As you probably know, “storm drainage” (that’s what storm drainage is often called) is preferable for arranging it in a variety of places: at a summer cottage, on road, construction and industrial sites, in parks and walking pedestrian areas... In fact, It is almost impossible to list everything.

But at the same time, the purpose of the storm drain, wherever it is installed, is, in general, one: to ensure the effective and unhindered outflow of melt or rain water from the site. Indeed, in the case of ineffective storm drainage, or its complete absence, such certainly not very pleasant phenomena may arise, such as:

- flooding and even waterlogging of the site;

- the formation of puddles that will make it difficult to move around the site and carry out any work on it;

- washing away the foundations of those structures located on the site;

- the formation of corrosion, fungi and mold on the walls;

- deterioration of health due to prolonged stay in conditions of high humidity;

- contamination of the object.

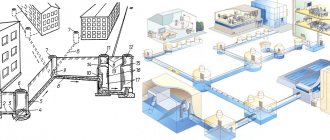

Storm sewer can be of two types: point - the flow of water is collected in a certain place and linear - storm water is collected along a line.

Of course, storm drainage will help avoid all this. Moreover, it comes in only two types - point type and linear. In the first case, water collection is carried out in any one place. In the second, rain collectors are located along a line and connected to each other with a special wire. But one way or another, in the vast majority of cases, when organizing effective storm drainage, you will need a device such as a sand trap for storm drainage.

What else you need to remember when arranging a storm drain

In order for a storm drain to successfully cope with all its responsibilities for draining water flow, it is imperative to take into account some points. First, in order to prevent clogging and clogging of the system, it is necessary to provide inlet protective grilles. They can be made of different materials and come in a variety of shapes. But they have one purpose. Or rather, two. Firstly, the retention of coarse debris - branches, stones, leaves, etc. Secondly, the gratings will guarantee the safe passage of people and vehicles.

The photo shows sand traps, storm water inlets, gutters with gratings of various shapes and sizes.

Important! When designing a storm drainage system, it is necessary to ensure that the optimal slope of the watercourse is ensured.

The water will simply flow away, obeying the force of gravity. The angle of inclination must take into account the diameter of the pipe. The relevant standards are found in SNiPs for storm drainage. But in most cases, for a private, not too branched storm drain, it will be enough to provide a slope of 1-2 centimeters for each meter of pipe.

Before entering the sand trap for storm drainage, the slope should be reduced somewhat so that the flow does not mix inside the trap box, and the sand fractions have time to settle in it. Absolutely all sewerage elements must be sealed. Even the slightest leak is not allowed. This will prevent not only erosion of the soil and damage, for example, to the road surface, but also the formation of mold, rot, etc.

Pipes that are corrugated inside are highly not recommended for storm sewer installations. After all, it is often in them that debris accumulates. In the future, this will inevitably lead to the formation of a garbage plug, getting rid of which may not be a simple task, as it may seem at first glance.

When designing a storm drainage system, it is necessary to provide for as few possible joints, differences, and changes in direction as possible. After all, it is in these places that depressurization of the system most often occurs.

You should take your measurements especially carefully. Footage is a very important component of the project. Even in case of doubt, it is better to purchase pipes with an inlet. Modern plastic pipes can be cut to the required length very easily and quickly. But it will be very disappointing if in the end it turns out that literally 10-20 centimeters of pipe are missing. The same applies to purchasing all the necessary adapters, fittings, seals, etc. You need to make a detailed list of everything you need to purchase in advance.

When organizing inspection wells, it is recommended to install them more often. In this way, it will be possible to monitor the state of the entire system more efficiently. In general, the following rule works here: the smaller the diameter of the pipe, the smaller the distance between the wells should be. Indeed, in this case, the risk of a blockage also increases, and it will be a shame not to get to the area needed for cleaning just because the inspection well cannot reach there.

The process and specifics of installing storm drains

The rules for constructing storm drains are similar to those used when installing conventional gutters. However, if the house does not have a drainage piping system, it must be installed.

