Technological production cycles of chemical, metallurgical, energy and defense enterprises use, in addition to basic materials and raw materials, ordinary water, which plays a large role in product production technology. Large volumes of fresh water used for the preparation of reagent solutions and as auxiliary cooling operations contain simply a huge amount of chemical impurities and additives that make such water dangerous even in the form of industrial wastewater.

The problem of purifying such waters, their use in a further technological cycle or discharge into the general sewer system today is completely handled by chemical wastewater treatment equipment, which ensures not only the preparation of water to the standards of household wastewater, but also even bringing purified fresh water to the standards suitable for technical use.

Basic methods of chemical treatment of industrial wastewater

Chemical methods for purifying industrial wastewater today are used mainly to bind and remove hazardous chemical elements from the volume of process water and bring the main parameters of such wastewater to standards that allow further conventional biological treatment.

Literally, in the process of such purification, the main types of chemical reactions are used:

- Neutralization of hazardous compounds and elements;

- Oxidative reaction;

- Reaction of reduction of chemical elements.

In the technological cycle of treatment facilities of industrial enterprises, chemical treatment is applicable:

- To obtain purified technical water;

- Purification of industrial wastewater from chemical compounds before discharge into the sewer system for further biological treatment;

- Extraction of valuable chemical elements for further processing;

- When carrying out post-purification of water in settling tanks for discharge into open water bodies.

Chemical treatment of wastewater before discharging it into a general sewer can significantly improve safety and speed up the biotreatment process.

Recovery

The reduction technique is used quite rarely, since it is not as effective as oxidation. However, using this technology it is possible to convert oxidized forms of toxic arsenic, mercury, chromium, heavy and transition metals into a molecular state. This is necessary for their further removal from water when pumping it through chemical filters.

With the correct use of chemical reagents, it is possible to achieve the required quality when purifying water of various volumes. Due to this, such methods have become very popular among large enterprises.

Neutralization of industrial wastes

Most industrial enterprises using chemical treatment of industrial wastewater most often use in their treatment plants and complexes means to neutralize the acidic and alkaline indicators of water to an acidity level of 6.5–8.5 (pH) acceptable for further processing. A decrease or, conversely, an increase in the acidity level of wastewater allows the liquid to be further used for technological processes, since this indicator is no longer dangerous to humans.

Water brought to this level can be used for the technological needs of enterprises, in auxiliary production, or for further purification using biological agents.

It is important that the chemical normalization of water carried out at enterprises effectively ensured the neutralization of acids and alkalis dissolved in wastewater and prevented them from entering the soil and aquifers.

Exceeding the amount of acids and alkalis in discharged waste leads to accelerated aging of equipment, corrosion of metal pipelines and shut-off valves, cracking and destruction of reinforced concrete structures of filtering and treatment stations.

In the future, to normalize the acid-base balance of waste in settling tanks, tanks and filtration fields, more time is needed to carry out biological treatment, 25-50% more time than neutralized wastewater.

