A significant number of country houses and dachas are deprived of access to a centralized sewer system, and their owners have to independently solve the problem of removing and disposing of wastewater and organic waste. The only way out of this situation is an autonomous sewer system, the choice of design of which falls entirely on the shoulders of the owners.

It is worth noting that the task of getting rid of sewage waste is one of the main ones, along with water supply and heating, when solving life support issues in individual houses. Therefore, its solution must be approached as responsibly as possible, armed with a solid store of knowledge. Any owner who independently deals with the problem of waste disposal should know how an autonomous sewage system works, study the principles and various options for its construction, the main engineering structures and their distinctive features, advantages and disadvantages.

Rice. 1 Sewer system of a private house

What is an autonomous sewage system and its purpose?

Autonomous sewerage is a system of engineering structures for wastewater treatment using mechanical and biological methods with the disposal of most of the wastewater within the boundaries of the site or in the surrounding area. In this case, waste that cannot be processed or filtered is disposed of and transported off private territory using special equipment.

An autonomous sewage system for a home must solve the following problems:

- Drain gray water and sewage from restrooms away from the home.

- Collect wastewater in any volume (reservoirs, pits, wells).

- Ensure safe accumulation of sewage for people: odors should not penetrate into the home, and contaminated wastewater should not enter underground water sources.

- Dispose of sewage waste in whole or in part on a private plot of land, as well as using special equipment.

- Ensure environmental cleanliness when disposing of wastewater on private property.

Rice. 2 Sewage system with septic tanks made from concrete wells

Installation features

Installation is possible in early autumn, and even at the beginning of winter, but the optimal time for installation is summer.

When installing, please consider:

- Soil type.

- Groundwater level.

- The distance of the entire sewerage system, according to sanitary standards, from the house and other outbuildings.

In addition to digging a pit and a ditch for discharge pipes, as well as installing the septic tank itself, a number of other works must be performed. This includes sealing a hole in the wall of a house or foundation, connecting the entire system to electricity, installing ventilation pipes, insulating the septic tank and pipes, backfilling the septic tank itself with a cement-sand mixture, and bringing the site to almost its original condition after all construction work.

It is also necessary to install sewerage in the house itself, and it is best to have a specialist handle the installation of all the pipes there.

When installing a sewer system, you must follow safety rules.

Sometimes the pipe layout in a house can be quite complex. They must be carefully connected to each other and firmly secured using special clamps and hooks. The toilet in the house must be installed as close as possible to the common riser.

The principle of operation of the autonomous sewage system of a private house and its main components

To understand what an autonomous sewage system means, it is worth considering its main components and the functions they perform. In modern country houses, individual sewer systems include the following components:

Pipeline. Wastewater from kitchen sinks, showers and bathtubs, as well as sanitary fixtures, is sent through gray polyvinyl chloride (PVC) or polypropylene (PP) pipes for internal sewerage to a central riser with a diameter of 110 mm. At the highest point of the sewer system in a private house, a drain pipe is installed, connecting the riser pipe to the ventilation system on the roof.

At the bottom point of the vertical riser, an elbow is mounted to transfer to the horizontal section of the external pipeline made of unplasticized polyvinyl chloride (UPVC) with a diameter of 110 mm, red in color.

An external pipeline with a slope of 20 mm per linear meter is laid underground and directed to a wastewater collection tank.

Storage or treatment tanks. In the simplest form of sewerage, wastewater is collected in storage polymer (concrete) containers and, after filling, is pumped out using a sewer truck.

In some cases, most often in summer cottages and houses in rural areas, sewage waste and gray water from household activities - washing dishes, laundry - are separated. The owners of such houses install a separate outdoor toilet, and contaminated water after use in the household is sent to cesspools.

Rice. 3 Sewerage with septic tank and filtration field with installation dimensions

Related article:

How to install sewerage inside a private house. It may be interesting to read a separate article specifically dedicated to the installation of internal sewer systems, the nuances of laying pipes and connecting engineering equipment!

Almost all autonomous sewer systems of cottage-type country houses are built in such a way that human waste (black water) and gray waste are mixed and sent to septic tanks. There, a gradual separation of solid fractions from liquid occurs as a result of settling and partial decomposition of waste.