Construction of the roofing component

When installing a drain, home owners perform the following actions:

- holes are made in the floors of the house for water collectors. After installation and installation of rainwater inlets on bitumen, the places where they adjoin the storm drain are carefully sealed;

- then, install drainpipes and risers;

- elements of the drainage pipeline system are attached to the cottage or country house with clamps;

- upon completion of the work, trays are installed - when installing a linear type drain or a water drainage tube, if the drainage pipeline system is installed according to a point pattern.

Water drainage from the roof

Installation of the underground part

After drawing up a storm drainage plan - taking into account the slopes and the specific installation depth of the channels installed in a particular region of the Russian Federation - a trench is made.

If you need to insulate the pipeline with geotextiles and crushed stone, or you need to build a sand cushion, the plan for installing the underground part of the sewer system also takes into account the power of the storm drainage elements.

Next, perform the following actions:

- Before starting installation work, the bottom of the trench is compacted. At the same time, large stones are removed from the trench, the holes from which are subsequently filled with soil;

- a sand cushion is placed on the bottom, the thickness of which is 20 cm;

- the result is a pit in which the collector is installed. A plastic container purchased in advance is used as a collector. However, you can make a collector well yourself - just pour the concrete solution into the pre-prepared formwork;

- Next, tubes are placed in the grooves, which are connected into 1 system using fitting pipeline elements;

- then, inspection wells are placed on straight 10-meter branches of the storm drain;

- Sand traps are installed at the connection points between the water collectors and the pipeline;

- As a result, all elements of the storm drain are connected into 1 circuit. In this case, the junctions of such elements are carefully sealed.

Before filling the trench, its performance is checked by pouring water into it.

If no weak points are found during testing of the trench, then after the test the pipeline system installed in the trench is buried, filling it with soil. Also, in such a situation, gutters and drainage trays with gratings are installed on the storm drain.

Upon completion of installation, the owner of the cottage or summer cottage connects the storm drainage system to the general sewer system.

So, when installing a storm drain yourself in a private household or in a country house, you need to use all the recommendations and rules for installing a drainage system that were given in this article.

Using this information, you can easily troubleshoot problems that arose during the installation of the storm drain.

By improving the storm drainage in the house and in the surrounding area, the life of the house is extended, puddles and slush do not form on the roads to the cottage or dacha, and the rotting of plants also stops.

WATCH THE VIDEO

Each owner of a country house can independently install a storm drain - without turning to professional builders for help. In such a situation, you just need to get to the heart of the matter - and everything will work out.

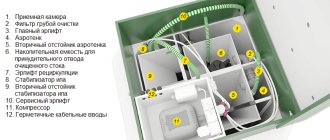

Sand trap for storm drainage as an integral part of the system

Almost any storm drain requires the presence of the following elements:

Shown here is a detailed diagram of the storm drainage system with all its integral components.

- rainwater inlets. They, as you can guess from the name itself, are designed to absorb water. As a rule, the rainwater inlet is located either under the drainpipe or in the path of the flowing water flow;

- door trays - have the same functional purpose as storm water inlets, but are installed only in front of doors and gates. In this case, the owner of the property will not observe the accumulation of puddles in front of his door after every rain;

- gutters or pipes - they are a kind of drainage main through which flows from the storm inlet enter the collector or other designated container;

- A sand trap for storm drainage is a special device, thanks to which not only sand, but also particles of suspended soil comparable in size settle in the box and do not enter the drainage system.

Also, depending on the design features, storm sewerage may include the presence of all kinds of filter structures, wells, etc.

Principle of operation

The functioning of sand traps is based on the use of gravity

When calculating the characteristics of a structure, it is taken into account that sand and other heavy particles should precipitate in them, but impurities of organic origin should not settle. For urban wastewater treatment plants, sand traps are built from reinforced concrete elements

Aerated sand traps are structures with translational and rotational movement of liquid. They are constructed in the form of elongated tanks. The rotational movement of wastewater in these sand traps is created by the aeration of the wastewater that is contained in it. In addition, horizontal and vertical sand traps are designed (design of a receiving unit).

