CJSC "Expertise of Communal Networks" conducts tele-inspection of water and sewer pipes (sewer diagnostics), gas pipelines, stormwater, drainage, drainage systems, heating networks, cable lines and communications (for example, telephone sewerage), and other pipeline communications in all regions of the Russian Federation.

There is a diagnostic laboratory for teleinspection of sewerage and other pipes on the basis of a van, including specialized robots, pushed devices and professional endoscopes, a floating module in the form of a raft (for main sewers with intense flow), the necessary equipment and additional equipment.

We carry out tele-inspection and diagnostics of pipelines, as well as main collectors of storm and domestic sewers of any diameter, clogging and filling, search for lost and buried wells (under ground, asphalt), identify damage and defects of pipes, determine the routing of pipelines and sewerage networks (clarification of location on the ground) using tele-inspection and sounding methods:

- Pipeline diameters range from 3 cm to 2 m.

- The lengths of “spans” (the length of the survey between entry points into the pipeline) can reach 200 m or more.

- Teleinspection is carried out at different pipe fillings and sediment levels, both with a temporary stop in flow and during normal operation of the network.

Television diagnostics of pipes (television of pipes) with a video camera allows you to accurately determine the location of damage, cracks, displacement of joints, corrosion zones and other defects, and assess the technical condition of the pipeline. During the inspection, potentially emergency areas, violations, deficiencies, and causes of possible blockages are identified. Also, television inspection is necessary to search for lost wells underground (soil, asphalt) when tracing sewers and other communications.

Prices for teleinspection services for pipes and sewers

Television inspection of pipes and sewerage - from 100 rubles/m

Find out prices in more detail

Carrying out a television inspection of the sewer system in case of frequent blockages, its long service life, accidents or a high degree of wear. Based on the results of video diagnostics of pipes, technical conclusions and recommendations are issued that allow the most effective planning of measures for the repair and reconstruction of networks, making decisions on the feasibility of relaying pipelines, sanitizing and selecting the most emergency sections of pipes.

Cost of services

1. Tele-inspection, video diagnostics, tele-diagnostics of pipes, sewerage and storm water pipelines, video camera inspection - from 120 rubles/m

2. Search for water and heat leaks in pipelines, underground - from 100 rubles/m

3. Expertise, diagnostics and inspection of the technical condition of heating systems, heating networks, water supply and sewerage systems, assessment of the level of wear and the possibility of further operation - from 150 rubles/m

4. Search for lost (buried, paved) sewerage and water supply wells - from 150 rubles/m

5. Search for engineering systems, communications, cables and pipelines underground, tracing of water supply pipes, heating networks, sewerage - from 120 rubles/m

6. Inspection of water supply, engineering and plumbing knowledge systems (heating, water supply, sewerage, drainage) - from 150 rub./m

7. Measuring water and wastewater flow in pressure and gravity pipelines, canals, wells - from 20,000 rubles.

Video diagnostics and monitoring of pipeline transport in water supply and wastewater systems

Rice.

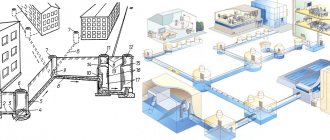

Fig. 1. Self-propelled robot cart with a video camera for telediagnostics of pipelines Fig. 2 Pushed teleinspection system Today, telediagnostic systems are used by many enterprises that own engineering infrastructure, including Russian Railways, city engineering protection services and even airports.

Of course, there was and remains one more “eternal” problem: as usual, there is no money. But times are changing, and water utilities, water supply shops and engineering protection services are more willing to purchase video diagnostic systems for pipelines and sewerage . The advisability of using such equipment is also indicated by tragedies with human casualties, such as what happened in Bryansk in January 2012, when in the center of the city a mother with a stroller, in which there was a one-and-a-half-year-old baby, fell into a sewer. After the death of the baby, money was immediately found in the local budget to resolve many issues, and - after the prosecutor’s orders - a wave of purchases of telediagnostic systems .

The Bryansk tragedy unexpectedly acutely highlighted and showed a very close connection between such seemingly very distant things as the safety and preservation of people’s lives and the diagnostics and monitoring of the condition of equipment, in this case, the condition of the sewer collector.

As practice shows, the issue of money is just a matter of priorities and organization of the facility management system, including such dangerous ones as pipeline systems.

