In the modern world, not only production technologies are subject to changes, but also materials. Metal pipes are not popular due to the complexity of installation, heavy weight and susceptibility to rot. They were replaced by low-density polyethylene or HDPE.

This material has many advantages: plasticity, increased strength, unpretentiousness, long service life. A water supply system in a dacha made from HDPE pipes will last up to 50 years, and you can assemble it yourself.

Advantages of polymers

Pipes and connectors are made from durable, thick material.

Its popularity lies in its low cost and ease of installation compared to others. To manufacture systems you do not need to have special education, knowledge or skills. The connection of the pipe with the fitting is done manually, since there is a factory thread, you need to be careful and follow the assembly sequence.

Advantages of HDPE pipes:

- not subject to rotting and external influences;

- environmentally friendly;

- light;

- resistant to deformation;

- resistant to changes in water pressure;

- high maintainability;

- little heat dissipation.

Metal-plastic pipes

Laying pipes made of metal-plastic, as mentioned above, is the most suitable option for people who want to do all the work themselves. Metal-plastic parts consist of 3 layers: outer polymer, middle metal (usually an aluminum layer) and inner polymer.

Metal-plastic pipes, rolled into small coils, are very convenient for transportation and storage, which cannot be said about steel products

Metal-plastic communications are installed in two ways:

- Using threaded connectors that include sealing gaskets. The seal is necessary to achieve the required tightness in the system.

- Using compression fittings.

Products made of metal-plastic have resistance to the destructive effects of corrosion, and due to their smooth internal walls they are characterized by high throughput. And thanks to the smooth walls, such products do not accumulate salt deposits inside themselves, which can, over time, lead to a narrowing of the lumen of the pipe and its complete blockage.

How to lay out metal-plastic pipes with your own hands? To lay out metal-plastic pipes with your own hands, you need a pipe cutter, pressing pliers and reamers. It is strictly not recommended to carry out hidden wiring of metal-plastic water supply in the walls. This is due to the fact that sealing elements lose their useful properties over time and connecting units may leak, so it is necessary to provide quick access to the pipeline for repair work.

Types of installation

Each method has its pros and cons.

Surface - for summer water supply

Connection using a split fitting

Ground installation is intended directly for summer cottages in order to timely water your garden, shrubs and trees. There is also an option for supplying water to auxiliary buildings: a sauna, a utility room, or a summer house.

The layout of the summer water supply system at the dacha repeats the layout of the underground one, but is as convenient as possible for repair, disassembly, and alteration if necessary. It can be dismantled for the winter or in case of redevelopment of your summer cottage.

If necessary, within half an hour you can easily change the junction and the location of the water supply on the site.

To avoid accidental damage to pipes located on the surface, it is necessary to provide stands or supports.

Many people install summer or, as they say, temporary water supply according to the principle of how they assembled it or cobbled it together from what was there, directly at the location.

It is preferable to draw up a diagram of the house’s water supply system in advance if the site is planned into zones. On the drawing, the first thing to note is the main consumers of water: the house, shower, trees, hedges, and the points where the taps will be located.

The pipes must be placed at an angle directed towards the consumer, since a drain valve is installed at the lowest point.

Capital system

Underground installation

A system designed for a home with year-round use will require much more time to think through the project and carry out excavation work. In this case, the principle of assembling a country water supply system from HDPE pipes must be changed, since additional compressor equipment, a hydroaccumulator and a closed arrangement method will be installed.

Do you need running water at your dacha?

Living in an apartment or private house, a person gets used to using running water and perceives it as something permanent. However, at the dacha the situation is different. Here you often have to adjust your life gradually. One of the important issues is the need for regular watering of garden and vegetable plants.

Of course, you can carry water in buckets. However, if you need a lot of it, you have to look for a solution to the problem. Self-made water supply from plastic pipes can be an effective solution to the problem.

It is not difficult to do - even those who do not have professional skills for such work can do it. However, in order to do it efficiently, you need to have a good understanding of what needs to be done and in what sequence.

How to choose

Manufacturers make several types of HDPE pipes to choose from. The first difference is what the water with different color stripes will be used for.

For use in drinking water supply systems from wells and boreholes, HDPE pipes with a blue stripe should be used.

To make gas pipes, additives are used that change the composition of water. Pipes with yellow markings can also be used for country water supply, but their cost is noticeably higher. These pipes are designed for high pressure gas and have increased strength and a higher price.

HDPE pipes without markings cannot be used for drinking water supply. These are technical products made from recycled polyethylene. They can release toxic substances into the water.

