In the modern world, more and more attention is paid to sanitary standards, both at the industrial and household levels. One of the latest useful developments in the field of plumbing services is septic tanks, which replaced cesspools. Therefore, I propose to consider how to make an aerator for a septic tank with your own hands - this is directly related to the possibility of the functioning of aerobic bacteria.

Aerator for septic tank

For a country house, the efficient functioning of the wastewater system is very important.

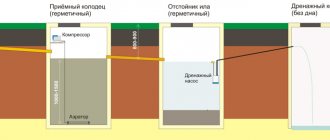

A sump tank is used to clean wastewater from private houses. The best option is to use a sump with a forced aeration function. For this device to work, you will need a special device - an aerator.

Purpose

Why is it needed? To do this, we will consider the processes of purification of drainage masses in the sump structure. A septic tank can have one, two or three compartments.

The operating principle of all sedimentation tanks is similar. In fact, everything is represented by an ordinary sealed container with the cleaning processes of the drainage masses occurring inside. Contaminated liquid from your home is pumped into it, processed and initially purified.

A septic tank made of concrete rings can also vary in size. So, one- and two-chamber septic tanks hold different volumes of wastewater. Whatever design is used, the purification property of the septic tank lies in the internal process that occurs, because of which the wastewater is purified.

Bacteria living in the sump trap the pollutants. Thus, due to the activity of microorganisms, biological purification takes place. Microorganisms decompose organic matter into liquid and insoluble sediment - silt. As a result, all harmful elements fall to the bottom of the sump.

These devices contain 2 types of bacteria - aerobic, which require oxygen to maintain life, and anaerobic, which do not need it.

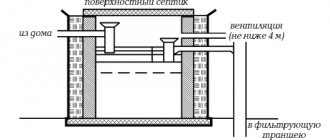

Ventilation of the sump is necessary because these bacteria produce toxic gases.

The settling tank must have a ventilation system, since anaerobic bacteria release ha and, as a result, an unpleasant odor.

Conventional energy-dependent installations are designed in such a way that cleaning processes occur due to anaerobic microorganisms. But they do not completely decompose organic matter, and they also act rather slowly.

For better wastewater treatment, a biological treatment method is used, which occurs using forced aeration. Aeration is the forced supply of oxygen under pressure. Aerobic installations of new production already have an aerator. If you have a simple sump built a long time ago, then it can be improved by using additional equipment.

Simple settling tanks are equipped with vent pipes to allow gases from decomposed organic compounds to escape. But this type of system will not be able to create the volume of air you need in the tank.

The normal operation of a septic tank depends, in addition to ventilation, also on oxygen saturation. And if your task is to benefit the sump, then you need to provide properly functioning aeration and ventilation to remove toxic gases retained in it.

Therefore, a ventilation pipe is built into the septic tank, the function of which is to remove these gases using pressure. An important point is that the pipe must be at least half a meter above the ground. This helps to remove all toxic elements that cause harm and clog the sump.

And to do the job you will need an aerator. This device is installed on the bottom of the container, provides internal ventilation and, accordingly, air ingress. The treated oxygen is removed through the normal ventilation system.

Principle of operation

The aeration element in the sewer system serves as a distributor of air masses. Better wastewater treatment occurs due to fine aeration. This is when oxygen enters liquid masses in small bubbles.

The principle of operation is that the aerator has many tiny holes through which oxygen passes, supplied by the compressor. Oxygen passes through the aerator and forms many bubbles that are distributed throughout the liquid. The environment is saturated with air due to the fact that, according to the law of physics, oxygen bubbles tend upward, and a cleansing process occurs.

The active biological mass is mixed with contaminated water, which ensures complete water purification. During the cleaning process, no unpleasant-smelling gases are released and the operation of the septic tank does not create uncomfortable conditions for residents.

A septic tank can also have intermittent aeration. But you need to take into account the nuance that at the moment when air does not flow, the holes must be in the closed position, otherwise silt particles may enter the device.

Types of devices for the cleaning system

Membrane compressors for septic tanks are considered more popular devices

Manufacturers offer two types of devices: screw and membrane compressors for septic tanks.

A screw compressor for a septic tank is a device equipped with two rotors, which, through rotation, pump air masses into the chamber. Due to its small dimensions, the aeration unit is indicated for use in tanks with limited volume. During operation, the aerator makes virtually no noise and is also economical in energy consumption.

Important! The screw aerator into the sump can be dry compression and low-fill. Such models are not often used in household devices, as they are large in size and require frequent maintenance.

Membrane compressors for septic tanks are considered more popular devices. Ease of operation, minimal maintenance requirements, economical energy consumption, and affordable prices are clear advantages that the aerator has. The air flow in the devices is forced by the movements of the membrane, which operates from the movements of a piston connected to a hydraulic drive structure.

Important! A membrane-type aeration unit is considered more practical to use and has an extremely low noise threshold, which allows the use of membrane compressors for a septic tank in conditions close to home ownership.

Aerator for sewerage

Types and design of aerators

You can buy a ready-made aerator or you can equip it yourself. It must be resistant to corrosion as it operates in a hostile environment. It must also be reliable because it is mainly installed at the bottom of the septic tank and replacing it is not the easiest solution. Its operation should not be accompanied by constant noise, which will naturally irritate those living in the house.

Aerators can be tubular or disc shaped. The tubular model is the simplest option.

The tubular device has positive qualities:

- are flexible;

- long service life;

- minimal likelihood that the holes may become clogged;

- it has a function for maintaining the supplied pressure;

- distributes oxygen evenly throughout the medium; The material is resistant to mold formations.

