The simplest and most common option for assembly in a private home is a sewer system made of concrete rings. Construction of a well from 1-3 elements assembled from special standard concrete components.

This concept, among other things, implies the use of amenities provided by connecting housing to the main utility networks of the public infrastructure. There are not always central communications for water supply and disposal of household waste in the area of residence. Therefore, amenities, in the form of an autonomous sewerage system, have to be created independently.

All property owners want to make permanent residence in a private home and seasonal stay at their favorite dacha comfortable. Let's look at what a sewage system made from concrete septic tanks is like.

Benefits of concrete

A septic tank for receiving household waste can be made of brick, polymer materials, stone, metal, concrete. The resulting structure is not overly loaded; its durability is affected by the resistance of the source material to aggressive substances and constant humidity. Constructing the walls of a sewer well from concrete rings is considered an ideal option for the following reasons:

- Concrete elements are used when constructing a septic tank on various soils; their resistance to compressive deformations allows them to withstand pressure from displacement of soil layers and groundwater.

- Availability of material.

- High speed of sewerage installation using concrete products.

- Sewerage made from concrete rings is durable and easy to maintain.

- Rings allow you to make a device of the desired depth and diameter.

- Resistance of the material to aggressive substances, groundwater composition and temperature changes.

- Easy to install yourself.

- A large selection of waterproofing materials to protect the walls of the future well.

- Thanks to metal reinforcement elements, concrete products are highly durable.

- Factory-produced products are designed for tight joining.

Concrete products are durable, but they also have their disadvantages.

The main disadvantages during operation: weight, certain difficulties with delivery and loading, the possible need to use lifting equipment and additional labor.

Recommendations

In order for the process of constructing a septic tank to be successful, you need to consider a couple of simple tips:

- During the installation of the septic tank, you should not make sharp turns. The angle between the incoming and outgoing pipes must be at least ninety degrees. In this case, the turning radius must be at least equal to the diameter of the pipe.

- Laying along shelygs is possible if several pipes are laid, the diameter of each of which is different.

- The rotation must be at least equal to the diameter of the pipe.

Types and types of concrete components

There are two types - wall and additional .

wall products in the shape of a ring can have the following dimensions: internal diameter - 0.7-2.0 m ; wall thickness – 70-100 mm ; standard height – 890 mm . With their help, the necks of any wells are erected. For sewerage in a private house, built from concrete rings with your own hands, products with an internal diameter of 1.5 m .

Additional products differ from wall products in their non-standard height. With their help, the required depth is adjusted when it is not a multiple of the height of standard rings.

The following types of rings are used in this work:

- Having a solid bottom . Needed for overflow sewers, the settling wells of which accumulate silt at the bottom (periodically removed with special equipment).

- Without a lock . Conventional straight rings, for the connection of which cement mortar is used.

- With locking connection . This type is distinguished by notches on one side and protrusions on the other. Installation of products consists of inserting and fixing them by inserting the protrusions into the recesses. Such a lock will prevent the elements from moving during operation of the sewer well.

- Filtration . Walls with evenly spaced holes allow liquid to escape into the ground. These rings are intended for the construction of filtration wells.

example

Rules for using concrete septic tanks

The owner of the site on which the sewerage system is located must bear mandatory responsibility for the operation of this structure. The septic tank begins to function fully only a year after its construction. If you add starters, the process will speed up significantly.

Note : If the septic tank is working properly, there will be no smell of hydrogen sulfide. As for the color of precipitation, it will have a dark gray tint.

In order to monitor the level of precipitation, a wooden stick is lowered into the hole. If there are only twenty centimeters left to the pipe tee (outlet), then a special machine will be required. If there is silt, then you should not completely get rid of the sediment.

It is also necessary to monitor the degree of purification of the liquid that penetrates the drainage structure. If the water is clear and odorless, then it is normal.

In winter, to prevent the well from freezing, the hatch is insulated.

Stages of installing a sewer well

Let's look at how to make a sewer system in a private house with your own hands from concrete rings. And if a decision is made to entrust the work to a specialized organization, then the information received will help to carry out high-quality control over the installation progress and facilitate communication with workers.

Selecting a location

The location of the sewer septic tank is selected taking into account certain standards and requirements. It should be no closer than: 5 m – from the boundaries of the estate; 5-10 m – from a residential building (so as not to wash away the foundation); 30 m – from the shore of the nearest body of water; 20 m (50 m) – from the water intake on clay (sandy) soil; 3 m – from paths, roads, trees, bushes, vegetable gardens. The bottom of the well should always be above the groundwater level in the area. An access road must be provided to the selected location or subsequently built for periodic pumping of sludge using special equipment.

