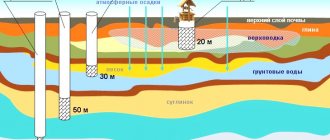

For individual water supply to private houses, water intake is most often used from wells and boreholes, the quality of water in which is determined by the depth and structure of the aquifer. In common sand wells, it is necessary to have filter elements at the end of the casing, which are supplied and manufactured at the factory. But in some cases, it is more practical to make a filter for a well with your own hands, most suitable for a specific water intake source and in no way inferior to factory samples.

To do this, it is necessary to study existing methods of filtering well water and build your own system based on them. Carrying out this work does not require expensive special tools and can be done with your own hands without a lot of time if you have the appropriate components and knowledge of the technology.

Fig. 1 Types of filter casing pipes

What is a well filter and its structure

Water purification from a well occurs in two stages - with a well filter and surface filtration systems built into the water main. In this case, the well filter has a structure consisting of three main elements:

- Above-filter area. The part that plays the role of fittings when mounted on a column.

- Filter elements. Includes the holes in the pipe of the correct size and the external materials that are attached to it.

- Sump. The space for placing soil particles trapped inside the source or screened out by filter elements is the lower part of the filter without perforation. The sump for water from the well is about 0.5 m long.

Rice. 2 Filter design

Why do you need to purify water from a well?

The water in a freshly drilled well does not remain pure for long. At first there are almost no impurities in it. Over time, you can even visually notice cloudiness, the appearance of sediment, a specific odor and a slight color. In this case, reliable filtration will help.

A number of reasons indicate the need for filtration:

- If you do not periodically clean the well, substances may accumulate in it, which will trigger putrefactive processes and contribute to the formation of sludge.

- Infrequent water purification leads to the fact that the liquid begins to acquire a metallic, very unpleasant aftertaste.

- Plumbing fixtures, appliances and dishes become yellowish after prolonged use of untreated water.

- Groundwater contamination can cause harmful contaminants to accumulate in drinking water.

- Silty and cloudy sediment in a container of water indicates the development of harmful bacteria in it.

- If you do not periodically filter the water, this will lead to the appearance of a corrosive smell of “rotten eggs” or hydrogen sulfide when you turn on the tap.

For research purposes, water is delivered to the laboratory to conduct a full chemical analysis (after all, we need to achieve compliance with sanitary standards). Diagnostics before the filtration procedure should be carried out regularly, since even replacing individual elements of the water treatment system will not save you from contamination over time, and the water may deteriorate. The results of the analyzes will prompt the solution of the main issue - the choice of a water treatment system. Today there are several types of such systems.

Why do you need a well filter?

The need for filtration inside the well is caused by the following circumstances:

- Purified well water, unlike contaminated water, increases the service life of submersible and surface pumps for a well - impellers, membranes and other moving components wear out less.

- Filtered water, when further passing through the pipeline, pollutes less filters in water purification systems located in the water supply system - this allows you to save money on the purchase of new cartridges and increases their durability.

- Filtration increases the service life of automatic control systems for pumping equipment - pressure and idle speed switches, hydraulic accumulator.

- Purified water contributes to better permeability of the water main and increases the service life of plumbing units (check valves, ball valves, mixers).

- Additional well treatment contributes to better quality of drinking water used in households.

Rice. 3 Filter element design

Disinfection

An important step to ensure that water meets regulatory requirements. To remove bacteria and unwanted microorganisms, the following are used:

- Blocks filled with sorbents of various types . Products containing coal have become widespread in everyday life. Thanks to its use, the filter improves the organoleptic properties of water.

- Ultraviolet . The device consists of a steel case with a quartz case and an ultraviolet lamp located inside. Passing through the device, water is irradiated by an ultraviolet stream and is thereby disinfected. The radiation dose depends on the level of contamination of water by microbiological organisms. The device allows vertical and horizontal placement.

- Chlorination, fluoridation . The method can be called traditional. The resulting suspension is subsequently removed. It is practically not used in private home water supply systems.

Materials for filtration equipment

The efficiency of cleaning depends on the quality of the filtration material; a limited number of them are used in wells, the main ones being:

- Stainless steel. In addition to strength, the material has flexibility and excellent corrosion resistance; the durability of stainless steel is tens of years. It is used to make strong meshes and wires that are mounted on top of the pipes. The disadvantages include the high cost of stainless steel products.

- Plastic. Plastic is another common material for the manufacture of filters in water sources; meshes and cords are made from it, which are cheaper than stainless steel. Plastic is corrosion-resistant and inert to most chemicals, easy to install and has a long service life. The disadvantages of plastics include low physical strength, which does not allow them to withstand heavy loads at significant depths.

