Updated: 02/21/2021 14:01:48

Expert: Konstantin Borisovich Polyakov

*Review of the best according to the editors of expertology.ru. About the selection criteria. This material is subjective in nature, does not constitute advertising and does not serve as a purchase guide. Before purchasing, consultation with a specialist is required.

Wastewater treatment in aerobic septic tanks is carried out by the breakdown of complex substances into simpler ones under the influence of bacteria that process the incoming material. As a result, water and sediment (silt) are formed. The degree of purification can reach 96-98%, so the liquid can be used for irrigation and other technical needs. But the design of the septic tank requires tightness, so compressors are needed to supply air inside (to support the life of bacteria). How to choose them and what customers like most from the assortment available in the Russian Federation, read below.

What is a septic tank

For most summer residents and owners of country houses, this is an ordinary cesspool where the owners dump all their wastewater from bathtubs, washbasins, washing machines, etc. As the cesspool is filled, it is emptied using a sewage disposal machine. This operation is carried out, under a contract, by utility service specialists. The work is harmful, the service is paid. Alas, for the majority of village residents, the cesspool remains the only way to dispose of household wastewater.

Today, owners of suburban housing have access to a modern way to solve these problems - installing a local treatment plant (LTP) on their site, an integral part of which is a septic tank.

Interesting! A septic tank or septic tank is a specially equipped reservoir, the purpose of which is to collect wastewater from low-rise residential and public buildings built in areas not equipped with a centralized sewage system.

The local treatment plant implements three cleaning methods:

- gravitational – contaminated water settles until heavy suspended matter precipitates;

- bioenzyme – post-treatment with aerobic and anaerobic bacteria;

- filters.

Purified water is useful for watering plants in the garden. The accumulated sludge is used as fertilizer. This method of drainage is very environmentally friendly. Installation costs will quickly pay off, since the owner will not have to pay utility services. And, importantly, proper operation of local treatment plants guarantees the absence of odors characteristic of sewerage devices.

Modernization of the settling chamber

If the settling chamber is to be upgraded with a compressor, the septic tank is supplemented with an aeration tank

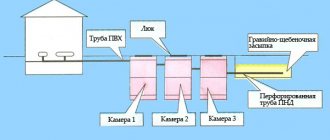

If the settling chamber is to be upgraded with a compressor, the septic tank is supplemented with an aeration tank. To do this you will need:

- determine the location for the new section;

- dig a hole where to install a container or concrete ring;

- install a homemade or purchased compressor made for a septic tank;

- Be sure to install a perforated pipe sealed at the bottom into the aeration tank.

Important! Such a pipe can be made from any suitable length. Drill holes, spacing them evenly and observe the appearance of air bubbles on the surface during startup - this means that the compressor installed for septic tanks is working normally.

By adding a mixing structure to the entire installation, it is possible to improve the distribution of masses so that the air flow flows evenly, this will improve the process of decomposition and recycling of accumulations. As a means of post-treatment, it would be a good idea to install an additional chamber where the wastewater will settle and be clarified.

Why does a septic tank need a compressor?

At the stage of bioenzyme wastewater treatment, two types of bacteria are involved in the fight against sewage:

- Anaerobic. They decompose sewage into simpler fractions without air access.

- Aerobic. They also process and decompose wastewater, but require the constant presence of oxygen.

The tightness of the tank does not allow aerobes to obtain oxygen naturally. To solve the problem, a compressor is installed in the system, which not only creates conditions for the life and work of bacteria, but actively mixes sewage, crushing it to accelerate decomposition.

Interesting! The amount of oxygen in the air depends on the sampling location. In the forest or on the ocean coast it reaches 21.9%. In urban areas this figure drops to 20.8%. Oxygen concentrations below 16% are considered dangerously low for human health.

On average across the planet, an oxygen level of 21% is considered normal. This is quite enough for beneficial microorganisms to work in the sump.

