The installation of sewerage in an apartment building and the disposal of household waste is an integral part for the comfort of living.

The presence of uninterruptedly functioning water supply systems and its disposal with other household wastewater has long been considered a common and obligatory phenomenon, both in all apartments of any high-rise building, and in the premises of multi-level individual buildings.

For those living in an apartment, the sewage system visually ends with a riser (often placed in a special vertical niche or in the corner of the toilet), into which wastewater from all internal sanitary fixtures flows. But the installation of a sewer system in a multi-story building is much more complicated. The operation of this system without accidents depends on compliance by all residents with simple operating rules, timely preventive maintenance, and carrying out the necessary repairs with the possible replacement of individual elements. To do everything correctly and on time, you need to know the purpose of the sewerage elements and the operating principle of the entire system as a whole.

The principle of operation of home sewerage

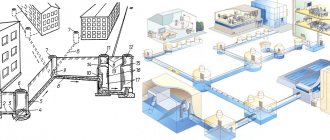

Let's consider a simplified diagram of a typical sewer system in a standard apartment building.

The bathtub, toilet and sinks of a separate apartment are connected to a vertical riser using pipes. It receives drainage from apartments located one above the other in the same entrance. The risers of one or more entrances are connected to the house horizontal collector (it has a certain slope, calculated when designing the system), from which wastewater is moved into the yard sewer by gravity. Subsequently, through a system of pipes with control wells, the wastewater enters the central (external) city sewerage system.

Knowing how a typical sewer system works in a multi-story building, it is important to remember that the principle of its operation is based on the movement of wastewater by gravity .

Elements of the sewer system

The purpose of this section is to list what is included in the sewage system of a house or apartment, indicate the purpose of each element, possible problems during its operation and methods for eliminating them.

Comb

A comb is a pipe in a separate apartment for collecting waste from all appliances. It passes horizontally through the walls of the adjacent rooms of the bathroom, toilet and kitchen. The diameter of the pipe is 50 mm, at the toilet connection point – 110 mm. The tilt of the comb for gravity flow of liquids is adjusted by a difference in the vertical position of the pipe of 3-3.5 cm per meter. Plastic pipes of the comb can be laid on brackets or attached to the walls using clips or clamps every 45-50 cm. All connections with bends are reliably sealed with cuffs or standard seals.

Comb

Riser

A vertical riser is a pipe for collecting and draining wastewater from apartments located one above the other. It is assembled from elements with a diameter of 110 mm, the sockets of which are oriented upward. At the level of interfloor ceilings, tees (less commonly, crosses) are installed to connect to the combs. After three floors or more, an inspection window is provided for routine inspections and pipe cleaning. Inspections are also required at the extreme levels and before connecting to the basement bed.

The main problems of sewer risers of any residential building and their solution:

- Blockage with partial or complete blockage of the passage. The pipe is cleaned through an inspection window, which is necessarily located above the clogged area.

- Annoying noise in a riser made of plastic elements. To soundproof pipes, roll insulation, a box made of wall panels or plasterboard, or a special “shell” made of polystyrene foam can be used. Another solution to the problem is to replace PVC pipes with silent ones that have a noise-absorbing effect due to the presence of three layers with different densities of materials, the inclusion of mineral components, and increased wall thickness. Such pipes are up to 4 times more expensive than conventional ones.

- Depressurization of the connection. For plastic risers, it is enough to replace the seal and cuff. At the junction of the cast iron elements, the socket will have to be re-embossed, having first removed the cement seal and the old cable.

- Destruction. The reason for cast iron elements is a violation of the integrity of the couplings or sockets due to the weight of the product or due to corrosion. The area with the destroyed socket is cut out, and a compensating pipe with a connecting coupling is installed in this place. An element of a damaged plastic riser can be completely replaced. It is not expensive and does not take much time. In all the considered cases, the joints are reliably sealed.

Fan pipe

This is the upper part of the riser, which is its ventilation outlet to the roof. The fan outlet can be personal for each riser, or it can combine the outputs of several (up to five) risers. The main functions of this part of the system are the removal of sewer odors and the prevention of water hammer that disrupts the water seals of plumbing fixtures. Sometimes a section of the drain pipe is replaced by installing a vacuum valve at the top of the riser. The solution is controversial, because when there is draft in the pipes, odors will escape through the nearby depressurized connection.

The main problem of the vent drain - poor ventilation - is associated with the seasonal freezing of wet vapors on the inner walls of the pipe. Over time, the internal lumen may close completely. In order for frozen vapors to thaw and clear the ventilation passage, hot water is poured into the pipe from above. But this is a temporary solution to the problem. To avoid sudden temperature changes on different sides of the pipe wall, leading to the deposition of frost, the fan riser is insulated in advance with reliable insulating material.

Fan pipe

Lezhnevka

A bed or deck chair is a horizontal pipe in the basement that combines risers from one entrance. It must have a slope of 2 cm/m towards the outlet pipe to the well. Laying methods - supported by basement bulkheads or prepared supports, using steel hangers. For plastic pipes, the step between supports or adjacent fasteners is 0.8-1.0 m. Increasing this distance leads to sagging of the pipe with the formation of unwanted counter-slopes. For each cast iron pipe, at least one hanger or support element is used. To avoid destruction of the socket seals, cast iron pipes are fixed rigidly. If necessary, the deck chair is cleaned through standard inspections or specially installed plugged tees. Revisions should be on the bends of the bed and meet every 8 m on linear sections.

