Advantages and disadvantages of structures made of reinforced concrete rings

In most design characteristics, a well made of reinforced concrete rings is better than similar products made of brick or polymers. Structures mounted from reinforced concrete have the following advantages:

- Increased strength. The devices are immune to strong horizontal and vertical loads resulting from seasonal soil mobility.

- Design integrity. Sealing is ensured by special ledges along the edges of the rings and the use of seals. In excessively mobile soil layers, shaft fragments are connected by welding.

- Immunity to aggressive influences. Concrete is resistant to acid and alkaline components contained in the soil. It is also not subject to destruction under the influence of plaque or silt. Neither mice nor insects can ruin reinforced concrete.

- Construction speed. Using an excavator, installing a well will take only half a day.

- Easy to maintain. The process includes systematic replacement of the filter and timely cleaning of the well walls from deposits.

- Long service life.

The disadvantages include the large mass of the rings, which requires hiring special vehicles equipped with units for lifting and moving. There is a need to arrange access roads to the installation site.

Construction materials

Wells used to create a drainage system on a personal plot with your own hands are usually assembled from concrete rings or purchased in plastic containers of certain sizes.

How to make a drainage well and what materials to use is decided by each owner of a country house himself. But it should be taken into account that the cost of the first option is cheaper, but requires more labor, and the second is much easier to manufacture, but its price is higher.

The assembly of wells from concrete rings requires solving a number of problems. Due to the significant weight of the rings, it is necessary to order special equipment and pay for the labor of assistants. In concrete wells, you need to create holes for laying pipes, and such work is difficult.

As a result, the labor intensity of installing a concrete structure is compensated by its durability, strength, reliability and affordable cost. Such a self-made drainage well has increased resistance to negative influences. It can be placed anywhere, as well as in areas located on soils subject to heaving when they freeze or in the event of hydrothermal shifts.

Under the same operating conditions, plastic products for wells can be deformed, despite the fact that they are easy to install, reliable and convenient. Their body already contains holes of the required diameter, intended for laying and connecting pipes.

Often owners prefer combined installation options. They buy plastic tanks for rotary and inspection structures, and create filtering and storage wells from concrete rings. There is another inexpensive option - this is the independent production of containers from plastic pipe products.

Types of concrete drainage wells

Concrete rings are the most common material for installing drainage systems. They are an excellent option for arranging any type of well.

Types of drainage well systems:

- collector (storage);

- filtration (absorption);

- viewing (inspection) rooms.

The first option is suitable for installation on loamy soils that cannot absorb a significant amount of water. Used when it is impossible to discharge excess liquid outside the territory. The design of a sealed collector involves the flow of wastewater from the drainage system into it and its subsequent use for technical purposes.

Two or more installations may be located in a large area. When constructing one well, several drainage lines are connected to it. Typically, plastic products with a cross section of 570 mm are used. The filling speed of the tank depends on its volume, and it is collected in the lowest place so that the connected pipes are located above the tank itself.

Inspection well

Absorbers are installed if it is impossible to remove moisture from the site beyond its boundaries or into the citywide sewer network. Their design features imply a volume of wastewater not exceeding a cubic meter in 24 hours. The depth of the structure must be more than 2 m. Broken clinker is poured onto the bottom of the device or a slag and gravel layer approximately 300 mm thick is created to facilitate moisture absorption. The top of the well is covered with geotextile material and backfilled with soil. Most often, filtration wells are installed on sandstones and sandstones. These types of soils absorb moisture well.

Inspection devices are used to identify and remove blockages in lines. Moisture does not collect in them. Installations with a small cross-section (up to 46 cm) are designed for washing pipes. Workers descend into wide wells with a diameter of up to two meters to carry out manual cleaning. Inspection structures are erected at the junctions of pipeline sections or on long straight lines.

A type of inspection wells are rotary structures. They are erected at the intersection of pipe sections, at corners and turns of communication lines.

Plastic well for drainage

Plastic products

Advantages:

- service life exceeds half a century;

- the corrugated pipe sits securely in the ground thanks to the stiffening ribs;

- pipes can be at any angle;

- due to the light weight of the product it is easy to transport;

- quick and easy installation;

- no crane needed.

However, it will cost several times more than concrete. You can save money if you do the installation yourself.

To work you will need:

- corrugated pipe;

- bottom;

- seals.

Process:

- The pipe is cut off. Then holes are made through which perforated pipes are passed. Place the cuffs.

- They dig a hole. Create a cushion of crushed stone and sand. Fill with cement and lay geotextiles.

- They make the bottom. Then a pipe is connected to it. The junction is sealed with mastic.

- Connect the pipes. The joints are sealed with mastic.

- Install the pump.

