Septic tanks for toilets, depending on the principle of operation, come in three types of designs: a sealed tank, a septic tank with filtration fields, and a biological treatment station. When choosing a septic tank, you need to pay attention to the following factors: level of water consumption, geology of the site, financial resources allocated for construction.

The use of sewer water treatment devices in a country house becomes consciously necessary, since dirty water immediately returns to the person who drained it, causing considerable harm.

Wanting to reduce cleaning costs, many residents of country houses install systems that operate on the principle of a septic tank without pumping.

In addition to reducing waste disposal costs, such devices make it possible to ensure a degree of water purification at the outlet of up to 98%. We suggest that you familiarize yourself with information on how to choose a septic tank for your dacha.

Types of storage tanks and the principle of their operation

First of all, you need to agree on terms:

- pumping is an action associated with the complete removal of the contents of a septic tank or cesspool using special equipment, in particular a suction machine;

- cleaning – removal from the storage chamber of solid sedimentary masses that have accumulated during long-term operation at the bottom of the container.

If a septic tank without pumping is a very real structure, then such devices simply do not exist without removing solid contaminants, since the formation of sediment is part of the principle of wastewater treatment and they must be removed in a timely manner so as not to disrupt the process.

The principle of operation of a cesspool

These are storage devices whose contents must be pumped out regularly.

Such structures are usually installed in summer cottages, where waste accumulates slowly. In conditions of permanent residence, even a family of 2-3 people produces such a quantity of wastewater that pumping will need to be done almost monthly.

The frequency of waste removal can be somewhat reduced if special bacterial compounds are used for processing sewage waste. Currently, the construction of cesspools is prohibited, but previously built ones continue to be used.

Instead of classic cesspools, septic tanks without pumping are often installed in dachas. The design and operating principle of this device is similar to filter wells up to 2.5 meters deep.

Its filtering capacity is extremely limited, and the proximity of aquifers does not at all guarantee that even the minimum requirements for water quality are met.

In this case, it is necessary to be sure that the aquifer in this place is at a greater depth during the period of maximum seasonal level.

The principle of operation of a dual-chamber drive

The construction of a two-chamber storage tank is the first step towards a septic tank without pumping and odor, since at this stage bacterial preparations are introduced to process wastewater. It uses anaerobic compounds that work without the participation of oxygen.

In this case, living bacteria are introduced directly into the waste mass and decompose solid organic inclusions, releasing carbon dioxide and forming a sediment called activated sludge.

It is such because biobacteria live, work and reproduce in this environment. Along with the decomposition of feces in the drains, the unpleasant odor is also neutralized.

The settled clarified water overflows and flows further through the external sewer system. In a single-body septic tank, divided into separate chambers by partitions, relatively pure liquid is transferred between them by overflowing over the edge, and in multi-body installations, the connection between individual tanks is made through pipes.

For this, in most cases, plastic pipes with a diameter of about 110-150 millimeters are used. The connections between the pipes and the septic tank bodies are sealed.

The operating principle of three chamber drives

Final wastewater treatment is carried out in septic tanks consisting of three chambers (they operate without pumping and without emitting an unpleasant odor). An additional container allows you to introduce another cleaning method - aeration.

In this case, the contents of the septic tank are purged with air. Excessive oxygen content in water triggers aerobic bacteria, which further destroy the elements of drain water. The degree of purification of the sewage liquid is 98-99%, and it is quite natural that there is no specific odor.

Such liquid can be quite safely poured into the nearest body of water or simply onto the ground, passing through which it undergoes additional filtration.

Septic tank designs without pumping are popular, in which the final purification of sewage liquids is carried out in a filter well. It is arranged as the third section of external treatment networks and is a well up to 2.5 meters deep.

The lower section of the drainage well is perforated, and it is from the holes that the formation of the filter zone without pumping begins.

The filter consists of the following elements:

- It is better to make the bottom layer from broken red brick, fraction 5-15 millimeters. Its thickness must be at least 30 centimeters.

- The middle layer is formed from gravel of the same fraction up to 50 centimeters thick.

- It is better to fill the top one with blast furnace slag in granules up to 10 millimeters in size. This material has strong adsorbent properties and deposits dirt and harmful inclusions.