- Non-ferrous metals. Copper, brass, and bronze can be used in the manufacture of water filters without any restrictions; they have high corrosion resistance and a long service life. Soft alloys with a high copper content are recommended for use at shallow depths to avoid deformation from strong water pressure. In the manufacture of filter elements, brass mesh and thick wire made of brass or copper are used.

Rice. 4 Filter for casing pipe - installation in the well

- Steel. Steel filters are susceptible to corrosion and can be used as a budget option in water intake sources intended for technical needs. Increased content of iron oxide in water as a result of iron corrosion of more than 0.3 mg. per liter leaves a yellow residue on water main equipment and plumbing fixtures. Galvanized steel also rusts over time to form zinc oxides, which are harmful to human health - this material is not recommended for use in water filter elements.

Briefly about the main thing

The filter is an important element in the water supply system of a private home, using a well as a source. With the correct selection of the model, it allows the produced water to comply with regulatory requirements. This makes it possible to use it not only for technical needs, but also for drinking.

Before you begin selecting filtration equipment, you should do a chemical analysis of the water. It will allow you to understand what impurities need to be gotten rid of and in what quantities.

To achieve the best effect, you should take care of multi-stage cleaning. Consistently passing through filters of different types, water can get rid of mechanical impurities, harmful substances and bacteria. Subsequent enrichment with useful elements will ensure compliance with regulatory requirements.

Ratings 0

Types of filters and their features

Well filters can be divided into two large groups:

- simple - with various types of holes in the bottom casing pipes;

- complex - they are a separate structure placed at the location of the bottom pipe or with filter elements mounted on the casing pipe.

In simple devices, round or slot-like holes are cut in the pipe surface; in more complex designs, wire is wound in dense rows or a fine mesh is fixed.

Reverse osmosis plants

The devices help to completely disinfect water. They allow you to get rid of unwanted bacteria and achieve high-quality cleaning. A multi-stage well water purification system allows you to get rid of various types of impurities. The operation of such equipment is based on the principle of liquid passing through a membrane under high pressure. A special pump is used to supply water.

The design of the membrane is such that only water molecules pass through it. The impurity remains outside. After cleaning, the accumulated dirt is simply washed off the surface of the membrane and sent down the drain. The presence of a self-cleaning function significantly increases the efficiency and service life of such equipment.

Having passed through the membrane, the water enters the flasks with a carbon backfill or a mineralizing layer. This is necessary to enrich it with microelements necessary for humans, since after passing through the membrane, the water’s parameters are close to distilled.

Do-it-yourself well filter - how to make it

Well filters are installed on the bottom pipe and lowered into the source along with the casing; making them yourself is pointless if you are not involved in downhole drilling. The problem is relevant for drilling organizations and individual drillers who want to make an inexpensive, high-quality filter with high characteristics and parameters that are most suitable for a specific well (depth, soil composition).

Gravel

To install a gravel filter with your own hands, proceed as follows:

- First, the size of the gravel backfill is selected taking into account the granulometric composition of the aquifer sand. To do this, contaminated water is removed to the surface, and after it is filtered, the size of the sand particles is determined.

- The gravel fill should have a granule size approximately 8 times the minimum diameter of the sand particles or 5 times their maximum diameter. For example, if the dimensional parameters of aquifer sand are 0.5 - 1 mm, the backfill should have dimensions of 4 - 5 mm, with sand grains 0.25 - 0.5 mm. gravel sizes are 2 - 2.5 mm.

- The gravel fraction selected by size is immersed in the well bottom using the free-fall method in a water flow; its minimum thickness is 50 mm.

- Multi-layer backfilling is allowed, starting with larger fractions and moving on to small particles.

Rice. 11 Sprinkling the casing

Hole filter for perforated well

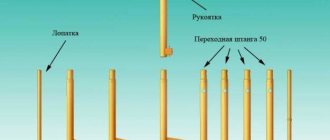

You can make a perforated filter yourself without much effort if you have a simple tool (a drill with a suitable drill bit). When installing a perforated filter from 125 HDPE casing pipe, proceed as follows:

- Markings are made, noting the distance from the bottom plug to the end of the sump about 50 cm, the length of the filter part with perforation is 110 cm.

- Draw 4 equally spaced lines along the pipe, drill 4 rows of holes with a diameter of 20 - 22 mm. with a feather drill for wood - they need to be done in a checkerboard pattern. The distance between them should be about 10 cm.

- The burrs formed during the drilling process are cleaned with sandpaper, or they can be scorched with a gas torch.

If the depth of the source is small, the number of holes can be increased to 8 rows, and also holes can be made for almost the entire length of a 3-meter pipe, their number will be about 20 - 25 pieces in a row.

