SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

From this article you can learn the features of such a communications element as a sewer drain pipe: its purpose, types of existing products that can be purchased in stores, their characteristics and prices. The text describes the specifics of drains and recommendations for installing a sewer system riser, including instructions for dismantling the old pipeline.

Corrugated pipe for sewerage drainage

No. 1. Material of internal sewer pipes

Internal sewerage can be done using the following pipes:

- cast iron. Previously they were installed everywhere, but today they are practically not used;

- polyvinyl chloride (PVC);

- polypropylene. Looking ahead, we note that this is the most optimal option;

- polyethylene. Infrequently used;

- steel and copper. Expensive pipes that are not used, but are sometimes still used due to their appearance.

Despite the fact that polypropylene and PVC pipes are most widespread, when choosing, do not rush to immediately discard the other options, since in some cases cast iron and even copper pipes may be useful.

Chemical removal of blockages

If there is no plumbing cable, remove the blockage chemically. There are special formulations for this. Before you purchase a product, make sure it is suitable for your type of pipe. The most popular are “Mole”, “Tiret”, “Mr. Muscle”, etc. They are produced both in the form of dry powder and in liquid form. The principle of their operation is the same.

Clean the pipes as follows: scoop out the water from the bowl. Fill or pour the product into the drain hole. Leave the sink like this for 1.5–2 hours. After the specified time, fill the sink with a small amount of water. Perform several active thrusts with the plunger. After these manipulations, the water forms a funnel and goes into the sewer. Wear gloves when using aggressive substances. Avoid contact with clothing or skin. If this happens, rinse the affected area with plenty of water.

No. 2. Cast iron pipes for internal sewerage

Several decades ago there was no particular alternative to cast iron pipes, so they are widely found in old houses. Today, cast iron is being replaced by plastic, but is still used. Such pipes are made from gray cast iron by centrifugal casting. To protect the material from corrosion and make the internal surface smooth, the pipes outside and inside are coated with a bitumen compound. The diameter of cast iron pipes ranges from 5-15 cm, the wall thickness is 10-12 mm.

Advantages of cast iron pipes:

- durability. The service life reaches 50 years and often exceeds this mark. Some data suggests a longevity of 90-100 years;

- high strength and resistance to deformation. On the other hand, the material does not tolerate shock loads well;

- the ability to withstand long-term exposure to hot waste (from a washing machine or dishwasher, for example);

- resistance to temperature changes;

- fire resistance;

- environmental Safety;

- good sound insulation.

Surely, cast iron pipes would have remained among the leaders if not for significant shortcomings:

- the walls become overgrown with sediment over time. This is all due to the roughness of the material, which even with a bitumen coating cannot be completely eliminated. The process of overgrowing leads to a narrowing of the pipe lumen and a decrease in its throughput. Anyone who has seen what a pipe looks like after many years of use will never forget this terrible sight;

- heavy weight of pipes, which complicates transportation;

- complex installation, which is explained not only by the large weight, but also by the peculiarities of connecting pipe sections. In order for the sewer system to be airtight, it is necessary to correctly connect the elements. Usually they use the method of caulking or caulking using a heel;

- susceptibility to corrosion processes;

- high price.

Cast iron pipes are not used today to build a new sewer system, but they may be needed when existing systems are being reconstructed. At the moment, the use of cast iron pipes is also justified when arranging external sections of private sewers and intra-house risers.

When choosing, it doesn’t hurt to carefully examine the products and tap each of them. This way, it is easy to detect cracks and other defects that form when the manufacturing process is disrupted. A defective pipe does not have a long service life. Various types of fittings, plugs and sockets are produced for connecting cast iron pipes.

Features of operation

This section will discuss the most common problem that arises in connection with the use of the sewer system - its clogging. To do this, we will look at how to unclog a drain pipe in the kitchen or anywhere else in your home.

The instructions allow you to use several methods to complete this task:

- Regular boiling water with added soda. This mixture will corrode fatty deposits, freeing passage for larger debris.

