Did you know that a video camera inspection of a sewer system is called a sewer television inspection? So what is it, what types of devices are there, and when does the need for this method arise.

It often happens that blockages constantly occur in the same section of the sewer system. Determining the reason for this persistence is extremely difficult. Usually there is no assumption that may become an obstacle to the free passage of wastewater. It is not always possible to dig a trench and carry out an inspection. The problem area may be under highways, structures or other objects. Visual inspection of pipelines using special equipment, or tele-inspection of sewerage, allows you to get an answer to all questions. Let's take a closer look at this method.

Possibilities of the modern teleinspection method

Teleinspection (video diagnostics) allows you to determine:

• Exact location of the studied engineering systems;

• The presence of any defects or damage (cracks, chips, breaks, deformation, etc.); • Presence of a foreign object inside the object; • The most accurate location of the blockage or damage; • Condition of pipes, wells, ventilation ducts, to identify the need to repair or replace the damaged area. Teleinspection: checking the connection of sewer pipes in an inaccessible area.

An inspection through a tele-inspection helps to check the quality and correctness of connections of sewer pipes, drainage pipes, and pipeline systems, and allows timely detection of any blockages or damage, assessment of the quality of installation of engineering systems and compliance of the actual location of all pipes with the design slope.

Where is television inspection used?

The method is widely used in the diagnosis of pipelines, air vents, wells and boreholes, chimneys, and drainage systems. It can also be used to clean sewers or chimneys and remove accumulated contaminants from ventilation and air vents.

To contents

Video diagnostics of sewerage and drainage systems

Video diagnostics allows you to accurately and quickly check the condition and serviceability of sewerage and drainage.

Video diagnostics allows you to accurately and quickly check the condition and serviceability of sewerage and drainage. Diagnostics of sewer collectors, wells and water supply systems is needed to accurately identify the location of damage or blockage. This is necessary to carry out timely local or major repairs and prevent failure.

With the help of television inspection, it is possible to determine the location of paved and lost wells. The method helps to thoroughly examine the technical condition and detect defects in sewer lines, so it is often used as a preventive control measure.

Teleinspection has important practical significance. Clearing blockages in sewer collectors in a timely manner prevents sewage from spilling into the street. Timely detection of a damaged sewer section allows it to be repaired, preventing overload of treatment facilities caused by storm water entering the sewer network.

Benefits of use

This equipment is used not only for sewage, but for any other pipelines: for ventilation, heating, water supply, heat exchangers and other systems.

There are three advantages of conducting a tele-inspection of sewer pipes: the price of the procedure, the speed of the work and its effectiveness. Of course, today this is the most cost-effective and effective way to detect pipe blockages and ruptures.

We are pleased to offer you to buy high-quality systems for teleinspection of pipes from our company. The presented models for video diagnostics are distinguished by high-quality characteristics and reasonable prices. Place an order with us by calling, and our specialists will help you choose a system specifically for your needs. We work throughout Russia and the CIS; our equipment is already operating in more than 103 cities, including Moscow and Novosibirsk. Please ask our managers any questions, they are always in touch!

VIDEO: TV inspection. Sewer video diagnostics

Television sewer inspection. This video shows how, with the help of a television inspection, the cause of frequent blockages in the sewer system was found, namely a tool (building level) forgotten by workers when installing the sewer system.

After the diagnosis has been carried out, all that remains is to choose the most effective method of cleaning sewer pipes, or decide to repair the damaged area. Timely diagnosis is a guarantee of stable operation of sewerage systems, treatment and drainage communications.

To contents

Why conduct a pipeline inspection? Here are some examples of when you should do this:

- In case of accidents and emergency situations during the operation of pipelines.

- Before commissioning new and restored sections of sewer lines.

- When searching for lost and abandoned wells.

- To obtain information about the length and location of internal and external sewer lines.

- To obtain information about the condition of the inspected areas.

- To make a decision on the possibility of further maintenance and operation of utilities.

- To solve problems that arise during the performance of work by company employees.

- To draw up utility diagrams.

Pipeline diagnostics, inspection of pipes and wells

Teleinspection allows you to quickly find problem areas of pipelines without digging trenches.

Damage or blockage in the pipeline can cause serious problems that require immediate attention. Before the advent of the video diagnostic method, to remove various faults it was necessary to dig long trenches, which took a lot of time and effort.

Today, these labor-intensive works are replaced by convenient and efficient television inspection, which allows you to quickly examine problem areas of pipeline systems to most accurately determine the nature of the destruction and its location.

Teleinspection makes it possible to find and eliminate almost any blockage and eliminate the damage in a timely manner, preventing the occurrence of emergency situations. Diagnostics can be carried out both before the start of work on creating communications in order to identify the presence of “problem areas”, and after their completion.