Self-installation

When upgrading and making your own septic tank, you can install the compressor yourself. The selected model is installed on a special frame or platform located above the wastewater level in the tank. The method of fastening depends on the features of the purchased or homemade design. Following the manufacturer's instructions, the outlet pipe of the device is connected to the aerator pipe. After connecting to the power supply and checking its functionality, the supercharger is covered with a protective cover. After sealing, the septic tank is ready to start.

The connection of the new device must be carried out by specialists. The customer will only have to accept the completed work. Another advantage of this option is a guarantee for the quality of installation and proper functioning of the device.

Need to know! Owners of autonomous treatment systems from well-known companies - Topas, Unilos, DKS, Tank and others - receive fully equipped deep cleaning stations for use. There is no need to select and install a compressor. Its repair and replacement after the expiration of the warranty period is entrusted to the specialists of the service center.

What types of compressors are there?

Piston

Structurally similar to an internal combustion engine. The piston moves along the cylinder, compressing the medium that enters the chamber through the intake valve. The compressed air is forced from the chamber into the manifold through the exhaust valve. Since there is no cooling system, such mechanisms get seriously hot.

Centrifugal

It is more complex than a piston. It can be single or multi-stage, single or multi-rotor.

Screw

Complex design. A centrifugal fan forces atmospheric air into the housing, where screw pairs are located, rotating in different directions. They provide the specified pressure. The unit is highly efficient, but noisy.

Membrane

The second name for such machines is diaphragm compressors. Simple, reliable, durable, inexpensive. The principle of operation is based on the reciprocating movement of an elastic diaphragm pinched in the body. When the diaphragm moves in one direction, the intake valve opens and the chamber is filled with air, which is compressed by the reverse movement of the membrane, and then pushed into the manifold through the exhaust valve.

For a septic tank, the best option is a diaphragm compressor. These devices are much quieter than others. There are no rubbing parts in the mechanism, so the machine does not heat up and does not require lubrication. The final product reaches the consumer without mixing with oils. The output is small, but sufficient to provide oxygen to the VOC. The package includes spare membranes.

Purpose of units

Disinfection and disinfection of the contents of cesspools is carried out with active substances. Their danger to the environment and humans has been proven. Therefore, sensible owners are moving to a safe biological method of combating pollution using colonies of living bacteria. Feeding on organic matter from household and household waste, bacteria break it down into water, carbon dioxide and safe sludge.

Biological products for septic tanks contain one of two types of microbes - anaerobic, aerobic, or a combination of both (used in the simplest single-chamber structures). Heavy solid waste settles in the first chamber. They are carried out by anaerobic microorganisms that can survive without oxygen and decompose (oxidize) wastewater into low molecular weight compounds. Cleaner wastewater with small particles ends up in the second and third tanks of the septic tank. Aerobic bacteria are used for their processing, the vital activity of which is impossible without access to molecular oxygen. The activity of microorganisms increases with increasing volume of supply air.

Compressors for autonomous septic tanks connected to aerators are necessary for uninterrupted pumping of oxygen through the volume of waste liquid with aerobic microflora. This is an electrical device for moving gaseous mixtures - it pumps air into the aerator. The latter is a perforated pipe or hose that is laid at the bottom of the tank. Through the holes in the pipe, the supplied air escapes from the aerator and moves upward. Along the way through the thickness of the liquid, part of the oxygen dissolves in it and ensures the vital activity of microorganisms.

By volume of septic tank

To provide a sump with a volume of up to three cubic meters with the required amount of oxygen, a device with a capacity of 60 l/min is sufficient. For a five-cubic-meter tank you will need a device that produces at least 80 liters of air per minute. For containers with a volume of 6 cubic meters. you will need a device with a capacity of at least 120 l/min. It should be remembered that as the device’s performance increases, its energy consumption also increases.

Important! When operating the compressor, you need to take care of your own safety by following the simple rules described in the user manual.

Sound level

No matter how quietly a membrane unit operates, as its performance increases, so does the noise level it produces. To ensure that the device does not reduce the level of comfort with its hum, you should choose models with a sound load level of no higher than 35 or 40 dB.

