The well is an ancient hydraulic structure that has not lost its relevance to this day. Owners of country houses and summer cottages will agree with the need to have such a structure on the site. It can be a traditional source of water or serve as the basis for the construction of an autonomous water supply system.

In any case, from time to time you have to clean and repair the well: it’s quite easy to do it yourself. Next, we will tell you in what cases repairs are necessary and how to carry them out without the help of specialists.

Signs of destruction

To maintain the source in good condition, the water quality should be regularly checked and the mine inspected. In this way, the reasons why it is necessary to repair it are determined. There may be several of them:

- drying out;

- water pollution;

- trunk destruction;

- violation of the waterproofing layer.

- The most common reason for repairing wells is when they dry up. That is, the depth is not sufficient to reach the surface of the aquifer. During restoration, the depth is increased by drilling a hole in the bottom or driving pipes to the water level.

- Pollution is caused by the appearance at the bottom of a sediment of small particles of sand and silt. To eliminate this problem, pump out water, clean and disinfect the bottom. If necessary, you should deepen the bottom of the source and install a filter to purify the water.

- Shedding of the trunk walls often occurs. This can occur due to the destruction of concrete rings and their displacement. Sewage and dirt penetrate inside. The cracks are repaired with cement, and the rings are securely attached to each other.

- Violation of the waterproofing layer leads to groundwater and wastewater entering the well. To eliminate this problem, the seams between the rings are putty and cracks in the walls of the barrel are sealed. The work is carried out from the outside, for which a repair trench should be dug. After the work is completed, the pit is filled with clay, which serves as an additional waterproofing material.

Safety precautions when working in a well

Working at depth is very dangerous, so neglecting personal safety rules is unacceptable. Experts recommend enclosing the mine with boards placed on edge during the period of repair work.

In addition, the area around the well mouth should be cleared of foreign objects so that nothing could accidentally fall into the trunk. Especially if there is a working person there.

All tools and equipment must be in good working order and safe. Be sure to check the tensile strength of the rope that will be used to lift the container with silt or soil.

If work is to be done at a depth of more than 6 meters, another safety rope must be tied to the tub. Lifting mechanisms, if used, must function flawlessly.

Before the first descent into the shaft, as well as after breaks and every morning, it is necessary to check the air quality in the well. This can be done by lowering a burning candle down; if it goes out, it is necessary to take measures to ventilate the barrel.

Then check the air quality again. If the influx of harmful gases in the well is strong and constant, continuous ventilation is necessary.

For these purposes, a fan or a burning stove installed on the surface is used, the ash of which is connected to the bottom of the shaft through a pipe. When lowering or lifting any objects, you should always notify those working below. During the immersion process, the depth of the barrel wall unprotected by the fastening should not exceed one meter.

To clean the walls of the well from deposits, you can use a high-pressure washer. The process will go much faster with it

Maintenance of wooden

Both the above-ground part and the underground part, which is a wooden frame, are vulnerable.

In case of damage, the part of the structure located above the surface is not difficult to replace. It is carefully disassembled so that debris does not fall into the water, and reassembled. Sometimes damaged elements of the above-ground part are repaired using concrete mortar and formwork. To carry out the work, it is necessary to prepare the site.

- It is knocked down from boards in such a way that it fits freely into the shaft.

- They hang it on the beams using cables and get to work.

- We remove the old material from the damaged area of the head and formwork is made using reinforcing mesh.

- The result is a gap between the mesh and the barrel wall, which is filled with cement mortar.

Repair of the underground part of a wooden well begins with a routine inspection of its crowns. During operation, logs become rotten and must be replaced. In case of minor damage, they are cleaned and treated with protective material.

In some cases, they get by by replacing several logs of the log house. For this:

- pump out water if damaged logs are below its level;

- then it is necessary to strengthen the part of the wooden structure located above the damaged logs. This requires the construction of a special device. Large trestles are installed on the surface on both sides of the head. A log is laid on them, to which two long boards are attached. Their lower edge is lowered into the shaft and nailed to the crowns located above the part of the frame being replaced;

- long boards can be replaced with strong ropes with hooks. The main thing is that the whole part of the log house is suspended;

- After strengthening the structure, the damaged elements are removed and raised upward. Based on their shape and size, new parts of the log house are prepared. It is necessary that the new log fits into the grooves of the existing structure. It is placed in place and securely wedged.

