With a clear and correct approach to organizing a water supply system from a well in a dacha, its quality will be an order of magnitude higher than tap water in a city apartment.

It is recommended to use water obtained from a well for drinking after a water analysis; to do this, you need to contact SES specialists to analyze the composition.

There are many filter units for wells in stores, and they are not cheap. Among the store options offered by sellers are:

- Filters – with silver purification,

- A little cheaper with activated carbon,

- The most affordable models are models with pebbles.

As an alternative, you can not buy a filter element in the store, but make a bottom filter with a simple design with your own hands. It will provide effective cleaning and will allow you not to worry about the quality of water all year round.

Why do you need a bottom filter in a well - operating principle

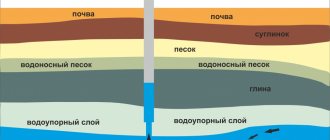

To understand the need to install such a filter on your site, you need to determine what kind of rock is at the bottom of the structure.

The following options are possible:

- If the bottom is made of dense clay and there are gushing springs, then the water will be clean and installation of a filter is not required.

- Soft clay washed away by water will make it cloudy, so it is recommended to fill the bottom with pebbles or crushed stone at least in a layer of 20-30 cm.

- Water seepage through sand requires the installation of a bottom filter.

- If there are swimmers, then you cannot do without this type of filter, as well as the protection of a shield made of mesh or wood.

The principle of operation of the bottom filter is quite simple. For its production, only natural materials are used. They are laid in layers of 20-30 cm in one order or another to perform the function of a natural layer and purify water from contaminants.

It is important to use only clean materials, otherwise, if they have already been used in other purification systems, the water, on the contrary, will become contaminated.

Materials used to create a well bottom filter:

- Quartz sand of fine fractions. Pre-wash 2-3 times. Can be replaced with geotextiles with a density of up to 100 grams per square meter.

- Shungite. Cleans well from heavy metals and organics. Resistant to erosion, medium grain size.

- Crushed stone. Under no circumstances should it be intended for construction work; granite stones, which will pollute the water, are also not suitable.

- Sea and river pebbles. The material is cheap, you can collect it yourself, but be sure to rinse it before putting it in the well.

- Jade. Filters water from microorganisms; water after purification with jadeite has a beneficial effect on plants.

Some care tips

The bottom filter, after proper assembly, does not require special attention, but if it is not cleaned in a timely manner, the quality of the water will deteriorate significantly.

- Inspect the filter once every six months. If plaque has formed on its upper layers, it is time to clean and rinse the barrier.

- Once a year, stones (especially shungite) must be washed with citric acid or calcined (~300 C).

- Every five years, it is imperative to replace all layers and components of the filter, especially the shield (if it is made of wood).

- After installing the filter, you cannot immediately use the source. Better to let it sit for a day or two.

Types of bottom filters for wells

Today, two main types of such filters are used:

1.Direct. The bottom is covered with material with large fractions, and fine-grained backfill is poured on top. This is the best option for bottoms with loose clay or quicksand.

Installation procedure for direct bottom filter:

- removal of contaminants from the bottom,

- pouring material 20 cm of coarse fraction,

- pouring crushed stone 30 cm of medium fraction,

- formation of a top layer of sand and pebbles.

2.Reverse. Recommended for sandy wells with a calm flow. Material with small fractions is placed at the bottom. Large ones form the top layer. The return filter holds the sand, preventing it from rising to the top. As a rule, river sand is placed on the bottom, then shungite, gravel with a fraction of about 1 cm, for the top layer crushed stone with a fraction of 5 cm is used.

Installation procedure for the return bottom filter:

- pouring river sand,

- pouring gravel, pebbles, shungite,

- a pile of crushed stones and large stones.

The recommended layer thickness in both the first and second cases is at least 25 cm. Both types of filter require periodic cleaning, as well as, after several years, replacement of individual layers or the entire filter.