Compressor dimensions and weight

The air pump is located in a special compartment of the tank, immediately under the manhole cover. Before buying a mechanism, you should take the dimensions of the compartment where the product will be mounted, taking into account the height of the device, so that the hatch closes freely. And the lighter the device is, the better for the sump. To eliminate vibration, vibration isolation mounts are used.

Control system

Management is simple and includes the following elements:

- On/off button.

- Circuit breakers.

- Overheat protection. Provided in expensive models that work around the clock.

The electrical connection diagram of the device provides for emergency shutdown. For septic tanks, differential circuit breakers with an RCD function are often used.

Homemade aeration devices

For septic tanks with small tank volumes, a low-performance blower (up to 20 l/min) is suitable. Craftsmen have learned to use compressors from refrigerators and cars to aerate such structures. Cheap, accessible, simple.

A perforated hose is easy to make from a plastic pipe. One end of the homemade aerator is put on the outlet pipe of the supercharger, the other is sealed or hermetically sealed with a plug. Enough holes are made in the body of the pipe to work correctly with the used aggregate model.

The disadvantage of such devices is their small working resource. They are not designed for continuous operation. With the air flow, lubricant quickly leaves the device; installing oil traps has little effect on the situation. When using a homemade device, you need to be prepared for its failure, be able to fix common breakdowns, and perform the necessary maintenance. And in case of critical breakdowns, it is advisable to have a serial model with the necessary parameters in mind.

The best manufacturers

Jecod

Chinese manufacturer of budget air pump models. The owner of the trademark is Jebao. The main production facilities, equipped with the latest technology, are located in the city of Zhunchang (Guangdong Province). Each new product undergoes serious laboratory tests before being put into production. The quality meets international standards.

AirMac

The company's production activities began in 1988 at the Taiwanese enterprise Diann Bao Inc. Over the past thirty years, the company's specialists have gained significant experience in the development and assembly of reliable and economical devices. Popular AirMac models are selling well in the European, Asian and American markets.

Hiblow

The trademark belongs to the Japanese company Techno Takatsuki, the first manufacturer to introduce customers to electromagnetic membrane compressors of the Hiblow brand in 1967. Since then, more than six million units of such products have been produced. The popularity of Techno Takatsuki models has long gone beyond the Asian market. Its products are in high demand all over the world for their reliability, reliability, efficiency, and stylish design.

Thomas

Products from the Japanese brand Yasunaga are sold under this name in Europe. Thomas devices are famous for their reliability, environmental friendliness, and low power consumption. They are durable, reliable, low noise, and do not require lubrication. They are used in conjunction with local treatment facilities of various companies.

Sera

A German company specializing in the production of products for the care of aquariums and their inhabitants. This includes food, the aquariums themselves and equipment, including air compressors of various capacities, for aerating ponds, decorative bubble columns, large aquariums, septic tanks, etc. The company's branches are open in Europe, China and the USA. Its products are in demand in more than 80 countries around the world.

Medo

The owner of the brand is the Japanese company Nintto Kohki. On the market since 1956. The company specializes in the production of pneumatic tools for various purposes. The quality is excellent, the design is stylish, the mechanisms are reliable. Buyers are happy.

Hailea

Chinese company. Specializes in the production of compressors and aerators for hydroponic systems. Its products are in demand in Germany, Japan and Russia. Environmentally friendly materials and technologies are used. Devices of varying power and performance have been developed and produced. The minimum service life is at least two years. Advantages of Hailea devices: reliable, low noise and economical, affordable.

Secoh

Japanese company. On the market since 1966. Manufactures electromagnetic diaphragm blowers. The equipment and technologies are the most modern. Quality control is carried out at all stages of production. Secoh devices are distinguished by high quality and reliability. They work almost silently. The list of the best manufacturers could take a long time. In order to decide which company’s product is better to buy, you should take the following steps:

- listen to advice and recommendations from experienced users;

- select several models from different manufacturers, find out their technical characteristics, carefully study the description of each device;

- find out how much a particular model costs;

- draw up a comparison table with the characteristics of several models and choose the best option that suits all parameters, including cost.