Sometimes individual elements cast from concrete are used instead of new logs. This makes the structure more durable.

The work uses a wooden ladder of the required length or a rope ladder with a significant depth of the source. Complete replacement of the frame of an underground structure is a painstaking process and requires the installation of new crowns.

Brick structure repair work

Brick-lined wells are the easiest to repair. Their cladding elements are small and easy to replace. First of all, the walls need to be thoroughly cleaned of dirt, otherwise it’s easy to miss the damage.

If through gaps have formed between the bricks, they should be properly sealed from the outside of the structure. We are preparing a repair trench. Having reached the defect, we clear it to 10 cm in depth.

After this, we thoroughly coat the crack with clay, going at least 5 cm deep. Inside the well, work boils down to replacing damaged bricks and restoring crumbling plaster. We carefully hollow out the defective brick or its remains from the wall. We take a new part and insert it in place of the old one, laying it on cement mortar.

Brick-lined wells are quite easy to repair. The damaged brick is carefully hollowed out and replaced with a new one.

Before plastering, carefully prepare the base. We clean it from dirt and mucus with a steel brush, otherwise a cavity will form under the solution in which water can accumulate. And this will lead to rapid destruction of the new plaster.

We carefully tap the old coating and remove all unreliable areas and crumbled fragments. After this, we clean the base again and begin plastering.

How to repair a shaft made of concrete rings

Despite the strength of the material from which the source is made, there is often a need for its restoration.

The reason may be poor-quality installation of the structure and displacement of the rings under the influence of various factors. The result of mine destruction is pollution due to the ingress of wastewater and soil.

Repair work consists of sealing seams and cracks. The reason for their appearance may be destruction under the influence of moisture or displacement of the lower rings, for example, under the influence of quicksand.

The order of work is as follows:

- To choose the type of repair, you should determine to what extent the seam is damaged or how deep the crack is. This is done by tapping.

- When only the outer layer is shed, work is carried out from inside the source. Clean the inner surface of the collector. At the same time, all chipping parts of concrete are carefully removed. The holes that appear are carefully sealed with a high-quality solution.

- if the crack is through, work should be carried out both inside and outside the source. To do this, dig a shaft around the perimeter so that there is enough free space for repairs. The damage is well cleaned of dirt from the outside of the trunk and the crack is sealed with cement mortar. The repair area is covered with an additional waterproofing layer.

You can prevent the rings from shifting at the stage of their installation. To do this, the joints are additionally secured with metal brackets measuring 4 x 30 cm. At least 4 such plates are placed at each joint. The brackets are secured with bolts by drilling a hole in the concrete. This event will prevent the rings from moving relative to each other.

If the shift problem does occur, it must be eliminated. To do this, the trunk is dug up in a circle until the ring has moved. They put it in place and cement the joints on the outside and inside of the shaft. For greater reliability, metal staples are installed at the joints so that the rings no longer move.

If this method is not acceptable, a repair shaft is made from plastic pipes, the diameter of which is slightly smaller than the concrete rings. Elements of the plastic structure are lowered along the entire length of the shaft, connecting them using threads, and the space between the repair pipe and the rings is filled with sand or a cement-sand mixture.

Restoration is also carried out in more innovative ways. These include pneumatic repair of concrete surfaces using special protective and restoring compounds. These products significantly increase the resistance of concrete to mechanical damage. They also have other advantages:

- resistance to temperature changes;

- protection of fittings from corrosion;

- reliable waterproofing performance.

Before applying the composition, the surface is cleaned of dirt and moistened with water. The mixture is prepared immediately before work in strict accordance with the instructions. The roughness of the base promotes better adhesion of the material.

Popular materials used for sealing wells

Photo of the finished mixture for waterproofing well joints.

Now there are many materials for sealing seams in a well. Each of them has varying degrees of effectiveness and features, so let's look at the most popular options in more detail.