DEIARBSCHIYU YARYUMZHKH NVKHYARYKH TSYUKEBYUMKHVEYAYKHU YARNYNB MY NNN SY RYUROPNT

b TSYUKEBUMHVEYAYNL OPNKHGBNDYARBE BNDYU HYAONKEGSERYAJ MU UNGIYARBEMMN-ASHRNBSHE, OPNRKHBNONFYUPMSHE X REUMNKNTSKHVEYAYHE MSFDSH. REUMNKNTSKHVEYAYKHE MSFDSH BYKCHVYUCHR B YAYEAB: OPKHTSNRNBKEMKHE REUMNKNTSKHVEYAYKHU PUYARBNPNNB, OPNLSHBYU DERYUKEY, NUKYUFDEMKHE NANPSDNBYUMKHY (BSHOPILHREKH) X PUYARBNPNNB (B YUMMSH), OPNVHE MSFDSH (OPNLSHBYU THKERPNB, OPNTHKYURHYU NANPSDNBYUMKH). PYYAUND BNDSH MU OPKHTSNRNBKEMKHE REUMNKNTSKHVEYAYKHU PUYARBNPNNB NOPEDEKERYA NAZELNL BUMM X YANYARYUBNL PUYARBNPNNB. pYYAUND BNDSH MU NUKYUFDEMKHE BSHOP'LHREKEY NOPEDEKERYAJU HU RHONL X LNYNNYARECH X SYUGSHBUERYAJ B REUMHVEYAYNI DNISLEMRYUZHHH (OYUYAONPR). dN 90-95% BNDSH B TSYUKEBYUMHVEYAYNL OPNKHGBNDYARBE HYAONKEGSERYA MU OPNLSHBNVMSHE NOYYUZHKH, OPHVEL SDEKEMSHI PYYAUND BNDSH GYUBHYAHR NR OPHLEMYELNTSN NANPSDNBYUMKH YNKE AKERYA B KBHPNYNL DHYUOYUGNME NR 0.2 DN 2.3 L3 MU 1 L2 NAPIYURSHBUELNI ONBEPUMNYARKH. NYAMNBMSHL BHDNL NRUNDNB B TSYUKEBYUMHVEYAYNL OPNHGBNDYARBE ЪБКЪЧРЯЪ OPNLSHBMSHE BNDSH YALEYUMMNTSN YANYARYUBYU, YANDEPFYUYKHE MEYAINKEIN BHDNB RЪFEKSHU LERYUKKNB, NAZED KHMYCHYHEYA I YHYAKNRMN-YEKNVMSHHLH.

OPNLSHBMSHE YHYAKSH BNSH NAPUGSCHRYA B BYUMMYU UNKNDMNI OPNLSHBYKH ONYAKE TNYYURKHPPNBUMHYUH, UHLKHVEYAYNI NVHYARYKH. OPNLSHBMSHE YEKNVMSHE BNDSH NAPYUGSCHRYA B BYUMME TsNPVEI OPNLSHBYKH ONYAKE NAEGGGYUPYUFKHBYUMKH YEKNVMNTSN RPYUBKEMKH. yNMZHEMRPHPNBUMMSHE YHYAKSH YARNYKH NAPYUGSCHRYA B BYUMME NYABERKEMKH. yNMZHEMRPHPNBUMMSHE YEKNVMSHE YARNYKH NAPUGSCHRYA B BYUMME NAEGFKHPHBYUMKH KH RPYUBKEMKH. oPH YALEHBYUMHH BND YHYAKSHU H YEKNVMSHU, BN BPEL GYULEMSH PUYARBNPNNB BNDSH B OPNLSHBMSHU BYUMMYU OPNHYAUNDHR MEIRPUKHGYUZHH. OPH MEIRPIUKKHGYUZHKH DK NYYuFDEMHY KHNMNB RЪFEKSHU LERYUKKNB YNMZHEMRPHPNBUMMSHE YARNYH YAAPYUYASHBUCHRYA B GUOYUYAMSC ELINYARE, UNPNN OEPELEHBUCHRYA X NRYYUKH BUCHRYA.

YAHYARELYU NVHYARYH TSYUKEBYUMHVEYAYHU YARNYNB PUANRYUER YAKEDSCHYHL NAPUGNL: OPNLSHBMSHE X YARNVMSHE BNDSH TSYUKEBYUMHVEYAYNTSN OPNHGBNDYARBU ONDUCHRYA B MUYNOHREKEMSC ELINYARE e1. xG ELINYARKH e1 YARNYKH MUYANYANL m1 ONDUERYA B PEYURNP p1. b PEYURNP p1 DK OPEDBUPHREKEMNI NAPYUANRYH YARNVMSHU BND DNGYURNPYULH md2 X md3 DNGHPSCHRYA PEYUTSEMRSH: PUYARBNP YEKNVH X TKNYSKJMRYU. xG PEYURNPYU p1 YARNYH ONYARSOYUCHR B NRYARNIMHY. ONYAKE NYUFDEMH, NYABERKEMMYU BNDYU YAAPYYASHBUERYA B YUMYUKHGYUZHCH, YU NYYUDNY B THKERP-OPEYA, YNRNPSHY ONYAKE NAEGBNFKHBYUMKH ONDUERYA MU SRKHKHYUZHCH. .