This approach always allows you to find the best option and make a successful deal.

Exploitation

It should be noted that compressors for local treatment systems and septic tanks are reliable devices that can please owners with uninterrupted operation for many years in a row.

The average service life for a compressor is 10-15 years. To prevent premature failure, it is necessary to replace the membranes regularly (approximately once every 1-2 years). To do this, purchase the appropriate repair kit. Replacement can be done either independently or with the assistance of specialists.

It is the replacement of membranes that is included in the main maintenance of the compressor. A damaged membrane is the only reason for the failure of a quality device before the expiration of the service life guaranteed by the manufacturer.

Where can I buy

Small-sized compressors with low performance can be found in stores selling power tools. This is the easiest and most reliable option for purchasing such equipment. Here you can examine the product from all sides, touch it with your hands, check its serviceability and issue a warranty card.

Visiting the manufacturer’s official website will help you make your choice. On its pages you can find popular models and new items of the season, study characteristics and prices. If the manufacturer has its own distribution network, you can find store addresses on the website.

If the buyer has studied the market and decided on the brand of the product, it can be ordered online in an online store.

Fecal pump with grinder

The purpose of a household sololift is to raise wastewater to the height of the building's gravity sewer and drain it into it. Since the waste can also be feces from the toilet, to make it easier for the pump to pump them, a toilet grinder is built into it, turning soft fractions, toilet paper and small waste into pulp.

Not all sewage pumps are equipped with a grinder; this must be taken into account when choosing one, taking into account the composition of the waste and its formation.

Rating of quality compressors for septic tanks

Products at an affordable price

5.Hailea HAP-80

The device is from a well-known Chinese manufacturer. Used as an aerator for small ponds and large aquariums. It is built into the circuits of local treatment facilities to supply air oxygen to septic tanks. It is powered by a mains voltage of 220 V. With a power of 60 W, it provides a flow rate of 80 l/min, with a pressure from 90 to 250 mbar. With dimensions 210x185x171 mm, it weighs 7 kg. Works quietly. The noise level does not exceed 40 dB. The average price is 7900 rubles. According to buyers, this is the best combination of price and quality.

Hailea HAP-80

Advantages:

- reliable;

- compact;

- quiet;

- inexpensive.

Flaws:

- not identified.

4.Jecod PA-100

Diaphragm compressor from the Chinese company Jebao. With a power consumption of 65 W, it has a fairly high productivity of 100 l/min. Excellent performance for aerating VOC lagoons, fish ponds, large aquariums, bubble columns. The dimensions of the machine are quite compact: 300x155x210 mm. Weight – 3.6 kg. The average price of the product is 9199 rubles.

Jecod PA-100

Advantages:

- compact and lightweight;

- works quietly;

- economical;

- productive.

Flaws:

- not identified.

3.Thomas AR-60/80

Our review includes another relatively inexpensive Japanese diaphragm air pump for septic tanks and more. Simple and reliable machines are used for aeration of ponds and fish baths, wastewater treatment plants, decorative bubble columns, in medical facilities for hydromassage, etc.

Thomas AR-60/80 is a very economical device, with power consumption from 41 to 57 W and productivity from 60 to 80 l/min. Working pressure 200 mbar. The sound load level does not exceed 34 dB. Dimensions 190x172x199 mm. Weight - 5.8 kg. The average price is 9200 rubles.

Thomas AR-60/80

Advantages:

- easy;

- compact;

- reliable;

- quiet.

Flaws:

- productivity is low.

2.SUNSUN ACO-012

Compressor from a well-known Chinese manufacturer. The device is universal. It is used to supply air to various installations and structures:

- ponds;

- septic tanks;

- fish baths;

- bubble columns.