- Plunger. A compact and inexpensive tool that should always be close to the drain point. If the water in the sink has become dry, place the cup-shaped part of the device against the drain hole and press several times, then pull it out sharply. The garbage plug will move under pressure and collapse.

Breaking through a clog with a plunger

- Steel rope. The most stubborn blockages can be eliminated by inserting a special metal string into the sewer pipe using rotational movements.

No. 3. Polyvinyl chloride (PVC) sewer pipes

For arranging internal sewerage, PVC pipes are considered almost the most suitable option. During the production process, some other substances are added to polyvinyl chloride, which include stabilizers and polymers. Elements of the required shape are formed from the heated mass.

PVC pipes can be of two types:

- pipes made of plasticized PVC (PVC) have good elasticity and low strength;

- pipes made from unplasticized PVC (PVC-U) are more rigid and resistant to aggressive influences.

Of course, it is better to use unplasticized PVC, but in practice both types of pipes are used. The diameter of the products ranges from 2 to 20 cm.

Main advantages:

- affordable price;

- light weight;

- ease of installation. Separate sections of pipes are connected by couplings and connecting rings - everything is done without welding;

- low temperature coefficient of expansion. With a short-term or constant increase in the temperature of the drains, the pipes will not sag;

- sufficient strength and durability up to 50 years;

- sufficient resistance to ultraviolet rays, so that some sections of pipes can not be afraid to run on an open surface;

- resistance to corrosion and some aggressive substances;

- Thanks to the smooth inner surface, the walls do not silt over time.

Minuses:

- limited operating temperature range. With constant exposure to negative temperatures, pipes become fragile and lose their tightness, and with constant exposure to temperatures above +60...+700C, the material can deform and also lose integrity;

- insufficient fire resistance;

- The inner walls of PVC pipes are smoother than those of cast iron, but over time they will still develop plaque. In addition, the internal diameter changes over the years. As a result of exposure to high temperatures, the circular cross-section is transformed into an ellipsoidal one, and this impairs the throughput and contributes to the occurrence of leaks;

- some aggressive substances contained in drains can still lead to the gradual destruction of pipes.

To install internal sewerage from PVC pipes, appropriate connecting elements are used. These include an elbow designed to rotate the pipeline at an angle from 20 to 87 degrees, a tee for arranging branches, a cross for connecting four pipes, and a reduction for connecting sections of pipes of different diameters.

Connecting elements

Types of fittings

When laying a socketless pipeline, various fitting connections are required:

- sweeps;

- tees and crosses;

- squares;

- bends;

- audits;

- adapters.

Squares are found in 15 degree increments, usually using angles of 45 degrees. It is not advisable to make 90 degree turns, as this increases the likelihood of blockages. They also try to install the bends not straight, but at 45 degrees, taking into account the possibility of cleaning through the hole in the plumbing fixture; the flow from the bend should enter along the flow in the main pipe. Revisions can be built into other fittings. The adapters are asymmetrical - the smaller hole should be higher when installed longitudinally.

All connecting elements have gasket seals that ensure tightness. They must exactly match the pipe diameter and fitting type.

No. 4. Polypropylene sewer pipes

Polypropylene pipes today are actively used in the arrangement of heating systems, cold and hot water supply. The properties of a material strongly depend on its structure. Pipes made from a copolymer of propylene and ethylene ( PPR ) are suitable for internal sewerage; they can withstand temperatures up to +700C. the PPs type behave even better , which can easily withstand temperatures up to +950C and short-term exposure to even higher temperatures. Reinforced pipes will be more durable, and fiberglass reinforcement is considered optimal. The product labeling also indicates the operating pressure: for internal sewerage, PN10 (withstand 1MPa), but more often they take PN20.