The settled, cleaner liquid is sent for further filtration, and the gradually accumulated sludge that has settled to the bottom is pumped out using a sewer truck and disposed of.

If financial resources allow, instead of septic tanks, owners can install deep biological treatment stations (HBT). The stations, through the use of electricity and automation of cleaning, as well as the use of aerobic bacteria, make it possible to obtain 97-99% purified water at the output, which is then simply drained into the ground or used for domestic needs.

Solid sewage waste in a biotreatment plant is converted into harmless sludge with a high content of microelements, which is a good fertilizer for plants. It is used in the garden or disposed of.

Filtration facilities. The degree of wastewater purification after settling in septic tanks does not exceed 70%, so the water needs further purification before being sent deep into the ground. For these purposes, drainage wells or filtration fields are installed. Fine crushed stone and sand are used as filter layers. Passing through them, the wastewater is further purified and does not harm the environment when supplied to the ground.

To ensure a constantly high level of water purification, contaminated crushed stone and sand from wells and filtration fields are regularly changed every 3 to 5 years.

Rice. 4 Types of concrete rings for constructing cesspools

Comparison of VOCs and a homemade septic tank

Getting a septic tank is relatively easy; you can simply buy it. Modern VOCs - local treatment stations - are high-performance devices, reliable and easy to maintain.

This can be a relatively compact unit, internally divided into compartments with overflows. Processing of wastewater in such units is carried out by settling without the participation of technical devices.

If the units belong to high biological treatment systems, they are equipped with pumps and aeration systems to supply oxygen. This option depends on the energy supply.

Local biological wastewater treatment plants are high-tech complexes that are quite expensive and usually require access to electricity

As a rule, biorefinery stations are already insulated and equipped with a reliable sealed lid. VOCs that produce a high degree of purification are equipped with compressors that pump air into the device and actively aerate the wastewater.

This allows the use of both aerobic and anaerobic bacteria in the wastewater treatment process, decomposing more than 95% of all wastewater.

But all such devices have significant drawbacks - high price and dependence on the availability of electricity necessary for the operation of technical equipment.

Options for overflow septic tanks of industrial production, in which no compressors are provided, are quite inexpensive and are quite suitable in price and durability for arranging a summer cottage.

But such models, in fact, are a modernized version of a cesspool. The degree of purification here reaches only about 60 - 70%, the water is suitable only for technical use after ground purification in an absorption well or filtration field.

More detailed information about the existing types of septic tanks, the principle of their operation and recommendations for choosing the appropriate option for your needs is provided here.

Image gallery

Photo from

Sewage station for deep cleaning

Use regardless of geological conditions

Expensive technical components of the installation

A way to reduce energy costs

All this encourages owners of private houses to independently build a septic tank, which does not require constant removal of wastewater. This is not to say that this is a simple and easy job, but if the master has experience, for example, in building his own well, then he will be quite capable of creating a homemade septic tank.

In terms of money, it will definitely be cheaper than purchasing VOCs. And the result will be much better than using a conventional cesspool.

To make a septic tank, you need to choose a location, dig one or more pits, build sealed containers in them connected by overflows, make a filtration well, etc. No super complex equipment or special construction skills are needed.

Cesspools

If you are installing an autonomous sewer system with your own hands, one of the simplest and most cost-effective ways to dispose of wastewater is to dig a cesspool.

The structure is a container for collecting gray wastewater located underground, while the toilet is installed outside on the site in any convenient and environmentally safe place. Theoretically, a cesspool can be an ordinary hole with a top lid, dug in the ground, however, due to the erosion of the walls by water, it is not very rational to use this option.

Usually the pit is made with walls made of concrete rings or other materials, large-volume polymer tanks. Special concrete rings with slots in the side walls for drainage are excellent for constructing cesspools.

A pipeline is connected from the house to a hole underground, through which wastewater flows. Liquid is absorbed into the soil through the bottom and side walls in some structures. The volume of the pits is selected based on the amount of wastewater of about 0.5 cubic meters per person per day.