Due to the movement of water, each particle in the drain is influenced not only by gravitational, but also by centrifugal forces. As a result of this, an intensive process of separation of sand from water and organic particles occurs, which, due to growth, remain in a suspended state.

The amount of sand that falls in aerated sand traps depends on many factors:

- length of the sewer network;

- slopes on pipeline sections;

- the sewage system used;

- composition of wastewater;

- network operating conditions, etc.

For the city sewer network, the following volume of sediment in sand traps is accepted per person per day (with a humidity of about 60% and a density of 1500 kg/m3):

- with a general alloy system - 0.04 l;

- with separate – 0.02 l.

Fig 02 – Sand trap

Characteristics and Features

Aerators are tripled along the wall of the aerated sand trap (45–60 cm from the bottom of the tank), under which trays are laid to collect sediment. For efficient operation, the bottom of the sand trap is arranged with a slope of 0.2–0.4 to collect sand. When calculating a sand trap, a rotational speed along the perimeter of the structure’s section is assumed to be 0.25–0.3 m/s and a translational speed of 0.08–0.12 m/s. The residence time of wastewater in an aerated sand trap is 2–3 minutes.

To maintain the required rotational speed, 3–5 m3 of air per 1 m2 of structure area is supplied to the sand trap tank per 1 hour. The rotation is maintained at a constant level without reference to the volume of incoming wastewater. If all necessary conditions are met, the output from aerated sand traps is a sediment with a minimum amount of organic impurities. The resulting sediment contains up to 95% sand, which does not rot during long-term storage.

Aerators, which are used in sand traps, are made of plastic pipelines with holes up to 5 mm. Sand is removed from the surface of the tray using a flush pipeline. The sediment is washed off without stopping the structure. The wastewater cleared of sand is fed into settling tanks.

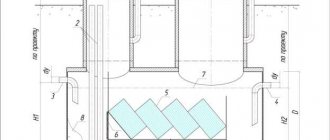

Fig 03 – Diagram of an aerated sand trap

In addition to aerated ones, other types of sand traps are used at urban sewage treatment plants:

- horizontal (more than 10,000 m3/day) – elongated rectangular tanks with linear movement;

- vertical - with the movement of wastewater from bottom to top (rarely used in modern conditions);

- tangential, which are a structure with rotational movement of wastewater (up to 50,000 m3/day).

The installation of sand traps is mandatory in structures with a volume of processed wastewater above 100 m3/day.

| We work all over Russia | Contacts. Tel/f +; [email protected] |

- Terms of use

- Personal data processing policy

Purpose of a storm drain sand trap

In principle, you can guess its purpose just by the name of this device. Indeed, a sand trap for storm sewers is designed to prevent not only sand from entering the drainage system, but also other fine debris that is not retained by the protective gratings of the storm drains. This will reduce the load on the treatment system and prevent the formation of premature blockages in the sewer.

Typically, sand traps are installed at the entrance to the main water intake, forming a “trap” for sand. It settles inside the box, and the purified water continues to flow further.

What is it used for?

The use of sand traps in water purification systems is due to the fact that in settling tanks it is difficult to separate mineral contaminants from organic ones . Difficulties arise in removing sediment.

The system becomes clogged with debris, water has difficulty passing through the pipeline, and this reduces its performance.

Therefore, designers have developed sand traps that are installed after the grates in front of the primary settling tanks.

They can also be used as an independent unit for domestic or small industrial purposes , but only in cases where the waste water after passing through the sand collector is suitable

- for further use in production

- or discharge into natural bodies of water.

That is, when it does not pose a danger to the environment.

Then the devices are installed in the pipeline before entering the sewer. This could be, for example, in workshops at catering establishments, under the sink in restaurants, cafes. In other cases, sand devices are part of the cleaning system.

