Here you will learn:

- Drilling depth

- Types of drilling methods

- Features of manual drilling

- Auger drilling

- Rotary drilling

- Core method

- Hydro drilling

- Drilling stages

- Which technology is used most often?

There are the following methods for drilling water wells: auger, rotary, percussion-rope drilling, core, hydraulic drilling, percussion method. The choice of method depends on the depth of the well.

Drilling depth

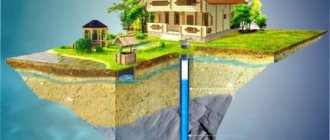

The location of aquifers relative to the soil surface depends not only on the region and hydrological features. The quality of water that is the target of drilling plays a role. Experts distinguish three key aquifers that differ in water quality, capacity of moisture reserves, and depth.

Not far from the surface (3-10 m) there is the first layer of water, called perched water. This is exactly the kind of water that you can get to without much difficulty if you drill with your own hands. It is extremely rare to encounter hard rocks along the drilling path, therefore, with a little experience and a simple tool, it is possible to construct an Abyssinian well (this is the name of a well for extracting moisture from perched water). The thickness of the surface water layers is small, so you should not count on a debit higher than 0.5 m3 per hour. The quality of water in most cases is low, which is only sufficient to meet technical needs.

The occurrence of sandy aquifers is at a depth of 10-35 m. The water here is of satisfactory quality, the inflow capacity is greater (discharge up to 1 m3). It is hardly advisable to drill with your own hands to a sandy water carrier, although experience shows that some diligent water “prospectors” succeeded in this if the horizon was at a shallow depth (up to 15 m). In most cases, mechanized drilling methods are used to construct a well “on sand”.

The deepest are the limestone aquifers (30-250 m), which you definitely cannot reach by drilling with your own hands given their very superficial location relative to the soil surface. In order to get loose limestone that carries the highest quality artesian water, sometimes not every drilling technique is suitable. The water inflow here is much higher (3-5 m3) and depends on the thickness of the formation and the perfection of the well. Now let’s look at the currently used methods of drilling water wells, including those that can be done with your own hands.

Device and circuit

The diagram shows water layers. The high water is fed by precipitation and lies at a depth of up to 10 meters. The quality of the water allows it to be used immediately for drinking. A source with interstratal waters is made independently. To obtain better quality water, an artesian well is made.

According to SNiPs and established standards, the source is protected from any kind of pollution. The distance from the septic tank is 15 meters. Cesspools at least 50 m away. More than 100 meters from warehouses and industrial enterprises. The distance from a neighboring source, residential buildings, chicken coops and barns is also taken into account.

Advice: drilling a well for water near trees with a large root system is difficult.

Types of drilling methods

Previously, drilling of water-bearing wells for personal use was carried out mainly by hand. This was a labor-intensive and lengthy process, so not every owner of a plot or cottage could boast of having their own source of water supply.

Gradually, mechanized drilling replaced manual methods due to the significant facilitation and acceleration of the process.

Today, almost all aquifer wells are drilled using a mechanized method, which is based on the destruction of soil, supplying it to the surface in one of two ways: dry, when waste soil is removed from the well using mechanisms, and hydraulic, when it is washed out with water supplied under pressure or gravity.

There are three main methods of mechanical drilling:

- Rotational (soil is developed by rotation).

- Impact (a drilling projectile destroys the soil with impacts).

- Vibration (soil is developed by high-frequency vibrations).

The rotational method is considered the most highly productive, 3-5 times more efficient than the shock method and 5-10 times more efficient than the vibration method. In addition, the rotational method is the most inexpensive and accessible; it is often used as the main method of manual drilling.

Mechanical rotary methods of drilling water wells have replaced ineffective manual methods.

In turn, the rotary drilling method, widely used for the construction of water wells, is divided into four main types of drilling:

- core;

- screw;

- shock-rope;

- rotary.

Each type of rotary drilling has its own characteristics and is performed with equipment specially designed for this purpose. Let's look at these types of drilling in more detail, determine what their differences are and what method needs to be used in each specific case.

How to drill with your own hands at the dacha or in a private house

Perform a number of preparatory steps:

- The selected location should not be the lowest point on the site.

- The ground slope is no more than 35 degrees.

- When using special drilling rigs, it is important to organize a place for access.

- The area on the summer cottage must be at least 4 by 9 m.

Advice: manual drilling of water wells requires less preparation, but when it comes to using special equipment, it is necessary to coordinate all the nuances.

Features of manual drilling

The manual drilling method requires a lot of physical strength, but allows you to save on equipment. It is used when installing wells no more than 25 meters deep and is carried out until the drill reaches the waterproof layer.

