The sewer collector of a private house is a pipeline made of pipes (pipeline) through which sewage is discharged and the wastewater collection tank itself is a regular cesspool, septic tank, VOCs, etc. Such a system is also sometimes called a channel. There are three types of collectors:

- domestic;

- shower;

- drainage

Wikipedia says that:

The collector is the main channel of the drainage network.

It is a large diameter pipe. Sewers are part of the city's sewer system; they collect wastewater and transport it outside the sewer system to pumping stations, treatment plants or to a discharge point into a reservoir.

Sometimes small rivers flowing within the city are collected into sewers. Collectors are constructed primarily from large concrete and reinforced concrete blocks.

On the territory of Moscow, about 150 watercourses flow in collectors with a total length of several hundred kilometers. During a rainstorm, a so-called “collector wave” can occur in drainage collectors - a rapid increase in water level.

Source Wikipedia

City sewer collectors, unlike domestic ones, are complex hydraulic structures that run under the entire city. For private housing construction, such systems are more modest in size and length. Let's take a closer look at what a household sewer collector is, its components, etc.

Video: Sewer

storm sewer collector

English-Russian Dictionary of Technical Terms. 2005.

See what a “storm sewer collector” is in other dictionaries:

storm sewer collector — — Energy industry topics in general EN storm sewer ... Technical Translator's Guide

SEWER WATER COLLECTOR - a collector for collecting and discharging wastewater from the storm sewer network (Bulgarian language; Български) drainage sewer collector (Czech language; Čeština) dešťový kanalizační sběrač (German language; Deutsch) Abwassersammelkanal (Hungarian ... ... Construction Dictionary

sewer drainage collector - Collector for collecting and discharging wastewater from the storm sewer network Topics water supply and sewerage in general EN storm sewerstormwater sewer DE... ... Technical Translator's Guide

Kamenka (river, flows into the Sea of Japan) - This term has other meanings, see Kamenka. Kamenka Upper Kamenka Characteristics Length ... Wikipedia

Samorodinka (river) - Samorodinka Valley of the Samorodinka River Characteristics Length 7 km Basin area 11 km² ... Wikipedia

Flon (river) - Flon fr. Flon Upper reaches of the Flon ... Wikipedia

Igumenka (river, Chelyabinsk region) - This term has other meanings, see Igumenka. Igumenka is a small river in the city of Chelyabinsk, 9 km long, a right tributary of the Miass River, almost completely enclosed in a collector. When open, it leaks from... ... Wikipedia

Collector wave - A collector wave is the occurrence of a large flow of water in the collectors of underground rivers and streams during a rainstorm. This is due to the fact that storm sewer systems are usually connected to the collectors of underground reservoirs. Therefore, during... ... Wikipedia

Underground passages of Minsk - The building of the Republican Prosecutor's Office on the site of the former Church of St. Wojciech There are not many historical dungeons in Minsk, mainly in the historical center in the area ... Wikipedia

dic.academic.ru

Polyvinyl chloride

PVC pipes are environmentally friendly. PVC pipes, specially made for pressure sewerage, are used in private homes, as they are environmentally friendly and safe for health. Such pipes are not flammable and do not emit harmful substances and hazardous chemical compounds in the event of a fire. PVC is resistant to temperature changes, is not afraid of ultraviolet radiation and is not exposed to aggressive environments. The presence of chlorine atoms in the composition of polyvinyl chloride makes pipes made from it indispensable in fire-hazardous areas, since such a compound gives the material the ability to self-extinguish and contributes to the speedy elimination of a fire.

https://masterseptika.ru/youtu.be/MJamp08QWU4

The throughput of the pipes is high, and the possibility of self-cleaning allows the system to clog less often. In this case, no additional processing is required, there is no need for painting or applying a special layer, PVC resists the effects of external factors well. PVC pipes are durable and will last a long time. For a private home, they may be more suitable than cast iron ones, as they are light in weight, which makes installation easier. They are connected either by welding or using embedded couplings, which provides good sealing and does not require heavy and complex special equipment.