How to install a bottom shield with a filter yourself

In situations where the water at the bottom of the well moves too quickly, as well as when there are quicksand nearby, it is necessary to protect the bottom from erosion. To do this, use a special shield, which is made from a mesh of metal or wood (aspen, oak, larch, juniper and other types of wood).

Wooden shields are more popular than metal ones, as they have the following advantages:

- are made from environmentally friendly materials,

- wood has disinfecting properties,

- availability of material, including cost.

The process of creating a straight filter with a wooden shield

The sequence of manufacturing a well bottom filter is as follows:

- A shield is made with a diameter corresponding to the size of the well. The shield will require durable boards in which holes are specially drilled to ensure water circulation.

- At the bottom of the shield, a 5 cm high beam is attached - these will be the “legs”.

- The finished shield should be lowered to the bottom of the well, and a layer of large stones should be placed on top of it. This is how the shield is secured.

- For the first layer of the filter, river pebbles or gravel are used, for the second - pebbles, but of a smaller size, for the third - quartz sand, and for the fourth - shungite. The optimal thickness of each layer is about 150 mm, but the upper layers can be smaller, up to 5 cm. Thus, the bottom filter will take about half a meter of the entire well depth.

Such a filter for a quicksand well can be made with your own hands.

Do not forget that the bottom filter requires cleaning and rinsing every 6 years . As for the shield, it is necessary in cases where there are quicksand below or the speed of water inflow is very high. It is recommended to make it from wood with antibacterial properties - for example, juniper, oak is also suitable, but you can also use a metal mesh with cells no larger than 2 * 2 mm.

Important: A wooden shield will last no more than 5 years. You can increase its service life by wrapping it in geotextiles.

river sand

This is a fine-grained material with a high content of quartz and a small amount of clay or other impurities. Before filling into the bottom part of a well shaft, river sand must be washed with water several times. This will allow you to almost completely remove any unwanted suspended matter from the filter system.

Review of filtration materials

The principle of operation of the filter is simple and well known to everyone. It is necessary to pass water through a layer of filtration material. The filler can be different:

- textile;

- cotton wool;

- paper napkins;

- gauze;

- sand;

- grass;

- coal;

- Lutraxil.

Filters made from gauze, cotton wool, paper napkins, fabric and other similar materials are quite effective, but short-lived. They need to be changed quite often. However, they are quite suitable as a temporary option.

You can buy charcoal in a store or make it yourself

For regular use, other materials are used, mainly charcoal. It is laid in layers, alternating with sand, gravel, grass, etc. Lutraxil is a synthetic material made from polypropylene fibers.

Pebbles

Pebbles are used as backfill for medium or large fractions. Such material is represented by differently rounded rock fragments, the diameter of which varies between 1–15 cm. Sea pebbles, as a rule, have a flatter shape compared to river stone. Before backfilling, the material is washed.

What materials can be used?

Let's get acquainted with the materials that can be used when arranging a bottom filter. These include:

- sand;

- jade;

- pebbles;

- shungite;

- crushed stone;

- gravel.

Prohibited materials

The fine fraction backfill is river sand . It is mined, as you probably already guessed, in quarries located on the river bed. Good sand contains a lot of quartz, but, on the contrary, there is little silt, clay and other impurities. For the material to be such, it must be properly prepared before filling it into the well.

How is river sand mined?

Step 1. To begin with, sand is poured into a large container about 1/3 full.

Step 2. Then the sand is filled with a large amount of water.

The sand needs to be filled with water

Step 3. Sand and water are mixed with a stick until a mass of homogeneous consistency is obtained. Then you need to wait 30-60 seconds for the impurities to float to the top and the heavy sand to sink to the bottom of the container. After this, the water is carefully drained.

Step 3. The procedure must be repeated up to 3 times (the exact number depends on the condition of the sand). The output is washed and ready-to-use material.

river sand

On a note! Sometimes geotextiles are used instead of sand - they are laid on or under the backfill (this depends on the type of bottom filter, we discussed this above).