The disk model is no less convenient to use.

Disk device properties:

- very durable and reliable;

- has no connection, i.e. has structural integrity;

- easy installation;

- resistant to corrosion formations;

- has maintainability;

- there is no risk that water or dirt may get into the device;

- slight decrease in pressure;

- it can be used in high-performance systems.

Making your own aerator

You can modify a conventional septic tank, manufacture and install an aerator installation yourself. This is not difficult and even an inexperienced master can do it. Moreover, there are a lot of training videos on the Internet.

Manufacturing principle of a tubular aerator

Manufacturing principle of a tubular aerator:

- The base is taken. A one or two meter pipe, fifty centimeters in diameter, is suitable for this, depending on the volume of the container;

A plug is placed at one pipe end;- The other side is equipped with a pipe for connecting the pipe and the compressor hose;

- From 200 to four hundred holes are drilled into the pipe, always of the same size and equally spaced around the entire perimeter. This is necessary to ensure complete air exchange.

- The aerator is installed in chamber 2 of the settling tank, where wastewater, already purified from large masses of wastewater that settles at the bottom of the primary compartment, enters.

Is it worth carrying out this modification at all? What does this aeration give? Installing an aerator, firstly, significantly reduces wastewater processing time and improves the quality of treatment.

It is possible to reduce the volume of the septic tank by reducing the time while maintaining the same productivity.

The presence of this device eliminates bad odors that appear in anaerobic settling tanks. This will significantly reduce costs for sewage disposal services, and it also eliminates contamination of water and soil with sewage.

To summarize, we find that thanks to the aerator system in the settling tank, the environment is saturated with oxygen, which promotes the favorable existence of aerobic bacteria. Upgrading the septic tank with this installation and compressor significantly increases the efficient operation of the treatment device and eliminates unpleasant odors.

Equipment features and recommendations for selection

The main task of compressors for a septic tank is to supply air masses into the chambers

It is important to note that the devices only work when power is supplied. The main task of compressors for a septic tank is to supply air masses into the chambers, which means that the selection of models depends on the volume of the tank: in large settling tanks it is better to install several aeration devices. Such a system will allow for more thorough wastewater treatment. Most often, the system is equipped with a compressor in the septic tank, and this is a device built into the pump complex, the installation of which is not required separately.

When choosing a device for a sump tank, you need to pay attention to the following parameters:

- settling;

- fermentation;

- aerobic decomposition.

The flawless operation of the settling tank depends on compliance with these parameters. And if the first two indicators are carried out in a sealed chamber, then for the latter you need an air aerator, otherwise - a compressor for equipping septic tanks. If you immediately purchased a septic tank that does not have a compressor, then it is quite possible to retrofit the system by choosing a device based on such indicators as:

- reliability;

- resistance to aggressive environments, since compressors for septic tanks work with biological waste;

- resistance to corrosion;

- long service life;

- sufficient power;

- low noise threshold.

Expensive equipment for a sump pump in a country house will not be entirely appropriate, especially if the system is used only in the summer, so the price of the device is also important. As for the power of the device, the aerator must ensure the normal functioning of bacteria, therefore both increased and decreased oxygen supply is harmful.

The most popular models are devices from Japan. Distinguished by their versatility, Japanese compressors for septic tanks come in single and double versions. These membrane aeration systems have low energy consumption and are equipped with a silencer chamber, which allows the devices to operate extremely quietly and without pulsation. Some Hiblow brand models have a magnetic core, so such compressors for household septic tanks are installed even for home systems. The complete absence of moving parts in the equipment and the moisture-proof housing are also advantages, since the device wears out significantly less during operation and can be placed in a humid environment.

DIY septic tank aerator

An important factor in home improvement is autonomous sewerage. The use of a septic tank in solving this issue simplified the maintenance of the system. The purpose of the structure is to purify sewage wastewater for further infusion into the soil. Inside the septic tank, a fermentation process occurs based on special bacteria. Some of them exist due to air. They are called aerobic bacteria. Other bacteria are anaerobic and do not depend on the influence of external factors. That is, they do not require access to air.

Particles that require air release a large volume of harmful gases that must be removed from the septic tank chambers to avoid accumulation. To ensure proper operation of the entire system, aeration and ventilation processes are organized.

Why is an aerator needed in the cleaning system?

It is this element that provides air supply inside the cleaning chamber, which increases the activity of microorganism colonies

The design of the water purification system is aimed at processing and purifying waste sewer streams from accumulations. The structure consists of a tank containing:

- pump;

- compressor for septic tank;

- piping system.

It’s clear why pumps and pipes are needed, but compressors for septic tanks raise questions. But it is this element that provides air supply inside the cleaning chamber, which helps to increase the activity of colonies of microorganisms responsible for processing and decomposing waste. Compressors for septic tanks, as shown in the video, force air masses inside, accelerating the process of dissolving biological accumulations.

Aerator for a septic tank - technology of the aeration process

Aeration is the release of oxygen under pressure. Translated from Greek, this word means ventilation. With aeration, air comes into contact with liquid, providing biological balance. The issue of environmental pollution, in this case soil, is very important.