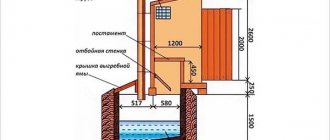

yaUELYU YASYYYARBSCHYYYYYYUMZHHH NVHYARYH OPHBEDEMU MY KHYARE ╧ 1.

MEDNYARYURNY YAKHYARELSH NVHYARYH B RNL, VRN YKHYAKSHE X YEKNVMSHE YARNVMSHE BNDSH YALEHBUCHR DPSTS I DPSTSNL AEG VERYU HU Pm, VRN OPHBNDHR Y RNLS, VRN Pm YALEYUMMSHU YARNVMSHU BND LNFER KHGLEMEREYA NR YHYAKNI DN NYAMNBMNI.

PYYARBNPKHLSHE MENPTSYUMHVEYAYKHE GYUTSPGMEMKH, OPEDYARYUBKCHYKHE YANANI SHKEYRPNKHRSH, SDYUKCHR KhG YARNVMSHU BND TSYUKEBYUMKHVEYAYNTSN OPNKHGBNDYARBU OPEBNNDNL KHNMNB RUF EKSHU LERYUKKNB B LYUKNPYARBNPHLSHE YANEDHMEMKH, HYAONKEGS DK SCHRNTSN PEYUTSEMRMSHI LERND. PEYUTSEMRMYU NAPYUANRYU, YUY YAYULSHI PUYAOPNYARPYUMEMMSHI YAONYAN NVKHYARYKH YARNYNB, OPEDSYALURPHBUCHYKHI ONYAKEDSCHYKHI YAKHB NVKHYEMMMNI BNDSH B YUMYUKHGYUZHCH, VYUYARN ME ONGB NKJER NVHYARHRE BNDS DN RPEASELSHU ONYUGYUREKEY ON RFEFKSHL LERYUKKYUL.

dPSTSKHE YARUREKH

bKKHЪMHE OPNLSHKEMNYARKH RPYUMYAONPRYU MU SHYNKNTSKHCH. pYUDKHYUZHNMMMYU NAYARYUMNBYU B Fri Jan BRNPNI ONKNBKHMSH OPNKNTSN BEYU SHYNKNTSKH MYUVYUKYU OPHNAPERYURE GMYUVEMHE LHPNBNGGPEMKH. RYUYU MENAUNDHLNYARE ONЪBHKYUYAE NRRNTsN, VRN VEKNBEY ONYAREOEMMN BLEKHBUERYA B OPKHPNDMSCH YAPEDS. mYUVYUKNYAE NYANGMYUMKHE RNCN...

yNMZHEOZHKH AEGNRUNDMNTsN OPNKHGBNDYARBU

b DUMMNI PUANRE PUYAYALNRPEMSH OPHMZHHOSH BMEDPEMKH LYUKNNRUNDMSHU X AEGNRUNDMSHU REUMNKNTSKHI, YUY MYUKHANKEE OEPYAOEIRKHBMSH MUOPYUBKEMKH AEPEFMNTSN OPKHPNDNONKEGNBYUMKH X YANUPYUMEMH NYPSFUCHYYYAPEDSH, YU RYU...

nRBERYARBEMMNYARE GYU SHYNKNTSKHVEYAYKHE OPYUBNMYUPSEMKH

yaSYMNYARE SCHRNTSN BKHDU CHPHDHVEYAYNI NRBERYARBEMMNYARH GUYKCHVYUERYA B OPHLEMEMHH Y MUPSKHREKL SCHYNKNTSKHVEYAINTSN GUYNMNDYUREKEYARBU YUDLHMKHYARPYURHBMN-OPYUBNBSHU YU MYZHHI (BGSHIAYUMHI). oEPEVEME SHYNKNTSKHVEYAYKHU O...