Attention! When discharging more than 100 m3/day of industrial and domestic water into the sewer system, it is necessary to install sand collectors, regardless of the contamination of the wastewater.

Sand trap for storm drainage: design and principle of operation

Despite all the variety of types and models (this will be discussed a little below), the design of all sand traps is, in general, the same. Structurally, they are presented in the form of a special container with a bottom, the body of which is provided with special pipes. The pipes are located slightly above the bottom and upper compartment of the receiver. There is also a filter grid between the receiver and the bottom. It traps particles of dust, sand, clay and soil.

Water, moving at a fairly high speed through pipes or channels, enters a sand trap for storm drainage through a receiver. Since the catcher has a much larger volume compared to the pipe, the pressure and speed of the water drop sharply. At the same time, it is also recommended to slightly reduce the slope of the pipe immediately before entering the sand trap, further reducing the speed of the water flow. In this case, heavy solid particles of suspension, which were previously contained in the water, fall down under the influence of gravity, falling through the grate. Pushed from behind by the streams, the water continues its journey further, but now free of solid impurities.

The principle of operation of a sand trap for storm drainage is that sand and other heavier particles settle at the bottom, and water passes further through the system without clogging the pipes.

Naturally, you need to ensure that the sand trap tank does not overfill. Its volume must be selected in accordance with the degree of expected pollution of the water flow. If you do not clean the sand trap in time, it will simply stop coping with its duties and will not retain dirt. As a result, the sewage system will quickly become clogged, and an increased load will be placed on the filtering and treatment equipment. Which will also lead to its premature failure.

Prices for sand traps

| Model | Price, rubles |

| ACO SELF Euroline with galvanized grille, 50x11.8x32 cm. | 5500 rub. Buy |

| Single-section, 500x640x1000 mm. | 28,000 rub. Buy |

| Gidrolica Standard DN100 C250, 500x160x420 mm. | 1500 rub. Buy |

| Multi-section Gidrolica intermediate part, 560x490x520 mm. | 4500 rub. Buy |

| Gidrolica BGU with galvanized nozzle, 500x326x740 mm. | 8300 rub. Buy |

| Gidrolica Light set made of plastic, galvanized) | 1300 rub. Buy |

What models are there sand traps for storm drains?

For all its, without exaggeration, ingenious simplicity, a device such as a sand catcher can be made in the form of different models. It is very important to choose exactly the model that will justify installation in a particular case. After all, a storm sewer is a very complex engineering structure that requires precise calculations when installing it. And each element must be, as they say, “in its place.” And even a device such as a sand trap for storm drainage, chosen incorrectly, can significantly reduce the efficiency of the entire system and even lead to its early failure. Currently, the following types of catchers are distinguished:

- vertical type sand traps;

- horizontal type sand traps;

- tangential catcher;

- aerated sand catcher.

In order not to make the right choice, it makes sense to take a closer look at how these types of sand traps differ.

Vertical sand traps

They got their name due to the vertical orientation of the device box. Moreover, its shape is cylindrical. Water gets inside the device and, as already mentioned, loses significantly in speed. The sand settles to the bottom of the tank - and the purified water goes further. Vertical devices have a large capacity, so their use can be justified with large water flows, or when servicing large areas.

Scheme of a vertical sand trap for linear sewerage.

Horizontal sand traps

Due to the simplicity of the design and at the same time great efficiency, it is horizontal sand traps that have become most widespread. These are, as a rule, plastic cylindrical containers, into which water gets in with the impurities of sand and soil it contains. There are two chambers inside. Once in the first, the water is filtered and goes further into the second, while the sand itself remains inside the tank.

The diagram shows all the components of a horizontal sand trap.

Sometimes industrial facilities may have special pumps installed for improved sand removal. It is also worth noting that the sand that was obtained by any model of catcher can be subsequently used for any purpose - construction, decorative, etc.

