There are many options: steel - seamless, seam, galvanized. Different grades of steel, different diameters and wall thicknesses.

Plastic HDPE (low density polyethylene) and uPVC (unplasticized polyvinyl chloride).

Which ones to choose? Depends on how much you are willing to pay. The most durable are seamless steel pipes 20 with a wall thickness of 5.0 mm, they last up to 50 years, but they are the most expensive. In the current economic situation, everyone is looking for cheaper options, mainly by reducing wall thickness.

Attention: sometimes, as a marketing ploy, they use the cheapest pipes, prohibited for drilling, 3.5 mm thick with welded tips 10 cm long from normal pipes at the joints, calling them reinforced. And you will notice that the casing is rotten when the short warranty period ends. In this situation, for those who like to save endlessly, we can recommend a foil casing.

Purpose of the casing pipe

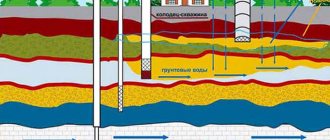

The casing is designed to protect the walls of the well from collapse, so that mined rocks from the adjacent soil do not fall into its trunk. Therefore, tubular products should be lowered into the well during its development. The connections of the casing elements are characterized by high density, which prevents the penetration of untreated soil water into the shaft. As a result, the consumer receives clean drinking water extracted from deep aquifers.

The process of operating an underground well involves exposure not only to heavy loads, but also to various aggressive environments.

Answering the question of which pipe to use for a water well, we can say that the casing pipe must be made of materials that meet the following requirements:

- High strength characteristics.

- Resistance to significant pressure from the ground.

- Resistance to the formation of corrosive processes due to constant exposure to the aquatic environment.

Such properties are inherent in the following materials:

- Stainless steel and galvanized steel.

- Various polymers.

- Asbestos cement.

The choice of a specific material for the manufacture of casing pipe is influenced by the geological features of the soil at the site and other conditions characteristic only of this area. You need to know in advance how to pull the pipe out of the ground when needed.

For the well to function properly, it is necessary to select the correct pipe diameter for the water well. The optimal value of this parameter should not be less than 110 mm; in this case, it is easier to select a pump for the well.

How to correctly calculate the diameter of pipes

The performance of the entire structure depends on how well the diameter of the column is chosen. The larger the diameter, the greater the throughput capacity of the well. Proper calculation of the diameter of the pipes will help to obtain the required water flow and at the same time save.

Casing pipes have the following standard values:

- 13.3 cm;

- 12.7 cm;

- 11.4 cm;

- 10.8 cm;

- 8.9 cm.

To determine what pipe diameter to choose for a well, you need to understand where the water will be used. For example, for a shower, for work in the kitchen, for watering a garden and a vegetable garden, in a washing machine, approximately 3 cubic meters per hour are required.

Advice! The internal diameter of the casing, regardless of the pipe material, must be at least 110 mm. This size is optimal for the normal flow rate of the well, and in addition, in the future it will be easier to select a suitable submersible pump model for it.

Next, select the pump. Based on the required amount of water, we select a pump of the required power. For 3 cubic meters, a pump with a diameter of 7.5 cm or more is suitable. In order for the pump to pass freely into the well, add another 4 mm to the diameter. We also add the thickness of the pipe used (for example, 8 mm) and get the value of the required diameter. In our case it turns out to be 8.7 cm.

Features of pipes for wells made of ferrous metal

Ferrous metal, as a material for the manufacture of casing pipes, is very popular when drilling water wells. A casing with a wall thickness of over 6 mm is classified as an eternal material, so the well can function flawlessly for half a century.

The use of such material makes the life of the well and the aquifer the same.

The steel used to make casing pipes has some features that you need to know to fully understand wells of this type:

- Steel is an environmentally friendly material, so its contact with water is not accompanied by the release of chemicals. Rust that forms on metal surfaces does not dissolve in water and does not increase iron levels, as many people believe. Rust is removed by passing water through a regular household filter (more details: “How to choose a filter for a water pipe - an overview of possible options, pros and cons”).

- High strength characteristics and impact strength prevent the formation of defects or destruction of the casing pipe during installation or operation.

- Clogging or silting of the well, as well as accidental entry of foreign objects, is eliminated by additional drilling or performing other work using drilling tools.

- Steel casing makes it possible to drill wells even if the aquifer lies very deep.

With such positive characteristics, the high price of the material, which is considered its main negative quality, becomes less relevant. The main thing is to correctly calculate the operating period for the well.

Advantages of using asbestos cement

Asbestos cement products are gradually going out of fashion. The reasons why they are gradually being squeezed out of the market can be reduced to four main ones:

- Fragility and tendency to delamination.

- They do not provide resistance to sand, so it is advisable to exclude their use in the presence of sand impurities in the water.

- Quite a significant weight.

- Distrust of asbestos as a material with a faulty environmental reputation. Although the threat comes only from dust of exclusively amphibole asbestos.

Note! The use of chrysotile cement products for water supply is recognized as absolutely safe for health.