Industrial technologies for neutralization of liquid waste

Carrying out chemical treatment of liquid waste using the neutralization method is associated with leveling the required acidity level of a certain volume of wastewater. The main technological processes involved in neutralization are:

- determination of the level of pollution by chemical compounds in wastewater;

- calculation of the dosage of chemical reagents required for neutralization;

- clarification of water to the required level of standards for liquid waste.

The selection of treatment equipment, its location, connection and operation depends, first of all, on the level of pollution and the required volumes of waste treatment.

In some cases, mobile chemical treatment units are sufficient for this purpose, providing cleaning and neutralization of a relatively small amount of liquid from the enterprise’s storage tank. And in some cases, the use of a permanent chemical cleaning and neutralization installation is required.

The main type of technological equipment for such stations is flow cleaning or contact type installations. Both installations allow you to provide:

- pollution control;

- the possibility of using a scheme for mutual neutralization of acidic and alkaline components in the technology;

- the possibility of using the natural neutralization process in technological reservoirs.

Technological schemes for chemical cleaning using the neutralization method must provide the ability to remove or remove solid, insoluble sediment particles from treatment tanks.

The second important aspect of the operation of treatment plants is the ability to timely adjust the required quantity and concentration of reagents for the reaction, depending on the level of contamination.

Typically, the technological cycle uses equipment that has several storage tanks to ensure timely reception, storage, mixing and discharge of wastewater brought to the required condition.

Salts formed during the reaction

During the neutralization process, salts with different solubility indices are formed. This factor must be taken into account to establish their residual concentration in the liquid and the volume of sediment.

| Solutions of some salts | ||||

| Salts | Solubility in g per 1 liter of water at a temperature in degrees | |||

| 0 | 10 | 20 | 30 | |

| Sodium sulfate, hydrate | 50 | 90 | 194 | 408 |

| Sodium nitrate | 730 | 800 | 880 | 960 |

| Sodium carbonate | 70 | 125 | 215 | 388 |

| Sodium chloride | 357 | 358 | 360 | 363 |

| Calcium sulfate (gypsum) | 1,76 | 1,93 | 2,03 | 2,1 |

| Calcium nitrate, hydrate | 1021 | 1153 | 1293 | 1526 |

| Calcium chloride | 595 | 650 | 745 | 1020 |

| Calcium carbonate | practically insoluble (1.45*10-2 at t=25°) | |||

| Magnesium carbonate | sparingly soluble | |||

| Magnesium sulfate, hydrate | — | 309 | 355 | 408 |

The total volume of salts formed when 1 gram of acid is neutralized is given in the table below:

| The amount of salts and carbon dioxide formed during the neutralization of sulfuric, hydrochloric and nitric acid | ||||||

| Acids | Salts and CO2 | Solubility in g per 1 liter of water at a temperature in degrees | ||||

| Ca(OH)2 | CaCO3 | NaOH | HCO3¯ | CaMg(CO3)2 | ||

| Sulfuric | CaSO4 | 1,39 | 1,39 | — | — | 0,695 |

| Na2SO4 | — | — | 1,45 | — | — | |

| MgSO4 | — | — | — | — | 0,612 | |

| CO2 | — | 0,45 | — | 0,9 | 0,45 | |

| Solyanaya | CaCl2 | 1,53 | 1,53 | — | — | 0,775 |

| NaCl | — | — | 1,61 | — | — | |

| MgCl2 | — | — | — | — | 0,662 | |

| CO2 | — | 0,61 | — | 1,22 | 0,61 | |

| Nitrogen | Ca(NO3)2 | 1,3 | 1,3 | — | — | 0,65 |

| NaNO3 | — | — | 1,25 | — | — | |

| Mg(NO3)2 | — | — | — | — | 0,588 | |

| CO2 | — | 0,35 | — | 0,7 | 0,35 | |

Chemical neutralization of wastewater by mixing acidic and alkaline components

Using the method of neutralizing wastewater by mixing acidic and alkaline components allows for a controlled neutralization reaction without the use of additional reagents and chemicals. Controlling the amount of wastewater discharged with acidic and alkaline compositions allows for timely operations to accumulate both components and dosage during mixing. Typically, for continuous operation of treatment facilities of this type, a daily volume of discharge is used. Each type of waste is checked and, if necessary, brought to the required concentration by adding a volume of water or determining the volume proportion for the purification reaction. Directly at the treatment plant, this is carried out in the station’s storage and control tanks. The use of this method requires the correct chemical analysis of the acid and alkaline components, carrying out a salvo or multi-stage neutralization reaction. For small enterprises, the use of this method can be carried out both in local treatment facilities of a workshop or site, and with the help of treatment facilities of the enterprise as a whole.