- Drainage chamber;

- Working chamber;

- Filtering, sealing soil;

- Neck;

- Inspection hatch;

- Vengeance plate;

- Seal;

- Sealing hatch;

- Ventilation of the container;

- Top plate;

- Waterproofing material.

External sewerage without pumping can be equipped with a number of auxiliary devices that increase the degree of purification and disinfection of wastewater.

Fine filters allow you to retain fine particles. It is manufactured in the form of an airlift system and is installed immediately before discharging water onto the ground or into a reservoir.

Treatment of wastewater with ultraviolet radiation is carried out to destroy bacteria remaining in the liquid. For this purpose, special emitter lamps are used. They are placed in a sealed flask, which is installed in the drain pipe.

During operation in septic tanks, activated sludge precipitates. If the liquid fraction after cleaning can be safely drained, then the sediment must be removed using technical means. This operation will have to be performed regularly at least 1-2 times a year, depending on the degree of sewer load.

Stages of ground treatment

After a septic tank with anaerobic treatment, the wastewater has a low level of purification, up to 60%, and therefore it is mandatory to undergo ground treatment in infiltrators, on ground treatment fields or in drainage wells. Drainage wells can be constructed in sandy and sandy loam non-plastic soils. To make such a well, reinforced concrete rings, brick or stone masonry are usually used. Crushed granite or gravel is used as a filter component. The filter component layer is 1 m or more.

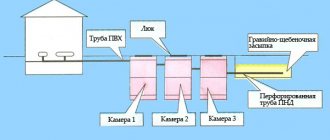

The procedure for constructing underground filtration fields, which can be installed on clay soils and in areas where it is possible to discharge treated wastewater into an unused reservoir:

- at a depth of 0.5-1.8 m, a gravel-sand cushion with a height of at least 200 mm is arranged;

- Perforated drainage pipes are laid in two tiers on the filter layer;

- The wastewater treated in the septic tank enters the pipes of the first tier, and then is collected in the lower pipe - the drain - through which it is sent to a reservoir or to the terrain.

For stable operation, it is necessary to regularly pump out the septic tank.

Let's consider the design of the device

The construction of external sewerage has the sole purpose of getting rid of human waste products. But before doing this, it is necessary to ensure the safety of the wastewater so as not to pollute the water that has yet to be used.

Traditionally, cesspools were used for this purpose to accumulate waste. Depending on the intensity of use, such devices require regular pumping of the contents; according to SanPin standards, such an event should be performed at least once every six months or when full.

Watch the video - operating principle, diagrams and experience of using sewerage without pumping

SEPTIC - PRINCIPLE OF OPERATION, DIAGRAM, EXPERIENCE OF USE. Sewerage without pumping. High groundwater

In some cases, the regularity of such an operation occurs within a month or two, and its cost ranges from 12,000 rubles.

The main components of a storage tank with pumping are:

- A durable sealed housing capable of holding contents without penetrating into the ground outside the cesspool. To do this, you need to thoroughly waterproof it.

- Natural tank ventilation system. When storing fecal waste, methane gas is formed, which in a certain proportion with air is a flammable or explosive mixture that must be regularly released from the chamber.

- Double cap on the neck. Internal wooden and external metal or plastic.

- A drain pipe through which wastewater flows from the internal sewer system to the external one.

The principle of constructing a septic tank without pumping is somewhat more complicated, since the processes occurring in wastewater during its processing are important.

Therefore, the main components of such devices are:

- Drain pipe between the exit from the building and the storage tank of the external sewerage system. Its diameter should be 100-110 millimeters, length at least 10 meters. For financial and technological reasons, plastic products are usually used.

- Next comes the storage tank, which performs several functions. The first is crushing the drain stream, for which a baffle plate is used, which directs the stream down and crushes it. In this case, heavy inclusions settle to the bottom, where they are processed by aerobic bacteria.

- When the liquid level rises to the overflow pipe, it begins to flow into the second container. An air atomizer and a low-power compressor for pumping atomized air are installed in it.

The sufficiency of oxygen in wastewater triggers the work of aerobic bacteria, which additionally process organic matter in the liquid being purified, bringing its degree of purification to 98-99%.

Further, various devices can be used in the form of chlorine cartridges, UV emitters, additional filters for final cleaning and disinfection of the drain.