A processed human waste product that has undergone aeration is safe for the soil and crops growing on it. In stagnant water, harmful substances accumulate and settle to the bottom. The aeration process prevents this from happening. Due to the saturation of wastewater with harmful chemical elements, an unpleasant odor is formed and its color changes. The aeration process in a septic tank breaks down harmful impurities and brings them to the surface. Further, through the ventilation system they enter the environment. To ensure proper operation of the septic tank, the issue of installing an aerator is resolved. They come in tubular and disk shapes. The presence of ventilation pipes is also mandatory. Harmful gases under pressure are released into the environment precisely with the help of these means.

The aerator for a septic tank serves as a distributor of air supplied by the compressor to the total amount of liquid. They come in several types. The most effective is finely dispersed. In saving plans, the aerator is made independently. But before that, you need to understand how the device works.

The aerator is a tube sealed at one end. Its surface is covered with a large number of through holes. The other end is connected to the hose. The compressor produces a volume of oxygen and pushes it through a tube to the aerator. Oxygen bubbles form in the waste liquid.

The air saturation of the waste increases and reaches a certain level, which depends on the size of the septic tank and the power of the compressor. According to Archimedes' law, oxygen is pushed to the surface of the water. It, along with harmful gases, is released through the ventilation system into the environment. According to these examples of the technology of the device manufacturing process, you can make an aerator for a septic tank with your own hands.

Aerator for septic tank - making at home

Aerators, like other mechanisms for septic tanks, are expensive. Creating it with your own hands will not take much time and effort. The manufacture of the aerator occurs in stages: 1. Take a plastic pipe 1-2 meters long and 0.05 m in diameter. 2. One end is sealed or clogged with a plug 3. The other end is connected to the compressor hose. 4. 200 holes of the same diameter are drilled in the pipe. Arrangement at the same distance from each other along the entire length of the aerator will give the desired effect.

Turning on the compressor to check the operation of the device The resulting device is perfect for a septic tank made of concrete rings. The quality of oxygen saturation of wastewater with a homemade aerator will differ from its expensive counterpart. For home use, air distribution throughout the volume of liquid is sufficient. Aerobic bacteria help increase the rate of waste liquid decomposition. This increases the productivity of the structure.

Disk devices are more difficult to make yourself. This is due to a number of positive properties of the aerator. Materials used to manufacture the disk device, allowing its use in aggressive environments. Liquid does not penetrate into the aerator. Complete tightness allows it to be used for servicing septic tanks. The pipes are also soldered to each other, placing the device along all the walls of the chamber.

Providing the liquid with oxygen will occur more quickly and evenly. In terms of its properties, the design will be comparable to a disk type or a pond aerator. Buying one of these will cost a pretty penny. A homemade analogue will not allow you to take advantage of all the properties of the purchased version, but it will cope with the main task. The waste liquid, under the influence of oxygen and aerobic bacteria, is more likely to be processed and becomes safe for the environment. This form of aerator is suitable only for straight-shaped septic tanks.

A concrete ring, as a building material for a septic tank, serves as a support for a home-made device of an oblong shape of short length. There is no threat to the condition of the soil saturated with wastewater. In the place where the water is released, various crops can be grown and eaten. These measures are only possible with a well-functioning septic tank aeration system. Using homemade materials does not give such an effect, so it is better to use high-quality branded products.

Positive factors of the operation of an aerator in a septic tank A septic tank with aeration does its job efficiently. In case of repair, this part can easily be replaced with the same one or purchased one. The use of a tubular aerator has positive aspects: • formation of a large number of bubbles; • high-quality durable material; • unlimited service life; • protection against contamination of holes; • constant level of air pressure; • high productivity of holes; • rapid saturation of the liquid volume with oxygen; • the ability to stop and regulate the flow of oxygen; • closing the holes to prevent liquid from entering the pipe; • the aerator material is not prone to the formation of fungal deposits on its surface.

The aerator time is only available on purchased models. It is difficult to make such protection on your own. To work in an aerobic septic tank, a homemade device is installed in the last chamber before the liquid is discharged. The distance from the bottom is 40-50 cm. The aerator will serve its service life efficiently. The plastic does not decompose and is ready for a hundred years of use. Replacing the compressor and other parts with new ones requires periodicity. The aerator only needs to cleanse the pores. The homemade device makes full use of its design features. Plastic as a material is very reliable and durable, and it does not corrode. When connecting to a hose, only one connection is used. This allows you to quickly install the aerator on the surface of the septic tank wall.

Dependence of the operation of the aerator on the power of the compressor The market for compressors for providing air to a septic tank is large. They all differ in their operating principles and performance. It is necessary to select the right aerator for the compressor power. The efficiency of septic tank aeration depends on this. Manufacturers indicate compressor performance for its use in vessels of the appropriate displacement. Compliance with this point is an important factor in the proper provision of oxygen to the sewer site.

Compressors are divided into screw and piston. The use of some piston devices has not found popularity in working with a septic tank due to its large size, loud engine operation and high price. Such devices are called dynamic. Screw and membrane compressors are suitable for use in septic tanks. Excessive pressure of such is pumped at low performance indicators.

Diaphragm compressors are ideal for supplying air to the aerator. Using a homemade tube or a purchased copy, units of this type are capable of enriching up to 120 liters of liquid with oxygen in 1 minute. Aerator sizing is important to ensure maximum system performance. If this fact is not taken into account, the bacteria will not receive the amount of oxygen necessary for their existence and the quality of the septic tank will be impaired.

What to consider when choosing

The effective operation of colonies of aerobic microorganisms depends on their stable supply of oxygen in the required quantities. Therefore, the main selection criteria are performance and pressure generated by the device.

