What it is

The impeller of a water pump is a wheel (propeller, turntable, blade) with side blades of various shapes, which, when transmitting a rotational impulse from the engine, directly contacts the water and forces it to move in a given direction.

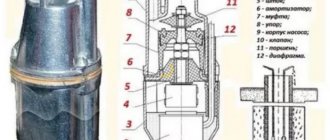

The practical purpose of a rotating propeller is to force water to move in the desired direction, while increasing pressure. The device consists of several elements, depending on the type:

- Pinwheel.

- Center axis.

- Bearing.

- Retaining ring for the disc head.

- Spring to compensate for water hammer.

Important: the package may sometimes include a rubber gasket.

Types

- Open . The propeller, which can be seen by turning the unit over. It looks like a disk with blades pointing down. There is a hole in the center for the shaft or bearing. The open supercharger has four, six, no more feathers. A device with such a wheel is used in a polluted environment. It has very low efficiency because there is no compression inside the unit. But there is one big plus - the blades can be easily cleaned of debris.

- Semi-closed . Widely used in devices for pumping relatively pure liquids. The wheel is located in a protective casing with a small hole on the side in which part of the blades can be seen. The disc has a minimum gap between the motor and the pad. The pressure that such a device creates is slightly greater than that of an open one.

- Closed . The most common type in centrifugal pumps. Two dense disks with wide blades between them. Water enters the housing through a special hole. The feathers rotate with minimal clearance between the discs, this allows high pressure to be generated at the outlet. But the closed type has a disadvantage - debris and dirt very quickly clog the cavity of the blades, which leads to breakdown. However, if you use such a pump in clean water, a drinking well, it will last quite a long time and the work will be effective.

Recommendations for installation and operation

- Entrust the work to specialists.

- Use filters.

- Set the settings in accordance with the instructions for use and technical characteristics of the device.

- Give preference to either metal pipes or PVC pipes, but with rigid reinforcement.

- The hoses must not be twisted.

Types of disk mounting on an axle

The impeller is attached to the station in various ways.

- Conical.

- Hexagonal.

- Cylindrical.

- Cross-shaped.

- A conical impeller mount is used if the wheel and blades are plastic. The replacement process is simple, which is why the cone is used for plastic. The blades often break and require replacement. The cone wheel fits very tightly on the shaft, and it cannot be rotated without the engine running. This type of fastening is used in pumps with open blades. In addition, a thread is drilled into the hub shaft. Having placed it on the pin, the supercharger is tightened with a bolt. A very ineffective way. At the moment, very few people use this type of fastener.

- The hexagonal impeller fit is a more reliable type of mounting the wheel on the shaft. In the center of the disk, holes are cut in a circle in the shape of a hexagon. There are eight sides and four. The rotational element of the engine itself is also made in the shape of a hexagon. The fit is very tight without an O-ring.

- Cylindrical mount . To prevent the wheel from rotating separately from the shaft, it has locking rings and protrusions. The lock nut is screwed on top. The downside of the cylinder is the need for precise adjustment of the shaft and hole in the impeller, as well as a rather complicated removal process.

- The cross-shaped fastening is the strongest. Used for pumping heavy liquids. It looks like a cross with four or six rays. Used in pumps with vertical and horizontal impellers. The fastening is duplicated with a nut or bolt.

The pump does not draw water

When it is discovered that the pump does not pump water, one of the reasons may be that the pressure in it is not adjusted correctly. Elimination of the problem is carried out according to the following scheme:

- the pumping station is switched off from the electrical network;

- water is drained from the water tank;

- the air pressure in the tank is measured through the nipple using a car pump with a pressure gauge or compressor, its optimal value is 90-95%;

- air is pumped into the water supply system.

- water is poured into the station;

- connects to a network with pressure control.

The air in the water supply system is pumped as follows. The cover from the pressure switch is removed by removing the plastic screw and changing the tightening force of the existing springs of the unit. By turning one nut, the lower pump value is turned on. Clockwise rotation causes the pressure to increase, while counterclockwise rotation causes the pressure to decrease.

Turning the other nut adjusts the pressure range between the lower and upper limits. The range boundaries are changed by rotating the element clockwise to expand, counterclockwise to decrease it. After the steps have been completed, the pumping station is connected to the electrical network and its functionality is checked.

What are they made from?