The aluminum body transfers heat well to the atmosphere. The flow is calm, without pulsations. The material of the cylinder and piston is modern, with high wear resistance. The nominal operating mode is 24 hours a day. The productivity is quite high - at least 150 l/min, with a pressure of 0.42 bar. Power supply from 220V network. The engine is powerful, 185 W. The average price is 10,500 rubles.

SUNSUN ACO-012

Advantages:

- compactness;

- wear resistance;

- high-quality assembly;

- performance.

Flaws:

- not identified.

1.Sekoh EL 60

A budget option of membrane type, from a famous Japanese brand. Placed in a plastic case, it measures 250x180x200 mm and weighs only 5 kg. It is powered by a 220 V network. It supplies the consumer with 60 liters of compressed air at a pressure of 147 mbar per minute. The design is extremely simple, the number of parts is minimal. The working life is at least 20,000 hours without maintenance.

The housing has good soundproofing characteristics and is equipped with a muffler integrated into the bottom of the device. Such design features ensure a sound load level of no more than 43 dB. The EL designation in the product marking indicates that the case is waterproof. The average price is 10,500 rubles.

Sekoh EL 60

Advantages:

- compact and lightweight;

- oil-free;

- reliable and durable;

- low noise;

- inexpensive.

Flaws:

- low productivity.

Dear models

5.Blowtac AP 200

Model made in Taiwan. Diaphragm option. There are no rubbing or sliding parts, so there is no need to use lubricant. The air flow enters the system uncontaminated. It is used for aeration and mixing the contents of septic tanks. The functionality is quite wide. The device is used in solving many different problems:

- pond aeration;

- air supply to pneumatic drives of equipment and tools;

- tire inflation, preparation for launching rubber boats.

Capacity not less than 210 l/min. Sound pressure during operation is no more than 45 dB. Dimensions (LxWxH): 2615x1780x2281mm. Weight 10.1 kg. The design is stylish, the body colors are pleasant. The average price is 31,000 rubles.

Blowtac AP 200

Advantages:

- low noise;

- oil-free;

- productive;

- easy to maintain.

Flaws:

- not identified.

4.Thomas LP-150 HN

Japanese development of a membrane compressor. The model is intended for septic tanks that are part of treatment facilities and sewer systems. Air is sucked in and injected into the tank due to the oscillatory movements of the elastic membrane. There are no rubbing parts in the working chamber and there is no need to lubricate the mechanism. Thanks to this feature, oil particles are not injected into consumers. This allows the use of such units in medical institutions, in biological wastewater treatment systems, aeration of fish ponds, aquariums, etc.

The device with a power consumption of 130 W provides an air supply of 150 l/min. with a pressure of 200 mbar. The sound pressure level during operation does not exceed 43 dB. Device dimensions: 227x179x218 mm, weight - 8.6 kg. The average price is 40,000 rubles.

Thomas LP-150 HN

Advantages:

- lightweight and compact;

- low noise;

- oil-free;

- with a wide range of applications.

Flaws:

- high price.

3.AirMac DBMX-200

The device is made in Taiwan. It has a long service life (at least 76 years). It is equipped with spare parts, membranes and valves, which the manufacturer recommends replacing after two to three years of product operation. Following these recommendations will significantly extend the life of the product. The range of application is quite wide:

- local treatment facilities such as Topaz, Topaero, etc.;

- pond aeration;

- aeration of ponds and aquariums;

- water treatment

The power consumption of the model is 230 W, the sound level does not exceed 30 dB. Air is supplied evenly. There is no pulsation. Dimensions: 272x226x247 mm. Weight - 9.0 kg. The average price is 40,500 rubles.

AirMac DBMX-200

Advantages:

- powerful;

- very quiet;

- reliable;

- compact and lightweight.

Flaws:

- Expensive.

2.Hiblow HP-200

Compressor of Japanese design, Philippine assembly, power consumption 210 V, capacity from 200 to 280 l/min. The diameter of the connecting pipes is DN (nominal diameter) 20 mm or ¾ inch. Dimensions: 256x200x222 mm, weight 9 kg.