The amount of pressure determines whether the air in the aerator can overcome the resistance of the liquid column and rise to the surface. The deeper the sump tank, the greater the outlet pressure the device must create. Most septic tanks have a depth of up to 2 m. They are equipped with compressors with a pressure range of 2-2.5 atm.

Productivity - the volume of air pumped per unit of time - depends on the power of the device. It becomes a determining factor in the productive treatment of wastewater by bacteria.

Remember! The active life of aerobic microorganisms is equally adversely affected by a lack and excess of oxygen concentration in water.

The volume of the tanks (with the exception of the volume of the first chamber with heavy waste, which contains anaerobic microorganisms) affects the required productivity of the device. For example, for containers of 2-3 m3 and 4 m3, blowers with a capacity of 60 l/min and 80 l/min, respectively, are suitable. The use of a more productive model will require the introduction of automation into the operating circuit to periodically stop the air injection process. This mode will reduce the durability of the device.

Aerator for a septic tank: device and principle of operation, do-it-yourself manual

Recently, a lot of people wanted to equip their dachas and houses outside the city as best as possible.

Well, of course, if you are building a house outside the city, then sewerage becomes one of the key issues in this difficult matter.

Fortunately, especially for such masters of arrangement, in recent years, more and more information and methods for solving this very simple task have appeared. And, of course, to create a normal and good sewage system, if it is naturally not a dry closet in the yard, you will need to understand structures created in the likeness of septic tanks.

Types of equipment

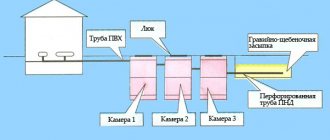

All septic tanks represent the same thing, although they are divided into:

- single-chamber;

- two-chamber;

- three-chamber.

And, in fact, they are an ordinary container, impenetrable both from the inside and the outside. Contaminated water from your dacha is pumped there and processed to purify it at the primary level.

Just according to the above-mentioned chambers, and septic tanks are also distinguished by size. So single-chamber and double-chamber can accommodate different numbers of drains. But whatever the design, the treatment properties still depend on the processes that occur inside the septic tanks, and with the help of which the wastewater is cleaned.

What are the disadvantages of aeration plants?

- Quite a high cost, especially for high-quality products.

- Relative complexity of the design: there are moving elements.

- Energy dependence. Although the energy consumption for VOC operation is relatively small, when the power is turned off, the installation quickly ceases to function normally.

- Unstable work under the condition of non-permanent residence in the house, which means uneven flow of wastewater.

- The need to preserve the installation for the winter if you do not intend to live in the house at this time of year.

- VOCs require regular maintenance (often 3-4 times a year), which can be a hassle for homeowners.

- Compared to septic tanks, aeration systems are not as “omnivorous”: there are serious restrictions on what can be discharged into the sewer. Most often, you cannot dispose of leftover vegetables and fruits, spoiled food, construction waste, filter rinses, large amounts of wastewater containing chlorine-containing products, etc. There, however, you can throw toilet paper, kitchen drains, and drains from dishwashers or washing machines there.

Sergey ShemaevCEO

When preserving an aeration plant for the winter, it is strictly forbidden to pump water out of it, otherwise the station may be deformed or squeezed out onto the surface of the earth. To avoid this, be sure to leave the unit filled with clean water.

How does cleaning happen?

Wastewater is purified due to the biologically active substances it contains.

It is these microorganisms that live in septic tanks that feed on all such pollutants.

Ultimately, everything that can harm you flies out in the form of sediment and simply falls to the bottom of the septic tank, like ordinary neutral sludge.

At the same time, there are two types of organisms in such devices:

- aerobic - those that need air to function and survive inside the septic tank;

- anaerobic - those that do not need air at all, and they can quite easily perform their functions without ventilation of the room.

Compressors: types, performance, the right choice

In the device, gases are compressed and supplied under pressure. The process takes place in a special chamber where the air is retained and then released outside.

principle of operation of a compressor for aeration. Some installations also provide additional devices, such as an intercooler-cooler or an air dryer. Purchasing them for the purpose of modernization, however, will be a waste of money. There are volumetric units that increase gas pressure, reducing its volume. These include piston and rotary mechanisms, which differ from each other in the principle of gas injection into the chamber. In the first case, the pressure arises due to the piston movement, and in the second - due to the screw block. Among piston compressors, the membrane type stands out. Its main advantage is the ability to pump pressure even at low productivity. The piston supplies air directly to the diaphragm or crank mechanism. In this case, the membrane is progressively displaced, and the air in the chamber of the device is compressed. The dynamic view involves the injection of air, due to an increase in speed and conversion to a higher pressure. Such devices are represented in most cases by centrifugal options, among which there are axial and radial ones. However, they are too big, noisy and expensive. Therefore, they are almost never used for septic tanks. For autonomous cleaning or a post-treatment system, the best option is a membrane-type device, a mini-compressor. It is inexpensive and works quietly. You can also choose screw compressors, but not dry compression, as they are too large and require special care. The performance of the unit depends on its type. For septic tanks with a volume of two to three cubic meters, a compressor with a capacity of sixty liters per minute is suitable:

- for devices with a volume of four cubic meters - a capacity of eighty liters per minute;

- for six cubic meters - one hundred and twenty liters per minute.

Septic tanks with biofilter: design, types, principle of operation

Such devices, as a rule, are most suitable for small areas where it is not possible to allocate space for filtration fields.

design of a septic tank with a pre-installed biofilter. A septic tank with a biofilter consists of:

- a septic chamber where waste enters;

- a secondary settling tank or intermediate chamber, where the wastewater is cleared of small inclusions;

- the third chamber, where a biofilter is installed, thanks to which entire colonies of special microorganisms multiply.