An autonomous sewer system for a summer house or cottage with a cesspool must meet the following distance standards:

- be located no less than 5 m from the house;

- the distance to water intake sources of drinking water should be at least: 20 m for clay soil, 30 m for loam, 50 m for sandy loam;

- the bottom of the pit must be at least 1 meter from the groundwater surface.

Pipe laying - selection of material and dimensions

This stage is the most important. The future quality of the system will depend on it.

The laying technology is designed for plastic pipes. But no matter what material is used, blockages and plugs will still form.

Pipe size and laying rules

The movement of waste occurs by gravity. Therefore there must be a bias. You need to think about it during design, so that this question arises during installation. This parameter is observed for both internal and external sewerage.

Basic Rules:

- For washbasins, pipes with a diameter of 32 - 40 mm are suitable;

- If you are choosing pipes for sinks and bathrooms, those with a diameter of 50 mm or more are suitable;

- If several devices are connected to one node at once, pipes with an internal cross-section of 70-85 mm are needed;

- If there are turns, their angles should be as small as possible, otherwise blockages will form;

- If pipes are laid in a cold room, then they need to be insulated.

Do-it-yourself pipe connection

To connect plumbing fixtures, conventional connections are used. The drain pipe is included in the sewer riser. The toilet is connected using a wide pipe.

Of course, it will be better if you use detachable type elements. This is explained by the fact that if some area needs to be repaired, it can be easily removed and put back in place.

When connecting plumbing to the riser, it is necessary to maintain the maximum distance between these elements:

- The toilet should be installed no further than one meter from the riser;

- Other devices may be located no more than 3 meters from the riser.

Storage containers

Typically, large-volume polymer containers are used to collect sewage, which are buried underground. A sewer pipeline is connected to them from the house at a slope, through which contaminated liquid is transported.

You can also make a storage tank for a private home yourself from concrete well rings with a lock, placing them on a round slab and covering with a top lid with a hatch. As a result, a sealed concrete well will be obtained, part of the wastewater from which will go into the ground through moisture-absorbing concrete walls.

The storage container is periodically emptied as it is filled, calling a sewer truck for this purpose.

It is rational to use waste collection tanks in summer cottages with periodic presence of people. In this case, the tank will not have to be emptied so often, which is compatible in terms of costs with the installation of more complex and expensive treatment facilities.

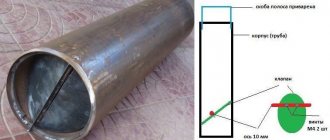

How are overflows installed?

According to SNiP 2.04.03–85, in the Moscow region the pipeline tray can be laid at a minimum depth of 1.1-1.2 m. The pipe supplying wastewater to the filter well is located 10 cm above the bottom, and its open end is placed in center of the well.

The overflow pipe should run with a slight slope - only 2 cm per linear meter. This reduces the risk of large solids getting stuck in the pipe. The inlet pipe should have a diameter of 10 cm and be located 5 cm above the outlet pipe. Floating substances in the inlet and outlet pipes can be retained using vertical pipes whose open ends are immersed in water.

In a multi-chamber treatment plant, it is also necessary to provide a ventilation system and leave holes for the ventilation pipe between the sections.

Local treatment facilities

In contrast to the previously reviewed methods for disposing of semi-liquid waste, any autonomous sewage system for a country house is designed for their processing and partial cleaning directly on an individual site.

The wastewater is divided into fractions and purified using various methods, while most or almost all of the waste is disposed of in the deep layers of the soil and in external ditches.

Rice. 6 Operating principle of three-chamber septic tanks

Related article:

Sewerage in the country - options, design diagrams and installation. If you need to install a sewer system in your dacha, then in a separate article read about all the possible expensive and cheap options for arranging a sewer system in your dacha. Nuances, types, schemes.

Septic tanks

Septic tanks are engineering structures for mechanical wastewater treatment.

Their operating principle is to settle all wastewater in a number of interconnected containers. In this case, the liquid from the first reservoir, as it accumulates and settles, rises and enters the next container from the purer surface layers. There it further settles, and when the tank is filled, clean water masses flow through a pipeline to the next water treatment plant.

Septic tanks typically contain two or three septic tanks.