Designed for septic tanks with a volume of up to 10 cubic meters, ponds with a volume of 1200 cubic meters, aquariums with a capacity of 40 liters or more. Widely used in local treatment plants, autonomous sewage systems, wastewater treatment systems TOPAS, Unilos, Eurobion, Biotal, etc. The average price is 42,400 rubles.

Hiblow HP-200

Advantages:

- modest size;

- light weight;

- high performance;

- stylish design.

Flaws:

- high price.

How to choose

Compressors for septic tanks are represented on the market by Japanese, Chinese, German and Russian manufacturers.

The most common models in stores are from the following companies:

A Japanese brand that is focused on producing membrane-type compressors. The company's products are used at stations such as UNILOS and TOPAS. SECOH produces compressors in three lines - SLL, EL and JDK.

Specializes in the production of equipment for septic tanks - compressors, spare parts and consumables. The company's products are covered by a two-year manufacturer's warranty. Compressors are available in three lines: HP, XP and DUO.

Russian manufacturer of compressors and components. The devices produced by the company operate at speeds from 40 to 200 liters of air per minute. Compressors are available in the DB, DBP and DBMX lines.

Depending on the operating method, compressors are divided into four categories:

- membrane - the optimal solution for small country and home-made septic tanks. Air compression in such models is responsible for the oscillation of the membrane, which performs piston movements. Membrane compressors are usually located in local stations intended for biological treatment;

- centrifugal - there are radial and axial compressors of the centrifugal type. Air injection in these devices occurs due to the speed of movement. For septic tanks, models of this group are rarely used. They are difficult to install and further manage, and are also large in size;

- piston - easy to operate and undemanding to environmental conditions. The main disadvantage of such devices is low efficiency (compared to other categories). Air injection occurs due to the movement of the piston group. The pumps are noisy, which makes them not the best choice for country septic tanks;

- screw - reliable and silent in operation, have high efficiency. Dry compression screw compressors require expensive professional maintenance to install. For this reason, screw mechanisms are in little demand at home.

What compressor is installed on your septic tank?

DiaphragmPiston

Before purchasing a compressor, you must have an accurate idea of the size of the septic tank. The capacity of the model, which will be needed for complete cleaning, depends on the volume of the tank. When choosing a compressor, characteristics such as electricity consumption, noise level and operating speed are important. Those compressors that are supplied with spare parts have an advantage.

Types of equipment

In terms of themselves, all septic tanks are the same thing, although they are divided into:

And, in fact, they are an ordinary container, impenetrable both from the inside and from the outside. Contaminated water from your dacha is pumped there and processed to purify it at the primary level.

Just according to the above-mentioned chambers, and septic tanks are also distinguished by size. So single-chamber and double-chamber can accommodate different numbers of drains. But whatever the design, the treatment properties still depend on the processes that occur inside the septic tanks, and with the help of which the wastewater is cleaned.

Connection procedure

To properly install a toilet with a pump, you need to learn the basic rules. It is important that the package contains all the necessary elements, fasteners and connecting pipes.

Connection steps:

- The preparatory stage consists of choosing the installation location and preliminary marking. It is important that there is a power outlet near the pump. You should also take into account the height of the drain and the accessibility of the mounting location.

- After securing the housing, proceed to the next stage. To connect communications, you should use a connection pipe. It is necessary that the diameters match, otherwise leaks are possible. A slope of 3-5 cm should be provided so that the wastewater is discharged by gravity.

- Unused inputs must be secured with plugs. The toilet drain is connected to the sewer system using corrugation. The device needs to be tested for leaks. Joints and cracks can be coated with a special compound.

- If there is no filtration system, proper ventilation must be ensured. If the design includes filters, they must be changed periodically.

- Before connecting to the network, you need to check that the socket is installed correctly. It is recommended to build in an overload protection system. The first launch is made only after checking all the mechanisms.