Conclusion

With correct calculations and adherence to the scheme, the efficiency of wastewater treatment in home-made devices is not inferior to factory designs. But the feasibility of independent construction depends on the groundwater level. With a low groundwater level, it is cheaper to make a septic tank with your own hands, and with a high groundwater level, it is better to buy a ready-made sealed product.

The participants of our portal and experts in the topic “How to understand which sewer system to make?” will help you make the final choice. The topic about autonomous sewerage systems includes information on regulatory documentation, treatment plans for different groundwater occurrences and useful videos. Our other topics will help you install an aerobic septic tank and figure out whether bacteria can be added to the septic tank. This article about collective wastewater treatment systems talks about the advantages and disadvantages of sewage systems “for three”. The video contains recommendations from a specialist on choosing sewer pipes.

Subscribe to our Telegram channelExclusive posts every week

Pros and cons of septic tanks without pumping

The construction of treatment facilities requires careful design and precise execution, otherwise all sorts of troubles are guaranteed. But a properly designed drive during operation provides the user with a number of advantages:

- There are no unpleasant odors from sewerage on the site.

- There is no need to often call sewage disposal equipment, since almost the entire volume of wastewater passing through the sewer system is technologically neutralized.

- The risk of soil contamination is significantly reduced, since the degree of disinfection is very high. However, you must comply with the requirements for removing septic tank elements without pumping from sources of drinking water - wells and wells.

- The duration of use of treatment facilities can be tens of years.

However, for septic tanks without pumping there are specific disadvantages that may affect their performance:

- Before choosing the design of a sewerage facility, it is necessary to study the nature of the soils on the site. There are situations when installing your own treatment system is completely impossible, for example, if at the installation site there are dense clay soil substrates that prevent filtration.

- The treatment system must be properly designed taking into account the slopes of the connecting pipes.

- It is necessary to ensure 100% tightness of the entire system, taking into account seasonal soil movements. In this case, it is preferable to use solid-body systems made of plastic.

Sewage without pumping after a year.

The negative aspects in the use of such elements are very significant and require increased attention, but they do not at all indicate the impossibility of their use.

If all calculations are carried out correctly and the project is executed exactly, problems with the use of VOCs will not arise for 25-30 years.

Model selection

The choice of tank volume, number of chambers and operating principle of a septic tank for a summer residence and for a home largely depends on operating conditions. The functionality of a treatment facility at a dacha, where people come for a few hours or days, differs from how a septic tank works in a private house with a shower, kitchen, toilet and water-consuming household appliances (washing machines, dishwashers, etc.).

In a house with permanent residence, not only is the volume of wastewater larger, but its composition is also more complex, which includes both organic and chemically active substances. In this case, it is important to ensure the possibility of high-quality cleaning for drainage into the ground, so that you do not have to constantly call a sewer truck. Investment in the purchase of an effective aerobic energy-dependent septic tank and the costs of its operation in this case will pay off. But during breaks in operation at a summer cottage, bacteria can die.

We talked about what products are available for septic tanks and cesspools in another article. Features of the use of chemical and biological drugs.

You will learn how to make a wastewater treatment plant from Eurocubes yourself by reading this article.

You will find a review of models of peat country toilets here https://okanalizacii.ru/postrojki/tualet/torfyanoj-tualet-dlya-dachi-kakoj-vybrat.html

Productivity and volume of septic tanks without pumping

To completely purify wastewater passing through the external sewer, it must remain in the storage tank without pumping for at least 3 days. It is believed that this time is sufficient for complete processing of contaminants.

On the other hand, the current norm of water consumption per day for a country house is 200 liters. This takes into account not only direct spending, but also laundry, cooking, washing dishes and other needs.

If 3 people live in a house, then the total water requirement will be 600 liters. And this amount must remain in the septic tank for three days in order to undergo complete processing. Thus, the minimum capacity of this drive is 1.8 cubic meters.

However, let's look at this issue from the other side. The activity of bacteria remains in the temperature range of +3 - +30 degrees, so it is natural to assume that in cold weather conditions the ability to process wastewater will decrease.

Sewerage without pumping: part 1

It is possible that guests will appear in a country house, increasing water consumption for some time.

Taking into account the above considerations, it is better to play it safe and double the volume of the septic tank by 2-2.5 times. We suggest using an online calculator to determine the volume of the storage tank.