Construction of a sewer collector

Sewage collector is a system of pipes and pipelines designed to carry sewage and waste to a collection point, which is usually served by a reservoir or, simply, a cesspool. This is the most standard sewer well device, however, there are other, more complex, but also more practical, sealed and non-poisonous soils. Absolutely all types can be equipped with your own hands, all you need is an investment of finances and labor costs.

Methods for arranging a sewer collector

It is worth immediately noting that this is not a heating collector, but another device, which is a pipeline from a system of pipes laid in trenches. Sometimes a sewer structure is called a channel, and this will make it clearer what a sewer collector is and why it is needed.

A regular cesspool is a device that receives all wastewater. At the same time, a pit can be equipped literally in a matter of hours, simply by digging a foundation pit on the site, covering it with brick or something else, as shown in the photo. At the same time, we must not forget that the drain must be cleaned using a vacuum cleaner.

A septic tank is another option for collecting sewage and waste. As shown in the photo, this is a sealed structure that accepts a piping system that transports drains from plumbing fixtures. Such a device requires some preparatory work, but the general principle is the same: a pit is dug into which a reservoir is mounted, drainage pipelines are connected to it, and then the sewerage collector is put into operation.

Installation of a sewer collector

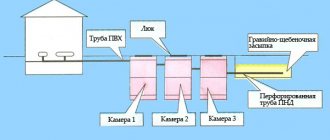

The collector structure is shown at the stage of laying the foundation. The process is simple and does not take much time:

- Below the freezing point of the soil, a trench is dug for the pipeline,

- A sand cushion (up to 20 cm thick) is placed at the bottom of the trench, compacted,

- Pipes are placed on top. For a gravity sewer system, the pipeline is installed with a slope towards the collector reservoir. The maximum slope size is 2 cm per 1 m of pipe,

- The pipeline is insulated,

- The tightness of the joints of the elements is checked by filling the structure with water,

- The trench is dug, the outlet of the pipeline is first lowered into the hole or connected to a septic tank, as shown in the photo.

The system is installed in pressure structures, which are installed in cases where gravity sewerage cannot be installed for one reason or another. Pressure sewerage consists of a tank for collecting wastewater and a pipeline. The line of pipes laid in trenches rises as it approaches the wastewater reservoir, and to prevent the flows from stagnating, the sewer collector is equipped with a pump. Such a system ensures ease of laying sewerage on any terrain and helps to increase the cleanliness of the system as much as possible.

The sewer collector is an important part of the sewerage system, without which it is impossible to construct an autonomous structure. Therefore, the arrangement of the pipeline and reservoir requires care and patience.

Materials for production

To make a collector unit, you can use pipes: metal (round and rectangular) or polypropylene. The connection of the outlet circuits to the collector pipe is made through ball or valve valves, with the help of which the supply of coolant to each section of the heating system is regulated.

Polypropylene knot

For this, pieces of polypropylene pipe are used, for example, with a diameter of 32 mm (you can use leftovers from the construction of a heating system at home) and several fittings in the form of tees with dimensions 32/32/32 - it is installed at the end of the collector unit, and 32/32/16 - intermediate elements for connecting to outlet channels in sections.

Photo 1. A manifold for a heating system made of polypropylene. The red lines indicate the coolant flow.

The first tee is mounted perpendicular to the main pipe. Its two outer pipes, located vertically, are connected as follows: the air vent is connected to the upper one, and the drain valve is connected to the lower one. A valve or ball valve is mounted to the opposite end of the collector installation. A pipe will go from it towards the boiler.

The intermediate tees are connected into one structure, which will be called a manifold. Therefore, the manifold installation is first assembled by welding tees 32/32/16 with pieces of 32 mm pipes, after which a tee 32/32/32 and a tap are installed on the opposite side. Next, taps or valves for 16 mm pipes are connected to the intermediate fittings. It is with their help that the coolant supply to each circuit will be adjusted.