- The resulting space is filled with crushed stone.

- They make a lid.

Preparing for work

Before constructing a well installation, it is necessary to purchase suitable reinforced concrete rings that are resistant to moisture. Dimensions and cross-section depend on the purpose of the device and the functions of the ring itself.

Products are produced in different sizes. Diameter can be from 0.7 to 2.5 m, height - from 0.1 to 2.5 m: the range of options is wide.

For a drainage well, products are usually chosen with a height of half a meter and a cross-section of 0.7–1.5 m. Their weight depends on the size and can be from 200 to 900 kg.

Absorption devices are placed on a bulk filter pad. It must be made at least half a meter high from sand and gravel-crushed stone mixture. The arrangement of the pillow will be required even when the lower reinforced concrete ring is equipped with a built-in filter bottom.

Storage tanks and inspection devices are installed on the bottom slab or on a cement screed. The bottom of the pit must first be compacted. The rings are placed one on top of the other with strict adherence to the vertical. The joining areas are sealed with bitumen mastic or liquid cement. In order for the prefabricated elements to be securely fastened, they are connected from the inside with metal ties so that one edge of the plate is held on the upper ring, the other on the lower one.

Conclusion

Making your own drainage well is not at all difficult, so every home craftsman can handle this task. The main thing is to determine the most optimal location of structures, and decide where and what type of structures should be used. Otherwise, you just need to follow the above recommendations. (See also the article Sealant for concrete: features.)

You can get more information on this topic from the video in this article.

Location on the site

Before planning the construction of a well on a site, be sure to follow the rules for its location relative to other objects. All distances and standards are indicated in SNiP. If you do not comply with all these standards, the SES will not issue a construction permit.

The storage system is sealed, water does not enter the ground. The minimum distance for a storage well is 5 m from the foundation of a residential premises. But it is better to increase this interval to 10 m, if the territory allows. This will prevent the penetration of unpleasant odors into the house and protect the foundation from destruction. The distance will allow you to create the required slope of the pipes during excavation work and will help the entire sewer system operate properly.

General information

Properties of materials

Other materials have differences such as:

1.red brick implies additional work on waterproofing walls on the inside and outside of the structure. The products do not have a long shelf life because they cannot withstand destruction from the aggressive sewage environment.

2.metal products form corrosion, this applies to aerobic septic tanks when exposed to oxygen. Structures that use black steel are short-lived, while stainless steel is expensive.

3.plastic structures are light in weight, which is their disadvantage. A septic tank full of sewage can float if the soil swells. The structure must be anchored to a reinforced concrete base. Plastic containers are thin-walled and require protection from a metal frame so that they do not burst under soil pressure.

Sewerage using concrete rings can be built quickly; if you use special equipment, then all work can be completed in one day. The structure is durable; the structure does not move when the ground moves. If the rings are made at the factory, they have a low level of moisture absorption. When carrying out waterproofing, complete tightness is achieved.

Attention! In the city sewer system, treatment structures are made of reinforced concrete, which indicates that the structures are durable and strong.

Various schemes for the sewer system

Treatment facilities have at least one chamber, usually two or three. When choosing the number of sections in a septic tank, rely on:

1. time of residence in the house: permanently or periodically.

2. how many people live in the house, the volume of wastewater.

3.the amount of money that can be spent on the building.

The simplest structure is considered to be a container with one chamber, which has sealed walls and a bottom. Accumulated wastewater is removed from it using sewage disposal equipment. The volume of wastewater affects the frequency of the need to pump out sewage. As soon as the well is filled, the sewer trucks must be called immediately. This scheme is best used for seasonal living in a house, or if a family has a maximum of two people.

An anaerobic septic tank has two chambers. With the help of bacteria that do not require oxygen to live, wastewater is broken down. There is no need to call a vacuum cleaner to pump it out. But the scheme involves the construction of a well for post-treatment, in which there is no bottom, a trench, or a drainage field. Purified water flows into the soil. In rural homes, this scheme is often used because it is simple and does not require electricity. The main disadvantage is the need for periodic cleaning and replacement of the filtration pad, which is made of sand, crushed stone, and gravel.

An aerobic septic tank has two to three chambers. Currents flow from one section to another, where they are purified to almost one hundred percent. First of all, anaerobic bacteria come into work, then aerobic microorganisms are involved. Aerobic organisms require oxygen to reproduce, so a compressor is used to supply oxygen to the septic tank. As a result, wastewater is purified up to 98 percent. Water can be removed into a reservoir, into the soil, or used to water the beds.

Attention! Aerobic bacteria need oxygen; without it they cannot live. If the compressor does not supply oxygen for two or three days, the microorganisms will die. This factor must be taken into account in the presence of frequent power outages.