Calculations and septic tank diagram

To install a sewer system in a private house with your own hands from concrete rings, you will need a construction diagram drawn up based on preliminary calculations of the volume of water consumption by all residents. The volume of the septic tank must correspond to the amount of water consumed by residents in three days. The daily norm for one resident is 200 liters. The final figure for the minimum internal volume of a septic tank is obtained by simple multiplication.

The obtained value is very important if you are building a sewer system in a private house with your own hands. The ring scheme provides for the presence of 1-3 septic tank chambers. The number of wells depends on the composition of the family, the number of sanitary devices and mechanisms, and the intensity of their use. A septic tank of three chambers can be considered a real biotechnical complex. Its construction and maintenance will cost more, but the productivity and quality of wastewater treatment is significantly increased.

From three chambers:

- 1st – settling of received wastewater;

- 2nd – purification of liquids (already clarified) from contaminants;

- 3rd – filter chamber.

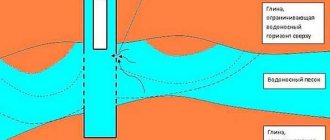

In treatment chambers, the lower concrete ring must have a solid bottom to protect against leakage of untreated liquid waste. The third chamber is distinguished by the presence of a lower ring with perforation, as well as a drainage layer at the bottom of the well. After passing through the drainage, the purified liquid is absorbed into the soil. Inlet holes are made in the predetermined walls of the rings to connect the wells with overflow pipes. In the first chamber of the septic tank, a hole is also prepared for the pipe coming from the house. This pipe must be below the freezing level of the soil. All pipes are laid with a slope to ensure gravity flow of wastewater.

Each connecting pipe leading to the next chamber must be lower than the level of the wastewater inlet in the previous well. Violation of this requirement will lead to looping of the stream and incorrect operation of the system.

For all wells, round concrete slabs with holes for installing inspection hatches and ventilation pipes are purchased.

Drawing up a preliminary sewerage diagram helps to prevent possible errors, outline the order of work, make high-quality preparations for a set of construction activities, and calculate the number of necessary products and materials.

You may also like: Sewerage in the country - choice and design

Features of the design

Sewage wells are designed to collect wastewater from domestic use.

There are types of sewerage devices, the type depends on the design:

1.drain pit.

2.storage well.

3.septic tank from several chambers.

All structures vary in shape and size. But they have mandatory design elements, and consist of:

1.neck, which is closed with a hatch or lid.

2.working compartment.

3.drainage or sealed bottom.

Soil development

The pit for the chambers can be individual (for one well) or common, in which all the structures of a unified system for receiving and treating wastewater will be erected.

For a separate well, the dimensions of the pit should be 25-30 cm greater than the diameter of the outer surface of the concrete ring selected for installation. The resulting gap will facilitate the process of installing and displacing sewer rings using special equipment. The main disadvantages of such pits: work with the soil is carried out manually, the impossibility of high-quality sealing of joints and waterproofing work on the outside of the rings with a sufficient depth of the structure being built.

A common pit facilitates all types of construction work. Using special equipment, it will be ready in 1.5-2 hours.

In places where the receiving chambers are installed, the bottom of the pit is compacted, lined with waterproofing roll material (usually roofing felt) and filled with concrete mixture. Such a pedestal will not be needed if the lower rings were purchased with a ready-made concrete bottom. At the site of future installation of the filtration chamber of the septic tank, a crushed stone cushion (from 0.5 m) is installed. It allows the purified liquid to pass to the ground without obstacles and be absorbed into it. In addition, such a pillow performs final purification of the liquid.

Calculation of the cost of hiring equipment and purchasing materials

Digging a pit manually is long and difficult, so it is recommended to hire special equipment - an excavator, a bulldozer for removing soil and a dump truck for removing excess soil.

You will also need a crane to install the concrete rings. Cost of corrugated pipes for sewerage

How much does it cost to call a technician? The average price for digging a pit and removing soil does not exceed 350 rubles per 1 m³. Let's calculate the cost of installing 3 pits. The volume of each pit is 1.5 m³, which means that for excavation work you will need approximately 1,600 rubles.