Important nuances

Since the principle of operation of a septic tank is based on the gradual sedimentation of impurities, the efficiency of its operation and the absence of impurities in the purified liquid depends, among other things, on the speed of water flow from one tank to another. A fast flow will not only impede the movement of sediment towards the bottom, but will also raise the silt that is already there.

It is extremely undesirable for inorganic substances with a very long decomposition period to enter the septic tank. It is important to ensure that polyethylene, plastic, etc. do not get into the sewer.

The diagram of the septic tank and the principle of its operation is shown in the video.

How do septic tanks work without pumping?

The designs of external sewerage devices are very diverse, but they all work on the same principle - separation of media by density for the purpose of recycling one of them. When using bacterial treatment, the drain is disinfected at the same time.

Most septic tanks without pumping for a private home or cottage are energy independent, since there is no way to regularly monitor their operation. The use of such treatment facilities does not make it possible to obtain a purification degree of more than 70%; final filtration occurs in the soil.

After several years of operation, the soil becomes so saturated with untreated water that a persistent sewer smell appears and can only be eliminated by replacing the top layer of soil to a depth of up to half a meter.

In energy-dependent septic tanks without pumping for a summer residence, the degree of purification is much higher, since additional treatment of wastewater with aerobic bacteria is carried out, additional airlift filtration and UV irradiation of purified water are often installed.

Sewerage without pumping

Let's consider the principle of operation of septic tanks without pumping of various modifications.

Termite

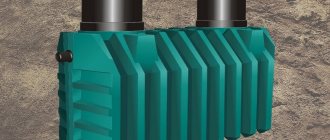

A number of products with this name are manufactured in one housing, divided into three chambers, connected to each other by overflow tubes.

The first two serve as settling tanks for separating wastewater into fractions; in the third chamber, bacterial treatment of wastewater is carried out. The degree of purification in such a device does not exceed 78%, which does not allow free drainage of liquid onto the ground without additional treatment. Further processing takes place in a specially designed filter.

Finely crushed pumice is used as a filler. After this, the purification is 95%, which allows the drain water to be discharged to the ground for additional purification through natural filtration.

The service life of a Termite septic tank reaches 45-50 years, the cost of the product is up to 24,000 rubles.

Septic tanks Topas

Autonomous treatment plants with this name are monohull devices, internally divided into four chambers. Each of them performs a certain cleaning stage.

All sections of the device are equipped with devices for aeration, which allows you to obtain a degree of purification of up to 98% using bacterial preparations. The operating principle of a septic tank is as follows:

- in the first chamber, contaminants are crushed and partially processed by bacteria under aeration conditions;

- in the second - further processing under the same conditions;

- the third and fourth compartments are arranged similarly.

As a result of intensive processing with aeration, the purification rate at the outlet is up to 98%.

This type of installation is energy dependent and can only operate using electricity. When left without it for 4-6 hours, the bacterial environment dies and needs to be restored.

A volley discharge of wastewater in such a device is unacceptable, so the capacity should be selected by volume with a substantial margin, or the number of guests received at the same time should be adjusted.

The cost of such a device is about 82,000 rubles. If you want to learn in more detail how the Topas septic tank works, read the article.

External sewerage devices "Tank"

Almost all septic tanks of this type are three-chamber and have the following operating principle:

- in the first of them, accumulation and sedimentation of filtered masses occurs;

- in the second chamber, chemical neutralization of wastewater and its biological disinfection is carried out;

- in the last tank, final filtration and additional purification using biobacteria are performed.

After passing through all stages, the degree of purification reaches 74%, and then the wastewater is further filtered as it passes through the ground. For this purpose, filter fields are installed using infiltrators.

They are box-shaped containers that are installed upside down. Filters are formed from sand, gravel and geotextiles.

Cleaning devices, which are of a block design, can be supplemented with standard elements and additional equipment.

By their nature, Tank devices are non-volatile and have the following advantages:

- Long lasting, seamless housings made of thick plastic can last up to 50 years.

- Easy to maintain.

The volume of processing of fecal wastewater in such a septic tank ranges from 600 to 1800 liters, respectively, and the price, taking into account the configuration, ranges from 20,000 to 69,000 rubles.

Septic tank "Triton"

The Triton brand of sewerage systems, well-known on the Russian market, offers a variety of products in terms of processing volumes. Miniature models have a capacity of 0.45 and 0.75 cubic meters.