For underground installation, two types of polyethylene are used:

- HDPE PE 100 according to GOST 18599-2001. The diameter of the products is 20 to 1200 mm, the appearance is a black pipe with a longitudinal blue stripe along the entire length.

- HDPE PE PROSAFE is produced in accordance with GOST 18599-2001, TU 2248-012-54432486-2013, PAS 1075, they are provided with an additional mineral protective shell up to 2 mm thick.

A pipe with a diameter of 40 mm is suitable for connecting the house. For other consumers, 20 mm or 25 mm is sufficient.

Video description

This video shows the technology for assembling water pipes:

It is necessary to ensure the possibility of drawing water from a well that is available on the site. To do this, it is necessary to pump water using a special pump into the tank, and from there distribute it through pipes for irrigation.

When choosing pipes, some main parts of the main line are made of metal, and bends are made of polymer pipes. In winter, water is removed from this system. In this case, metal pipes are left underground. And the plastic ones are disconnected and stored. In the spring, the water supply system will be reinstalled from them.

Typical system structure

Although it is necessary to plan a specific type of water supply. Nevertheless, it will be useful to understand what a typical plumbing system is, which can be used as a basis in the future.

Connecting elements - couplings and fittings

HDPE compression fitting

Couplings of 2 different types are used as HDPE connectors:

- Compression ones, which are screwed onto the pipe pieces being connected. The elements are sealed due to rubber sealing rings. Assembly is carried out manually, since the use of gas keys can lead to overtightening and mechanical damage.

- Diffusion couplings. Designed for high-temperature welding with a special soldering iron. Without the use of additional seals, it is of higher quality compared to compression.

Types of fittings:

- Docking joints are used to connect pipes of the same diameter;

- transitional, for connecting pipes of different sizes;

- plug, disconnecting an unnecessary branch.

If necessary, purchase watering heads, drip hoses, and watering guns for a more comfortable arrangement.

Physicochemical characteristics

Let's start by studying the basic properties of low-density polyethylene (HDPE).

It is resistant to aggressive environments and any biological influences.

The elasticity of the polymer makes it possible to supply small-sized pipes in coils.

- Like all other polymers, polyethylene is a dielectric.

- Softening temperature – 80-120 degrees Celsius.

- Adhesive properties are at an extremely low level. Simply put, other substances do not stick to polyethylene. Water doesn't wet it either.

- The price of polyethylene is the lowest among all plastics - both due to the manufacturability of production and the low cost of gaseous raw materials.

Depending on the polymerization conditions of the raw material - ethylene - there are three types of this plastic.

| Polymer type | Polymerization conditions |

| HDPE (low density polyethylene) | 0.1 – 2 MPa, 120-150С |

| MSD (medium pressure polyethylene) | 3 – 4 MPa, 100 – 120С |

| LDPE (high-density polyethylene) | 150 – 300 MPa, 200 – 260 C |

Of these materials, HDPE has the highest mechanical strength. It is this polymer that is more often used for the production of pressure pipes than its related polymers.

Large-diameter polyethylene pressure pipes are used to lay pipelines that supply water to entire cities.

Compression fittings for pipes of small diameters are also made from it, allowing you to combine sections into an arbitrarily complex pipeline without the use of tools.

Work order

Before installation, the length of the water supply pipeline from HDPE pipes to be laid is checked directly on site. To do this, it is necessary to transfer the diagram to the ground by marking with the placement of control pegs and pulling a cord that follows the contour of the future pipeline.

Only after this the excavation work begins. They measure the length again and begin shopping based on the measurements and calculations made.

The algorithm for performing the work is extremely simple:

- The trenches are dug at a slope at the connection point; the angle should not be large for its further exit into the horizontal plane.

- The bottom of the trench must be equipped with a sand cushion with additional waterproofing. This is done to smooth out any unevenness that will inevitably appear.

- HDPE pipes are cut directly when they are laid in a trench. Docking to the water intake point first, then laying along the site. We insulate pipes with pre-selected material. After completion of the work, connect the pumping station.

Compression connectors are installed in the following sequence:

- The couplings are disassembled, the clamping part and the gasket are removed.

- The gasket and clamp are installed in the reverse order on the tabs.

- The nodes are joined, the fitting is screwed on manually, without much effort.

If the elements are connected by soldering, then the following rules must be followed:

- The joints are cleaned, degreased, and dried.

- Work is allowed to be carried out at temperatures greater than +5C.