So, sealing the seams in the well is carried out mainly using the following list of materials:

- Ready-made dry mixes. These new generation materials are created on the basis of cement with the addition of chemically active additives, due to which they acquire improved waterproof properties. Their advantage is also that such mixtures are able to adhere well to concrete surfaces, so this option is preferable for sealing wells made of this material. For example, high-tech mixtures “Penetron” or “Waterplug”, which have proven themselves in waterproofing work, make it possible to create an almost monolithic surface that is indestructible for many years. Ready-made dry mixtures are sold in specialized stores.

Schematic representation of waterproofing a concrete structure using Penetron and Penecrit.

- Bitumen-gasoline solution. Such a mixture can be prepared with your own hands from gasoline and bitumen, the grade of which should be chosen at least 3. Sealing of well joints with this material should be carried out in 3 layers, the first of which will be a primer. For the first application of the primer, the solution is prepared in a ratio of 1 to 3, and for subsequent layers - 1 to 1. This mixture is applied using special equipment that supplies liquid building material under high pressure, for example a cement gun. This solution is flammable, so sealing seams in the well with its help must be carried out in strict compliance with fire safety standards.

The process of sealing joints with a bitumen mixture.

A mixture of cement (not lower than grade 400) and PVA. Sealing well joints using this thick mortar is done by plastering using a regular spatula. Often, to enhance the sealing effect, liquid glass is applied over the cement and PVA mixture. Insulating tapes (rubber, jute or linen, impregnated with fiber rubber). These building materials are used in cases where there are no other means at hand to eliminate a well leak. This process occurs using the caulking method. Caulking with such tapes allows you to seal the seams of the well if they do not exceed 7 mm. However, it should be noted that this is not the most reliable way to achieve excellent results for a long time

Therefore, when the question arises of what is the best way to seal the seams in a well, it is first advisable to turn your attention to other materials.

Plastic mine

Plastic rings for wells are increasingly being used. They are light in weight, highly durable and do not affect water quality.

- They are made from polypropylene or polyethylene.

- These materials are inert, which is why they are resistant to exposure to aggressive environments.

- They are used at temperatures from +50 °C to -70 °C.

- No additional costs are required for waterproofing, since the material is non-hygroscopic.

- When constructing a source, there is no need to use heavy equipment, which reduces the cost of work.

- Mounted using threaded connections. Since the rings are prefabricated, they can be installed to the required depth.

Plastic elements are used in the construction of sewer and drainage systems, as well as in the repair of existing water sources made of brick or concrete rings.

If the well is old, then work to replace its individual elements can lead to new damage and its complete destruction.

In this case, the best solution would be to use plastic rings to repair the shaft. With their help, you can repair an existing source and even restore an abandoned well from wood.

This material has a dense structure; the walls of the rings cope well with horizontal loads.

Repair an old well or dig a new well

In some cases, digging a new well is more justified than resuscitating one that has fallen into disrepair or has a weakened water flow.

But the decision in favor of one option or another may only seem simple. Because it does not come down to just comparing the budgets for repair and construction of wells, but requires taking into account a number of factors, none of which should be overlooked.

What do you need to know to make a decision about digging a new well on your property to replace the old one?

Firstly , a geodetic survey should be carried out to determine the presence of aquifers in those places where the construction of a new well is consistent with the layout of the site and the location requirements for digging a well.

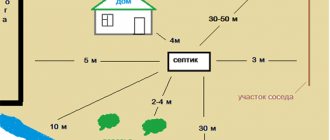

The new well should not be located closer than 5 meters from permanent buildings, 2 meters from fences and barriers, and also closer than 20 meters from septic tanks and other sources of possible soil contamination.

Secondly , knowing the state of the watercourse in your old well, the flow rate of wells in nearby areas and their location, taking into account distances and elevation changes, predict the level of occurrence and intensity of aquifers in the places where they are found by the results of a geodetic survey;

Now that there are basic parameters for comparing what you are looking for and what you are willing to give up, you can analyze the situation.

The cost of repairing the old well and building a new well, the quality and quantity of water in both water intakes, the cost of transferring water supply communications to the new well, and possibly the accompanying additional costs for making changes to the sewer system, comfort and convenience factors associated with the changes - associated with the changes comfort and convenience factors will all influence the final solution.

We carry out the audit ourselves

Under the influence of various factors and with regular use, the source, regardless of its type, may lose its performance. To prevent such a situation, maintenance work should be carried out.

First of all, this is carrying out audits and monitoring the condition of all structural elements, its preventive repairs and major replacement of individual elements.