Such installations are sufficient for houses with 1-2 residents and fully satisfy their needs. For larger households, a range of containers up to 40 cubic meters can be used.

In this case, the septic tank body consists of a single chamber, before the exit of which a biological filter with floating biomass is installed. With this design, the entire volume of purification is guaranteed to pass through the bioload, obtaining complete purification.

The water receives final filtration in the infiltrate, after which it can be discharged onto the ground without fear of contamination of groundwater.

The service life of the filter field is about 10 years.

Depending on the volume, such a device can be purchased at a price from 9,000 to 25,000 rubles.

Septic tank Ecopan

With this name, this product is a full-fledged VOC, characterized by the following positive qualities:

- The degree of wastewater treatment is 98%, regardless of the nature of the pollution.

- Can be used in difficult geological conditions - on heaving and clayey soils.

- The use of stiffening ribs provides greater mechanical strength of the housing.

- Easy installation and operation.

- Resistant to external and internal corrosion.

- The use of double walls ensures operation in severe frost conditions.

The disadvantages include the need to regularly clean the brush load.

Reliable and durable sewerage devices of the Ecopan series can be purchased at prices ranging from 82,000 to 265,000 rubles.

Septic tanks Rodlex

To reliably describe the entire variety of products of this brand, you will need a much larger volume than the scope of a short message provides.

But we advise you to pay close attention to these products. Simple but reliable technical and technological solutions place these products among the leaders in their class.

Pipes are the most important element of sewerage

Not least important when installing an autonomous system are the types and installation of sewer pipes. The material used to make pipes, their slope during installation, the number of bends and diameter significantly affect the performance of the sewer system.

When laying all types of sewerage, building codes allow the use of the following pipes:

- Cast iron;

- Ceramic

- Asbestos-cement;

- Plastic;

- Reinforced concrete.

For sewerage in a country house, pipes made of cast iron and polymer materials (plastic) are more often used.

5.1 Cast iron pipes

They are almost absent on the building materials market, but they can always be ordered.

Their main advantage is mechanical strength, which allows them to be carried out in places with heavy loads. However, the strength of cast iron is combined with its fragility and heaviness.

Cast iron drains silt up very quickly, require cleaning and are quite expensive.

The quality of cast iron pipes is regulated by GOST 6942-98 “CAST IRON SEWER PIPES AND FITTINGS FOR THEM”.

5.2 Plastic pipes

When constructing sewers in a private house, they are most often used. They have many advantages:

- No corrosion;

- Resistance to aggressive environments;

- Ability to withstand severe loads;

- The presence of a smooth inner surface, reducing the risk of blockages;

- They have fairly high strength.

Plastic pipes mean products made from such types of polymers as:

- Polyethylene (PE), which comes in high (LDPE) and low (HDPE) pressure;

- Polyvinyl chloride (PVC);

- Polypropylene (PP).

5.2.1 Polyvinyl chloride (PVC)

PVC pipes have been used in sewer installations for a long time. Their features and advantages:

1) There is no need to use special tools to make connections. They are connected “into a socket” or with glue;

2) PVC pipes are very rigid, and therefore it is necessary to use fittings to turn them;

3) Can be used for open, hidden installation of pipelines;

4) They have a fairly attractive appearance that does not disturb the interior when carrying out external installation;

PVC is one of the cheapest polymers, so it has an affordable price.

5.2.2 Polypropylene (PP)

An example of a pipe and some fittings made of PP: 1 - pipe, 2 - tee 87.5o, 3 - tee 45o, 4 - bend 87.5o, 5 - coupling

Polypropylene pipes can be single-layer or multi-layer. They are often performed in the following way: aluminum foil is attached on top of a polypropylene pipe, which is covered with a small layer of polymer on top. The layers are connected using holes in the pipe. The pipes are connected using special fittings using the cold welding method.

Septon

Septic tank "Septon" - new for 2021! Serves 3-15 people. The station provides deep wastewater treatment thanks to bacteria contained in a separate block of the station for up to three months without the entry of organic matter. The model range of septic tanks without pumping is attractive with a variety of options with different capacities, volume of volley discharges, and insertion depth of the supply pipe. The “Smart” module (crushed stone-free drainage system) is optional.

