organized in it is capable of:

- maintain safe concentrations of gases;

- create a comfortable habitat for aerobic bacteria;

- have optimal temperature and humidity in the compartments.

Operating on the principles of biological decomposition, autonomous sewage systems release chemicals during operation. If they are not vented, the fumes will enter the home through the pipes. High concentrations of methane and hydrogen sulfide in the air can cause serious harm to human health.

Device and principle of operation

The purpose is to prevent water from being sucked in from the water seals of the plumbing fixtures. When the sewer pipe is filled (when flushing the toilet, using the sink), a vacuum is formed inside and a rarefied environment is created, as a result of which water can completely leave the siphon, and air and an unpleasant odor, on the contrary, will penetrate into the room. To avoid this, it is necessary to let air into the pipe cavity.

The design of the ventilation system is quite simple. To prevent moisture from the sewer from entering the ventilation shaft, it is located above the last plumbing fixture. If we talk about the air duct, according to technology it must be installed above the roof at least two meters.

Design features

Regardless of the type of drainage system: with concrete rings or with polymer chambers, a number of elements must be present in its design. For successful air exchange, several important elements must be installed.

- Incoming pipe. Through it, fresh air from the street enters the chamber. It is necessary for the normal functioning of aerobic bacteria in a chamber designed to capture wastewater.

- Gas outlet insert. Through it, substances released during the decomposition of wastewater are removed. These include methane, phosphorus compounds and hydrogen sulfide. In addition to the potential health hazards, they also emit specific unpleasant odors.

- Fan. It is mounted as needed to strengthen and stabilize weak traction. Recommended for installation only in systems connected to power supply.

Three components will be enough to maintain proper air circulation inside the chambers. But installation of supply and exhaust ventilation is not mandatory. In most cases, natural air exchange is sufficient.

Types of ventilated systems for septic tanks

Ventilation of a septic tank is organized according to 1 of 2 common schemes. In modern autonomous sewers, combined solutions are additionally used. They contain chambers containing both aerobic and anaerobic bacteria. Air exchange here is always arranged so as not to disturb the biological balance.

Supply

Such a system uses traction, the intensity of which depends on:

- correspondence of the pipe diameter to the volume of the air chamber;

- the angle of its location;

- length of the formed channel.

The air masses formed inside exit naturally through the second hole.

The operating principle of the channels is directly related to the difference in medium pressure. In the chambers of the septic tank it is higher, outside the indicators are lower. Due to this difference, draft is formed in the pipe. The air duct is installed in the container lid. The element is made from reinforced plastic or standard pipe with a diameter of up to 100 mm.

The length of the formed ventilation duct is not standardized. Its outer part is located above the level of snow drifts in winter. This indicator is calculated with a reserve. The distance of the lower edge of the pipe inside the septic tank is limited to a height of 200 mm from the usual drainage level.

Forced

Such ventilation is installed where the design of the septic tank itself does not allow the creation of normal draft. Insufficient air supply can cause not only discomfort associated with the appearance of a specific odor. It negatively affects the overall flow of processes inside the chambers.

Forced air supply makes it possible not to depend on the intensity of movement of air flows inside the tank. The flow is injected and discharged at a certain speed; the parameters of these processes can be adjusted depending on the intensity of operation of the structure.

Installation of this type of pipeline is carried out in a closed space of the tank. The ventilation in the septic tank is connected to the waste pipe. This will ensure the absence of odors in the area and will help cope with the problem of toxic gases entering residential premises.

Installation of forced ventilation wiring is required where the septic tank:

- serves many water discharge points;

- regularly takes large volumes of liquid from the bath or swimming pool;

- equipped with a sewer riser with a diameter of up to 50 mm.

Natural, forced-air options are cheap to install, but in the long term they are ineffective. Autonomous forced ventilation will allow you to maintain the normal course of all processes in the septic tank, less often perform its maintenance, extending the service life of the entire system.

Operating principle of a sewage disposal machine

The main elements of any sewage disposal machine are: a reservoir (tank) for transporting liquid, a vacuum pump, a pipe for pumping water from septic tanks, sewer wells, drainage systems of car washes, natural reservoirs, etc. The operating principle of such equipment is as follows:

- One end of the pipe is connected to the machine, and the other is lowered directly into a container of liquid.

- Using a vacuum pump, water mixed with sludge is pumped into the tank. The process continues until the septic tank is completely empty or until the tank is full.