The process consists of the following types of work:

- visual inspection;

- scheduled mine cleaning;

- preventive repairs and scheduled maintenance.

External inspection is carried out regularly and does not require any additional devices. The integrity of the head and shaft is visually assessed.

Carrying out preventive cleaning of the source depends on the material from which it is made, its depth and soil composition. This work should be carried out every six months. Although, with proper operation and normal condition of the aquifer, cleaning is carried out every four to five years.

Between such planned well maintenance activities, you need to constantly monitor the quality of drinking water in it. If factors appear that affect the condition of the source, it should be cleaned unscheduled. The reasons for this may be:

- violation of the tightness of the seams between the shaft elements. As a result of such destruction, unfiltered groundwater may enter the well;

- ingress of dirt from the surface into the source. Occurs in the event of destruction of the above-ground part of the well;

- accumulation of sediment and silt at the bottom. This leads to a gradual restriction of clean water entering the mine;

- bacterial and chemical contamination.

Particular care should be taken when inspecting the well in the spring, after the passage of floods and thawing of snow. In winter, mines are subject to additional stress. Freezing of the soil leads to its swelling, which can lead to damage to the joints between structural elements.

Causes of dirty water

Quite often, in a well that has recently regularly supplied clean water, the liquid acquires an unpleasant taste and smell, and it becomes colored, indicating the presence of foreign impurities. Such water cannot be used for drinking or culinary purposes. In addition, an increased amount of impurities can damage plumbing fixtures and household appliances, and quickly render filter cartridges unusable. Whether you will need to repair wells at your dacha yourself can be decided in each specific case after a thorough inspection of the structure , but cleaning and eliminating the causes of contamination is always required. There can be several reasons for the appearance of dirt.

- Natural silt deposits on the walls and bottom of the canal, which are a mixture of unicellular algae, microparticles of organic matter, bacteria, etc. that have entered the water. Like any organic matter, such a mixture begins to decompose, giving the water an unpleasant odor and taste.

- Large contaminants accidentally falling into the well - leaves blown by the wind through the upper part that is not closed with a lid, small animals that have fallen and drowned, etc.

- Soil particles and organic matter from the soil entering through the walls when their tightness is broken.

Deposits on the walls of the well need to be cleaned regularly.

If in the first two cases you can limit yourself to cleaning and sanitation of the structure, in the latter you will have to think about how to repair the well.

For repair work, you will probably need a rope ladder for the well. Read how to make it yourself in our separate article.

You will also need a drainage pump for dirty water to pump it out. We described how to choose it in another material.

Regular cleaning of the well is the key to its long functioning and the presence of water in it without impurities and contaminants. There is information on how to do it here.

Plastic and reinforced concrete wells: which ones cause more problems and why?

The most common types of wells are plastic and reinforced concrete. The modern version is plastic, which has recently been installed everywhere. Their high popularity is primarily due to the fact that the structure lasts for several decades and does not require repair work. There are many more problems with reinforced concrete structures, which is associated with the prefabrication of the structure, the presence of seams and individual structural elements.

Plastic and reinforced concrete wells are part of the sewer system, which allows you to audit, control and operate the sewer system.

Over time, the quality of concrete can change significantly, cracks and various other defects appear on the surface. Waterproofing is also affected.

Safe waterproofing materials

Now let's talk about how you can seal the seams in the well, depending on one or another sealing method. The construction market offers many waterproofing materials for creating watertightness in large containers.

In sealing work using safe materials, the following types are used:

- Dry composition, which is prepared at the factory. They are created from very effective new substances based on cement, to which moisture-proof additives are mixed. Thanks to them, the finished mixture has the best ability to adhere perfectly to the surface of the rings. The use of ready-made mixtures will be the most effective and preferred option. The following options for dry mixtures for joining joints are often offered for sale: “Penetron”, “Waterplug”. Tested repeatedly in use, they have proven themselves to be excellent in creating a moisture-proof connection in the space between the concrete rings of wells. It has been established that as a result of their application into the gaps, a strong, monolithic well structure is created. Moreover, it is not susceptible to the destructive effects of temperature and moisture for many years. You can purchase ready-made dry moisture-proof compounds in specialized stores.