Advantages of a polypropylene device

First of all, it is necessary to note the low cost of the design, because for this you only have to purchase a small number of tees and taps. Other advantages:

- if the welding is carried out correctly, then such a structure will not leak;

- polypropylene is not subject to corrosion, does not rot and does not change its characteristics under the influence of water and high temperatures;

- light weight of the device;

- ease of installation.

From brass fittings

To assemble such an installation, fittings and valves made of brass are used.

To do this, you need to connect the same tees with double-sided couplings using a threaded connection with mandatory winding of a sealing material on the threads.

Moreover, if the threads on the tees are internal (which is most often the case), then the couplings must have external threads and tightening nuts.

The number of tees is the number of circuits, plus one. The latter is installed at the end of the manifold and is connected by two pipes to a drain valve and an air vent.

From a profile pipe

This is the most difficult process associated with metal welding. This requires skills and experience, because welding two pipes requires complete welding of the joint throughout the entire thickness of the products being connected.

It is recommended to first draw a sketch on paper with a precise definition of the location of the pipes. The pipes used are pipes with a diameter corresponding to the dimensions of the pipes of the outlet circuits. The parameters on paper are transferred to profiled pipes used as a collector. Their cross-section is either 80x80 or 100x100 mm.

Photo 2. Heating manifold made of profile pipes. Red indicates hot coolant, blue indicates cold fluid.

On one side of them are marked the locations of the pipes with a precise designation of the outer diameter. After that, holes are cut out with a gas cutter or plasma cutter. Spurs are welded to them strictly perpendicularly. At one end, the large pipe is closed with a metal plug (fastening is done by electric welding).

On the other side, a similar plug is installed, in which a hole is pre-cut for connection to a valve or tap. That is, the drive cuts into the hole. Welding areas must be cleaned with a metal brush to remove scale.

Two such elements are connected into one structure by installing metal profiles between them. One is connected to the coolant supply circuit, the second to the return circuit. It is better if you designate different groups with different colors: red is used for supply, blue for return.

Pressure sewerage system made from pipes

The main element of the pressure sewer system is the SPS (sewage pressure station). The sewage pumping station collects all wastewater located in the internal pipelines of the building. The force of a powerful pump transports waste to the place of disposal. The pumping station operates as a storage tank, but only up to a certain level (for more details: “KNS sewage pumping station - principle of operation and types of installation”).

If such a distance cannot be ensured for one reason or another, or if sewer pipes must be laid higher than water pipes, then protective measures must be applied. Such measures may include laying a water pipeline from steel pipes or a sewerage system from cast iron, laying a water pipe in a protective case with a length of at least 5 m in each direction from the intersection in clay soils and 10 m in filtering ones.

If the sewer collector crosses the walls of tunnels, chambers, basements, etc., it must be enclosed in a case, the ends of which extend 0.2 m from the outer plane of such walls. The vertical distance between the sewer pipe and other communications intersected in the tunnel is at least 0.15 m.[.

The reasons may be different:

• if there is no free-flow sewer nearby for tapping, pressure sewers pass nearby, and water discharge into free-flow networks is impossible; • if the organization of a natural slope is impossible due to the large distance to the free-flow collector; • if the water intake point is located at a great depth; • if laying a gravity sewer is expensive or troublesome.

How to install polypropylene pipes?

Which radiators are preferable to use in an apartment or house?

www.684015.ru

Principle of operation

Having found out what a sewer collector is, let’s consider the principle of its operation. Wastewater from plumbing fixtures enters horizontal yard networks. They are connected into quarters and eventually join the main highway. It transports wastewater to treatment facilities. Thus, the sewer collector is a common pipeline that connects all the small lines together. It itself never branches into parts.

In autonomous systems of private houses, the role of the main element of the sewer system is played by a horizontal pipe connecting the system exit from the house with the receiving section of the septic tank. Its length is usually short, but the function it performs is no different from the tasks of large sewer pipelines.