Choosing an asbestos-cement pipe when constructing a well has many advantages. These include:

- low cost;

- non-rotting and corrosion resistant. No special protection from groundwater is required;

- strength;

- low thermal conductivity, which makes it possible to avoid insulation;

- immunity to temperature changes, frost resistance;

- small, compared to metal structures, weight;

- durability of use.

Casing of a well or well can also be done with asbestos-cement pipes

During installation, asbestos-cement products can only be connected with couplings, with each link being attached as firmly as possible. Even if we have doubts about the environmental safety of asbestos cement, it is quite acceptable that it is used for irrigation and land reclamation. As a better option, asbestos cement is used when drilling in limestone soils.

Water pipes made of stainless steel or with additional coating

Sometimes a controversial situation may arise as to which casing pipes for a well are better: metal pipe products with an additional anti-corrosion coating or made of stainless steel?

The solution to the issue is a simple truth: why pay more for stainless steel products if ferrous metal products have a service life that is almost equal to the operating period of the well.

In this situation, special attention should be paid to ferrous rolled metal with a galvanized surface. If such a coating is exposed to water for a long time, then the formation of zinc oxide can be observed on it. This substance poses a danger to human health. Therefore, galvanized pipes can only be used in wells for industrial water.

Types of materials

Each type has pros and cons. Comparative characteristics will help you choose the right one.

Metal

It is believed that metal structures are characterized by reliability, stability and have undergone long-term operational testing.

Of course, metal has its advantages, but such elements also have disadvantages, for example, susceptibility to corrosion, which negatively affects water quality.

NPVh and HDPE

When choosing a material for a limestone or sand well, preference is increasingly given to plastic products - HDPE or NPVh. In this case, the best option is the second type.

Thus, structures made of uPVC have smooth internal surfaces, which reduces resistance to water flow and allows the diameter of the pipes to be reduced.

Long-term operation does not affect the throughput, hydraulic resistance, and also does not affect the smell or taste of the resulting water.

Asbestos cement pipe products

Also, the casing can be equipped with asbestos-cement pipe products, and they can easily replace steel products with good material benefits. But asbestos cement has some special properties that should be taken into account when installing the casing.

Among the important characteristics of asbestos cement pipes are the following:

- The material meets environmental requirements and is neutral towards chemicals. These properties of the material indicate that during operation the possibility of harmful elements entering the water is eliminated.

- There is an opinion that asbestos has carcinogenic properties, but it has no justification. Yes, there may be fibers of the material in the water, but in small quantities, which can be easily removed using household water filtering devices.

- Asbestos cement is fragile, therefore, it requires caution during installation and operation. In addition, it is not recommended to carry out additional drilling of a finished well, the casing of which is made of asbestos cement.

- Asbestos-cement pipe products have fairly thick walls, which requires drilling larger wells to install such products.

- A pipe for the manufacture of which asbestos cement was used cannot be used as a filtration column in sand wells, therefore they are used only in artesian wells.

- The physical properties of the material allow the use of pipes in wells up to 100 meters.

Which column assembly option is better?

A set of requirements for casing pipes and technologies for connecting well string segments is reflected in GOST 632-80. The regulations allow the use of different assembly methods.

Based on the joining method, the appropriate type of pipe is selected, so this issue must be resolved at the well design stage.

No. 1 - permanent contact of pipes for welding

Welding provides the most rigid connection of metal pipes. The main advantage of the method is now being questioned by representatives of a number of drilling companies.

Arguments against using welding:

- the likelihood of insufficient sealing of the weld;

- the possibility of pipe deflection along the vertical axis, which makes it difficult to install the column in the well;

- insufficient corrosion protection of the seam.

However, with a high level of professionalism of the welder, the listed defects will not occur. Most building structures (bridges, trusses, oil pipelines) are made of steel and, as a rule, they are welded.

Another issue is that high-quality work requires welding equipment and the involvement of a qualified electric welder. These measures increase the cost of work performed, reducing the profit and competitiveness of the performing organization.

Welding electrodes use a protective coating, which ensures alloying of the weld seam. This increases the strength of the metal and increases the corrosion resistance of the joint.

No. 2 - water-lifting channels with threads

When casing a well with rolled metal, 90% of drilling companies use a threaded connection, pointing to GOST standards. It sounds quite convincing, but managers of organizations often keep silent that the standards are relevant for pipes with a diameter of 146 mm and a wall thickness of at least 6 mm.

The use of threaded technology significantly reduces the service life of the casing.

In a 4.5 mm thick pipe, the thread size does not always reach 1.2-1.5 mm. Knowing the rate of corrosion (0.1 mm/year), we can assume that in 12-15 years the pipe will rot at the junction

The use of a threaded connection on plastic lines does not have such disastrous consequences, but, on the contrary, is considered the most reliable.

There are several options for joining polymer pipes:

- Nipple . The thread is cut from the inside of plastic pipes. The two elements are connected through a nipple with an external thread. The diameter of the hole does not increase.