When solving the problem of how to choose a septic tank, it is assumed that their volume should allow the wastewater to settle without overfilling the tank for 3 days. In this case, the daily output of wastewater from one person is taken to be 150 liters.

In septic tanks, oxygen-free fermentation of waste occurs with the formation of explosive gases, so they must be equipped with a ventilation pipeline.

The most popular designs of septic tanks are special factory-made polymer tanks with partitions or self-installed closed concrete wells from two or three interconnected containers.

Septic tanks for physical cleaning have the following features:

- Types of autonomous sewage systems with septic tanks are capable of purifying black water by 70% with three chambers and 60% in two-chamber structures. Therefore, wastewater requires further treatment before being sent to the ground.

- Odors from the tank can spoil the air in the house, so they try to locate them as far as possible from the home.

- The sediment accumulated at the bottom must be periodically removed using sewer trucks (once every six months or a year) - this leads to additional financial costs.

- Sedimentation tanks do not require electricity to operate—this distinguishes septic tanks from other treatment facilities.

Rice. 7 Design of a septic tank with a biofilter

Septic tanks with biological treatment

Introducing bacteria into treatment systems can significantly increase the degree of water purification. Since there is no oxygen in the water layers of septic tanks due to stagnant water, they effectively use anaerobic bacteria that can multiply in an environment without access to air.

The design of different models of septic tanks-biofilters may differ, but the principle of their operation is the same and consists of the following steps:

- Sewage waste enters the first most voluminous chamber, where it settles. Through holes in the partition or a section of pipe, the purified liquid flows from above into the second tank, where it is further separated.

- From the second chamber, wastewater is directed to the biofilter. Depending on the manufacturer, it has different designs - expanded clay or polymer fillings, synthetic fibers, special closed chambers in which colonies of anaerobic bacteria are placed. Microorganisms are placed and retained on the surface of bulk materials, so that they are not washed out of the biofilter by the water flow.

- Bacteria process organic matter, which is necessary for their life, producing carbon dioxide and water. As a result, the output is wastewater with a purification degree of 90%. Theoretically, they can be used for household purposes.

It is worth noting the main disadvantage of biological treatment, namely the poor performance of bacteria in an environment contaminated with chemicals from laundry and dishwashing. Also, colonies of microorganisms periodically need to be replenished approximately once a month; they cannot reproduce at too low temperatures.

Rice. 8 Polymer septic tank Rostock - design features

Biological stations - what are they?

Unlike anaerobic bacteria, whose life activity occurs in an oxygen-free environment, aerobic microorganisms cannot reproduce without access to oxygen.

They are much more efficient at processing organic waste, which is why they are used in more productive automated installations - deep biological treatment stations (DTP).

Deep biotreatment plants consist of several chambers and differ in design from different manufacturers; almost all of them operate according to the following principle:

- Wastewater from the intra-house sewer system enters the first chamber of the station, which serves as a sump. In it, the liquid settles and the fatty films are removed using special devices. Then the wastewater is sent to the next chamber using airlift technology, lifting it through the tube using air bubbles. In this case, large fractions are separated from the settled liquid using a filter. The air is pumped by a compressor located inside the installation on an isolated area.

- The second chamber, called the aeration tank, houses a colony of aerobic bacteria. To maintain their performance, air is supplied from the bottom or side from the compressor, resulting in continuous aeration of the water masses. After the bacteria work, the aquatic environment is filled with sludge, which is a product of the vital activity of aerobic microorganisms. Also in the liquid medium there is part of the untreated organic matter and bacteria - this entire mixture (activated sludge) freely flows into the next compartment, called the secondary settling tank.

Rice. 9 Operating principle of biorefinery stations

- In the second settling tank, the final separation of the fractions occurs - all suspensions sink to the bottom of the storage tank, and the purified water is sent out. As the settling tank fills with silty sediments during the operation of the installation, they gradually move back into the aeration tank chamber, thus performing a circular circulation.

- During the life of bacteria, active sludge that is not completely processed accumulates in the aeration tank. When a certain volume is filled, the automation is activated and sludge deposits are sent through a hose to the sludge stabilizer chamber using a pump. In it, thanks to the remaining bacteria, a gradual transition of silt deposits into the stabilization phase occurs, after which they become a harmless organic fertilizer. The settled silt masses sink to the bottom, and the surface purified water is drained.