In addition, there are storm drainage systems. They differ from household or industrial networks in their seasonal operating mode and relatively shallow depth of immersion in the ground. A storm sewer is a channel that carries rainwater to treatment systems. It can be implemented in the form of an underground pipe or in the form of an open gutter.

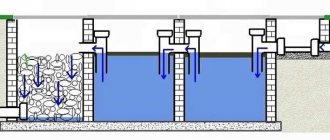

There are two types of channels, differing in the way wastewater moves:

- gravity type. Pipeline installed with a slight slope. Waste liquids move through it independently, under the influence of gravity;

- pressure sewer collector. Designed for forced supply of wastewater from a lower level to a higher level.

Gravity lines prevail because they are more profitable and simpler. However, sometimes it is necessary to use a pressure type sewer system if the terrain requires it, or if there are buildings, structures, or highways in the way of pipe laying.

A sewerage pressure manifold is a sealed pipeline designed for a certain fluid pressure. The wastewater is moved through it using a special pump. To reduce loads and save energy, the pressure sections of the collectors are made small. Typically, a sewage pressure station (SPS) is installed, which supplies wastewater under pressure to a certain height. The liquid then follows by gravity.

Sewer collector

Great Soviet Encyclopedia. - M.: Soviet Encyclopedia. 1969—1978.

See what a “sewer collector” is in other dictionaries:

sewer collector - sewer collector Pipeline of an external sewer network for collecting and discharging wastewater. sewer collector A section of an external sewerage network for collecting and discharging wastewater from one or more swimming pools... ... Technical Translator's Guide

Sewer collector - a pipeline of an external sewer network for collecting and discharging wastewater. Sewer collector A section of an external sewer network for collecting and discharging wastewater from one or more sewer basins.... ... Encyclopedia of terms, definitions and explanations of building materials

Collector (sewer) - Collector of the Neglinka River in Moscow. This term has other meanings, see Collector. Collector is the main channel of the drainage network. Imagine... Wikipedia

sewer collector - 3.9 sewer collector: Pipeline of an external sewer network for collecting and discharging wastewater. Source... Dictionary-reference book of terms of normative and technical documentation

SEWER COLLECTOR - a section of an external sewer network for collecting and discharging wastewater from one or more sewerage basins (Bulgarian language; Български) sewer collector (Czech language; Čeština) kanalizační sběrač (German language; Deutsch) Sammler... ... Construction Dictionary

basin sewer collector - A collector designed for collecting and discharging wastewater from the sewer network of one sewer basin Topics water supply and sewerage in general EN... ... Technical Translator's Reference

sewer drainage collector - Collector for collecting and discharging wastewater from the storm sewer network Topics water supply and sewerage in general EN storm sewerstormwater sewer DE... ... Technical Translator's Guide

main sewer collector - A collector that collects wastewater from two or more basin sewer collectors Topics water supply and sewerage in general EN main sewer DE... ... Technical Translator's Guide

suburban sewer collector - A collector that discharges wastewater in transit outside the city to pumping stations, wastewater treatment plants or to the point of discharge into reservoirs. Topics: water supply and... ... Technical Translator's Guide

sewer unloading collector - A collector installed in the system of an existing sewer network to unload existing sewer collectors that do not have the required throughput. Topics... Technical Translator's Directory

dic.academic.ru

Wells for removing excess water on the site

A drainage well is necessary on the site to maintain water balance. To do this, pipes are perforated in several rows. They open into a drainage structure that allows for repair work. The drainage collector on the site can be installed in several places. It performs many functions and has its own technical features.

Sewer collector - all about the main element in the sewerage system

Today it is difficult to imagine the appearance of modern cities if all wastewater were not disposed of by the sewer system. Without its development, installing a toilet inside a residential building would have been impossible. As a result, the installation of a sewer system is one of the most important tasks during the construction of a multi-storey, private house or country cottage. The entire system is connected by a sewer collector.