Pebbles are rounded pebbles that became such as a result of colliding with each other on the shore of a reservoir or at its bottom. The size of the pebbles varies between 1-15 cm, and therefore it can be used for both fine-grained and coarse-grained layers. The material has no problems with background radiation, so use it without any fears. But before backfilling, the pebbles should be washed in the same way as river sand.

Pebbles of large fraction

Medium river pebbles

As for gravel , it is a sedimentary rock and is used for the middle fraction layer. Gravel is porous and loose, it can absorb various substances, and therefore is a kind of adsorbent in the filter. But this is also a drawback of the material - the backfill must be changed periodically so that it does not “share” absorbed substances with water.

On a note! When buying gravel, be interested in its place of origin. Do not buy used gravel, because you do not know what it has absorbed during this time and how this will affect the quality of well water.

River gravel

Crushed stone is obtained by crushing rocks and metallurgical waste. The material in the filters is used as coarse backfill (bottom or top). When purchasing crushed stone, be sure to inquire about the presence of a certificate that confirms its environmental safety.

Photo of crushed stone

Shungite is also a rock, but has a different origin - in the past it was bottom organic sediments. Shungite is gray or black in color and is an excellent adsorbent. It is used, like gravel, as backfill for the middle fraction. It purifies water by absorbing harmful substances, and therefore needs to be changed regularly. Shungite must be washed before filling or, alternatively, filled in and not used for a while (about 24 hours) in the well so that the shungite dust settles to the bottom.

Shungite

On a note! Be careful when buying shungite - sellers often pass off shungite as it. Both materials look the same, but the second does not have useful adsorbing properties.

And the last material is jadeite . It is an aluminum-sodium silicate and has a greenish color, like jade. Used in filters for the middle fraction layer. It does not react chemically with water, which is good. As a rule, jadeite is purchased for sauna stoves, and therefore you need to look for it in the appropriate departments of construction stores.

Jadeite stone

Video - How to equip a bottom filter with shungite

Crushed stone

Stone of medium and relatively large sizes is obtained through the process of crushing certain types of rocks. Coarse backfill is used at the very top of the bottom of the well or at the bottom of the structure.

When choosing this filter material, you must ensure that there are no increased levels of radioactivity.

How do we achieve high-quality water?

One way is to install a bulk filter at the bottom. The need is determined, first of all, by the condition of the soil in which the well is dug.

If there is dense loam at the bottom, then a purification device is not installed: in such wells the water is always of good quality. Equipping with a filter will not improve the situation, but will even worsen it, since it will create a barrier to the access of water. Here springs flow and the well is filled through very small channels. The degree of filtration is high, there are practically no impurities in the liquid.

The water becomes cloudy if there is a bottom layer of clay interspersed with other soil. The liquid coming from the springs dissolves the loose soil and is enriched with substances of little use - this is undesirable. It is necessary to take into account the fact of filling the well pit. If the liquid rises high, then in this case the filter is not installed.

The main point is to avoid scooping from the bottom or in the immediate vicinity, so as not to muddy the water. In this case, use small stone (crushed stone, gravel) in a layer of up to 30 centimeters. Such a filter made of natural components will provide the necessary transparency, provided that the spring freely exits into the well. When installing a well in sandy soil, the need to strengthen the walls must be taken into account. Sand tends to wash up and fill the space provided, clogging the source and worsening the properties of the water.

A pump installed in a well with such a bottom quickly becomes clogged and requires frequent additional maintenance. To prevent this from happening, a wooden shield is included in the filter. It is usually made from boards. The type of wood chosen is moisture-resistant: oak, larch, aspen. Several holes are made in the shield. As an additional material, a metal mesh is attached to the shield, preferably made of stainless steel.

The shield is made in the following sequence. Measure its internal diameter (when the well is round) or perimeter (if it is quadrangular). The size is made 1.5-2 centimeters smaller than required. Determined by the type of wood. Select the material with the least amount of damage. The presence of knots and cracks will affect the service life. Connect the boards. Gaps between them are allowed up to 0.5 centimeters. Stainless steel screws or self-tapping screws are used as fasteners. Despite the selection of material, this part of the filter must be replaced every 4 years.