An important advantage of this system is the ability to conduct research at a depth of up to 10 meters, with a pipeline diameter of 50 - 1200 mm.

Possibilities of the pipeline television diagnostic method:

• quick determination of the cause of the blockage; • identification of the type and nature of damage; • determination of the most accurate position of damage in order to carry out the necessary repair work; • designation of places for replacing pipes without the need to dig trenches.

Based on the readings of the television inspection data meter, after taking all the necessary measurements and taking into account the distance traveled, the location of the communications system is determined, which greatly simplifies the task of drawing up estimates.

Teleinspection during pipeline rehabilitation

Regardless of what material the water supply or sewerage pipes are made of, their capacity only decreases every year for a number of objective reasons. If there is a sharp decrease in the performance characteristics of pipelines, you should immediately carry out professional sanitation of the water supply or sewer pipes.

Sanitation is a set of technical measures aimed at restoring the integrity, tightness and maximum throughput of the pipeline. The technique for carrying out sanitization work depends on the reasons that caused the deterioration of the technical characteristics of the pipeline and the variety of professional equipment and materials. The choice of method for restoring the maximum capacity of a pipe or its tightness depends on a number of factors:

• pipe diameter and length; • material from which the pipeline is made; • level of damage or degree of contamination; • purposes of further operation of the pipeline.

To select the most appropriate sanitation technology, flushing of the pipeline and its thorough television inspection . For washing, hydrodynamic or mechanical cleaning methods are used. In case of large contamination, the internal contents of the pipeline are first removed with special equipment. Tele-inspection is carried out to identify damage on the internal surface of the pipeline.

The following methods of pipeline rehabilitation are distinguished:

• Application of various coatings (cement-sand mixtures or coatings based on epoxy resins); • Installation of soft polymer hoses; • Introduction of smaller diameter pipes; • Repairing damage using sheet patches; • Use of spiral polymers from modern composite materials as shells or coatings.

Rehabilitation of pipes should be carried out not only to restore the throughput capacity of the pipeline, but also to improve its quality characteristics. This is due to the fact that even in a drinking water supply, after a short period of time, various salts are deposited on the internal surfaces of the pipe.

As a result of pipeline rehabilitation, all of its technical characteristics are significantly improved:

• The service life of pipelines increases; • Corrosion of metal pipelines is prevented; • Prevents mineralization and growth of pipelines by vegetation; • The overall capacity of the pipe increases; • Electricity costs for pumping water are reduced; • The high quality of transported water for drinking or technical needs is maintained.

To contents

How robots work

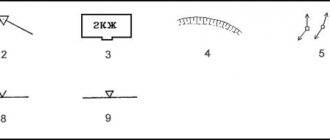

Depending on the diameter and configuration of the pipeline, the type and model of the robot is selected.

The selected robot for teleinspection is loaded and removed from the pipeline using a special winch. Starting from the moment of diving, the self-propelled equipment is in the on mode and provides continuous video recording. All received data is transferred online to the control panel and, thanks to the built-in software, undergoes digital processing. If necessary, it is possible to display graphically all diagnostic data, indicating results, parameters and adding text comments. Robotic systems are controlled remotely, which allows complete control of the actuators. And thanks to LED backlighting, visual inspection is possible in the absence of external light sources. The speed and method of movement depend on the tasks performed and can reach 27 meters per minute. The high-resolution color PTZ camera, which is remotely controlled by the operator, allows for thorough inspection, zooming in and recording in digital format. Thanks to the laser meter, it is possible to measure the exact size of the defect. A high-precision slope sensor and special software provide the ability to plot a pipeline slope graph. The exact location is recorded by a radio beacon.

Chimney inspection. Ventilation check

Checking the chimney and ventilation systems to identify defects and contamination.

Ventilation contamination can be of different types. Dust and dirt settle in the supply system, grease can accumulate in the exhaust system, fireplace chimneys gradually become clogged with soot, chimneys of stoves and barbecues accumulate a mixture of fat and soot.

Teleinspection helps to quickly and accurately examine chimneys and air ducts. A miniature video camera is able to quickly assess and capture the internal condition of the air duct and the type of contamination, and after cleaning work, a television inspection allows you to evaluate the quality of cleaning. It is only necessary to record the study and provide it to the Customer.

Checking chimneys and ventilation systems is necessary for:

• determining whether the ventilation or chimney is contaminated with dirt, dust, grease or soot; • assessing the quality of ventilation cleaning; • detection of damage, blockage or foreign objects in the air duct; • clarification of the position and nature of the defect; • assessing the technical condition of the entire ventilation duct before starting to repair or replace the damaged area.