The average cost of 1 concrete ring with a volume of 0.6 m³ is 4.5 thousand rubles. To build a well of 3 rings you will need 13.5 thousand rubles.

Cost of additional materials:

- 2 bags of cement (150–200 rubles);

- 100 kg of sand (120 rubles sand + 200–500 rubles delivery);

In total, a complete sewage system in a dacha for 5 people will cost you 43 thousand rubles.

Sewer pipe material

Final work

Holes for pipes are punched in the designated places of the concrete rings. A house drain pipe is inserted into the first well. Then pipes connect all the chambers of the system. The joints are carefully sealed with mortar.

The next stage is waterproofing the joints of the rings, joints with pipes, and the outer (and preferably inner) surface of the concrete well.

Now each well is covered with a concrete cover, monolithic inspection hatches and ventilation pipes are installed. The work is completed by backfilling the soil into the remaining space of the pit, compacting the layers every 0.2-0.3 m.

The resulting sewage system made of concrete rings, whether built with your own hands or with the help of professional workers, will ensure the removal and high-quality treatment of household wastewater, protect the soil and groundwater on your personal plot from pollution, and eliminate the inconvenience of living in a private house. An inexpensive and effective treatment system will last at least 50 years.

Selecting a location

In accordance with sanitary and hygienic requirements, the corner for the septic tank should be located:

- at a distance of more than five meters from the house;

- at a distance of more than fifty meters from the wells;

- on a hillock/hill (in this case, melt and rainwater will not fill the well);

- sewer pipes must be installed at a certain angle;

- in such a way that sewage disposal equipment can drive up to the well.

It is also worth noting that it is not advisable to build a septic tank at a significant distance from the home, thereby you will overuse the pipes, which will lead to additional costs.

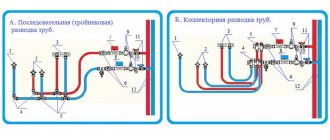

We install overflows

We can find out the installation depth of a pipe with a 50-centimeter cross-section by referring to SNiP 2.04.03–85, which recommends installation of communications 30 cm deeper than the point of penetration of negative temperatures into the ground, but not deeper than 70 cm from the point of the ground surface to the top point of the pipe. Based on the above, the smallest depth of penetration of negative temperatures into the soil for the Moscow region will be 110-120 cm, varying by type of soil.

Pipe sealing details

The difference between the bottom cut of the drain pipe and the top of the bottom filter element should be below 100mm. The end of the drain pipe must be located in the center of the well.

The overflow slope should be about 0.02 m/1 m to ensure the free movement of large particles, reducing the possibility of clogging communications. With a lower slope, such particles will remain in the pipe.

The inlet pipe is 10cm in cross-section and is installed 5cm above the overflow. The use of plastic pipes outside can lead to the system being out of service earlier than expected.

Along the edges of the overflows, tees are installed in a vertical position, directing the incoming flows downward.

Preparation of the solution

The quality of the prepared solution plays a big role here, so there is no need to skimp on it. As for cement, as a rule, grade M500 or higher is taken. The rings will be used in extreme conditions and if you use low-grade cement, they will quickly begin to collapse.

Quartz sand is traditionally used as a filler. But the sand must be clean and washed. A high silt or clay content can significantly reduce the quality of the solution.

The gravel should not be very rounded and well washed. Also, do not take layered or lamellar grains. As for the sizes, they are selected at the rate of up to ¼ of the thickness of the ring walls. So for a product with a thickness of 100mm, gravel is taken in the range of up to 25mm.

Important: for this solution, the frost resistance and abrasion coefficients are less important

Here you should pay attention to the shrinkage coefficient. The less concrete shrinks, the denser and stronger it will be.

To reduce this coefficient, there are special additives.

Concrete composition for cement M500

Metal formwork

This option is easier to manufacture, much more durable, plus the metal does not absorb moisture. But for it you will need 2 metal or plastic barrels or pipes of suitable diameter for the internal and external circuit.

Next, draw 2 vertical lines diagonally on the plane of the outer cylinder. On their border, on the outside, 2 - 3 window awnings need to be fixed, welded or riveted. After which the contour is cut with a grinder according to the markings. But be careful not to damage the awnings.

The fastening rods of the canopies are also cut off, but only on one side, so that they can be taken out and inserted back.

The internal contour is made in the same way, only the canopies are attached from the inside of the cylinder. The sizes of the sectors here need to be different, so they will be easier to remove. The smaller sector should be 1/3 of the cylinder diameter.