- After settling, the sludge is removed from the stabilizer chamber; it can be used as fertilizer or disposed of as harmless organic matter.

- Also inside the biorefinery installation there is a platform on which compressors are installed that supply liquid from the receiving chamber and the secondary settling tank to the aeration tank.

Filtration systems

Any autonomous sewer system of a private house with septic tanks, in which mechanical purification of black water is carried out using the sedimentation method, requires additional filtration structures. They are needed in order to reduce the degree of contamination of soils or underground water basins when wastewater is sent into the ground.

For this, two main technologies are used - filtration using fields or drainage wells.

It is worth noting that before installing an autonomous sewer system in a private house with filtration structures, a geological survey of the soil should be carried out. If the soil has a clay structure, the surface groundwater level is very high, or water is drawn from well sources, the following problems may arise.

Clay and high groundwater with additional water load will contribute to swamping of the area. And a shallow well source for water intake can be contaminated with wastewater if a significant distance is not maintained between it and the underground filtration system.

Rice. 11 Filtration field - arrangement diagram

Filtration fields

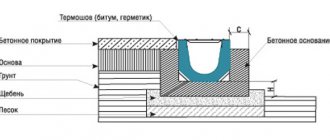

If an autonomous sewage system with filtration fields is being installed, the following technology is used:

- A rectangular pit with a depth of at least 700 mm of a pre-calculated size is dug in the ground.

- Sand is poured onto its bottom, forming a cushion about 100 - 200 mm thick. Crushed stone is poured on top of the sand cushion in a layer of at least 400 mm.

- A pipeline is laid from the septic tank to the pit and branches are made with drainage pipes over the entire area, maintaining a distance between them of 1500 mm.

- Next, the entire site is covered with geotextile fabric, the surface is leveled with a sand cushion with a layer of 100 - 150 mm and sprinkled with fertile soil 100 - 150 mm thick.

In many fields, special polymer boxes called infiltrators are used to increase productivity. When using them, water from the septic tank is directed through a network of pipelines into each of the inverted boxes or a tunnel of several infiltrators.

Thanks to these products, the efficiency of water treatment systems increases due to the fact that the upper layers of soil do not exert pressure on the drainage pipeline, and the liquid is freely absorbed into the crushed stone under the boxes over a much larger area.

Also, with high volumes of discharges, some of the wastewater may be additionally mixed in the free space of the infiltrators without reaching the surface.

Like septic tanks, infiltration fields are equipped with a ventilation system, bringing a section of sewer pipe to the surface.

The disadvantages of filtration fields, in addition to taking up a significant area on the site, which cannot be used for a number of economic purposes, include the fact that the filter crushed stone backfill and sand bed need to be replaced every 3 - 5 years.

Rice. 12 Fields with drainage pipes and infiltrators

Drainage wells

Since infiltration fields occupy a fairly large area, one of the good alternatives is the use of drainage wells.

Most often they are made from concrete rings, digging a hole several meters deep in the ground until a layer of sand is discovered. After installing several well rings with locks and a standard diameter of 1 meter, a layer of crushed stone about 400 mm thick is poured onto the bottom.

A pipeline is brought from the septic tank into the well, using a perforator to punch a circle of the required size in its wall, and cover it with a lid on top, leaving a hole for ventilation.

Rice. 13 Diagram of a conical drainage well

Nuances when laying pipes

Everything will be simple if the pipework has already been done before you. Then you just need to replace the old ones with new ones and that’s it. But this also has its drawbacks: it is no longer possible to change anything. If mistakes were made from the very beginning, it will not be easy to correct them. All that remains is to redo everything. To do this, you will have to raise the floor. It may even be necessary to deepen the outlet pipeline. Or rather, digging a hole under the foundation.

The bottom of the trench must be covered with a layer of sand of 20 centimeters. This will save the structure from high pressure.

All connections must be made efficiently and good fastenings must be used. Use inspections to insure against pipe clogging. Place it every 4-5 meters.