Tangential sand trap

When this type of “sand trap” is used, water flows through a specially equipped tube and swirls into a whirlpool. In this case, the sand settles on the walls of the container and falls to the bottom, and the purified water continues its path through the sewer.

The tangential sand trap operates on the principle of a “whirlpool”, as a result of which the sand falls into a special storage tank.

In this case, sand will be filtered out very effectively. But for a number of reasons, this type of sand collection is not widespread in domestic construction. But it has long been successfully used in European countries.

Aerated sand traps

This type of sand trap is often used in the food industry. After all, the water passing through the sewer in this case is often high in fat content and contains other foreign impurities.

An aerated sand trap is a horizontal tank. Its operation is based on the speed of the flow - this ensures that all organic suspensions cannot settle to the bottom and precipitate, causing rotting processes.

In order for aerated sand traps to work effectively, it is necessary to ensure a constant flow of air to them. One way or another, as the sand particles settle, they attract with them fatty particles, as well as other “dirty” substances. Additional purification is also achieved due to the fact that in the aerated sand catcher the particles rub against each other, contributing to additional purification of the water.

Sand traps can also be single-chamber or double-chamber. The former are used where there are no special requirements for water purification. They are the most versatile traps. Double-chamber ones are used at high concentrations of solid impurities in water - over 3,000 mg per milliliter.

Calculation of basic parameters

There are sand traps of varying sizes and efficiencies for both domestic and industrial use.

To determine which sand catcher you need to purchase in terms of size and performance, you should carry out a calculation using the following data:

- volume of water discharged;

- pollution parameters;

- flow speed;

- daily sediment volume;

- territorial conditions for installation.

Let's calculate the dimensions of the structure of a horizontal block with a rectilinear flow of water, consisting of two main parts: working and sedimentary.

Example.

Initial data:

- volume of discharged water – 130000 m3 or qmax=1.50 m3/s (130000/24/3600);

- permissible flow speed – 0.15-0.30 m/s;

- hydraulic fineness of deposited sand – 18-24 mm/s;

- the planned number of residents is 415,300 people.

Solution:

- Three compartments are selected based on the calculation of 50,000 m3/day.

- Determine the required cross-sectional area of one compartment:

ω=q_max/vn, Where- v – average flow velocity, m/s;

- n- number of branches;

- ω=1.50/(0.25×3)=2.0 m^2.

- Calculate the length:

L=1000KHv/u, Where- K – coefficient, taken from the table;

H – depth of the flow part, accepted for standard models in the range from 0.5 to 2.0 m, accepted 1.0 m;

- u – hydraulic sand size, mm/s, taken from the table.

- Find the width of one compartment, m:

B=ω/H.B=2.0/1=2.0 m.

- Based on the obtained dimensions of the sand trap, choose a standard one from the table or design it individually.

- Flow rate at different values:

υ_max=q_max/(BH n).υ_max=1.50/(2⋅1⋅3)=0.25 m/s.

- Time spent in the working area:

T=L/υ_max.T=13.43/0.25=53.72 s.

- Calculate the amount of sediment per day m3/day:

W_day=(Nq_2)/1000, Where- N – planned number of residents;

q_2 – specific amount of sand, taken from the table.

- Find the volume of one container:

W_о=(W_day T)/n, where T is the time between sand unloadings, should be no more than 2 days.W_о=(8.31⋅1)/3=2.77 m^3.

- Find the depth of the container:

h=W_о/B^2.h=2.77/2^2 =0.69 m.

- Calculate the height of sand sediment at the bottom:

h_os=(W_day k)/BnL, where: k is the coefficient of sand distribution along the bottom, taken equal to 3.h_os=(8.31⋅3)/(2⋅3⋅13.43)=0.31 m.

- Calculate the total building height:

H_str=H+h_os+0.5.H_str=1+0.31+0.5=1.81 m.

L=(1000⋅1.3 ⋅1⋅0.25)/24.2=13.43 m.

W_day=(415300⋅0.02)/1000=8.31 m^3/day.