In the production of devices, an inert material is usually used, for example, granular polymer, expanded clay, a mesh of plastic or polymer bristles. Subsequently, special bacteria are settled in the appropriate chamber. As a result of their work, layers of silt gradually accumulate. Therefore, it is advisable to regularly pump out and flush the septic tank so that the operation remains uninterrupted for a long time.

At its core, a biofilter is a filtration field, but it has compact dimensions, where bacteria are located throughout the entire volume, and not just in the top layer of soil, as in filtration fields.

Biofilters are aerobic and anaerobic. In the first case, good ventilation is necessary, and in the second, a sealed container is required. They can be dry or wet loaded. In the first option, cleaning liquid is constantly supplied to the biofilter, and in the second, it fills the biofilter completely. The advantages of these devices are:

- no restrictions in use;

- compact dimensions of the device;

- ease of installation;

- offline mode;

- no unpleasant odors.

Among the disadvantages are:

- higher cost compared to simpler designs;

- very careful use of the sewer, without throwing food debris, cotton swabs, hair, etc. into it;

- regular addition of biological bacteria;

- constant operation of the sewer system without downtime, that is, permanent residence in a country house.

Do-it-yourself biofilter for a septic tank

A video demonstrating the design of this device can be easily found on the Internet.

self-installation of a cleaning system for a septic tank For a conventional septic tank, you can make a biofilter yourself. The workflow briefly consists of the following steps:

- the foundation pit is being prepared;

- when using a ready-made plastic container, it is additionally attached to the reinforced concrete bottom;

- if a monolithic structure is being made, then formwork is first built in several layers;

- the prepared pit is filled with expanded clay or other prepared material;

- the structure is filled up;

- then a ceiling is installed on the well, which must be equipped with a ventilation system;

- the lid is insulated, for example, using polystyrene foam;

- From the biofilter, an outlet is arranged into a ditch or storage well.

With the help of this device, the quality of sewage treatment increases significantly and the need to install filtration fields disappears.

The aerator is a tube sealed at one end. Its surface is covered with a large number of through holes. The other end is connected to the hose. The compressor produces a volume of oxygen and pushes it through a tube to the aerator. Oxygen bubbles form in the waste liquid.

Why is ventilation needed?

In addition to the fact that these organisms cannot survive on their own, without ventilation, they also emit toxic compounds of various gases, which simply must be removed from the filter.

Thus, not only ventilation is necessary, but also aeration (oxygen saturation) of the septic tank.

Therefore, if you want your septic tank to be useful and function normally, then it is in your hands to provide it with normal aeration and ventilation of all those toxic substances that are retained in it.

For this purpose, septic tanks are often equipped with ventilation pipes, which, under pressure, remove all these gases to the outside. Moreover, it is very important that such a pipe is at least 0.5 meters above the ground.

Such ventilation allows you to remove all those substances that can harm you and clog the septic tank. Well, in order for the septic tank to function normally, it is necessary to use aerators.

Read an article on how to choose a septic tank for a private home here.

Types and characteristics of used superchargers

The work process of compressing and moving air is ensured by periodically changing the internal volume of the device chamber. The principle of oxygen injection is decisive when dividing compressors into types.

Screw

The working pair consists of two rotors with multidirectional profiles of their surfaces, reminiscent of a meat grinder screw. The meshing rotors rotate in a sealed chamber and compress the incoming air by sealing the gaps between the housing and the screw pair. Then the exhaust valve opens, and air is briefly released to the compressor outlet. The valve setting, the frequency of the profile turns and the area of the teeth determine the frequency of air discharge and the amount of air pressure. Advantages of screw designs:

- Durability of working screws made of high-strength steel.

- Economical energy consumption.

- Work with minimal vibration.

- Small dimensions.

- Good controllability of automatic systems.

- High price.

- If there is a breakdown inside the sealed chamber, the entire device is replaced.

- Dependence of efficiency on the gaps between screw rotors.

Membrane

The operation of the device is ensured by vibrations of the membrane with fixed edges. Its reciprocating movements are provided by an armature, which is under the influence of the magnetic field of an electric coil, or by a hydraulic piston. Two valves are located above the membrane. When it moves down, the inlet valve opens and the working chamber is filled with air. When the membrane moves back, the inlet valve closes, the compressed air opens the outlet and is pushed out to the outlet pipe. The popularity of the devices is explained by the following advantages:

- Economy.

- Easy to operate and maintain.

- Low price.

- Quiet operation.

- Resistance to the aggressive environment of treatment facilities.

- Compactness of compressors with an electromagnet.

- The need to frequently replace a membrane that has lost its elasticity.

- Low compression ratio. True, large values of this parameter are not needed for the aerator to operate.

Piston

In the working chamber of the product, alternating compression and rarefaction of the air above the piston occurs. The reciprocating movements of the working body and the activation of the corresponding valves ensure the movement of air from the inlet to the outlet pipe. The advantages of piston blowers - simplicity of design, low price, ease of maintenance - are lost against the list of disadvantages:

- Noisy work.

- Low reliability.

- Increased electricity consumption.

- Low efficiency.

- Increased vibration during device operation.

The use of piston units in septic tank designs is extremely rare. Important! Diaphragm and screw type devices can operate continuously, while piston type devices require periodic stops to prevent overheating.