Advantages:

- durability up to 50 years;

- resistance to corrosion and almost all aggressive substances (acids, alkalis and salts will not damage the material);

- high strength of pipes and connections. Polypropylene is stronger than polyethylene and PVC, it is more resistant to cracks, and joints are less likely to depressurize;

- light weight;

- an absolutely smooth inner surface, so there will be no problems with pipe overgrowing;

- resistance to high and low temperatures, which allows the pipes to be used in almost any conditions. The pipes are not deformed;

- relative ease of installation. The connection of individual sections is made with a special welding machine, which almost anyone can learn to work with;

- relatively low price, but polypropylene pipes will cost more than polyvinyl chloride pipes;

- polypropylene type PPs belongs to the group of flame-resistant materials.

Among the disadvantages of polypropylene pipes, one can note only temperature deformation, so they will either have to be insulated or equipped with compensators.

Specificity and types of pumps for sewerage in an apartment for the kitchen

The sump pump looks like a plastic reservoir, similar to a toilet cistern. It has threaded holes that are used to connect pipes.

Sewage pump

Pump Internal Parts:

- engine;

- automatic starting device;

- chopper

The pump has a simple operating system. Water coming from household appliances or from the sink flows into a plastic tank. When the container is full, a switch equipped with a float is activated, which starts the motor and chopper blades, if present. The crushed debris along with water is forced through the filter system, and then, under pressure, enters the sewer system.

There are several types of sewage pumps for the kitchen, differing in purpose and characteristics:

- sanitary (simple devices under the sink);

- forced sewerage stations;

Kitchen sewer pump

- stationary.

Sanitary pumps are not capable of discharging hot water and most often do not have blades. Their operating temperature is only 35-40 ºС. For the kitchen, it is better to choose forced sewage stations that can handle large volumes of liquid, perfectly grind organic waste and have high power. Stationary devices are suitable for installation in a closet, however, they are rarely used in apartment conditions.

Installing a sewer pump at home

Installation of sediment under the sink is carried out in the following order:

- The drain pipe is disconnected from the sink.

- A mounting fastener is installed on the sink over the rubber gasket, which is included in the standard configuration of the pump.

- The body of the device is connected to the sink drain using polypropylene pipes.

- Using plastic pipes, a connection is formed between the outlet of the central sewer system and the pump housing.

- Connecting the device to the power supply.

Sewage pump in the bathroom

Note! It is not allowed to combine several pumps into one network.

Installation of a pressure pump is also possible in other places. For this, open areas of the room, niches or cabinets located under the sink can be used. In this case, you can choose an inclined or vertical position for placing the pipes, because the liquid will move by gravity.

No. 5. Polyethylene sewer pipes

Polyethylene pipes are rarely used in the construction of internal sewage systems. Typically, either low-density polyethylene or cross-linked polyethylene . The first option can withstand a maximum of +400C, so it makes sense to use it only in places with cold drains. Cross-linked polyethylene is designed to operate at temperatures of 0...+950C; for a short time it can withstand temperatures from -50 to +1200C, so it is usually used. The material has the following advantages :

- high strength, wear resistance and flexibility;

- corrosion resistance;

- smoothness of the walls and almost complete resistance to the formation of growths;

- light weight;

- resistance to pressure changes;

- durability;

- flexibility and easy installation;

- relative availability in terms of price.

Minuses:

- fear of ultraviolet rays;

- Oxygen can pass through the material, which will damage the metal elements in the system. The manufacturer applies a special coating, but it is quite delicate, so during installation you must be extremely careful so as not to damage it;

- low abrasion resistance.

Rules for installing the drain hose

Make sure you raise the hose (or pipe) to the correct height. According to the diagram, it should not be located too low or too high: the laws of physics apply here too. Use each channel feature optimally, the goal is to extend the service life of the machine.

Check that all connections are made efficiently and the pipe hangers are securely fastened.

If the hose does not go down its entire length, then it cannot be extended to more than 2 meters. This extension will place a high load on the pump.

After installation is complete, perform a test wash. Make sure that water is not leaking anywhere - as soon as the drain is drained for the first time.