Operating principle

The number of chambers in a septic tank does not affect the same principle of operation of the device.

In the first section, heavy particles sink to the bottom. Anaerobic bacteria complete the cleaning process. The resulting gases exit through the ventilation pipe. The drains form a greasy film on top. In order to protect the other chamber from film getting into it, you need to install a tee on the overflow pipe, which should be located lower than the film. If there is no second chamber, then the clarified wastewater flows into filtration tanks, where the post-treatment process ends. This type of septic tank is suitable for summer residents who rarely live in the house. A septic tank with one chamber forms sludge on the walls and bottom faster than in other structures, so it must be cleaned more often. In chamber two, post-treatment processes take place. Anaerobic bacteria process organic matter, and sludge settles at the bottom. The wastewater then flows for further filtration, or flows into an aerobic septic tank, where post-treatment is completed.

Design dimensions

In SNIP, a person spends about two hundred liters of water per day. The well should contain approximately six hundred liters of wastewater per person over three days. This value must be multiplied by the number of people living in the house to obtain the volume of capacity required. If there is a two-chamber septic tank, 2/3 of the total volume should be placed in the first section, and 1/3 in the second section.

Having calculated the volume of the well, select suitable rings. The marking will tell you the necessary parameters. It indicates the type of reinforced concrete products in letters, and the numbers indicate the diameter of the ring with its height, expressed in inches. The rings have a standard height of 0.9 meters, but can be 0.6 meters with a cross-section of more than 1.5 meters to reduce the weight of the product. The standard diameter for rings is 0.7 - 2 meters.

Let's look at the example of decoding the markings on a ring. By size you can calculate the volume of the product. For example, KS 10 - 9 has a diameter of one meter, a height of 90 centimeters, and a volume of 0.24 cubic meters. If the septic tank has two chambers, then three parts will be required for one person. If you have a family of three members, you will need 2 or 3 of these containers. By increasing the diameter of the ring, the volume increases, but not by increasing the number of rings.

Attention! It is not recommended to install a structure consisting of more than three rings, because the stability of the structure is reduced.

The bottom can have diameters equal to 150 cm, or 200 cm, or 250 cm. Installation becomes easier, while the tightness increases, when replacing individual parts with one monolithic structure with a bottom. There are overlaps for different types of rings, they are not only in KS 7. They have a hole offset from the center, with a standard diameter of 0.7 meters.

Types of concrete products

The rings are made using the same technology, but they have different purposes. The main types include:

1.wall rings are used to build chambers in a septic tank. This is a through-type product installed on a solution.

2.Perforated rings have holes on the walls. They are used to construct filtration wells; through the holes, water quickly drains into the ground.

3. auxiliary rings can be additional or support rings. With the help of additional ones, the height of the well in the sewer network is increased. The support type is needed in order to install it on a finished well structure in order to install a hatch covered with a lid at the desired height.

Types of rings

Rings vary in type of design. They are:

1. rings with a bottom are lowered into the hole first. Wall products are placed on the ring. The rings are needed to provide a tight seal to the device. They have a height of 0.9 meters.

2.Lock rings have special recesses at the top and bottom. They are needed to firmly join the parts. Such elements are required if septic tanks are installed on quicksand.

3.rings with a lid become the final details when building a well. They have a hole for a hatch in the ceiling. This detail increases the strength of the structure.

What is it, how does the device work?

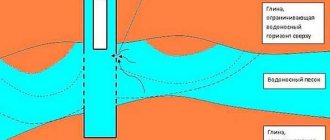

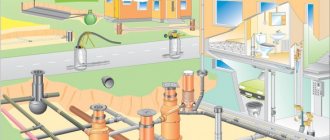

A drainage well is a special shaft in the ground made of reinforced concrete or PVC. It consists of a bottom, a working area, a hatch and allows you to collect excess water from the area. All moisture enters the shaft through the pipe, and it allows the entire system to be cleaned.

Drainage is especially necessary when the house is located in a lowland, and the area has a relatively high level of precipitation or there is groundwater very close by.

Installation of a drainage well:

- eliminates flooding of the cellar and basement;

- reduces groundwater pressure;

- drains the soil on the site.

The inspection shaft diagram consists of the following elements:

- Luke. It prevents excess debris from entering the pit and also allows for servicing the collector;

- neck – load-bearing part of the structure;

- shaft - vertical tunnel;

- bottom - used to collect sediment.

Inspection systems for drainage are required:

- for periodic washing of the structure;

- monitoring the performance of pipes;

- carrying out scheduled maintenance.

In the absence of this communication, water will accumulate in the local area. Even if you lay a drain and do not install an inspection well, the entire system will become clogged and moisture will remain in the soil.