The general rule for using a well after installing the shield and filter filling is the time when it can be used. It is a day. Practice shows that with constant monitoring of the taste and smell of the liquid, the service life of the shield can be determined. The filter elements used (stones of different fractions) should be washed periodically. This is a labor-intensive process, which is a major disadvantage.

When using a well with a sandy bottom, it is necessary to draw water only from the upper layers of the well. By picking it from the bottom, you will inevitably reduce clarity and quality.

The most unfavorable type of soil at the bottom is quicksand. This is a layer of soil - very moist and consisting of a mixture of clay and sand, which constantly flows into the well. It is necessary to go through a layer of quicksand to reach denser soil. But when there is quicksand, a bottom filter is required. A shield with a metal mesh is also used. This type of soil tends to absorb everything in its path. If the shield is not installed, the stones intended for filtration will become covered with a layer of unwanted mixture.

Methods for installing bottom filters

Today, there are two known options for installing bottom filters: direct and reverse installation. The main difference is the order in which the filter layers are poured.

The direct method is to arrange the filter stones on the shield in order of decreasing size. The shield is used in sandy soils and quicksand. Large fraction stones are placed on it, then medium ones and then small ones on top.

The reverse method speaks for itself. Laying begins with fine stones, and large filter elements with this method end up in the top layer.

The size of the filter stone strips in both methods usually does not exceed 150 mm. The difference in the amount of filler for each subsequent layer should be 6 times.

Components that are not hazardous to human health are used for filtration. In practice, natural ingredients found in nature are used: wild stone of various sizes, crushed stone, coarse sand. Before placing them in the well, they are inspected to ensure that organic substances do not accidentally get into it.

Shungite

One of the rocks in the form of ancient bottom, but already petrified organic sediments. Shungite can have a black or grayish color. A highly effective adsorbent easily purifies water and is most often used as a backfill for the middle fraction, which serves as a worthy replacement for traditional gravel.

The bottom filter is an important part of any well shaft, so the materials used to equip it must meet a number of requirements, including resistance to water erosion, cleanliness and safety.

When organizing the water supply of a site, owners often consider several options. As a result, many people opt for wells, expecting to receive clean, fresh, tasty water, regardless of the whims of utility services and other organizations. There is a reason for this, but you need to take into account that building a well is a responsible undertaking. The master faces many questions. For example, is it necessary to install a filter for a well? What material should I choose for it? After all, the quality of water, and therefore health, depends on it.

When is drinking well cleaning necessary?

The well receives water from clean underground sources, however, the well is constantly polluted, there can be many reasons, for example:

- Organic matter that accumulates on the walls of a wooden or concrete ring well, loving a humid environment. Algae, growing and then dying and decomposing, poison the water, lead to its darkening, and impart a musty taste;

- Often, an open well lid leads to the fact that leaves, sticks, algae, or even small animals can get in there, and the water can turn green;

- Damage to a well due to depressurization of pipes leads to a deterioration in water quality, the entry of bacteria or other contaminants into it;

- Mineral substances, sand, clay, etc., entering well water during floods lead to cloudiness;

In all these cases, cleaning the well is necessary, however, even if the water is visually in order, after winter it is imperative to carry out preventive procedures to avoid contamination after a flood.

To be or not to be a bottom filter?

Experienced craftsmen assure that installing a filter or even a simple gravel fill is not necessary in all wells. In most cases, they will either be useless or even harmful.

The fact that cleaning the well in the future will most likely have to be paid for at double the rate is also not in favor of the filter. Often the best solution is to leave the bottom in its natural state. How not to make a mistake?

The bottom filter is usually a layer of stones that retain all harmful substances.

You can answer the question of whether a bottom filter is needed for a well in your particular case by paying attention to some factors, in particular the bottom:

- If the well is dug in clayey soil, and its bottom is dense clay from which fontanelles gush out, then there is no need to install a filter. In this case, it can only do harm by “clogging” the water vein. The water in such wells will be clean and fresh even without filtration.