- Bitumen-gasoline mastic. This version of a moisture-resistant solution is suitable for those who want to mix all the components with their own hands. When choosing bitumen, the brand must be used with a parameter of at least 3. Sealing of joint gaps from this composition should be carried out in at least 3 layers. The first layer is a primer. For it, mastic is diluted in the proportion of 1 part gasoline to 3 parts bitumen, and further coatings are 1 to 1. A special device that sprays a rare composition under high pressure, for example, a cement gun, will help make the work easier and more efficient. You should not forget about safety precautions when sealing seams, since the solution is flammable.

- Plaster mixture of cement (high grades from 400) and PVA glue. Clogging of the gaps between concrete rings using such a thick solution is carried out by plastering using a conventional spatula. To improve the efficiency and waterproofness of the layer, liquid glass is additionally applied over the cement joint.

- Sealing strips, which come in different structures: rubber, linen, jute or impregnated with a special fiber-rubber coating. This type of building materials is used in cases where there are no other suitable means that could protect against the penetration of external liquids into the well. The gaps are sealed using the caulking method. Sealing joints with water-repellent tapes allows you to seal the space between the rings, not exceeding a distance of 7 mm. This method is the least reliable compared to previous methods. Solving the sealing problem with caulking will not work for a long time. This method is best used in the most extreme cases, but then it is better to seal the joints of concrete rings using more durable and effective materials.

Not knowing about its dangers, some well owners quite often include it in the solution to create sealed joints due to its excellent water-repellent properties.

Clay castle

Clay has always been an excellent sealant and barrier to water

- The well is dug from the outside, freeing 3-4 rings or about the same number of meters, filled with clay, and compacted well.

- The clay should be free of sand and soil to prevent water from reaching the well.

- You can fill the recess with cement mortar, which is prepared in the following way.

- Tools and raw materials are being prepared. Mixing container, cement, sand, electric drill or shovel, water.

- One part of the cement is diluted in a container with water and thoroughly mixed until a homogeneous cement laitance is obtained. Add 3 parts of fine, dry sand to it and mix it just as well with a shovel or drill. If the waterproofing work was carried out correctly and in compliance with all recommendations, then the taste of drinking water will be excellent.

Hydroseal - modern technology for sealing holes

A quickly hardening substance is called a hydroseal. A hydraulic seal is used for wells mainly in emergency cases when urgent and effective intervention is required. Where to get a hydraulic seal and how to prepare it? To seal concrete joints, it is recommended to use “Waterplug” and “Peneplug” together with “Penekrit” and “Penetron”, respectively. The mixture allows you to cover up fairly large holes, up to a hole with a diameter of 10–13 cm.

Hydraulic seal for well treatment

How to prepare a hydraulic seal for use (using the example of “Waterplag” and “Peneplag”)? Take 1 kg of hydroseal and mix it with 150 grams of water. If it is not possible to measure grams, then you can follow the proportions: 1 part water to 5 parts mixture. Kneading is done quickly and only in warm water (17–23 degrees).

Tip: Do not try to fill all the holes at once by mixing a large amount of mixture. The hydroseal sets so quickly that upon returning to the container with the mixture, you will find one frozen lump.

Sealing seams between rings - detailed instructions:

Well treated with Hydroseal

- Preparation of the working surface. We knock down the exfoliated concrete with a hammer drill or jackhammer, slightly expanding the damaged area;

- Mix the hydroseal in a metal or plastic container in a small amount. Form a lump with your hands and press with a sharp movement into the seam between the rings. Hold the filling for 2-3 minutes.

Sealing concrete joints with a hydraulic seal allows you to instantly get rid of leaks. The only drawback of this mixture is its cost - 3 kg will cost 800–1000 rubles.

Adviсe

If a source of water is required, for example, in a country house, then installing a well will be a simpler solution, since there is significantly less work to do with it, and the well requires more serious technological research. At the same time, the water from the well will be significantly cleaner, and the risk of blocking the water inflow will be less due to the greater depth and distance of the water from various infrastructure facilities that can cause pollution.

At the same time, the water level in the well does not fluctuate from season to season, as is the case with a well. Also, the well, despite its durability, requires constant care and maintenance. At the same time, the well does not require such serious care and frequent maintenance.