Centrifugal

The electric motor imparts rotation to the rotor with blades. By centrifugal forces, the air is thrown towards the walls of the housing and forced towards the exhaust pipe. Installations of the presented type are in demand in industrial sectors due to their good performance and ability to pump high pressure. For septic tanks, such indicators are unnecessary. Therefore, centrifugal blowers are not used in autonomous treatment structures.

These devices are highly reliable, their productivity can reach 200 l/min, but there are also less powerful models that are suitable for conventional septic tanks.

How does the aeration process occur?

Aerators are used to distribute the oxygen that the compressor can supply to the total volume of water.

And it is in septic tanks that it is used most often.

Well, if we consider various types of aeration, from the point of view of efficiency, then the most effective is aeration with fine bubbles.

But if you want, for example, to save money, then it is not always necessary to buy a professional aerator for yourself; no one is stopping you from making it yourself. To do this, we need to understand from the very beginning how aerators work.

More information about what type of unit to purchase

When choosing a compressor for a septic tank, you should know that these units are necessary to increase gas pressure, which occurs by reducing its volume. Installations operating on this principle can be screw or piston. They differ from each other in the principle of forcing gas inside. For example, piston ones provide pressure through the movement of the pistons; As for the screw ones, they work due to the block with the appropriate name. Some believe that it is worth choosing the second type, because such devices are more compact, durable and have a low level of vibration. Looking at piston devices in more detail, you can highlight one of their varieties - an electromagnetic membrane compressor for a septic tank. Such devices are also called diaphragm devices; they are intended for local sewage. Their main advantage is the ability to pump up pressure at low productivity. The principle of operation of such devices is as follows: by making reciprocating movements, the magnetic core moves in the electromagnetic field and activates the diaphragms, which are responsible for pumping air. On sale you can also find dynamic models that provide air injection with an increase in its speed and conversion into outlet pressure. When considering dynamic devices, you can highlight centrifugal ones, since they are the most common. They can be classified into axial and radial. These units are chosen less frequently because they are expensive, their operation is accompanied by a high noise level, and in addition, they are quite bulky. Such units are rarely considered as an aerator for a septic tank.

These devices contain 2 types of bacteria - aerobic, which require oxygen to maintain life, and anaerobic, which do not need it.

What is the operating principle of the device

Scheme of operation of a septic tank with an aerator. (Click to enlarge) On what principles does the aerator work:

- Under strong pressure, oxygen is pumped through any perforated materials that have a large number of pores.

- Because of this, a large number of oxygen bubbles begin to form in the liquid.

- They, in turn, begin to move under the force of Archimedes towards the water surface.

- The water begins to gradually become saturated with air.

- The air stops supplying as unnecessary.

- And after completing the entire oxygen saturation process, the pores close to prevent the entry of foreign bodies.

With such a simple diagram, it is quite easy to make an aerator yourself.

Read an article on how to make a septic tank from a Eurocube with your own hands here.

After reading this article, you will learn about the benefits of using sewage pumping stations.

Popular brands

Biological treatment plants of many domestic manufacturers are equipped with an installed air compressor. With rare exceptions, these are membrane-type models from Japanese brands Secoh and Hiblow. The specialization of both companies is the production of power plants and units using innovative technologies. Thanks to constant updating and improvement of design, brand products are distinguished by stable quality, reliability, and reasonable prices.

Secoh models are distinguished by:

- Low power consumption.

- Minimal pulsation with continuous air supply.

- Silencer chamber provided by design.

- Light weight.

- Compact.

- Waterproof housing.

- No overheating during long-term uninterrupted operation.

- Easy to maintain without professional training.

Characteristics of the well-known model EL-60: air flow - 60 l/min, maximum pressure - 2.5 atm, power consumption - 42 W, noise level - 33 dB, dimensions - 268.5x201x216 mm, weight - 8.5 kg. Options of higher power, without a significant increase in size, are obtained by integrating two compressors into a single housing.

The Hiblow HP-60 model of the same performance is characterized by the following parameters: pressure - 1.47 atm, power - 51 W, noise - 35 dB, dimensions - 280x190x171 mm, weight - 7 kg.

Compressor equipment from the following manufacturers also deserves attention: Friess and Thomas (Germany), Faggiolati and Doseuro (Italy), Matala (Taiwan), Hydrig (Russia).

Self-production

As a rule, aeration of septic tanks, if you do not want to buy expensive aerators, occurs according to this type:

- A PVC pipe is purchased, all the same as described above, 0.05 m in diameter. And in length, about one or two meters.

- A plug is inserted into one end of the pipe and a hose into the other to supply air.

- Thus, we get a homemade aerator, but in addition to this, as we remember, numerous holes are needed. They are drilled into a pipe from two hundred to three hundred, and it is very important that they are distributed evenly over the entire surface and have a diameter of two millimeters.

- And after this, oxygen is supplied to the resulting perforated material under pressure.

Watch the video in which the user shares his experience of maintaining a septic tank aerator with his own hands:

Operating rules

The impeccable functionality of compressors for septic tanks depends on the correct operation of the system

The impeccable functionality of septic tank compressors depends on the correct operation of the system. Here are some tips from the professionals:

- a membrane compressor in a septic tank can operate for no more than two years, then you need to replace the membrane and start the equipment again;

- the entire structure is in operation for an average of 15-17 years, the period depends on the intensity of work;

- When acid, alcohol, or rotting waste enters the settling tank, the service life of the compressor is significantly reduced. The septic tank is enriched with beneficial bacteria, and the substances are destructive to colonies that multiply through the intake of air. This means that the compressor, pumping air into the septic tank, will run idle.