Meanwhile, water supply and sewerage systems are types of pipeline transport, similar to oil pipelines, gas pipelines, and product pipelines, which require regular condition monitoring. And work in this direction is underway. Thus, it is known that MGUP Mosvodokanal creates automated systems for detecting damage (ruptures) in pressure pipelines using flow, pressure and noise sensors (according to the enterprise).

Thus, the use of diagnostic and monitoring systems for engineering infrastructure, including television diagnostics of pipelines and monitoring of pipeline networks, puts the control subject - the water utility - and the control object - the pipe in their place.

Typical tasks solved by pipeline telediagnostics systems

As a rule, video diagnostics ( television inspection ) is carried out on utility pipelines, including main water pipes and drains, which include storm or rainwater drainage, and is a planned event with a set frequency.

Problems solved during the inspection of water supply, sewerage and drainage (rain sewer) networks.

1. Determination of locations of damage, cracks, displacement of joints and other defects to prevent failures on roads and in residential areas, including the prevention of accidents; pollution of streets with sewage and forced interruption of water supply.

2. Identification of pipeline sections where urgent repairs are required and making an informed decision on the repair method. It also allows planning and budgeting of repair activities in conditions of limited funding, and not just reacting to a failure or breakthrough.

3. Detection of unauthorized taps and connections.

4. Identification of emerging blockages and determination of the cause of possible blockages, including those that may cause displacement of joints, destruction of pipes, etc. Sometimes the cause of blockages and poor water flow in gravity systems is the presence of a counter-slope. Modern models of telediagnostic systems include high-precision inclinometers that allow determining the slope angle with an accuracy of ±0.1°.

5. Determination of diameters, material, and slope of the pipelines being examined. There are often situations when these parameters are not reflected in the existing documentation for the pipeline.

6. Determination of the location of paved and lost wells.

7. Issuance of a technical report on the condition of networks and a video report. television inspection process is recorded on a video recorder and documented. As a rule, modern television inspection systems allow you to enter comments directly on the image during the process itself using a special keyboard.

In addition, telediagnostics of pipelines can solve the following tasks:

1) control during the construction of water supply, sewerage and drainage networks. Makes it possible to see the quality of joints, displacements, imperfections and deficiencies, places where construction waste accumulates, and eliminate them before acceptance;

2) acceptance of water supply, sewerage and drainage networks after construction. As in the previous paragraph, this makes it possible to evaluate the quality of the construction work carried out, mark places with garbage and possible obstacles to the free flow of the stream, in order to require the builders to eliminate deficiencies and accept a truly high-quality object. This practice exists in Mosvodokanal and water utilities in other cities, where mandatory acceptance of networks after construction is carried out with the help of television inspection, and its economic feasibility is established and verified;

3) inspection of pipelines before trenchless renovation. When using trenchless pipeline renovation methods, including the method of pulling a polymer liner followed by ultraviolet curing, pulling polyethylene pipes inside an old pipeline, cement-sand lining of an old pipe, etc., it is necessary to conduct an inspection before starting work to identify all elements that may interfere carrying out such work. Obstacles to trenchless renovation can be pieces of reinforcement protruding from pipes, bends, flashes or fistulas through which water infiltrates. Then, with the help of milling and repair robots, the obstructing elements are eliminated: the burrs are cut off, the fistulas are sealed using bandages;

4) inspection of pipelines during flushing. Some areas of the collectors cannot be cleaned, and blockages form in them again. Only telediagnostics allows you to establish the cause of such a situation and take measures to eliminate it.

Videos on teleinspection of pipes and sewerage

Teleinspection of storm sewer pipes

The BK3M robotic complex based on the P100 robot is used

Teleinspection of sewer pipes

Teleinspection of the sewer collector

The robotic complex CM2-DR is used based on the floating module W100

Teleinspection of industrial sewerage pipes

Uses push system CMO/TV5-50LC-1V/BK4-150/VM11-100

Teleinspection of the domestic sewerage collector

The W100 floating module of the CM2-DR robotic complex is used

Our advantages

Experience and reliability

has been providing engineering services for inspection, diagnostics and examination of pipeline networks for 15 years. We employ only highly qualified water supply and water supply engineers. During this time, hundreds of successfully completed works in different regions of the country, grateful reviews from clients were received, and strong partnerships were built with many design and survey institutions, construction companies, and equipment suppliers.