Rice. 12 DIY holey filter

Slotted

The manufacture of a slot filter is rarely carried out independently - the process is labor-intensive and time-consuming. When installing it, proceed as follows:

- Make markings along the pipe surface, dividing it into 8 equal-sized sectors, drawing 8 lines and retreating 50 cm from the ends.

- To cut slots, take a grinder with a disc for metal or concrete, but it should be taken into account that the slots from the disc for metal will have a smaller width.

- Cutting is done in increments of 10 mm. by the width of the sector between two lines, alternating free longitudinal sections with cut ones. In this case, stiffening ribs 20 mm wide are left between the slots. after 10 - 20 lines.

- After cutting out 4 longitudinal segments with slotted areas, their surface is cleaned of burrs with sandpaper.

Rice. 13 Plastic pipe with slots

The principle of choosing a system for a private home and cottage

Before becoming suitable for drinking, water often goes through several stages of purification.

Filters are selected based on the specific conditions of the well and the composition of impurities:

- Crushed stone and pebbles of large fraction (2-5 cm). A tubular filter with a slot base will be required.

- Gravel and pebble rock. A slotted structure with longitudinal perforation and a coating of coarse mesh will perform well.

- Sand and fine gravel (up to 1 cm). Option with a slot base. The quality of filtration will improve if you add a wire winding to the filter.

- Loose aquifers prone to collapse. The best option is perforated and slotted structures.

After mechanical cleaning comes the turn of fine cleaning, for which complex water purification systems are used for private homes and cottages.

They are selected based on an analysis of the water composition, which can determine the following impurities:

- Iron and manganese. When deferrization and demanganization, the principle of aeration is used. The water is saturated with oxygen, and the reagents accelerate the oxidation reaction. As a result, the metals are oxidized, precipitated and filtered out. There is an alternative option - reagent-free devices that use the principle of electrolysis. The water is additionally deprived of hydrogen sulfide, carbon dioxide and methane.

- Lime. To soften water (get rid of hardness salts), ion exchange filters are used. They improve quality by replacing calcium and magnesium ions with sodium ions.

- Hydrogen sulfide and chlorine. The carbon filter actively absorbs not only dissolved chlorine and hydrogen sulfide, but also organic and mechanical impurities. After purification, the water acquires a pleasant taste and clarity.

Attention. A reverse osmosis system is best suited for removing nitrates and pesticides, and ultraviolet filters are used for disinfecting bacteria and other organic matter. The decision on the number and types of filtration systems is made based on the following factors:

The decision on the number and types of filtration systems is made based on the following factors:

- Compliance with pumping equipment performance parameters.

- Intensity of operation of the water supply system. Water consumption will depend on the number of residents and the variety of household appliances. For a cottage and country house, it is recommended to purchase a system “with a reserve” of performance - water flow rate.

- Frequency of use. For a dacha where the owners visit periodically, it is more practical to purchase a budget option. A storage tank or an additional pump may be useful.

It is worth paying attention to the subtleties of service and finding out before purchasing such details as the cost of adjusting and cleaning the system, replacing consumables and components

Stationary filter device consisting of three flasks

Now let's figure out how to make an effective filter yourself to connect it directly to the system. For these purposes, we will need three flasks with the same geometric parameters into which we need to place the filler.

From containers prepared in this way, we will make a productive stationary filter for purifying tap water, guided by the following diagram:

- Take two 1/4 inch adapter nipples. Use them to connect all three flasks into one structure.

- Seal the joints of the nipples (their threads) with fluoroplastic sealing tape (the so-called FUM material).

- Using straight adapters, connect the 1/4-inch holes of the two outer flasks to the tube.

- Cut the prepared filter into the pipeline (you will need a half-inch connector and a tee).

- Connect a regular water tap to the filter outlet tube.

High-quality water in modern conditions, especially drinking water, is a very rare occurrence. If several decades ago there were still clean springs and wells, now they are very rare even in rural areas. Agricultural companies pollute the soil no less than industry and herbicides. Mineral fertilizers inevitably penetrate into the sources. Water filtration has become a necessity.

Jug-type installations have become frequent guests in kitchens in the city and in the country. They are effective for small volumes of liquid. But if you need to clean tens or hundreds of liters, such devices are unsuitable. When there is a well, borehole, or swimming pool on the property, water filters are necessary. You can buy ones designed for these purposes, but those made by yourself are always cheaper.

Video description

Reverse osmosis fights not only impurities, but also odors, as the following video confirms:

Systems are usually installed directly under the sink. A separate tap is used to supply drinking water. Replacement of the membrane and backfill must be carried out at specified intervals.

Purified water is close to distilledSource thewalls.ru