No. 6. Copper and steel sewer pipes

Copper and steel pipes can be called ideal in terms of durability , strength and corrosion resistance. They can withstand any temperature and pressure, are characterized by minimal thermal expansion, and have a smooth, non-overgrowing inner surface.

The main disadvantage is the high price. In addition, copper pipes require specific installation, which only a professional can handle.

It is justified to use such an extravagant version of sewer pipes when open installation is carried out, and plastic pipes will look ridiculous. Copper pipes are often used when creating a retro interior with a claw-foot bathtub.

Semi-automatic or automatic drain-overflow system: what is it?

Features of an automatic bathtub drain

The standard design of a bathtub drain has a hole closed by a simple plastic grid. The semi-automatic drain and overflow, like the automatic one, is equipped with a chrome grille and plug. The handle, attached to the overflow hole cover, has an attached cable that catches the plug at the other end. In order to open the plug, you do not need to bend over, you just need to turn the handle. Because of the mechanical action, the design is called semi-automatic.

Automatic drain-overflow differs in the presence of a self-opening and closing plug. The inconvenience is that you will have to “dive” into the bathtub if you need to open the hole and drain the water, since the plug operates by pressing and is located at the bottom of the bathtub. Therefore, professional plumbers, when installing a drain in a bathtub and carrying out other work, recommend installing a semi-automatic device.

No. 7. Size and diameter of sewer pipes

Before you start purchasing and installing sewer pipes, it is best to draw up a project where you indicate all the drain points and the type of plumbing equipment. This will help you figure out what diameter and length of pipes are needed. At this stage, it also doesn’t hurt to determine the number of auxiliary parts, which will depend on the number of turns and branches. Take into account the change in pipeline diameter in individual sections.

Depending on the type of plumbing fixture being connected, pipes with different diameters are selected:

- a sewer pipe with a diameter of 25 mm is suitable for a dishwasher and washing machine;

- for bathrooms, showers and kitchen sinks – 40-50 mm;

- for washbasin and bidet – 30-40 mm;

- for pipe routing – 40-50 mm;

- bends from the riser – 65-75 mm;

- the central riser and pipe from the toilet are 100-110 mm.

It is better to add a margin of 10% to the calculated length.

Pos

Popular model: EKODIN 5

up to 5 people

recycling 1 cubic m. per day.

Max. dump 250 l.

Check prices

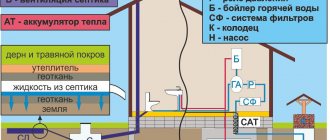

Your own home surrounded by nature, as an ecologically clean area, can be an ideal place to live. But this is only possible with careful preparation of all the necessary elements of comfort, which include sewerage.

You don't notice it when it is installed according to all the rules. But at the slightest violation, it can remind itself of itself with leaks and an unpleasant odor.

The most important task when installing a sewer system is the correct choice of pipes, the properties of which determine the final result of the work. On this specific issue, let us turn to the experience of specialists.

Installation

If you comply with all building codes, this allows you to accurately install the external sewer system, as well as the service life of all parts. It is necessary that the pipeline has the correct slope. This slope allows wastewater to drain naturally. According to SNiP, the slope of the pipeline should be towards the well.

The slope of the pipeline is determined by the diameter of the communication installation and ranges from two to three centimeters per meter of structure.

Important! It is necessary, of course, to produce the diameter of the pipes that will be supplied to serve the house or area. There are diameter standards for sewers that serve different numbers of houses. There are diameter standards for sewers that serve different numbers of houses

There are diameter standards for sewers that serve different numbers of houses.

If wastewater is discharged from several private properties, then the diameter of the pipe must be at least two hundred millimeters. And if wastewater is discharged from one house, then the diameter of the pipes should be one hundred or one hundred and ten millimeters. If pipes are installed between wells, they must be placed level, without any slope. When designing, you need to draw up a plan for the movement of communications, not forgetting to mark the pipeline and nearby buildings on it.