A calculation of the dimensions of the horizontal sand trap has been obtained, which must be used as a guide when designing equipment:

- width,

- height

- and length.

BxHxL=2 x 1.81 x 13.43 m.

Approximate diagrams of the main types of modern sand traps can be seen below.

Other devices can also be used to remove mineral suspended matter from wastewater:

- hydrocyclones

- and centrifuges.

Their designs work thanks to the rotational movement of the liquid, which separates particles with different specific gravity. The heavier ones fall down, the lighter ones are carried away by the water flow.

What materials can a sand trap for storm drainage be made from?

Mainly, concrete (polymer concrete) and plastic are used to make sand traps. Concrete catchers are durable and can last quite a long time. However, their very considerable mass does not allow us to recommend a concrete sand trap for storm drainage for use on private land. In most cases, concrete or polymer concrete structures are erected at large industrial facilities, airfields, etc.

To equip the storm drainage system of a private house, it is recommended to opt for a sand catcher made of plastic, since it is lightweight and, unlike a heavy concrete sand catcher, can be installed independently without the use of special equipment.

Concrete sand traps require the use of special equipment during installation, and in terms of price they are not the most affordable devices. And in contrast to them, you can offer plastic. Modern plastic sand traps can successfully withstand enormous loads, so they can be installed both at industrial facilities and in small areas.

Plastic is not subject to corrosion, it is chemically neutral and can be used in any type of soil and in any water – depending on its chemical composition. Of course, plastic is lightweight. And even plastic sand catchers that are quite large in size will not require the use of construction equipment during installation in most cases. If necessary, a plastic sand trap for storm drainage can be quickly dismantled, replaced with a new one, moved to another location, etc. And plastic sand traps are much more affordable in price.

Popular models of sand traps

Let us consider, as an example, several popular models of sand traps for sewage, indicating their main characteristics:

- Hydrolica Light. This is a horizontal type plastic trap designed to be installed in a plastic tray system. Equipped with a plastic grill. Its length is 50 cm, width - 11.6 cm, height - 32 cm. Load class - A15. Section width - DN100. The price of sand traps of this type is about 1000 rubles. Withstands loads of up to 1.5 tons. The catcher is used in systems of private houses, on pedestrian sidewalks, in parks, and on bicycle paths.

- Hydrolica Filcoten. It is made of composite concrete and can withstand a load of up to 25 tons. The length of the trap is 50 cm, width is 14 cm, height is 50 cm. Load class is C250. Section width - DN100. Similar devices are used in parking lots, garages, roadsides, and sports facilities. The cost of the trap is about 5,700 rubles.

- Hydrolica Super. Made from impact-resistant plastic. Has a reinforced steel nozzle. There are 2 types of traps available, differing in their dimensions and width of the flow area. Withstands a weight load of up to 60 tons. Dimensions of sand traps: length - 50/54 cm, width - 16/26 cm, height - 43.8/47.8 cm. Load class - E600. Section width - DN100/DN200. is 2100-4200 rub.

Where to install the sand trap

The installation location of the sand catcher is also very important. In a general water flow filtration system, sand traps are installed first. And the degree of load on the filter system may depend on them.

The sand trap is installed directly at the transition from the water intake gutter to the further main line. The entire operation of the stormwater system depends on a properly installed sand trap.

It is advisable to install a sand trap for storm drainage at a direct transition from the water intake gutter to the further main line through which water will flow into collectors, etc.

Storm drains and inspection wells can act as a kind of sand traps in a household system. After all, their diameter is larger than the diameter of the main stormwater pipes. Accordingly, it is necessary to monitor the cleanliness of inspection wells, periodically clearing them of sand deposits.

The efficiency of a sand catcher installed correctly and in the right place reaches 90 percent. Thus, almost all the sand will settle in the catcher.

What should you pay attention to when purchasing?

The design of the sand collector must ensure uniform movement of discharged water throughout the day and consist of two or more compartments. It is recommended to select a bunker for collecting sand according to the volume calculated for a two-day norm of sand. The diameters of the inlet and outlet channels must correspond to the performance of the treatment system.