- In a well with a bottom made of loose clay, the water very quickly becomes cloudy because the springs erode the soft layer. Large river pebbles or the so-called gravel fill 10-15 cm thick, which will trap clay particles, will help solve the problem. It is only important to ensure that the water source is not blocked.

- If a well is dug in sandy soil, pay attention not only to the bottom, but also to the “walls”. Sand washed away by water can turn clean, good water into undrinkable water. In such conditions, it is impossible to draw water using a pump: the equipment will fail almost immediately. It is in such cases that a well water filter is not only desirable, it is simply necessary.

How to make an aspen shield

The shield consists of boards and beams. The basis is made up of boards, which are fastened with slatted crossbars made of wooden blocks. It is better to fasten the parts with clamps or wedges made of aspen. There should be no metal nails. A square structure with a side slightly smaller than the diameter of the well is assembled from boards. They are laid with a gap of up to 5 mm. Then a circle is drawn on the shield and cut out with a jigsaw or hacksaw.

It is permissible to make 70-100 holes with a diameter of 10-20 mm in the shield. Before installation, it is wrapped in a piece of geotextile, immersed in a well and placed on quicksand soil. On clay soil, a filter element is not needed, since there is little suspended matter in the water.

Sand itself is able to clean water from impurities without additional devices.

Methods for installing such a filter

There are two ways to install a bottom filter: direct and reverse. They differ in the sequence of layers.

- When laying directly, the largest stones are placed at the bottom, then the medium ones, and small pebbles are at the top. This method is also used when using a shield that protects against quicksand.

- When laid back, the largest stones are on top, and the smallest ones are at the bottom. Sometimes the bottom is covered with a layer of coarse quartz sand.

The thickness of the layers (using any method) is 10-15 cm, and the “filler” fraction in each differs by approximately 5-6 times.

What you need to know

You can also make a bottom filter for a well from stainless steel. To do this, a stainless mesh is fixed between two steel circles of suitable diameter. In this case, the cell size should be within 1-3 mm. But shields of this type are quite thin and require frequent replacement due to the fact that they quickly get stuck in the sand.

To prevent the filter from being lifted by water, it is filled with large stones, on top of which pebbles or gravel are laid. Their total thickness should be at least 15 cm. If there is strong quicksand, systematic installation of a new shield will be required, since the old one will be sucked into the soil.

Filter materials and their preparation

The materials used to create the bottom filter must meet strict toxic safety requirements and not decompose or dissolve in water.

Those who don't have a lot of money can afford filters containing silver, for example. But inexpensive natural materials are more accessible: crushed stone, pebbles, gravel, river and quartz sand, shungite, jadeite. A good option would be special bath stones, which can be used to create the coarsest-grained layer.

Coarse-grained quartz sand perfectly retains suspended particles

Shungite well purifies water from oil products, heavy metals and various organic compounds, mineralizes

The ideal material for the filter is river pebbles

Crushed stone is not the best material for a bottom filter. Granite crushed stone is absolutely not suitable

Water filtered using jadeite does not contain microorganisms that can cause allergic reactions; it has a beneficial effect not only on humans, but also on plants

Before laying on the bottom of the well, all materials must be checked for the absence of organic impurities and washed. The sand is poured into a container, filled with water and mixed thoroughly, the water is drained.

And so on several times until the liquid remains almost clear.

When creating a bottom filter in combination with natural ones, you can use modern artificial materials, for example, geotextiles.

You cannot use materials that have previously been used in any other systems (cleaning, for example). Because the porous structure of many of them allows harmful substances to accumulate.

What care does the shield need?

Any functioning well requires maintenance. It is recommended to clean it every year. This procedure keeps the water level high throughout its service life. Its quality remains the same. Suspensions do not interfere with pump operation. When proper maintenance is carried out, the well does not silt up much, and cleaning work takes less time. After 5 years, the filter element is washed and cleaned. If the parts become unusable, another device is made.