- Disposal of reinforced waste products is carried out in strictly designated areas, taking into account environmental standards.

Theoretically, the transport tank and pumping equipment can be installed on any vehicle chassis that meets the technical requirements. In Russia, as a rule, GAZ, KamAZ or ZIL are used for such purposes.

Machine for collecting and recycling wastewater based on GAZ 3309

The maximum distance within which water can be drawn depends on the length of the pipe (hose). The standard length, regulated by the manufacturer, usually varies between 6-15 m. By individual order, this parameter can be increased to 25 m. Some sewer trucks use additional hoses, which allow increasing the length by another 5-10 m. However, even this is sometimes not possible enough to clean a septic tank located at a great distance from the roadway. In this case, additional measures will be required from the owners of the site.

How to organize ventilation in a single-chamber septic tank

In terms of its design, such an autonomous sewage system differs little from a cesspool with filtration fields. Waste is discharged into a settling tank-collector consisting of only 1 chamber. This option is relevant for housing designed for temporary stays with extremely low water consumption and discharge.

The upper inlet pipe is laid along the outer wall of the building. It connects to the sewer drain at the point where it exits the house. The outlet is mounted on the lid of the septic tank. Here standard pipes with a diameter of 100 mm are used, their edge is above the ground surface.

The diameter of the inlet part of the pipeline is made smaller. An inlet hole with a cross-section of 50 mm is sufficient. Through a special adapter, the part is connected to the sewer and sealed to remove unpleasant odors.

Typical installation mistakes

- One of the mistakes that is made is venting ventilation into the attic space, without wanting to organize the connection of the pipe to the roof. This can cause gases to accumulate and penetrate into the upper floors of the building.

- Wanting to improve draft, some install a weather vane instead of a protective fungus; this will not only not give the desired effect, but may even worsen the outflow of gases, which can result in an unpleasant sewer smell both in the bathroom and around the house.

- Installing a drain pipe on an external wall can lead to condensation problems.

Ventilation arrangement in a three-chamber septic tank

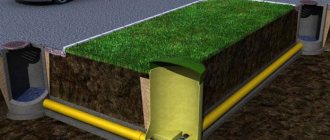

In country houses designed for permanent residence, more advanced treatment facilities are installed. A three-chamber septic tank allows you to increase the possible volumes of discharge without overflowing and flooding the territory. The installation of the ventilation pipe is carried out differently in such systems.

It is placed not in chamber 1, but in chamber 3, intended for wastewater treatment. The remaining tanks remain closed, there is no air access to them. Water that has undergone pre-treatment stages is discharged into special filtration fields.

In this case, the installation of ventilation ducts is carried out as follows:

- the edge of the drainage pipeline is brought to the ground level.

- ventilation pipes are installed 50 cm above the edge of the soil to avoid flooding by floods and melt water.

- Protective caps are installed to prevent precipitation and debris from entering.

Since vents are installed at drains, at the end of the sewer system, they can also be used in flushing and cleaning, introducing air or pressurized water into cavities to combat blockages.

Installation

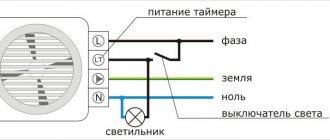

Parameters according to which vacuum valves are installed:

- placed on risers; if this is technically impossible, placement on any horizontal section of the sewer system is possible;

- can be installed either separately or together with fan ventilation;

- placement in such a way that the external temperature is always above 0⁰ C to avoid freezing of the valve;

- installed 10 cm higher than the highest drain outlet of the plumbing equipment (so that the valve does not become clogged);

- if there is a drain in the floor - installation above the floor level 35 cm;

- installed on the free end of the pipe or socket;

- installation in the attic or other room is possible (under certain conditions);

- joints must be hermetically sealed;

- the installation location must be determined in advance to ensure easy access to the valve for further maintenance;

- if the valve is placed inside a box or niche, a special hatch is equipped.

It should be remembered that vacuum valves do not prevent the penetration of odors from the septic tank into the room when the water seal is broken or it has dried out due to prolonged non-use of the plumbing.

Used in conjunction with fan ventilation, they almost completely guarantee the protection of premises from septic air flows.

The role of the vent riser in forced air exchange systems

A septic tank is a closed system of chambers in which natural air circulation may not be sufficient for effective removal of gases. The problem can be solved by installing a drain pipe separate from the general ventilation of the house, which will provide the sewer with an additional flow of oxygen.