Powerful instrument base

The company has dozens of pieces of equipment owned by the enterprise. We have the opportunity to perform work using several technologies and different types of instruments at once, and, by comparing the results, achieve the most reliable data, minimizing the likelihood of error. Often people come to us after bad experiences with other companies, and we find a solution to the problem.

Flexibility and mobility, following the client

In urgent and emergency cases, we are ready to go to the customer immediately and without prepayment. We take on complex and non-standard cases. Taking into account the requirements and wishes of clients, we are always focused on long-term cooperation.

Quality of services and responsibility

The company is accredited as a forensic institution; our reports and expert opinions are accepted by government and judicial authorities. Survey results and conclusions are always as substantiated as possible, and the equipment is certified and properly verified. We value our reputation.

Independence and confidentiality

We are professionals and respect our work and our clients. We carry out all work conscientiously and on time. The independence of the enterprise guarantees the objectivity of expert examinations and the maintenance of complete confidentiality. We have an individual approach to each client, since each case in our work is unique in its own way.

Teleinspection of pipes and channels: operating principle of the equipment

The system makes it possible to use a video camera to observe the processes that occur inside pipelines. The main piece of equipment is a video camera for transmitting images. Tele-inspection of pipelines makes it possible to perform a detailed inspection of all pipes without the need to dismantle them. The camera moves through the pipe on a self-propelled robot, raft or using a cable. To increase diagnostic information, the light source is moved along with the camera.

To perform tele-inspection of pipelines, equipment is selected depending on the diameter, configuration and filling of pipes. A television inspection of the sewer system is carried out before the start of repair work to determine its location and volume. After removing the blockage, diagnostics makes it possible to determine the quality and effectiveness of the work performed. To reduce the risk of emergency situations, telediagnosis is carried out regularly.

They often carry out diagnostics of new pipelines or sections after major repairs in the presence of the customer to confirm the quality of the work performed. Also, such an examination allows you to identify unauthorized insertion.

Diagnostic methods

During the operation of water supply and sewerage systems, sometimes emergency situations occur that are not so easy to understand - they are hidden inside the pipes. Currently, in such cases, video diagnostics are performed.

Video diagnostic methods:

- Magneto-optical flaw detection. Thanks to the magnetic flux in ferromagnetic materials, it helps to find defects. However, the depth of the defect and the cause of the malfunction cannot be determined in this way.

- Ultrasonic inspection of connections. It is carried out by examining the walls of the riser with a magnetic flux and ultrasound scanning. Calculate visible faults using magnetic flux.

- Crimping. It is produced under high pressure and is a test (hydraulic) of the sewer network for functionality. In this case, the pressure is measured and a pressure gauge is used.

In difficult situations, a check is required when the location of the blockage is unclear. It is possible to accurately determine this and take urgent measures to eliminate it.

The use of video sewer inspection allows you to quickly identify problems and determine the causes of their occurrence. By periodically checking your networks, you will be able to respond to violations in a timely manner.

Equipment for teleinspection of pipelines and sewerage

The laboratory includes various types of equipment for any conditions during work, depending on the diameter, degree of clogging, and filling level of pipes:

- Tele-inspection complexes (pushing systems) SMO\TV5-50LC-1V\ВК4-150\VM11-100 and endoscope video cameras are designed for tele-inspection of pipes with an internal diameter from 30 mm to 600 mm using pushing. There are special nozzles for different pipe sizes. The length of the surveyed area (length of the cable rod) reaches 100 m.

- The self-propelled robot P100/BK3M is designed for telescopic inspection of various pipeline communications with an internal diameter from 300 mm to 2000 mm using a transport module equipped with bright lights. The length of the surveyed area (cable length) reaches 200 m.

- The floating module of the robotic teleinspection kit CM2-DR/W100 (based on a floating raft), designed for large-diameter sewer collectors (from 500 mm to 2000 mm) with water flow, is equipped with powerful lighting.

Video diagnostic capabilities

A specialized video diagnostic system reveals a whole range of possibilities, in particular:

- without resorting to dismantling the sewer riser. its condition is assessed and the absence of vertical or horizontal displacements, the level of quality of connections and the integrity of the sewer pipe are checked;

- you can find out not only the location of blockages, but also their causes inside the system, check whether there are foreign objects in it;

- a complete picture is created, on the basis of which it is decided where to repair the sewer and change the section of the riser.