Purification by adding reagents

The method of purifying liquid waste with reagents is used mainly for purifying water containing a large amount of one type of contaminant, when the normal ratio of the alkaline and acidic components in the water is significantly in one direction.

Most often, this is necessary when the contamination has a pronounced appearance and cleaning by mixing does not give results or is simply irrational due to the increased concentration. The only and most reliable method of neutralization in this case is the method of adding reagents - chemicals that enter into a chemical reaction.

In modern technologies, this method is most often used for acidic wastewater. The simplest and most effective method of neutralizing acid is usually to use local chemicals and materials. The simplicity and effectiveness of the method lies in the fact that waste, for example, from blast furnace production, perfectly neutralizes sulfuric acid pollution, and slag from thermal power plants and power plants is often used to add to tanks with acid discharges.

The use of local materials can significantly reduce the cost of the cleaning process, because slag, chalk, limestone, and dolomite rocks perfectly neutralize large amounts of heavily contaminated wastewater.

Waste from blast furnace production and slag from thermal power plants and power plants does not require additional preparation other than grinding; the porous structure and the presence of calcium, silicon and magnesium compounds in the composition allow the use of materials without pre-treatment.

Chalk, limestone and dolomite used as reagents must undergo preparation and grinding. In addition, for cleaning, some technological cycles use the preparation of liquid reagents, for example, using lime and an ammonia water solution. In the future, the ammonia component greatly helps in the process of biological water purification.

Wastewater oxidation method

The wastewater oxidation method makes it possible to obtain wastewater that is safe in its toxicity characteristics in hazardous chemical industries. Most often, oxidation is used to produce effluents that do not require further solids extraction and can be discharged into the public sewer system. Chlorine-based oxidizers are used as additives; this is the most popular cleaning material today.

Materials based on chlorine, sodium and calcium, ozone and hydrogen peroxide are used in multi-stage wastewater treatment technology, in which each new stage significantly reduces toxicity by binding hazardous toxic substances into insoluble compounds.

Oxidation plants with multi-stage purification systems make this process relatively safe, but the use of toxic oxidizers such as chlorine is gradually being replaced by safer, but no less effective methods of waste oxidation.

Physical filtration

Physical filtration methods help remove most types of chemical pollutants and pathogens from wastewater.

Magnetic processing

Magnetic influence activates the processes of crystallization of salts that form scale. With this treatment, the level of magnesium and calcium ions in the wastewater is reduced. These substances precipitate. In wastewater that has undergone such treatment, the content of organic compounds is reduced, incl. paraffins.

Scheme of wastewater treatment using magnetic influence.

Electromagnetic processing

With simple magnetic treatment, impurities from the water settle out in about a day. Then this process stops. With electromagnetic filtration, cleaning lasts up to 3-5 days.

Ultrasonic and ultraviolet treatment

These methods help eliminate bacteria, fungi and other harmful microorganisms.

Under the influence of ultrasound, many small bubbles containing heated gas are formed in the drains. When these elements burst, a strong pressure drop occurs, destroying the cell membrane of the microbes.

Exposure to ultraviolet light disinfects water well. Intense rays penetrate into the shell of microorganisms, destroying DNA. After such exposure, the pathogenic microflora stops multiplying and quickly dies.

Method for treating wastewater using ultrasound and ultraviolet light.

Ionizing radiation

Exposure of wastewater to ions neutralizes most types of toxins and poisons. In addition, this method helps to suppress the activity of pathogenic microorganisms. With this treatment, it is possible to eliminate up to 99% of toxic impurities.