If you look from a financial point of view, a well is a more affordable option than a well. Moreover, sometimes the cost of a well exceeds the cost of a well. But the reason here is simple - the complexity of drilling and the need to attract specialized drilling equipment.

You can be convinced that it is quite possible to carry out repairs of wells and manholes with your own hands. Before carrying out work, you should clearly understand the algorithm of necessary actions and know what exactly you have to deal with, as well as what result you want to get. But even a person who has never encountered such work before can do the repair of a well or a well with his own hands without any special difficulty.

From the video below you can learn how to clean a well from sand.

Cleaning steps

The well is cleaned in stages.

1. Before moving on to any other work, the mine will need to be cleared of water. Since it is impossible to stop the flow of liquid during cleaning or repair, pumping (using a pump) will have to be done several times:

- entirely as preparation for examination and further operations,

- as necessary - during repair or cleaning to ensure ease of operation,

- after completion of all necessary activities.

2. By cleaning the walls, you not only remove organic matter polluting the water (deposits removed from the surface with a brush should be removed from the shaft), but also prepare the surfaces for inspection.

3. The cleaned walls are carefully inspected: the integrity of the structure itself, the coating, and the joints of the elements are checked (often repairing a well made of concrete rings with your own hands is required when they are displaced relative to each other and cracks form). Detected violations are eliminated.

4. Cleaning the bottom most often involves removing sediment and replacing the filter layer. The easiest way is a bucket on a rope and a shovel. More experienced homeowners often use a grab for this purpose.

Insulation

In central Russia, it is highly advisable to insulate a well, especially with a closely located water surface, in the fall, otherwise it will be difficult to use it in winter. To do this, it is enough to cover the shaft with a 50 mm thick polystyrene foam cover. If the above-ground protective and decorative part is made of plywood or other thin material, the mouth of the shaft must be wrapped in a layer of polyethylene foam 10 mm thick. Another option is to insulate the soil around the well with sheets of extruded polystyrene foam before constructing the blind area.

To seal the mine, prefabricated and solid casing pipes made of low-density polyethylene (HDPE) and unplasticized polyvinyl chloride (UPVC) are used. These products are lightweight, have sufficient strength and are suitable for domestic and drinking water supply. Photo: Aqua Optim

- Water supply and sewerage

How to prepare water supply at your dacha for winter

Main structural elements of a sewer well

First, you should pay attention to what structural elements the sewer well has. The main ones can be called:

- Working tank.

- Mine.

- Neck.

- Bottom.

- Inspection hatch.

Also, in the case of using reinforced concrete rings, a layer of waterproofing is created, which can be represented by tape or waterproofing plastic materials. In the case of a plastic well, almost all structural elements are one design due to seamless production.

This image shows the parts of a sewer well: Manhole - cover - concrete ring - bottom (base) of the well.

Using plaster under compressed air pressure

Materials for work:

Cement gun is necessary to seal the well.

- cement gun;

- high-quality pozzolanic (not lower than 400);

- waterproof expansion cements;

- waterproof non-shrinking cements.

The entire process is carried out using a cement gun. The cement is laid in 2 layers with a thickness of 5-7 cm. Each subsequent layer is applied only after the previous one has set. This may take 10 days or more. The solution can only be applied at an ambient temperature of at least +5 °C. If sealing occurs in the summer, the coating must be watered with cold water every 2-4 hours. In the cool season - every 12 hours.

What is a hydroseal

A hydraulic seal is a special composition of hydraulic mixtures that are capable of very rapid hardening, making it possible to eliminate pressure leaks. Typically, hydraulic solutions are not practical to use in such situations; they are simply washed away with water, even before they have time to harden.

Until the hydraulic seal was invented, most well builders used wooden plugs or tow, which, when swollen, prevented water from leaking into the structure. But these materials had one serious drawback - they began to rot very quickly, emitting unpleasant odors, which caused changes in the taste and quality of water.

The appearance of the hydraulic seal made it possible to significantly improve the quality of work and increase the service life of the repair area, which became important. However, even in our time, there are companies that instead use the old-fashioned method of eliminating leaks to reduce costs, without even thinking about the consequences.