Problems of drainage care in cities

Every home, business, and public institution needs drinking and industrial water, which forms wastewater. The internal sewer system is connected to the street sewer, except in cases where the wastewater is treated by individual treatment plants.

A slope is always provided for drainage of wastewater, so it is not difficult to connect the building’s sanitary equipment to the public sewerage network. But in cities it often happens that the room is located below the level at which the sewer is located, and there is no free flow. If it is not actively filled, then it is not possible to remove wastewater from such premises. However, if the collector is subject to heavy filling, backwater occurs, which leads to flooding by backflow of water.

To solve this problem, a non-return valve is used, which protects the room from flooding. Also, in low-lying areas of the city, a pressure sewer is used, which can more efficiently receive wastewater. Individual pumps can be installed to improve the removal of wastewater from low areas of the city.

Note! For these purposes, it is recommended to use pumps that operate autonomously.

Pump - help for drowning people

The problem of sewerage connections is acute for residents of private houses. Let's figure out how to do this and connect to the collector output. This is the main task if the house does not have individual treatment facilities. For houses located on a hill, everything is very simple: a sewerage connection is made with access to the street communications network, and waste flows into them by gravity. It is more difficult if the house is below the level of the collector. Then it is necessary to make a pressure sewer with a pump.

For such sewerage, two types of pipes are used:

- Polyvinyl chloride (PVC),

- Polyethylene (PE).

Pipes with a diameter of up to 90 millimeters are supplied in coils, which reduces installation time. The pumping station can be located both inside the house and outside. The pump can operate for a long time without overheating, thanks to its reliable design, which gives the device greater strength.

Note! In a reliable pump, all parts are made of high-strength steel, only this can serve as a guarantee of its quality.

Principle of operation

In order for all the waste to get into the collector, a properly executed sewerage connection is necessary, only this guarantees reliable drainage of wastewater. The correct system functions as follows: all waste is moved into a special sealed container, then it is crushed by a pump and pumped into treatment facilities and a collector.

Important! Designing a pressure sewer is a complex undertaking, so it is better to contact a specialist. The diameter of the pipes for such a system is 32 millimeters, and their thickness is calculated so that the flow speed is no more than 0.7 meters per second

When this speed is reached, the self-cleaning system of sewer pipes comes into play.

The diameter of the pipes for such a system is 32 millimeters, and their thickness is calculated so that the flow speed is no more than 0.7 meters per second. When this speed is reached, the self-cleaning system of sewer pipes comes into play.

Advantages of pressure sewerage:

- The volume of excavation work performed is less,

- By using less material over longer distances, the cost is lower,

- Installation time is reduced,

- The service life of such a system is designed for 50 years.

Danger of using an underground system

Now it’s worth saying a little about diggers and other lovers of exploring underground communications - why are they so drawn to visiting underground tunnels? There is no single and correct answer to this, since young people are attracted by romance and adrenaline from what is happening, the desire to be in a forbidden and unknown place. Fantasy lovers want to imitate literary heroes, while more down-to-earth and selfish people are interested in the opportunity to find something valuable and sell it. But it should still be taken into account that in case of danger it is very rarely possible to quickly leave such a tunnel.

Do not forget that it is very difficult to get to the surface from such places, as many dangerous situations can arise:

- The possibility of a sudden discharge of wastewater in one gulp can lead to a short-term but complete filling of the canal, and this even has the risk of death for anyone who finds itself there.

- Security facilities that are connected to a city-scale sewer can attract the attention of criminals and simply dubious individuals, and meeting them underground will not do anything good.

- There is also a high probability of poisoning with methane gas (CH4), as well as toxic fumes, which is why everything can end sadly for travelers through the tunnels (even death).

- There are risks of vault collapses in old sewer sections, etc.

Please note that it is very easy for an unknowing person who gets inside for the first time to get lost. Such cases, unfortunately, are not at all uncommon, and not always everything ended well.