To organize such an auxiliary riser, pipes on a polymer plastic or PE base are suitable. The diameter should correspond to that used when laying the main communication lines. Cast iron and stainless steel products are also used.

The second name for a fan riser is a dry pipe. It has no functional load in the sewer system. Air is supplied through this channel and water is prevented from entering it. The entry point of the dry-air pipe into the sewer is at its upper boundary. The outer edge is covered with a cap.

At the design stage, the vent riser can be planned not outside, but inside the building. It connects to plumbing fixtures in the bathroom, toilet room, and kitchen. The discharge of water will be directed in one direction, the flow of gaseous substances in the other.

Using the Vent Valve

The installation of a riser, which is quite expensive, can be replaced with a special ventilation valve (the latter can be made at home). The main advantage of the valve is that it prevents warm air from escaping from the cleaning structure, thereby preventing the appearance of frost on the surface of the pipes. Simple risers do not prevent this, as a result of which the outer pipes often freeze.

Using the Vent Valve

The procedure for creating the simplest valve is as follows.

Step 1. Take a spring from a ballpoint pen and a self-tapping screw 4.5 cm long and with a diameter that fits it (the spring).

Step 2. Then a washer with a diameter of 5 cm is cut out of thick plastic. A hole is made in its center for a self-tapping screw, but so that the spring does not enter, but only rests against the washer.

Step 3. Another washer is cut out of foam rubber (diameter - 6 cm), and a hole is also made in its center. The washers are glued together using Moment glue.

Step 4. Three holes of 0.5 cm each are made in the cover of the end tee (it is important that the diameter is 10 cm). The distance between them and the center of the lid should be a maximum of 2-2.5 cm. The internal surfaces are cleaned of burrs, and a small hole is made in the center into which a self-tapping screw is screwed. As a result, all structural elements are assembled together.

Important! After manufacturing, the valve should be checked by blowing into each of the holes in turn. When blowing in, air should come out easily, but when blowing out, it shouldn’t come out at all.

Using such a valve will allow ventilation to work as reliably and efficiently as possible. If ventilation is installed in a two-story house, then each drain branch must be equipped with a valve.

Ventilation Valve Prices

ventilation valve for sewerage

Septic tank with ventilation without vent riser

If a special riser is not initially provided for by the design of the engineering systems, atmospheric air is supplied to the chamber by other means. The easiest way to do this is with ventilation vents. They crash into the highway at the point of entry into the house.

There may be several such outlets. They are raised above the ground to a height of 300 mm to avoid flooding during floods. Air flows through auxiliary pipes into the sewer drain, and through it into the settling chamber. The upper bells are protected by nets and caps.

There are many advantages to installing ventilation with outlets. It provides the necessary influx of air masses. It is easy to set up after laying communications. Through auxiliary outlets, the system is cleaned when a blockage occurs.

Why is it important to consider septic tank ventilation in the project?

When starting construction or improvement of a house, the installation of utilities must be carried out taking into account current standards. If a septic tank is installed on the site, the ventilation requirements in it will have certain features.

- For tasks above 2 floors. Such buildings require the construction of a sewer system with sewer outlets. Otherwise, the project will not pass the architectural commission.

- For buildings with 1 toilet and a bathroom. In them, a separate outlet is not required for installation. But it can be installed in case of subsequent improvement.

- When the toilet and bath are located on different floors. An auxiliary air supply system is included in the design.

- When the diameter of the air duct system is less than 100 mm. It is raised to the level of the roof of the building. This height compensates for the weaker thrust.

- If there is a swimming pool in addition to a bathroom and bathtub. A forced ventilation system is being installed.

This is a basic list of rules that should be taken into account when developing a project. If the house previously had a riser made of cast iron, it would be reasonable to replace it with a PVC option, which is easier and more practical to use.

Recommendations from experts

Sewer ventilation in a private house is not a simple system. And for it to work well, it is necessary:

- carry out calculations that mainly relate to the number of risers and the diameter of the pipes used for them;

- installation of sewer ventilation should be carried out strictly according to the chosen scheme, taking into account the calculations performed;

- a drain pipe must be installed, even if a vacuum valve is also installed;

- its output is only through the roof;

- if this is not possible, then the riser is installed near the wall with an outlet beyond the roof structure;

- install the vacuum sewer valve in the attic.