In the photo there is a damaged section of the seam between the reinforced concrete rings

In addition, pay close attention to what well workers are trying to stop live leaks. Remember that the mixture of sand, cement and liquid glass, which is used by approximately 80% of craftsmen, cannot stop them efficiently and reliably.

When working with a hydraulic seal, it is necessary to take into account all recommendations related to surface preparation, and when cracks and seams are small, they should be enlarged with a hammer drill to the required size. If the instructions are followed, it can withstand even very serious water pressure.

Prepare a solution to eliminate pressure leaks

From the previous paragraph we learned what a hydraulic seal is for. This fast-hardening material is capable of returning the structure to solidity in a matter of minutes.

When purchasing material, pay attention to the presence of a certificate from the seller, which confirms the safety of the components used in the hydraulic seal for drinking water

We can recommend materials such as “Waterplug” and “Peneplug”, which are used in conjunction only with “Pinekrit” and “Pinetron”. The mixtures instantly set when exposed to strong water pressure, simultaneously expanding and forming a waterproof layer.

Materials from other manufacturing companies that also specialize in producing instant mixtures for blocking pressure leaks are used in the same way

Particular attention should be paid to correct use with the attached instructions

Prepare the solution yourself

When you decide to prepare the mixture yourself, be sure to follow the recommendations of the manufacturer. The volume of the dry mixture depends on the activity of the leak.

Most often, the proportion is 1 kg of well hydroseal per 150 g of water. Another way to calculate it is as follows: take five parts of the mixture for one part of water.

The solution should be mixed at a water temperature close to 20°C. The kneading is done as quickly as possible - no more than 30 seconds, which should resemble dry earth.

Do not knead a large volume at once, take into account its instant setting. In this regard, it is wiser to prepare the mixture in parts, and after applying one to the site of a pressure leak, immediately begin preparing the next one.

Leak sealing technology

- At the first stage it is necessary to prepare the surface for work. To do this, use a perforator or jackhammer to free the internal leak cavity from exfoliated loose concrete.

- This repaired area must be widened to a width of 25 mm and deepened to 50 mm or a little more. In this case, the shape of the hole should be similar to a funnel.

- Stir in a clean container a certain amount of the mixture, the volume of which is necessary to seal the leak. Form a lump of mortar with your hands and press it with a sharp movement into the embroidered hole. Hold the water seal in place for 2-3 minutes.

Other places of application of hydroseals

Using quick-hardening solutions you can effectively resist:

- leaks of liquids from reinforced concrete tanks;

- water breakthroughs in tunnels, basements, adits, shafts, galleries;

- defects that may appear in the bowl of swimming pools and other artificial reservoirs;

- capillary leaks, which often appear at the junctions of walls and floors, as well as between foundation blocks.

Purpose of the pumping station

What are water supply installations used for? This is pumping water to the consumer from a water supply source (well, river, reservoir), and this requires a special pump booster device.

It is the pumping unit that takes water through suction pipelines and transfers it to a residential building or industrial building through pressure pipelines. No water supply system will work without pumping units.

Pumps are needed to supply water for drinking needs, to extinguish fires, pumping domestic and industrial wastewater, drainage of mines and basements, borehole and sand pumps. There are pumps for pumping solutions, feces, clean water, and petroleum products. The type and brand of pump is selected for each specific case.

Popular models: al ko (alco), grundfos, gardena 3000 4, grundfos, Gilex jumbo 60 35, marina, whirlwind, etc.

Under what circumstances do seams leak?

At the time of repair work, the well is a ready-made structure, which has some of its own structural features.

Based on this, there are many circumstances that could cause leaks in cracks:

- Rings, which are made by various manufacturers, can be with or without locks. Accordingly, the seams of the latter are less airtight.

- During the construction of the well, the builders did not seal the seams with tarred rope. The client must monitor this process during the work; otherwise, troubles associated with depressurization of joints will invariably appear in the well.

- The location chosen for the well was not entirely suitable. When planning, it is necessary to take into account the peculiarities of the hydrological and geological conditions of the area. In unstable soils, soil movement is likely, and as a result, the seams may separate, especially if the well was constructed incorrectly.

- If the upper seams are located above the soil freezing level, the cracks will be able to diverge due to demi-season freezing and freezing of the soil.

In any case, the problem can and must be solved by repair work, the quality of which will determine the level of water quality in the well.