Technological solutions for the best septic tank 2021

The Septon septic tank is made of homogeneous integrally foamed copolymer (polypropylene + ethylene) and can withstand operating temperatures of +40...-40˚С. The body is represented by a self-supporting cylindrical vessel equipped with a rectangular lid. The neck and lid are painted green. The round shape, one weld seam ensures long-term operation of the septic tank - 25 years. The product has minimal dimensions, occupying 2 m2 of area.

The wastewater is treated biologically using suspended activated sludge. Air is supplied by a membrane tubular polymer aerator. Nitrogen compounds are best removed during general biological treatment. Forced drainage systems are equipped with a built-in storage tank with a drainage pump. The liquid is disinfected with a built-in ultraviolet disinfectant. The GSM system (sold separately) notifies about changes in the operation of the septic tank and simplifies management.

The septic tank operates without noise, odor, and does not require pumping. The degree of wastewater recycling reaches 98%. Conversion of a gravity structure into a forced one is allowed. The absence of fragile parts prevents mechanical breakdowns.

Principle of aerobic biological action

Septon Smart septic tanks for private homes can withstand uneven flow of wastewater, operate effectively at low loads, and support the vital activity of bacteria during large burst discharges, eliminating the washout of microflora. Biological treatment, accompanied by oxidation with oxygen, reduces the BOD and allows clean water to be discharged without filtration fields.

Aerobic-anoxic wastewater processing allows activated sludge to absorb organic and chemical compounds in the presence or absence of dissolved oxygen. The sludge mass, incubated from bacterial strains supplied along with organic waste, forms colonies of bacteria in the form of flakes that are easily separated from clean water. Airlifts, which circulate the liquid with compressed air bubbles, help prevent the destruction of activated sludge flakes.

Contents of delivery

Basic modifications of Septon septic tanks without pumping include a housing, a compressor, a technical passport, and a 110x15° outlet pipe.

Forced drainage systems are additionally equipped with a storage tank, a good drainage pump with a float switch, a reinforced PVC hose, fittings and connectors.

Model range of VOC "Septon" for a private home

The Septon line includes septic tanks of gravity, forced type (PR), extended modifications “Long” (the entrance height is increased by 40 cm, the body length is increased by 50 cm). The numbers in the marking indicate the volume of salvo discharge. Technical characteristics of Septon allow you to choose the best solution for a private home or cottage:

200 SAM, PR - inlet tube depth 60 cm, number of users 3-4, peak discharge 200 l, daily productivity 0.6 m3. Dimensions: 85x85x228 cm, energy consumption 1 kW/knock.

250 SAM, PR - inlet pipe height 60 cm, 4-5 consumers, one-time water supply 250 l, capacity 0.8 m3. Dimensions of a popular modification for a private home: 90x90x228 cm, energy consumption 1.2 kW.

320 SAM, PR, Long - pipe insertion height 90 cm, recommended number of residents 5-6, one-time discharge 320 l. Minimum dimensions: 100x100x250 cm, best energy consumption - 1.6 kW.

500 SAM, PR, Long - connection of the pipe at a height of 90 cm, users - 7...8, one-time supply of liquid - 500 l. Basic parameters: 112x112x250 cm, electricity - 2 kW.

800 SAM, PR, Long - insertion height - 90 cm, consumers - 9...10, peak discharge - 800 l, standard tank dimensions: 155x155x250 cm, capacity 1.8 m3/day, energy consumption - 2.6 kW.

1000 SAM, PR, Long - connection depth 90 cm, residents of a private house - 15, capacity 3 m3/day. Basic parameters: 177x177x250 cm. Power consumption of a septic tank without pumping is 3.1 kW.

Price range: 77-180 thousand rubles.

With a water consumption of 200 l/day per resident of a private house, the septic tank completely processes waste within the established limits. Sludge is pumped out every 3-6 months. When concluding a service agreement, the manufacturer provides 2 free technical services and provides a 5-year warranty.

Let's sum it up

A septic tank is part of a sewer system.

Equipped independently or purchased ready-made.

It can be equipped with a cleaning and filtration system or simply cumulative.

To process waste, different types of bacteria or a natural filter are used.

They can be autonomous and subject to regular cleaning.

Installed on the surface and underground.

A combined installation option is often used. Two-chamber septic tank and drainage filter.