- Coupling . There is an external thread at both ends of the pipe. Docking occurs using an overhead coupling, which increases the diameter of the penetration.

- Socket threaded . Segments with threads on the outer and inner surfaces are used - joining is carried out without additional elements.

With socket joints, a slight expansion of the diameter at the joints is permissible.

The socket method of joining without threads is not used in wells - it is impossible to control the process of installing the pipe into the pipe. In addition, the connection does not provide the necessary tightness of the column and causes subsidence over time.

Double casing price: what are we paying for?

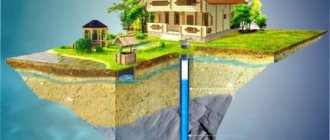

Obviously, two pipes will cost more than one. Drilling a well of increased diameter will also require additional financial investments. As a result, the total price of the well increases. We need to find out what we get by using double casing?

With the correct installation of both columns - casing and production - the degree of isolation of artesian water from contaminated water from the intermediate layers and upper water increases. A well-known advantage of plastic is its corrosion resistance, which is much higher than that of black steel. Steel rusts at a rate of 0.1 mm per year. In fact, this is very little - with a casing pipe wall thickness of 4 mm, a through hole due to corrosion will appear only after 40 years. Plastic extends the life of the well by approximately 2 times. If after 40 years a through hole appears in a steel pipe, the plastic will remain completely intact and will continue to protect artesian water from external contaminants.

Does a second plastic pipe protect against rust levels in the water? No, since rust (like hardness salts) enters the water intake not from the steel casing, but directly from the limestone. Food grade plastic was specially developed for parts and assemblies of various equipment that have constant contact with food and drinking water. Being chemically inert, even with constant contact with drinking water, HDPE or PVC pipes will not reduce its quality. It should be noted that general water supply systems use regular black steel pipes, but no one complains about the small amount of rust that gets into the water. This amount will further decrease with daily use of the water supply.

Only a well with a long life and a stable flow rate is suitable for organizing an autonomous water supply in a country house for permanent residence. An artesian well with double casing meets these conditions.

Against this background, the statements of some amateur “cheap” drillers about the needlessness of additional pipe protection - be it a higher level of sealing, an additional pipe inside the main one, etc. - sound especially unconvincing. The statement that double casing is needed only by drillers because of greater profitability is, at least, biased . Double casing significantly extends the period of trouble-free operation of the well, that is, it provides what the customer is directly interested in. It seems that the reason for negative reviews about double casing is simple - amateur drillers do not have the knowledge or equipment to produce high-quality casing of an artesian well with two pipes.

Tags on the page:

Our phones

Features of casing products

The casing pipe is installed as follows:

- first a well is drilled;

- then a column of pipes is lowered into it;

- the space between it and the soil is filled with concrete;

- All necessary equipment for further installation is lowered down the pipe.

Casing pipe operation diagram

When choosing a casing pipe, first of all, the developed project must be taken into account - the diameter, operational characteristics, etc. will depend on it. The dimensions of the well and, accordingly, the diameter of the casing will directly affect the cost of the project. The larger they are, the more financial investments will be required. “You can read what to choose a well or borehole on our page.”

It is necessary to familiarize yourself with their varieties, determine what diameter and type of connection are required, in order to determine the best pipes for constructing a casing well.

Results

When buildings with year-round habitation are being built, water pressure systems must remain stable and show a high level of reliability. Under such circumstances, it is recommended to give preference to plastic, from which two-pipe systems are built; steel is also suitable. Polymers are better suited for seasonal use; they lack the characteristics for permanent use.

You can first decide on the size of the well. And then ask the professionals which system is suitable in this or that case. It is recommended to take the pipe diameter with some margin. Then in the future it will be easier to expand and deepen if the initial characteristics are not satisfactory for one reason or another.

Areas of application

The products are widely used where qualities such as strength and rigidity of plastic bends are in demand:

- Laying pressure and non-pressure sewerage pipelines.

- Transportation of drinking water and other food liquids.

- Construction of drainage networks.

- Construction of casing columns on water wells.

- Manufacturing of protective equipment for athletes and other areas of human activity.

For well

In well drilling, one of the main problems is ensuring the integrity of the drilling rig and protecting equipment from various external mechanical loads. These problems are successfully solved with the help of casing pipes. Previously, steel and asbestos-cement bends were used for these purposes. Now they are being forced out of the market by cheaper and easier to install plastic pipelines. The most profitable and effective among them are pipes made of unplasticized PVC.

Asbestos-cement pipes: inexpensive, but fragile

Asbestos cement is chemically neutral, incredibly resistant to corrosion and has no restrictions on its service life.

Pipes made from this material will cost much less than steel. They would have ousted all metal structures from the market long ago, if not for one drawback: it is a rather fragile material.

Asbestos-cement pipes are a classic. They are great for use in wells and boreholes

As a result, in order to ensure sufficient strength, asbestos cement pipes are made with very thick walls, for which it is necessary to drill a hole of a larger diameter. In addition, work with asbestos cement should be done very carefully, but not all installers have a high enough professional level for this.