Video diagnostics also allows you to:

- install utility resources;

- conduct research on pipes, shafts, channels and ventilation bases;

- inspect new sewerage systems, monitoring their quality;

- find out the location of the riser wiring.

Using video diagnostics, it is easy to eliminate the consequences of an accident in the sewer network. The overall condition of the pipes is also simultaneously monitored and any faults are removed. To carry out this type of diagnosis, you do not need large, special equipment or many specialists.

The inspection is carried out in just forty to sixty minutes.

Video diagnostic methods

Currently, video diagnostics of sewerage systems is carried out using three methods:

- The camera manually inspects hard-to-reach places. Based on the information received, a report is generated with photographs, as well as videos created in the pipeline system. Recording is done automatically. The system consists of a comfortable handle - a pistol, as well as a screen and camera head. To get a better look at the system, it is possible to rotate the camera ninety degrees clockwise. In addition to the video camera, the device also has a microphone and headphones.

- Another method is pushing. Thanks to it, you can check pipes with small and medium diameters (pipes from 25 mm). In this case, a special remote control consisting of two joysticks is used to rotate the device.

- The third method, consisting of a robotic complex, is intended for pipes with a diameter of 150 mm. In this case, a robot is used that has a self-propelled platform, controlled via a remote control by the operator. It is equipped with LED lamps and has an independent power source. This ensures reliable operation, even in the presence of aggressive chemical environments. The cable is five hundred meters long. The robot is completely sealed, waterproof, and continuously displays an image of the pipeline from the sewerage system in color.

Recommended reading: How to soundproof sewer pipes in an apartment?

Diagnostic methods

Diagnostics can be applied in the following ways:

- Magneto-optical flaw detection helps to find defects in ferromagnetic material due to the magnetic flux. However, the cause of the malfunction and the depth of the defect cannot be determined in this way.

- Ultrasonic inspection of connections is carried out through ultrasound scanning and magnetic flux examination of the walls of the riser. Visible faults are calculated using magnetic flux.

- Pressure testing under high pressure is a kind of hydraulic test to determine the functionality of the sewerage network. In this case, a pressure gauge is used and the pressure is measured. When the limit guaranteed by complete air outlet is reached, the network is inspected for blockages or leaks. A drop in pressure on the pressure gauge indicates leakage. Then you need to decide how to seal the leak in the sewer pipe.

Feedback from V. A. Erin - head of the department of the mayor's office of the Tolyatti city district

The activities of JSC "Ekspetiza Utility Networks" in tele-inspection of rainwater drainage networks in the Central District of the Togliatti city district are assessed as positive. There are no complaints about the quality of the work performed.

The work was carried out in accordance with regulatory and technical requirements and safety regulations, using advanced technical means.

All contractual deadlines for completing the work were met.

During its activity, the organization has established itself as a reliable partner with competent specialists. The results are of practical value for the urban services department and will be used in our work on the repair and maintenance of storm drainage networks.

02.02.2011

Chimney inspection. Ventilation check

Checking the chimney and ventilation systems to identify defects and contamination.

Ventilation contamination can be of different types. Dust and dirt settle in the supply system, grease can accumulate in the exhaust system, fireplace chimneys gradually become clogged with soot, chimneys of stoves and barbecues accumulate a mixture of fat and soot.

Teleinspection helps to quickly and accurately examine chimneys and air ducts. A miniature video camera is able to quickly assess and capture the internal condition of the air duct and the type of contamination, and after cleaning work, a television inspection allows you to evaluate the quality of cleaning. It is only necessary to record the study and provide it to the Customer.

Checking chimneys and ventilation systems is necessary for:

• determining whether the ventilation or chimney is contaminated with dirt, dust, grease or soot; • assessing the quality of ventilation cleaning; • detection of damage, blockage or foreign objects in the air duct; • clarification of the position and nature of the defect; • assessing the technical condition of the entire ventilation duct before starting to repair or replace the damaged area.

Feedback from the director of MUP "Vodokanal" Klimovsk (A.N. Detkovsky)

CJSC "Expertise of Utility Networks" has been working with us for about a year, helping to localize damage to the water supply system, trace networks, conduct television inspections of pipelines, and flush out sewers. At first, we cooperated mainly in emergency situations, but now we carry out most activities as planned.

I would like to note the high quality of the work performed, efficiency and effectiveness. If any unforeseen situation happens in our network economy, I know who to turn to!

29.12.2008