The price of sand traps depends on the model of the device , which, in turn, has different modifications according to its performance, size and material.

- Household plastic models are considered the cheapest. They can be about 1500 rubles.

- A little more expensive - made of polymer concrete and metal.

- The most expensive are industrial ones made of concrete, which can cost several hundred thousand rubles.

For example, in Moscow and St. Petersburg you can buy a sand trap for washing a model, which is represented by two series “standard” - an economical option and a “pro” - with replaceable elements for ease of maintenance.

The difference in design is reflected in the price.

For example, model PE-1.5-100:

- “standard” series costs 14,950 rubles;

- "pro" series - 19,700 rubles.

The model for industrial purposes PE-36-5000 with a peak discharge of 5000 l is made in three modifications:

- vertical costs 149,200 rubles;

- horizontal – 149,200 rubles;

- rectangular - 181,700 rubles.

Expert opinion when installing sand traps

For sand collection devices, it is necessary to build a separate pit - regardless of the size of the device itself. It is also necessary to separately arrange a gravel or concrete pad for them. The upper section of the sand trap must be covered with a grid with locking joints. If the catcher is plastic, the grid must be plastic. The industry also produces concrete gratings for concrete catchers.

Alexei.

Particular attention should be paid to cleaning the sand trap and grate in the fall and spring, when the watercourse is particularly polluted. A sand trap for storm drains is an absolutely necessary device that will effectively protect the storm drain from debris and increase the efficiency of its operation.

Nikolai.

Principle of operation

Of course, the easiest way is to choose and purchase a ready-made sandblasting unit, but not everyone can afford it.

A way out of the situation may be to rent the device, but in this case its service life will be limited, and in the event of any breakdown, you will have to pay for repairs.

Anyone who is familiar with the basics of mechanics and regularly needs a sandblasting device designed to process various types of surfaces, but does not have extra money, can easily assemble it with his own hands.

Such an automatic homemade sandblasting machine, if the assembly technology is followed, will in no way be inferior in its functionality to a device assembled at a factory.

In this case, you will have to make some efforts and acquire all the necessary materials and tools that will be required during the work process.

First of all, it is necessary to thoroughly study the principle of operation of the sandblasting machine and understand the basic diagram of its operation.

The compressor, which is part of the operating circuit of the device, supplies air under high pressure, which, capturing the abrasive material, is delivered to the surface requiring treatment using a nozzle.

For a homemade device, it is better to use a factory compressor capable of creating the required pressure. In some cases, it is possible to create the necessary pressure in the system using a gas cylinder.

In addition to the air source, the general design of the device must include supply hoses of a given diameter, cables, and a main power source.

The operation of a sandblasting unit is also impossible without a special nozzle, which has some design features.

It should also be noted that the nozzle material should be either tungsten carbide or boron. You should absolutely not use nozzles made of cast iron or ceramics, as they will fail very quickly.

The photo below shows sandblasting machines and factory-made nozzles, which are suitable for processing various types of surfaces.

Manufacturing materials

Engineering devices for collecting dirt are made from the following materials:

- concrete;

- polymer concrete;

- plastic;

- stainless steel.

Concrete options are strong and stable, but they weigh a lot, which complicates installation. Over time, under the influence of water, small cracks appear and lose their tightness. Their cost starts from 3000 rubles.

Installations made of plastic are inexpensive: the price starts from 1000 rubles. Other advantages include light weight, ease of installation, immunity to corrosion, tightness, and resistance to temperature changes.

Devices made of polymer concrete combine the advantages of concrete and plastic structures. They are durable, but don't weigh much. Such products cost more than previous ones - from 5,000 rubles.

Stainless steel options are usually installed in factories. Sometimes they are equipped with aerators for more effective cleansing, especially from fatty and viscous suspensions. The minimum price of a stainless steel sand trap for internal sewerage is 15,000 rubles.