Lezhnevka

Constipation in beds is inevitable due to the large volume of waste passing through pipes with a slight slope. Cleaning is carried out through the nearest inspection upstream of the wastewater. Leaks at the junctions of adjacent elements are eliminated in the same way as when the riser joints are depressurized.

Outlet to the well

This pipe, with a mandatory slope towards the yard sewer well, is laid from the bedstead through the foundation to its destination. Through it, the drainage from the sun lounger enters the well tray. Behind the foundation, the outlet pipe passes under a layer of soil below the freezing point. Therefore, strict requirements are placed on its strength. For installation, cast iron pipes and PVC pipes of increased ring rigidity (orange) are used for external work.

In the basement, the beginning of the outlet drain should have a window for cleaning.

Blockages and grease plugs are common problems in this section of the sewer system in an apartment building. Cleaning from the side of the well or basement is carried out using sewer wire.

You may also like - SNiP - sewerage, external networks and structures

Well

The sewerage system in an apartment building has the final link - a well. Its walls are rings made of reinforced concrete, with step brackets fixed in them. To prevent the received wastewater from entering the ground, the bottom of the well is concreted. When concreting, a recess is made in the form of a guide tray to drain wastewater to the next well, and then further to the central sewer collector.

According to the regulations, the plugs between the wells are destroyed pneumatically using a compressor. But in practice, a sewer wire ending in a hook often helps out.

Reasons for repair

Repair of sewer networks is carried out in the following cases:

- soil subsidence causing destruction or deformation of pipelines;

- frequent occurrence of blockages, indicating the presence of obstacles or sharp turns in the line;

- the appearance of leaks in pipe connection areas;

- freezing of liquids due to the absence or poor quality insulation of pipelines.

Any of these reasons requires repair, but often there are several of them at once. The main problem of sewer networks is disruption of the routing, causing changes in slope or destruction of connecting elements. Often, repairs to sewer systems are carried out due to the destruction of pipe connections or walls. Gaps and cracks appear, and the tightness of the line is compromised. If soil gets into the internal cavity, a large and difficult to remove blockage will occur, requiring replacement of the line and strengthening of the trench. Soil waters, which erode the soil and cause subsidence, can change the position of pipelines. Not only the canal lines are destroyed, but also the inspection wells, which requires immediate restoration. The entry of waste liquids into the soil causes pollution or poisoning and renders wells or drinking wells unusable.

In addition, there are regulations that determine the timing and order of planned work. They are designed to identify faults, replace worn parts, and check connections. Each sewerage network has its own repair schedule, corresponding to the specifics of the work and the characteristics of the network. For example, repairs to the internal sewerage system can be carried out throughout the year, but work on stormwater networks is more convenient to carry out in the winter, when they are idle.

Sewage operating rules

Installation of sewerage in an apartment building according to the rules and regulations implies:

- Installation of pipes of the required diameter on each section.

- Maintaining the calculated angle of inclination of the pipes.

- Correct installation of sanitary products and household machines. Use them for their intended purpose.

When operating the sewer system, preventive inspections and work must be carried out on time, and the cleanliness of all components and devices must be maintained.

You may also like - Slope of sewer pipes according to SNiP

Water supply standards

As always, we will start by getting acquainted with the regulatory documentation. Water supply standards (including cold water) are established by the set of rules SP 30.13330.2012.

Here are the key requirements of this document:

- Water pressure on plumbing fixtures should not exceed 4.5 kgf/cm2;

Standard pressure at the cold water inlet

However: if a building is being erected in a microdistrict with an existing multi-storey building and is powered from a common water supply with the surrounding houses, the pressure can be increased to 6 atmospheres.

- The minimum water pressure must ensure the functionality of household and sanitary appliances;

Help: most washing machines, dishwashers and water heaters operate at a pressure of 0.3 atmospheres or higher.

- The composition and quality of water must comply with SanPiN 2.1.4.1074-01 standards;

Drinking water composition standards

- The pipes used for installing water supply systems must last at least half a century;

- During operation of the water supply system, its hydraulic resistance must remain unchanged.

It’s curious: this clause of the joint venture actually prohibits the use of non-galvanized steel pipes, which are used to install most of the water pipes in Soviet-built buildings. However, most of these buildings, along with standard water supply systems, continue to be used at the present time.

Typical condition of operating steel water pipelines

Typical problems

Typical problems with indoor wiring are blockages and depressurization of connections, which will be indicated by an unpleasant odor in the premises and leaks. The blockage can be removed with fat-decomposing chemicals and mechanically - by pushing accumulated deposits in the pipes with a plunger or destroying them with a special wire stack (cable). Rubber cuffs, installation of new seals, additional sealing of joints (for example, with FUM tape), and re-caulking of the socket (for cast iron pipes) help eliminate the cause of the smell.

A water seal at each drain point also becomes a barrier to odors. This is a lowering of the drain pipe in the shape of the English letter U, in which water constantly remains - it completely blocks the internal cross-section of the duct over the entire area. In bidets and toilets, such a seal is based on the shape of the products themselves. Siphons are installed on drains from sinks, bathtubs and showers. For a flexible corrugated drain, the water seal is made in place manually, the U-shaped section is fixed with rigid wire. There is no need for a water seal in front of dishwashers and washing machines. Its role is played by a check valve built into each product.

The rules for using sewerage in an apartment building for residents prohibit:

- Using water in excess of personal needs.

- Operation of faulty taps.

- Discharge of construction waste, food debris, metal, glass and wooden elements, fuels and lubricants, aggressive chemical compounds and other materials into the sewer system.

- Use of the system until any violation in its operation is eliminated.