Installing a bottom filter in a well is not a necessary measure to improve water quality. Many well and borehole owners avoid using shields because they make it difficult to purify their drinking water source. Its construction is necessary on moving soil. Choosing a filter device is a matter for every well owner.

With a shield or on a shield?

If there is quicksand at the bottom of the well or water flows too quickly, then before installing the filter, install a shield with holes. The material used for its manufacture is wood or metal mesh.

Wooden shield

It is quite possible to make a wooden shield yourself: you need to buy boards and knock them down close to each other.

Suitable wood is oak, aspen, larch or juniper. It is advisable to use stainless steel nails

Next, draw a circle along the diameter of the well (slightly smaller). Several holes are drilled closer to the center, about 5 mm. The shield is cut, sometimes wrapped in geotextile, and installed on the bottom. To prevent it from floating, large stones are placed on top, then covered with the selected material.

Important! Decomposing over time, almost any wood gives the water a sweetish putrid taste, and an unpleasant odor gradually appears. Such a shield needs to be changed after 3-5 years.

Experienced craftsmen recommend using a juniper shield when it is necessary to reanimate a well; this may be necessary if they have not been used for a long time. First, they are cleaned, then treated with a special disinfecting solution and installed a bottom shield with antibacterial properties.

Shield made of mesh

To reduce the amount of sand entering the mine, you can make a shield from a fine-mesh galvanized or stainless steel mesh (mesh size no more than 2x2 mm).

You will need two metal hoops, which can be made from either sheet iron or thick wire; a mesh is secured between them.

The outer diameter of the frame should be 2-5 mm less than the inner diameter of the well

The structure is installed on a bedding of stones, the thickness of which depends on the intensity of water inflow and ranges from 10 to 30 cm. It is secured using locking pins mounted in the walls of the well.

The bottom filter does not require special care, but when cleaning the well you need to pay attention to it: remove it, wash it or replace it.

Today, a well is not such a rare occurrence. In many localities in our country, this is a mandatory element of private housing construction. To purify fresh water sources in a well, a bottom filter is used.

Crushed stone is a necessary component of the bottom filter.

Reviews

Some users consider the construction of a bottom filter impractical. The following arguments are put forward: the water in the well is purified by settling, the main thing is not to select water too intensively. If the influx of water is weak, it is recommended to gradually pump it out into an intermediate container buried next to the well (if it is used only in the summer, it is not necessary to bury it).

Water is pumped in using a constantly running car pump or airlift, and from the intermediate tank water is used for irrigation or water supply as usual using a pumping station.

At the same time, an aspen shield is recognized as the best means of controlling quicksand, which can gradually fill the well. A more expensive, but also more reliable option is to deepen the well by selecting quicksand and installing the shaft on a clay horizon, which is always located under the quicksand. Users generally do not recommend backfilling with pebbles or crushed stone without installing a shield.

In order not to have to fuss with the filter and at the same time constantly receive high-quality water, experienced users advise ordering exploratory drilling before building a well.

Before organizing a well, you need to find the best place where there is a good aquifer. How to find water on a site for a well without involving specialists, read on. Observation of natural phenomena and exploratory drilling with your own hands.

Read about the advantages of organizing a well from polymer sand blocks in this article.

Crushed stone in the bottom filter

The design of the bottom filter is simple and ingenious. Essentially, this is a repetition of nature's natural method of filtering liquid. Water passes through several layers of bulk materials, which retain small particles and impurities. They absorb everything extraneous. In the classic version, there are three layers in which the grain size of the stone successively increases: the first layer is sand, then small fractions of crushed stone, and at the end they are filled with a large fraction, usually 40–70 mm. Sometimes two or four additional layers are poured.

Direct backfilling is necessary when placing a well on quicksand or loose soil. Backfilling is effective if there is sand at the bottom of the well and the water comes in slowly. Sooner or later, such filters become clogged. Experts recommend cleaning them every three to four years.