It is also better to place the water collector close to the roadway, but only if you plan to equip a cesspool (it is usually pumped out by a sewer truck). If an external sewer system is installed at bends or at differences in depth, then an inspection well must be constructed. Also, inspection wells are installed in cases where the straight section of the pipeline is more than 25 meters. And such a well is called an intermediate well.

The pipeline along its entire length must consist of pipes of the same material. Because different materials have different thermal expansion and for this reason a pipeline with pipes made of different materials quickly collapses.

So we have described the basic rules for the arrangement of external sewerage. When arranging external sewerage and, indeed, installing all types of sewerage systems, it is recommended to follow these norms and rules. Because if there are deviations during installation, this can subsequently lead to accidents on the routes and equipment failure. And this is very bad.

Fiberglass

Their main advantages:

- Even with their large dimensions, a diameter of over 500 mm and a length of 6 and 12 m, fiberglass products are relatively lightweight.

- The material of this type of pipe is durable and reliable, from an environmental point of view it is impeccably clean, and in terms of chemical aggression it is completely neutral.

- The service life of fiberglass pipes is more than half a century.

These pipes are connected to each other and to other shaped products using double-cone special couplings. On their inner side there are grooves for mounting elastomeric sealing rings - one on each side, and one ring is located in the center. Thanks to this mating, the joint is precisely centered and reliably sealed.

Main nuances when laying pipes:

When preparing a sewer system, it is important to know that the pipeline does not have to be laid deep. The standard option is when it is located above the pipelines of the general drainage system around a building or land plot. Despite the fact that the likelihood of storm drainage pipes defrosting is very small, experts still advise laying them at a depth slightly below the soil freezing level, which is typical for each region. If for some reason such actions cannot be performed, all pipes must be insulated and the thermal insulation layer covered with plastic film to prevent moisture from groundwater from entering it. For the system to function fully, the pipes must be laid at an angle in the appropriate direction. The slope of pipes for rainwater drainage, ensuring the free passage of waste liquid and its regular self-cleaning, should be from one to two centimeters per linear meter of pipeline

If this rule is not followed, the internal cavities of the system will often become clogged. Such unpleasant phenomena occur at pipe joints or corner turns.

Recent data on prices for stormwater pipes have shown that when designing stormwater drains, the best option would be to use a corrugated multilayer stormwater pipe. Compared to similar types, its purchase will provide significant financial savings of up to 30-50%.

If you correctly calculate and correctly install the sewerage pipeline system, then in general the entire stormwater system will function without failures for a long time.

Possible problems

If the SMA leaks (and floods the floor), then, in addition to unreliable connections of the pipes, nozzles and adapter, the reason lies in the fact that a leak may have occurred in the tank of the machine itself. This often happens when the SMA has not been used for several years. Disassemble the car and follow the trail left by the water to find the place where the tank is broken. The device tank will need to be replaced.

The drain or fill valve of the MCA is damaged, its fittings are faulty. Check their correct operation, whether they work at all. Both valves may not open, for example, due to damage to the return springs, membranes (or dampers), burnt out coils of electromagnets that attract armatures with dampers. The user can diagnose and replace the valves independently. The valves are replaced entirely - they are non-separable. Faulty coils are “ringed” for integrity with a multimeter.

There is no draining. Check

- whether foreign objects (coins, buttons, balls, etc.) have entered the drain pipe;

- whether the machine has filled with water, whether the washing process has started, whether the machine is ready to drain the waste water;

- whether unreliable connections have been disconnected;

- Is the water valve open, which shuts off the water supply in case of an emergency?

If the tank level gauge (level sensor) malfunctions, the machine can fill the compartment full, exceeding the maximum tank mark, and wash clothes completely submerged in water. When draining such an amount of water, a strong pressure is formed that can quickly overfill a small sink due to the insufficient capacity of the siphon.