The efficiency of wastewater treatment depends on the reliable operation of the compressor for a septic tank system, so it is not recommended to make a compressor for a septic tank with your own hands. However, if necessary, you can take the device from a vacuum cleaner or refrigerator; a compressor is ideal for a septic tank, but the easiest way is to purchase exactly the required device to ensure uninterrupted operation of the entire system. And to understand even better the rules for choosing compressors for septic tanks, watch a video from professionals.

Homemade VOC from Eurocubes: high groundwater level, swamp

When the site has permeable soils and digs and digs down to groundwater, there are practically no problems with sewerage - septic tanks made of concrete rings cope with the task quite well. In conditions when the high water is practically spade-deep for part of the year, and in the best case scenario it is 1.5 meters away, everything is more complicated. Ready-made aeration units (AU) cost quite a lot for the average consumer, but homemade ones must be sealed - either plastic or made of monolithic reinforced concrete. A member of our portal with the nickname aazinus did not have any extra funds, and since the construction took place in winter, he chose to assemble his AU from used plastic Eurocubes. His experience will be useful to anyone who has a similar situation with water treatment plants and does not have the financial ability to purchase factory VOCs (local wastewater treatment plant).

Content:

- Initial conditions

- Materials and components

- Assembly and installation of a septic tank

- Installation operation

Conclusion

As Topicstarter notes, a homemade aeration unit is a workable option if there is no money for. Especially if there is a danger of compression from frost heaving. However, carefully thought out and implemented homemade products are effective even in harsh conditions. And whether to assemble a “constructor” or install a ready-made aeration unit – as usual, everyone chooses for themselves and on their own.

All the details about the construction and maintenance of a homemade power plant are in the author’s topic, where you can also find other examples of the construction of similar treatment facilities. When groundwater is far away, you can get by with a homemade septic tank made of reinforced concrete rings. The video shows the features of choosing and installing a factory septic tank.

Subscribe to our Telegram channelExclusive posts every week

Initial conditions

The house stands on a bolt, the floating foundation is a caisson until it leaks. High water: off-season – 30 cm; in summer - 70 cm, in drought, it went up to 1.5 meters. Five people live in the house, sometimes seven. It had to be done in winter. I refused to pour concrete. In addition, pouring concrete into a swamp requires good pumps for pumping. According to calculations, the volume of discharge is 7×150=1050 liters, in total – cubic meters. Safety factor (cleaning time) – 3.5 days. The volume of the septic tank (more correctly, local treatment station, VOC) is 3-3.5 m³.

After studying the forum, aazinus chose a design scheme with aeration:

- the first cube is a settling tank;

- the second is aerated;

- the third is aerated, but weaker, so that the sludge settles.

Materials and components

Topikstarter purchased Eurocubes cheaply - three pieces for two thousand rubles. Looking ahead, we can note that such a low price is associated with the specifics of the application - the containers were used for chemicals (raw materials for superglue), while food containers are much more expensive. The remaining contents were cleaned and disposed of (washed with gasoline/acetone/solvent on an iron tray, the drain was burned, the coals were packaged and thrown into the trash). In addition to the cubes, for a future installation aazinus bought:

- compressor made in China (3 thousand rubles);

- finely dispersed aeration elements (2 x 800 rubles);

- American load for bacteria (2 thousand rubles) - in fact, just a plastic mesh, but expensive, so I sawed it and made loads from plastic mesh for fences.

The rest of the additions - all that was left from the construction was insulation (EPS), and sewer pipes (110 mm), and other “small things”.

Assembly and installation of a septic tank

I cut out “windows” on the top of the Eurocubes, drilled holes for the pipes (inlet/outlet/overflow), inserted the pipes, secured them with sealant, first connected them with wire, then welded the connection to the frame of the containers. I installed the aerators on stainless steel and hung the loads in the second and third cubes. The cubes were insulated with EPS sheets as ballast between the wall and the cubes so that they would not float up during the installation process; I used sand and expired building mixture. Meanwhile, no one is talking about force majeure. I buried it, insulated it and left it until the next stage.

Modernization of the settling chamber

If the settling chamber is to be upgraded with a compressor, the septic tank is supplemented with an aeration tank

If the settling chamber is to be upgraded with a compressor, the septic tank is supplemented with an aeration tank. To do this you will need:

- determine the location for the new section;

- dig a hole where to install a container or concrete ring;

- install a homemade or purchased compressor made for a septic tank;

- Be sure to install a perforated pipe sealed at the bottom into the aeration tank.

Important! Such a pipe can be made from any suitable length. Drill holes, spacing them evenly and observe the appearance of air bubbles on the surface during startup - this means that the compressor installed for septic tanks is working normally.

By adding a mixing structure to the entire installation, it is possible to improve the distribution of masses so that the air flow flows evenly, this will improve the process of decomposition and recycling of accumulations. As a means of post-treatment, it would be a good idea to install an additional chamber where the wastewater will settle and be clarified.

DIY septic tank aerator

One of the most effective types of treatment facilities for a private home is a septic tank. This device not only accumulates, but also purifies water, making it suitable for technical needs. An aerator will help increase the efficiency of water purification. We will look at what it is and whether it is possible to make it yourself without spending additional money in this article.

The decomposition of organic human waste occurs due to two types of bacteria:

- Anaerobic bacteria can exist without access to oxygen. No additional stimulants for the action of these bacteria are required.