Crushed stone is placed in a well for two reasons. The first is to provide additional filtration when using several fractions. Sand traps dirt and other particles. The crushed stone layer is designed to retain sand and all other impurities. In addition, it protects the well from agitation.

Well bottom maintenance

Every well requires constant maintenance. Regardless of the type of well and the method of arranging its bottom, we strongly recommend cleaning it at least once a year. In practice, we constantly observe the benefits that such a responsible approach provides:

- The well's flow rate remains consistently high throughout its entire operational life.

- The quality of water does not decrease over time, which has a positive effect on the operation of pumping equipment, allows for savings and more rational use of water treatment systems

- There is no heavy silting, so cleaning work takes much less time

- We promptly detect dangerous changes - the occurrence of cracks in aspen panels, rings

If the well is located on quicksand, an aspen shield is installed at the bottom and a reinforced filter is poured, then we recommend monitoring its condition twice a year.

Crushed stone or gravel?

In construction, it is customary to distinguish between the destruction products of various rocks - gravel and crushed stone. But the first one is the result of a natural process, and crushed stone is obtained artificially, by crushing rocks using special mechanisms.

Crushed stone is in demand in construction

The gravel turns out smoother, its dimensions do not exceed 20 mm. The crushed stone is much cleaner, without foreign inclusions, acute-angled, reaching 200 mm.

Thanks to this shape, the binding capacity of the stone increases significantly. It is added to concrete and reinforced concrete products to increase strength.

For the same reason, it is needed in the filtration layer of wells, drainage systems, and cesspools. The filtration layer of crushed stone is better than gravel at any compaction density.

Materials for filtration equipment

The efficiency of cleaning depends on the quality of the filtration material; a limited number of them are used in wells, the main ones being:

Stainless steel. In addition to strength, the material has flexibility and excellent corrosion resistance; the durability of stainless steel is tens of years. It is used to make strong meshes and wires that are mounted on top of the pipes. The disadvantages include the high cost of stainless steel products.

Plastic. Plastic is another common material for the manufacture of filters in water sources; meshes and cords are made from it, which are cheaper than stainless steel. Plastic is corrosion-resistant and inert to most chemicals, easy to install and has a long service life. The disadvantages of plastics include low physical strength, which does not allow them to withstand heavy loads at significant depths.

Non-ferrous metals. Copper, brass, and bronze can be used in the manufacture of water filters without any restrictions; they have high corrosion resistance and a long service life. Soft alloys with a high copper content are recommended for use at shallow depths to avoid deformation from strong water pressure. In the manufacture of filter elements, brass mesh and thick wire made of brass or copper are used.

Rice. 4 Filter for casing pipe - installation in the well

Steel. Steel filters are susceptible to corrosion and can be used as a budget option in water intake sources intended for technical needs. Increased content of iron oxide in water as a result of iron corrosion of more than 0.3 mg. per liter leaves a yellow residue on water main equipment and plumbing fixtures. Galvanized steel also rusts over time to form zinc oxides, which are harmful to human health - this material is not recommended for use in water filter elements.

About clean water

And perhaps it’s worth starting with the question because of which people resort to all sorts of tricks. Whether the water in your well is clean.

It is necessary to distinguish between the concepts of “clean” and “drinkable”. In appearance, the water in a well may be transparent and clean, but it will not necessarily be potable, that is, comply with sanitary standards. To determine this, chemical analysis is necessary.

Is the water in your well clean?

The well is fed by groundwater (you can read more about this in the publication Wells and boreholes: what are the types of aquifers). External water (atmospheric precipitation or water filling reservoirs) becomes groundwater, passing through the thickness of the earth. This cleanses it of most types of contaminants, including biological ones.

But at the same time, saturation with mineral elements occurs, because water is a universal solvent. There is nothing you can do about the chemical composition of groundwater, since it depends on the structure of the soil through which the water passes. But it is within your power to prevent moisture from entering the well that has not undergone natural filtration.