Typically, all tragic incidents occur due to the fact that rules and safety requirements are not followed. Such rules are collected in a document called “Inter-industry rules for labor protection when using water supply and sewerage facilities” and are intended for those specialists (primarily) who are directly involved in the repair and use of tanks and sewer wells.

In this document, which not only talks about the construction of collectors, in section 5.2 there is a mandatory list of devices and means (this includes measuring devices that each member of the team should have) that should be used during launch into the manhole, emergency tanks regulating type, sewer collectors and pressure drained water pipelines.

Here are some lines from the list:

- Gas analyzers or gas detectors.

- A rope for insurance, which is attached to a safety belt, its length should allow the possibility of lifting a worker even from the most remote workplace inside the well.

- Rechargeable flashlights.

- Gas masks with forced air supply.

- Fans.

- Tools for opening valves in a well.

- Rods for testing the strength of well brackets.

- Safety fences with safety sign.

- Portable types of stairs.

This is the most basic thing, and should always be with the master.

Types of wells and installation locations

The main task of wells is to monitor the general condition of systems.

Not so long ago, only concrete was used to create wells.

Reinforced concrete products such as rings, covers with holes for manholes, and bottoms, which are currently produced in large quantities, are used in the installation of high-capacity storm sewers.

In private houses, they made cesspools with their own hands, digging holes to a certain depth. After this, the walls were covered with bricks and waterproofed.

Today, concrete wells have faded into the background, giving all the laurels to plastic or fiberglass products. In addition, the developers of these wells have made a huge range of sizes, and this is very popular with designers when creating modern wells.

A well is a closed cylindrical vertical working chamber with embedded inlet and outlet pipes for the purpose of connecting to a storm sewer pipe system.

The well also has an inspection window or a service hatch, which allows you to go down to check the sewage system.

Another advantage of plastic wells is their ability to be assembled and disassembled.

Inspection wells in accordance with SNiP 2.04.03-85 are required to be installed:

- At the confluence of two or more water streams.

- At points where the direction of the sewer system changes.

- In places where the slope of the pipes varies.

- At points where a transition is made from pipes of the same diameter to other pipes of different diameters.

- On straight sections - at certain distances, depending on the diameter of the sewer pipe, for example:

- DN up to 150 mm – 35 m;

- DN 500-600 mm – 75 m, etc.

- DN 200-450 mm – 50 m

The dimensions of the pipes used will determine the diameter and height of the well.

In order to reduce hydraulic resistance in rotary wells, inserts are often used - these are gutters with a guiding function that ensure trouble-free passage of water flow in the required direction.

Wells are a very important element in the treatment of storm water collection.

Cleaning the cavity of a well is much easier than cleaning storm drains or flushing clogged or silted pipes.

For special differential wells, it is necessary to change the depth of the sewer pipes.

In this situation, the location of the outlet pipe of the required diameter should be higher than the inlet.

This may be relevant if it is necessary to reduce the depth of laid sewer pipes or to bypass underground obstacles. The installation of a storm drainage system at an industrial facility involves exceptional purification of the water flow before it is taken into a reservoir or onto a field with filtration.

In this case, specialized wells are equipped to take samples for the content of chemical components or suspended petroleum products in the water. They are installed after local stormwater treatment facilities in front of the output storage tank-collector.

Installation features

Sewerage construction is carried out on the basis of design data. Preliminary calculations and creation of an assembly diagram are carried out in accordance with SNiP and SanPiN standards, ensuring full compliance with all requirements.

The pipeline is laid at a depth exceeding the level of winter soil freezing. Procedure:

- excavation. They dig a trench for the pipeline. Immediately make nests for inspection wells;

- a sand cushion is poured onto the bottom of all recesses to level and give the desired slope;

- by laying pipes with a certain slope towards the receiving tank (usually for gravity systems 2 cm per meter);

- if plastic containers for wells are used, a concrete slab - an anchor - is first laid at the bottom. It prevents the reservoir from being squeezed out by groundwater;

- All connections are carefully sealed. Check the system for leaks. After this, the pipes are insulated and covered with soil.