- Aerobic microorganisms require constant oxygen supply. It is for this type of bacteria that an aerator is needed in the septic tank.

As a standard, each septic tank is equipped with a tube for removing carbon dioxide, which inevitably forms as a result of the decomposition of organic substances. To provide the air level necessary for aerobic microbes, such a device is not enough, so an additional mechanism is needed - an aerator. The device is placed at the bottom of an autonomous sewage tank and provides the necessary air flow. The waste oxygen exits without interference through a conventional ventilation system.

An aerator in a water purification system is necessary to ensure that the air inside the autonomous sewerage tanks is distributed evenly. The most effective option for an aeration device is fine aeration. This means that oxygen enters the purification medium in the form of small bubbles. This way, the used water is filtered better.

Stages of operation of the aerator:

- The aerator receives air, which is supplied by a compressor.

- The air passes through many small holes in the aerator and creates a lot of bubbles.

- The bubbles rise to the top, thereby evenly distributing oxygen in the substance and speeding up the filtration process.

- Stopping air supply to the system.

There are two types of aeration devices: tubular and disk. Each of them has a number of advantages.

Advantages of tubular aerators:

- Made from flexible yet strong and durable material. It is very important to choose an aerator made of high-quality material, since replacing or repairing it if it breaks is quite problematic.

- The long operating period of the aerator significantly simplifies the operation and maintenance of the septic tank.

- The tubular design minimizes the possibility of clogging of the permeation membrane. Thus, the compressor is protected from pressure drops in the system.

- The use of tubular devices reduces the possibility of pressure reduction.

- The case material is resistant to mechanical damage, as well as to the effects of fungus and mold.

- The tubular aerator distributes oxygen evenly in the container.

Advantages of disc-shaped aerators:

- The monolithic design and the absence of any connections increases reliability.

- Ease of installation reduces material and maintenance costs.

- Made from durable material - the device works for many years

- Availability of a range of different diameters.

- Preventing the possibility of liquid getting inside the device.

- Ease of maintenance. If it breaks, you just need to replace the polymer film.

- Can be used in high performance systems.

It is quite possible to make an aeration device for a septic tank with your own hands. This is easy to implement and will reduce material costs when installing an autonomous sewer system.

You can make a simple aerator with your own hands in a few steps:

- You need to purchase a PVC pipe with a length of 1-2 m and a diameter of 5 cm.

- A hose is installed at one end of the tube to supply air, and a plug at the other.

- This stage is the most labor-intensive. It is necessary to make several hundred holes over the entire surface of the tube. It is very important that they are evenly spaced and the diameter of each hole is approximately 2 mm.

- The aerator is ready. Now to start working you just need to supply air to the device.

In order to secure the aeration device in the septic tank, you need to purchase a compressor, an air pump and air ducts, and also do a few more works:

- Care must be taken to ensure that the compressor is isolated from any ingress of liquid. To do this, a separate sealed chamber is built for him.

- The aerator is placed in a container that performs the main filtration work.

- The aerator and air blower are connected by special tubes - air ducts.

- At the final stage, an air pump (airlift) is installed. It is necessary to move liquid from one chamber to another.

Thus, it is possible to do without a purchased aerator. This device is easy to make yourself. However, installing such a structure in a finished septic tank still requires certain material costs, in particular the acquisition of the necessary components for the forced aeration process.

How does the cleaning proceed?

To understand the loan you need an aerator, you need to familiarize yourself with how wastewater treatment occurs in a septic tank. Organic compounds are decomposed by bacteria, which are of two types:

- Anaerobes. These microorganisms exist without access to oxygen, so no additional devices are required for their existence.

- Aerobes. This type of microorganism, on the contrary, cannot carry out its life activities in the absence of oxygen. And it is precisely to ensure the conditions for the existence of aerobic microorganisms that the septic tank is equipped with devices for air intake.

In conventional septic tanks, ventilation pipes are installed to remove gases formed during the decomposition of organic matter. However, such a system cannot ensure that a sufficient amount of oxygen enters the tank.

Therefore, to ensure aerobic cleaning, it is necessary to install an aerator. These devices are installed at the bottom of the tank; they provide ventilation inside the septic tank body, thereby ensuring the flow of oxygen into the environment. Exhaust air is removed through a conventional ventilation system.

Principle of operation

The aeration element in the septic tank is necessary for uniform distribution of air in the cleaned environment. The most effective way to ensure high-quality wastewater treatment is fine aeration, that is, air should enter the liquid in the form of small bubbles. Principle of operation:

- the air supplied by the compressor enters the aerator - a device with a large number of small holes;

- when air passes from the aerator, many small bubbles are formed, which are evenly distributed in the liquid;

- According to the laws of physics, air bubbles rush upward, saturating the environment with oxygen and ensuring the cleaning process.

Advice! If the septic tank uses the principle of intermittent aeration, then while air is not supplied, the holes must be closed. Otherwise, sludge particles will get inside the device.

There are two types of aerators used in septic tanks:

Pros of the first option:

- excellent flexibility;

- long service life;

- low risk of clogging the holes;

- maintaining supply pressure;

- uniform distribution of air in the environment;

- resistance of the material to mold formation.

Pros of disk devices:

- strength and reliability;

- structural integrity, that is, the absence of connections;

- ease of installation;

- corrosion resistance;

- maintainability, if the aerator fails, it is necessary to replace the polymer film;

- no risk of water and contaminants getting inside the device;

- low pressure losses;

- Possibility of use in high-performance stations.