In the case of manual drilling, use:

- a set of drilling heads (drill bit, drill spoon, coils, bailers);

- rods;

- winch or electric hoist;

- casing;

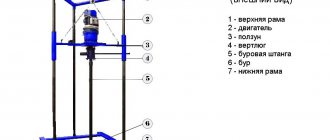

- for working at great depths - a drilling rig.

The shaft sinking process consists of the following steps:

- A small hole 40-50 cm deep is dug in which the drill will be placed.

- Then one person begins to rotate the drill; when it goes deep enough, you will have to rotate it with two people, then with four people.

- Every 50-70 cm of entry into the ground, the drill must be pulled out and cleaned so that dirt does not cover the entire head.

- If the soil is too hard, the resulting hole must be filled with water.

When the shaft is filled with water from the inside, work stops. Now all that remains is to pump out the dirty water with impurities - approximately 5-7 liters. For this you will need a pump.

The main advantage of the manual method is low cost, uniform barrel structure along the entire length. However, it can only be used at shallow depths. The flow rate and service life of such a well leave much to be desired.

Impact method

Using this method, the simplest needle well is installed - the Abyssinian well. This method is actively used by home craftsmen when drilling a well for water in their dacha. The design of the “drilling rig” is a barrel consisting of pipe sections and a tip that cuts the soil layers. The hammer is a weighty woman, which is raised and lowered with the help of ropes: when tensioned, a kind of hammer rises to the top of the structure, and when loosened, it falls onto the headstock - a device of clamps located symmetrically. After the trunk enters the ground, it is extended with a new section, the headstock is attached to the new part, and driving continues until the tip enters 2/3 of the formation into the aquifer.

The trunk-pipe serves as a hole for water to escape to the surface.

Important! The Abyssinian well raises the uppermost aquifer, which contains many impurities. Water from such a well can only be used for technical purposes. It is suitable for drinking only after deep cleaning.

The advantage of this well is that it can be drilled in a basement or other suitable room. This creates ease of use. The price is also attractive; drilling a water well in this way is inexpensive.

Impact drilling can be used on any type of soil

Cable-percussion drilling

The most commonly used method. This method involves breaking the soil by lowering a heavy drilling tool from a two-meter height. The design used for this type of drilling consists of the following elements:

- tripod, which is placed above the drilling site;

- block with winch and cable;

- driving glass, rod;

- bailers (for passing through loose layers of soil).

The glass is a piece of steel pipe, beveled inward, with a strong lower cutting edge. There is an anvil on top of the driving glass. It is struck by a barbell. Lowering and raising of the driving glass is carried out using a winch. The rock that falls into the glass is held in it due to friction. In order to penetrate the soil as deeply as possible, a striking rod is used: it is thrown onto an anvil. After filling the glass with soil, it is lifted up and then cleaned.

The operation is repeated until the required depth is reached.

Drilling a well on loose soils is done using a bailer. The latter is a steel pipe, at the lower end of which a retention drip is installed. After the bailer hits the soil, the valve opens, causing soil to enter the pipe. When the structure is lifted, the valve closes. After being removed to the surface, the bailer is cleaned and the steps are repeated again.

Cable-impact equipment for well drilling

Helpful advice! When performing cable percussion drilling, it is necessary to carefully monitor the verticality of the well. At the slightest deviation, installation of casing pipes may become impossible. To prevent problems, do not use a glass less than 2 m high.

The auger method described above is also effectively used for self-drilling. There is no point in further explaining how to drill a well with your own hands using an auger - the basic principle remains the same.

Advantages of manual drilling:

- financially economical way;

- repair and maintenance of a hand drill is easy;

- the equipment is not bulky, so there is no need to use heavy equipment;

- the method is applicable in hard-to-reach places;

- effective and does not require much time.

The main disadvantages of manual drilling include lowering to a shallow depth (up to 10 m), where layers mainly pass through, the water of which requires purification, and the inability to crush hard rocks.

Shock-rope scheme with a bailer and a punching bit

Tips before you start

In order to approach well drilling technology wisely and without disastrous consequences, you should pay attention to several important nuances.

Intensity. With uncontrolled and massive water intake, the so-called suffusion of the soil can begin, as a result of which it sinks quite deep, which is especially deplorable for areas with residential buildings.

Depth. When drilling independently on a plain in Russia, the critical depth is twenty meters. If you want to drill deeper, ask the experts how much such work costs, and you will be pleasantly surprised, since drilling a deep well yourself will cost much more.

Term of use. The period of operation of any well greatly depends on how often and how much water will be taken from it. If you use a sand well rationally, it can last 15 years, but an artesian well will wither within five years if you pump water from it uncontrollably.

Auger drilling

Blades are welded onto the pipe in a spiral, which is immersed in the ground with rotational movements. Not suitable for all soil types. Ideal solution for soft to medium soils.

Screw method:

- A pit is dug 1.5 by 1.5 m, up to 2 meters deep. Later there will be a caisson in it.