The material from which the impeller is made affects not only the environment where the pump can operate, the density of water, but also the economic component. A more durable unit will consume more energy, but the performance will be equivalent. Conversely, soft blades will help save on electricity, but with intensive use the wheel will have to be changed soon. Materials for making impellers for water pumps:

- Aluminum . A very common material among submersible pumps with open blades. Lightweight and corrosion-resistant, it can stay under water for a long time and work without heating up. Rotation requires a small amount of energy, so little electricity and pump life are wasted. Of the minuses: – aluminum is a fragile material; if debris or stones enter, the blades will be destroyed and will need to be replaced.

- Steel is more durable than aluminum and plastic. The impeller for the steel pump is cast or cut on a lathe. The petals must be absolutely symmetrically located and identical. In the center there is a hole for mounting to the hub. Of course, the engine will need more effort to rotate the wheel, and accordingly, electricity will also be wasted. There is another small disadvantage of a steel impeller - it is highly susceptible to corrosion when interacting with water.

- Cast iron . It is known that cast iron is less susceptible to oxidation and corrosion when working with water, therefore this material is used in pressure boosting stations and groups that are forced to work continuously in an aggressive environment. He also has a minus, this is his weight. A cast iron impeller is much heavier than a steel one and is more difficult to rotate. Such a wheel is cast to the required dimensions, but the cast iron does not always remain in the given shape - this is another difficulty. Sometimes the shaft has to be adjusted to fit the hole in the disk.

- Plastic, fragile and unreliable. Suitable for low power submersible and centrifugal devices. If the slightest debris gets in, the blades break and the disk becomes completely unusable. The advantages include the low cost of the impeller, as well as quick repair of the pump.

Operating principle of the equipment

If you plan to repair the device yourself, then you need to know not only what it consists of, but also how it works. In fact, this is easy to figure out.

There is a pump, it has its own individual technical characteristics (power, suction depth, speed of pumping working fluid - volume per unit of time, etc.). It requires electrical power and a hose to operate. All other details only improve the pumping process.

The principle of operation of a home pumping station and spare parts that may malfunction is as follows:

- The water does not enter the tap in transit, but first fills the accumulator. Its task, as is already clear from the name, is to accumulate moisture. To do this, the membrane bulb is filled and stretched, absorbing as much of the working medium as the maximum volume stated by the manufacturer. The effect on the membrane is such that the air in the adjacent chamber begins to compress and the pressure increases. When it reaches certain atmospheres (the values need to be adjusted or use the factory limits of 1.4 and 2.8 bar), the relay is activated. It opens the electrical circuit and, as a result, the electric pump turns off - the hydraulic tank is full.

- Then users turn on the faucet, shower, start the washing machine or dishwasher, and begin watering the garden. At the same time, the shut-off valve opens, the air strongly presses on the membrane, as a result, water comes out with a stable strong pressure. And when the air chamber becomes less than 1.4 bar (or another value set by the user), the relay closes the circuit and the pump turns on.

MBFT-75 Membrane for 75GPD

SF-mix Clack up to 0.8 m3/h

SF-mix Runxin up to 0.8 m3/h

If a situation occurs when a volume of liquid is consumed that exceeds the accumulated displacement in the tank, then the electric pump pumps in transit - from the well and to the tap without filling into the hydraulic tank. And only after shutting off the shut-off valves is the hydraulic accumulator filled.

Reasons for replacing the supercharger

The engine of the pumping station is located out of reach of the water, which cannot be said about the propeller. The fluid direction wings are constantly in an aggressive environment. Water and small particles in it hit the blades, affecting the material of manufacture. Accordingly, the impeller is destroyed. Signs of malfunction:

- A characteristic knocking sound of a bearing or a grinding noise in the supercharger housing. The wheel on the rotating shaft is centered, when one of the blades is destroyed, the bearing itself also breaks. It begins to knock and vibrate - this is one of the reasons for replacement.

- Loss of pressure at the pump outlet. Provided that no air has entered the housing, the pressure in the water discharge has decreased or disappeared completely, which means the device is broken. Before repairing the impeller, you need to check the pump motor to see if it rotates the shaft.

- The engine hums, but the shaft does not spin. This happens very rarely. The reason is the propeller sticking. Debris has gotten into the blades, or they have rusted and jammed the hub.

- With constant use, there is natural wear and tear on spare parts and mechanisms. There's nothing you can do about it, you'll have to change it.

- Depressurization of pumping equipment, namely the impeller. Due to improper installation or improper operation, a loss of internal pressure in the pump or impeller housing may occur. This will lead to serious damage and the need to replace the scratch disk.