- Pipes with a diameter of 50 mm or more must be chamfered.

Connection using electrofusion welding

For this method of connecting pipes, it is necessary to use shaped elements with electric spirals mounted inside. This coupling is put on the pipes, the spirals begin to heat up and melt the polyethylene, which is then tightly soldered. This pipe connection is quite reliable and is used when installing sections whose diameter is less than 160 mm or in cases where it is quite difficult to get to the joining point. In this case, you need to take into account that the cross-section of the pipes being joined should not differ by more than 10%.

If you want to connect pipes in this way, you need to clean the edges of the pipes from dirt and align them. During operation, it is advisable to securely fix the product using a positioner. After that, the two ends of the pipe are installed in the coupling and the welding machine is turned on. All data, such as soldering time and temperature, can usually be seen on the part's barcode.

How to weld pipes using an electric coupling, see below:

Output from the well

The pumping station must be located as close as possible to the well pipe. The pipe must pass inside through a special sleeve made of metal. It is designed to protect against destruction during seasonal fluctuations in ambient temperatures. The pipe is connected to the pumping station only after it has been fixed.

The HDPE pipe is inserted into the well immediately after the pressure regulating relay. Don't forget to include a prefabricated elbow. To do this, a coupling with an MRN thread is soldered onto a piece of pipe. It is installed on a tap to the relay. Then the head is attached to the well.

When laying a year-round system on the bends of the main highway, it is necessary to provide wells for maintenance and repair.

System planning

Due to the fact that PPR pipes do not bend, when developing a wiring diagram it is necessary to create as few detours and turns as possible. After all, they are all made using fittings, and they have a significant cost (compared to a pipe). Therefore, we try to optimize the wiring - make as few turns, detours and bends as possible.

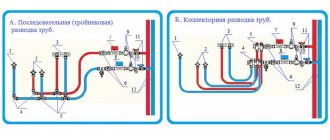

Serial (Tee) connection

Installation of water supply from polypropylene pipes with serial connection of consumers (plumbing and household appliances) is used in small systems. Usually they have 5-6 connection points. With this arrangement of the water supply system, one pipe leaves the riser and it sequentially bypasses all connection points. In the case of PPR plumbing, all branches are made using tees, which is why this type is also called tee.

Installation of water supply from polypropylene pipes with serial connection of consumers

The advantage of this system is that a small number of pipes are needed, and the disadvantage is that the pressure on each branch drops. As a result, with one or two working disassembly points, the third, located further from the riser, may simply not have enough pressure.

Parallel (collector) wiring

A parallel connection circuit is also called a collector circuit. This is because after the outlet from the riser, a special device is installed - a collector. This is an element with one input and a number of outputs. Available in polypropylene and metal. For water supply, polypropylene manifolds are more suitable (and cheaper).

The connection diagram is such that a separate pipe runs from each branch to each consumer (sometimes to a small group of consumers).

Parallel scheme for installing a water supply system from PPR pipes

Plumbing and household appliances

In each method of installing a water supply system made of polypropylene pipes, a pipe is suitable for a specific consumer. There are two ways to connect to the system: flexible and rigid connection.

Rigid liner is more reliable: PPR pipes and fittings have high strength. Moreover, in this case there is only one thread - at the consumer connection point. But this type of eyeliner requires high precision: the error can be only a few millimeters. This is difficult to achieve when installing a polypropylene water supply with your own hands, so flexible hoses are often used. Just be careful, in some cases it is impossible to use it: connecting gas boilers or gas water heaters, supplying water to storage water heaters, water heated towel rails is recommended only using a rigid connection.

Rigid liner options

Soft eyeliner, on the contrary, does not require high precision - errors are leveled out by a flexible stainless steel braided hose or a hose that is used to connect a washing machine or dishwasher. The tubes are removed approximately in the area where the equipment is installed or the plumbing is connected. It ends with an adapter for metal, to which a flexible hose is connected (its other end is connected to the device).

Flexible hoses are connected to the adapters

This option is less reliable, since much depends on the quality of the flexible liner. Also not the most pleasant moment is the presence of two threaded connections, and this is a potential place for a leak to appear.

Choosing material

As already mentioned, water supply and sewerage in a dacha are most often installed from what is at hand.

A study of existing sewerage structures made it possible to determine the main types of pipes used in country house construction:

Steel pipes for sewerage

- Steel pipes - this material is often left over after the installation of other communications or building structures; it can be purchased at scrap metal collection points at its residual value. But, before installing a sewer system in your dacha using such pipes, you should also become familiar with the disadvantages of this material. Firstly, finding material of a suitable diameter is quite difficult.