- If the soil is loose, then the walls are reinforced with wooden panels.

- The auger drill is rotated using a special clamp or key.

- If the soil is unstable, then casing with a PVC pipe is immediately performed during drilling.

- If the soil will be extracted directly through a pipe using an auger, then PVC will not work - metal is used.

- As the auger and casing advance, they are expanded using couplings.

- It is recommended to make no more than 5 revolutions in one pass. Otherwise, it will be difficult to lift the soil up.

- To facilitate the passage of the drill into the source, you can add water.

- A tripod with a block for lifting the drill is installed.

- Drilling goes all the way to the aquitard. If the sand is coarse and wet, then the aquifer is excellent.

Tip: As the auger sinks, control verticality; to level it, wooden wedges are driven between the source wall and the casing pipe.

Rotary drilling

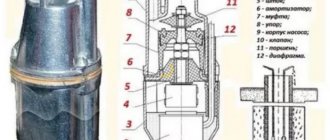

Drill Bit

Drilling in this manner uses a continuously rotating bit and a clay mud. The chisel breaks rocks, including rock, into small fragments, and the solution brings these pieces of soil to the surface.

For drilling to be effective, a mud pump is required. It will pump the clay solution and ensure its continuous supply.

When rotary drilling, reverse circulation can be used. It allows you to speed up the process. The aquifer is reached much faster and with better quality. During backflushing, the solution is supplied to the annulus and returned through the pipe.

The rotary drilling method has several advantages. In addition to the fact that this method can drill rocks, it should be noted that the penetration speed is higher. Slightly lower cost of work.

Among the disadvantages of the method are the difficulties of working in the cold season. Insulation of the flushing fluid circulation system is required. A sample from the aquifer can only be taken after casing and commissioning of the well. Limestone layers become contaminated with clay and solution water.

Core method

Mainly used for drilling industrial wells, as well as for research work. The rock is destroyed using a special chisel - a hollow pipe equipped with cutters. Penetrating deep into the soil, it cuts it off from the main structure, after which it is easy to wash it out using a directed stream of water under pressure.

The high functionality of the core drilling method allows it to be used not only when drilling wells, but also for construction work - for example, if it is necessary to make a hole in a reinforced concrete slab. The bit is driven by the drilling rigs of the mill.

- The advantages of the method are obvious - high speed, interaction with any type of rock, mobility and small dimensions of the drilling rig.

- Disadvantages include the small diameter of the chisel pipe (no more than 150 mm) and rapid grinding of the bits, which leads to additional costs.

Hydro drilling

It is carried out with a powerful jet of water from a special drilling tool. The advantage of the technology is that it is possible to drill wells in rocky soil.

The jet load is provided by the weight of the rod and drilling equipment. A special solution is poured into the installation, which is then sent to the prepared pit.

The main requirement is the use of a special installation for manual downhole hydraulic drilling.

Do-it-yourself hydraulic drilling sequence:

- First of all, a small-sized structure or MCU for hydraulic drilling is installed.

- It is best to start work in the morning.

- If drilling occurs in sandy soil, a large supply of fluid is required.

- Before work, the clay is mixed into a solution in a prepared pit. Kneading is done using a construction mixer. The consistency should resemble kefir.

- Next, the solution is supplied through the hoses to the operating drill.

- Gradually, the liquid polishes the walls and goes deeper into the soil. The solution is used in a circle.

This technology helps to further strengthen the walls of the resulting source.

Drilling stages

The entire drilling process can be divided into three parts: crushing the soil, removing it, strengthening the walls of the well.

The rock is crushed using the methods described above. Depending on the characteristics of the soil, special mechanisms are selected.

The process of extracting crushed rock also depends on the chosen drilling method. It is removed mechanically, hydraulically or pneumatically.

To prevent the walls of the well from crumbling, casing pipes are installed. They can be metal or plastic.

When casing is completed, filters and pumps are installed. After this, the well is ready to supply water.

What to do if there is little water in the well

The first step is to call the drillers and ask them to fix it. Even when they drill with augers, it happens that there is not enough water in the well. This happens very rarely, but it does happen.

In this case, drillers come and either lift the pipe one layer higher or bury it lower. That is why you cannot equip a well until you are 100% sure of it.

Plastic caisson for well

There is no need to try to pump the well, pour water into it, and then pump it out. It's just a waste of time. Drillers must initially ensure that there is enough water in the well.

In difficult places, drillers will immediately warn you that there may be little water. But all this must be done before drilling begins. So that you understand that if there is not enough water, then you need to install a storage tank and so on.

But if you are on the flat part of the Krasnodar Territory, then the flow rate of your well should not be less than 2-3 cubic meters of water per hour. If the flow rate is less, then most likely there is something wrong with the well.