Composition of the pumping station and purpose of parts

A pumping station is a collection of individual devices connected to each other. To understand how to repair a pumping station, you need to know what it consists of and how each part works. Then troubleshooting is easier. Composition of the pumping station:

- Submersible or surface pump. Pumps water from a well or borehole, maintaining stable pressure in the system. It is connected to the house using pipes.

- It is mandatory to install a check valve on the pipeline. It prevents water from flowing from the pipes back into the well or borehole when the pump is turned off. It is usually installed at the end of the pipe lowered into the water.

What does a pumping station consist of? - Hydraulic accumulator or membrane tank. A metal sealed container divided into two halves by an elastic membrane. In one there is air (inert gas) under pressure, in the other, until a certain pressure is created, water is pumped. A hydraulic accumulator is necessary to reduce the number of pump starts and extend its service life. Creates and maintains the required pressure in the system and a small reserve supply of water in case of station failure.

- Pumping station monitoring and control unit. Usually this is a pressure gauge and pressure switch, installed between the pump and the accumulator. A pressure gauge is a control device that allows you to estimate the pressure in the system. The pressure switch controls the operation of the pump - it gives commands to turn it on and off. The pump is turned on when the lower pressure threshold in the system is reached (usually 1-1.6 atm), and turned off when the upper threshold is reached (for one-story buildings 2.6-3 atm).

Each part is responsible for a specific parameter, but one type of malfunction can be caused by the failure of various devices.

Operating principle of the pumping station

Now let's look at how all these devices work. When the system is first started, the pump pumps water into the accumulator until the pressure in it (and in the system) is equal to the upper threshold set on the pressure switch. While there is no water flow, the pressure is stable, the pump is turned off.

Each part does its job

Somewhere they opened a tap, drained the water, etc. For some time, water comes from the accumulator. When its quantity decreases so much that the pressure in the accumulator drops below a threshold, the pressure switch is activated and turns on the pump, which pumps water again. It is again switched off by the pressure switch when the upper threshold is reached - the shutdown threshold.

If there is a constant flow of water (a bathtub is being filled, the watering of the garden is turned on), the pump runs for a long time: until the required pressure is created in the hydraulic accumulator. This periodically happens even when all the taps are open, since the pump supplies less water than flows out from all points of analysis. After the flow has stopped, the station operates for some time, creating the required reserve in the gyroaccumulator, then turns off and turns on after water flow appears again.

Repair

First, carefully inspect the device itself and its components. There is a very small gap between the disk and the pump body and the cause of the breakdown may be clogging of this gap. Especially if the station stood idle for a long time.

The reason for replacing the supercharger is the partial or complete destruction of its blades. The impellers installed in the pump have their own series and number, which corresponds to a specific type of unit. If the engine was previously equipped with an impeller with blades made of steel or cast iron, it cannot be replaced with a plastic spare part.

How to remove

The disc assembled or separately can be found in any store that sells pumping equipment and tools. When choosing a wheel, we independently measure all the parameters of the old one, as well as the seat on the shaft and its diameter.

- We remove the broken part.

- We unscrew the bolts securing the upper part of the rotation wheel chamber (four or six bolts) and remove the cover to the side. The wheel and its mounting location will become visible.

- A nut or bolt in the center of the circle secures the impeller to the pump shaft. It's not easy to unscrew. The hub rotates constantly, there is no locking ring and therefore the disk rotates with it. The shaft can only be clamped by unscrewing the rear cover of the pump. The element then becomes available.

- First, the impeller is clamped and, if it does not rotate, the nut will unscrew; if not, remove the back part.

- After unscrewing the clamping nut or bolt, the impeller is still difficult to remove. The shaft must be held with a gas wrench or a clamp, while simultaneously loosening the disk from side to side, gradually pulling it towards you.

- Pulling the wheel out will reveal the inner seal and bearings. They must be checked. The rubber seal protects the motor from moisture. Every time you replace the supercharger, it is also advisable to change the seal.

Pressure gauge.

Feel the difference. On the right is a crushed pressure gauge.

Perhaps the most harmless device at a pumping station, which, in principle, you can do without. I saw pressure gauges with broken glass, without a needle, crushed (they show more than they are), and I always persuaded them to leave everything as it was. The absence of a pressure gauge does not affect the operation of the station, but replacing it is such a hassle on a soured manifold! Want to check it out?