If the cause is found (by elimination) and eliminated, the waste water outlet is unblocked, then the drain line will operate normally, without leaking or slowing down the washing cycle of the SMA itself.

See below for connecting the washing machine drain to the washbasin siphon.

Types of water seals

A hydraulic seal is an effective means of combating odor. Different types of plumbing require their own specific device, so they come in different types:

- knee;

- bottle;

- double-turn;

- corrugated;

- water seal with overflow;

- dry.

Operating principle of the knee water seal

Thanks to its U-shape, this option is durable and can withstand pressure well. Made from plastic materials. Sometimes it is possible to adjust the height of the water by moving the tubes and fixing them at a certain level.

Features of the bottle siphon

The cost of such models is higher than the previous version.

Such siphons for sewerage have a number of features:

- Compact dimensions help to perform installation with any type of plumbing fixtures.

- The simplicity of the design makes it easy to clean.

- Valuable items that fall into the drain will remain at the bottom of such a device.

- Possibility of replacing various design parts.

Double-turn sewer water seal device

It is also called trumpet. In design it resembles a knee, but is more complex. It has a grille that prevents large food debris from getting into the pipes. Removable elbow helps collect debris to avoid drain clogs

. Can be made of plastic or chromed metal. This design of a water seal for sewerage has a number of advantages: a small number of connections guarantees the absence of leaks, and its small overall dimensions allow it to be installed in hard-to-reach places.

Advantages and disadvantages of a corrugated water seal

Use this option to organize a drain in the bathroom or under the washbasin. The advantage of the design is the ability to bend at a certain angle with rotation in any direction. This is convenient for non-standard system designs. Among the disadvantages, it should be noted that food or debris settles on the folds of the corrugation, which leads to clogging. But the blockage can be easily removed by removing the corrugation and washing it with soapy water.

The advantage of such models is their ease of assembly and installation.

Description of the water seal with overflow

The most common use of such devices is found in bathrooms. The water seal ensures the drainage of excess water when the bathtub overflows, which helps protect the room from flooding. Using a special tube, the upper drain hole is connected to the siphon.

What is a dry water seal for sewerage?

This option is acceptable if the drain is rarely used, which is observed in bathhouses, summer kitchens, and so on. When plumbing fixtures are rarely used, the water in the valve evaporates and it remains dry.

You can find installation options both separately and with other types of shutters.

Dry siphons are:

- Float The float remains on the surface of the water until the liquid has completely evaporated, after which it lowers and closes the passage.

- Pendulum. When attracted, the built-in pendulum closes the drain.

- Membrane. Under the weight of water, the shutter opens, after which the spring takes its original position.

For a summer house or other unheated premises, a toilet without a water seal is used, which has a vertical direct drain.

Main stages of work

Installation work is carried out in stages. Sometimes the order of events changes - much depends on the readiness of the premises and the specific layout.

But you still need to strive for the generally accepted order:

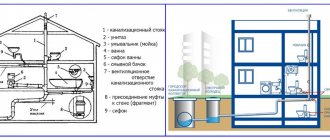

- Laying the outlet - a pipe connecting the internal and external systems. It passes through the wall, so it must be placed in a sleeve - a heat-insulated safety casing. There should be no connections or joints in the wall crossing area.

- Installation of a riser - a vertical pipe running through all floors and ceilings. Usually, 1 riser is installed, but if the length of the internal pipeline exceeds 10 m, then it is better to install a second one.

- Layout of pipes - bends leading to plumbing equipment. The diameter of the pipe leading from the toilet is the largest - 100-110 mm, the rest are 50 mm each.

And only after the installation of sewer pipes, the devices are connected, followed by testing of the system.

Recommendations for performing installation work:

Metal pipes and fittings have not been used for a long time. Cast iron was replaced by lightweight and practical polymers: PVC (gray), PP (light gray or white).

Plastic pipes have a perfectly smooth inner surface, excellent resistance to heat and aggressive substances. They are easy to handle and install due to their low weight.