- Thirdly, steel pipes are highly susceptible to corrosion; a significant layer of various deposits forms on their inner surface, so such a pipeline has to be cleaned quite often.

Secondly, installing a line from such pipes requires welding work, which leads to the need to hire professional performers.

That is why you should use steel pipes only if you have a surplus of this material and you do not know where to use it.

Sewerage made of cast iron pipes

- Traditionally, the installation of pipes in the country (for sewerage) was carried out using cast iron. Such pipes withstand the effects of groundwater well, they are more resistant to corrosion (compared to steel), and are highly durable. To reduce flow resistance, such pipes can be coated with bitumen compounds, due to which the amount of deposits on the internal walls is significantly reduced. The disadvantages of cast iron pipes are also traditional - heavy weight, complex installation (the need for embossing), in addition, cast iron is difficult to process, so cutting it can be significantly difficult.

- PVC sewer pipes are considered the best option today. The bell-shaped design using rubber seals makes installation very simple; even a person without construction skills can handle it. Working with this material will allow you not to think about how to lay pipes in your dacha for sewerage. Plastic is easy to cut, and the presence of a variety of fittings allows you to mount a line of even complex configurations. PVC does not rot, is not susceptible to corrosion, and the service life of such pipes is practically unlimited (subject to the installation technology). Another advantage of plastic is its low flow resistance, which eliminates the amount of deposits inside the pipeline.

If we talk about the cost of the material, then plastic pipes are rightfully considered one of the most profitable options, and there is a real opportunity to save on installation, which can be done independently.

Which pipes to choose is, of course, up to you.

Where to get water from

There are several traditional sources of moisture intake; which one is preferable for your site should be decided purely individually. We, in turn, will tell you about the most common ones.

Advice: if possible, it is better to start drawing up a project by interviewing your closest neighbors. By taking advantage of their experience and taking into account their mistakes, you can avoid significant costs.

Good old well

Output from the well.

If in your area the depth of the aquifer with high-quality drinking water is between 3 and 15 m, then there is no need to reinvent the wheel. A well will be the best solution for you.

The cost of constructing an average well will not be much higher than drilling a well for sand. If the site is not on rock, then 2 - 3 people can dig a well in 1 - 2 weeks.

The most convenient way to do this is with the help of concrete rings; the first ring is installed in the pit and the soil is removed from under it. As the structure goes deeper, it is built upon.

Important: unlike a well, the service life of wells varies around 50 years. Plus, during a power outage, water from the well can be lifted with a bucket.

Location of aquifers.

Well drilling

There are 2 types of wells, sand and artesian. The depth of the well in sand, depending on the location, ranges from 10 to 50 m. The horizon may begin immediately behind the first layers of dense loam. The same loam acts as a natural filter, purifying groundwater and melt water.

The water supply depends on the thickness of the formation, but on average, up to 500 liters can be obtained from such a well per day. Sand or silt clogging of submersible pumps and filtration systems can be a serious problem here.

Such structures most often do not last long, from about 5 to 20 years. But if you find yourself on a deep underground river and properly equip the wellbore, then such a source can last longer.

Experts advise drilling such wells manually, and it is better to look for a place to drill using old-fashioned methods. From experience, with this approach the likelihood of finding a quality source increases significantly. When machine drilling, you can simply skip the desired horizon.

Water in artesian wells is extracted from a limestone horizon. It is, of course, tougher, but it is exceptionally clean. The depth of occurrence here is not predictable.

In the rock formations you can stumble upon an underground lake already at 30 - 40 meters. But there is an option to drill more than 100 meters.

The construction of such wells is quite expensive and, as a rule, they are done together. In addition to serious financial investments, you will also need official permission from the authorities, because artesian water is the property of the state. But there is a high probability of providing ourselves with clean water within the next 50 years.

Alternative methods

A simple and relatively reliable option is to connect to a ready-made highway. Now this can be done directly under pressure. For this purpose, an overhead tee with a ball valve is used.

The tee is bolted to the line, after which a hole is drilled in the pipe and the valve is quickly closed. Then you can mount the branch.

Alternatively, you can use water from natural reservoirs located nearby, but no one will give you a guarantee of purity. Therefore, such water is more suitable for irrigation. It is also possible to collect rainwater in separate reservoirs, but of course we are not talking about any serious scale here.