When constructing pressure sets, the SPS is first assembled, after which the remaining trenches are laid according to the described scheme. For maintenance and repair of pumps, it is necessary to ensure access to the station at any time of the year.

Storage collectors for storm sewers

No matter how extensive the storm sewer project is, as a rule, it is “tied” to a single specific spillway point.

Thus, water flows are collected in one single channel or reduced to one reservoir. This deep technical plumbing equipment is called a manifold.

The collector can be a pipe made of reinforced concrete or polymer material, which is located horizontally. Pipelines from all water collection areas must cut into it.

If the collected water requires additional purification, then special filters of various types of purification should be placed on the collector.

After this, the water is diverted to drainage fields or discharged into reservoirs.

It is often more profitable to divert water into closed collectors than to discharge it. Closed-type collectors are sealed products with one chamber and the ability to purify water.

If you use a closed cycle on a storm sewer system, you can achieve significant water savings. This technique is used in industrial enterprises (such as, for example, car washes).

In a private home, such a technique can bring many benefits. As a rule, storm water in these situations is not contaminated and after stages of purification in sand traps for storm sewers, as well as after settling in closed-type collectors, this water can be used for domestic or agricultural purposes. In order to economically use storm water for these purposes, it is enough to install a submersible pump.

Often, instead of a collector, the above large wells are used. They can still collect rainwater and divert it to discharge points.

v-dom-voda.ru

Structural composition of the well and its purpose

The drainage well consists of:

a manifold cover allowing inspection of the device;

neck of the load-bearing part;

the bottom of wastewater accumulation.

The purpose of the drainage system depends on the type of well. For example, a rotary well is used to periodically clean a pipeline from accumulated substances under the influx of wastewater. This structure is installed at each bend of the pipe line. The inlet and outlet pipes to the well must have full access for maintenance.

The dimensions of the structure should be calculated based on repair and maintenance work, which involves the descent of a person. For these purposes, the width of the pit must be more than one meter. A drainage well can be an inspection well if there is a drainage system underground. Such a well is needed to drain the soil.

The absorber is built into the ground in the place where precipitation accumulates most. To do this, a ditch 2 meters wide is dug, the bottom of which is covered with a crushed stone-sand layer. Next, pipes are laid, which are completely covered with bitumen slag, gravel or crushed stone.

The gaps between the pipeline and the walls of the pit are compacted with brick filling. The upper part of the well is covered with geotextile and densely covered with earth. The design serves to drain wastewater naturally.

The water intake is a closed container for the drainage system. The structure serves for the accumulation of ducts, which at the outlet are used for domestic purposes or drain into the nearest body of water. The sewer tank can be purchased ready-made and consists of a plastic, hermetically sealed surface with a waterproof bottom.

Which is better - submersible or surface?

With the same output pressure, a submersible sewage pump consumes less power than its external self-priming counterpart. The former simply does not have to waste energy on sucking wastewater through the outlet from the bottom of the container to the working chamber. All the power of the electric motor is spent on creating pressure in the pressure line.

A pump completely immersed in wastewater produces an order of magnitude less noise than one installed on the surface. Water absorbs most of the sounds produced by the electric motor and the rotating working elements of the pump.

Surface equipment is noisier than equipment immersed in a sewer tank, which is cooled by the liquid around it

In terms of ease of use, the palm can be given to the surface model, but only if it is compact and portable. Plus, the correctness of its operation can be monitored simply by the noise it makes. If the electric motor does not operate correctly, extraneous sounds appear, immediately indicating problems.

With all other parameters and additional equipment being equal, a surface pumping station will almost always cost less than a submersible sewage pump. Of course, a lot depends on the manufacturer and competition in a particular region.

However, equipment immersed in sewage is, by definition, more technologically advanced and more complex, which determines its higher price.