Polymer sewer pipes are by far the most popular in the construction of drainage systems. Possessing excellent technical performance and a large assortment, they are used both in private housing construction and when laying centralized sewerage.

For installation of a gravity (non-pressure) system, one of the best options would be a Korsis or Korsis PRO pipe. Corrugated, double-layer pipes produced are lightweight and at the same time durable products, manufactured using Italian technology. They are produced in Russia at a plant in: Novocheboksarsk, Klimov, Angarsk, as well as in Kazakhstan.

Where is Korsis produced?

"POLIPLASTIC Group" is a reliable manufacturer of Korsis pipes, which have established themselves as one of the most reliable products on the plumbing market. The company produces its plastic pipes at factories in Novocheboksarsk, Klimov, Angarsk, as well as in the Republic of Kazakhstan.

By offering to choose Korsis pipes, we mean a whole line of polymer products designed for the following purposes:

- Laying sewer systems;

- Disposal of waste (rain and melt) water;

- Water drainage;

- Rehabilitation of throughput pipes in the roadbed.

Price

Below are the average prices for Korsis pipes; the current cost and other information can be found on the manufacturer’s official website: www.polyplastic.ru.

| Diameter | Price (rub) 1 m.p. | With bell | ||

| outer | interior | 1 p/m of pipes 6 m long | 1 p/m of pipes 12 m long | |

| 110 | 94 | 221 | ||

| 160 | 136 | 383 | ||

| 200 | 171 | 619 | ||

| 250 | 213 | 986 | 1032 | 1009 |

| 315 | 271 | 1563 | 1633 | 1598 |

| 400 | 343 | 2394 | 2525 | 2460 |

| 500 | 427 | 3615 | 3861 | 2738 |

| 650 | 535 | 5035 | 5490 | 5263 |

| 800 | 687 | 9381 | 9876 | 9629 |

| 1000 | 851 | 13350 | 14230 | 13792 |

| 1200 | 1030 | 18415 | 19905 | 19159 |

Classification of pipes "Corsis" and "Corsis PRO"

Different Korsis pipes have individual technical characteristics, so there is a simple classification system for them to make it easier for you to choose the right product:

- Korsis and Korsis PRO pipes are primarily distinguished by the material from which they are made: Korsis is made of polyethylene, and Korsis PRO is made of polypropylene.

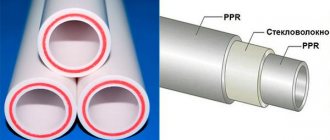

- The structure of both pipes is the same, but it also deserves attention. Korsis pipes consist of two layers: a smooth inner layer and a corrugated outer layer. Korsis pipes and Korsis PRO pipes can also be distinguished by the color of the inner layer: in the first version it is white, and in the second it is blue.

- SN is a measure of hoop stiffness. Each Korsis pipe has different SN characteristics, but the corrugated surface allows it to withstand heavy loads on the pipe rings of any product. When selecting Corsys pipes, it is necessary to carefully consider the required indicator of ring stiffness, because, for example, when laying pipes under a highway or under an aircraft, it is necessary to select only high-quality pipes with sufficient strength to withstand external mechanical influences, otherwise this may lead to an accident. The stiffness of pipes is measured in kN/sq.m., and the specific indicators of Korsis pipes are 4.6.8 kN/sq.m. for polyethylene products, and 12, 16 kN/sq.m. for polypropylene "Corsis PRO".

- The supplied pipes may also have different configurations. Typically, pipes are supplied either with a welded socket, which is attached to the sealing ring for pipes with a diameter of more than 250 mm, or without it.

- The length of the pipes is usually 6 or 12 m. The pipes are cut along the lower corrugation, so the manufacturer can allow deviations of 1% from the specified footage.

- Installation of Corsys pipes is carried out at temperatures from -40 to +60°C, and Corsys PRO can be installed at temperatures from -20 to +60°C.

- Corsis pipes for sewerage also differ in the maximum value of their operating temperature. The Corsys PRO pipe is capable of conducting liquids with a temperature of +95°C, but the Corsys pipe can only withstand liquids with a temperature of 40°C.

Installation

The pipes are connected into a single pipeline system in one of three ways:

- using couplings;

- welding;

- into the bell

In any case, the basic installation rules must be followed:

- installation should be carried out by specialists;

- joints must be cleaned of contamination;

- The connection points can only be lubricated with silicone grease, oil must not be used;

- it is necessary to use fittings and other components from the same company;

- operational requirements, such as: operating temperature threshold, etc. must be strictly observed.

Details about polypropylene pipes "Corsis PRO"

Having become familiar with the main differences and characteristics, let's talk about each class of pipes from. Let's start with the PRO series, which is manufactured using imported components, for example, high-modulus block copolymer. Thanks to high-quality raw materials, high reliability and durability of the finished product is achieved.

When choosing pipes, you must know what they are used for. The following systems are performed using Corsys PRO pipes:

- Domestic drainage;

- Disposal of industrial wastewater;

- Storm drainage (about

What it is

Products under the Korsis brand are manufactured by the domestic company Poliplastik, founded in 1991. The company is the largest manufacturer of polymer pipes, fittings for them, shut-off and control valves, plastic manholes and other plastic products in the post-Soviet space.

The purpose of the pipes is drainage and sewerage, and their key feature is the corrugation of the walls.

Corrugation increases ring rigidity with minimal material consumption. Relatively low plastic consumption means affordable product prices for the consumer.

Corrugation negatively affects the hydraulic resistance of the pipeline, and for sewerage it also means the accumulation of waste carried by drains in the depressions. In Korsis products this problem is solved simply and elegantly: their walls are made of double walls. The outer corrugated shell provides rigidity, and the smooth inner shell ensures trouble-free transportation of water and wastewater.

The smooth internal surface allows the hydraulic resistance of the pipeline to be reduced to a minimum.

Normative documents

All Korsis lines are manufactured in accordance with GOST R 54475-2011, which regulates the production of polymer pipes with structured walls, and according to technical specifications - specific for each line.

Similar products

Does Corsis have analogues? Of course, a direct competitor on the Russian market is produced by Pipelife under the Pragma brand.

Unlike Polyplastic products, Pragma sewer pipes are made only from polypropylene. This choice of material ensures high heat resistance and mechanical strength of the pipes.

Another analogue of Korsis is produced under the Pestan brand. These are two-layer polypropylene pipes with dimensions of 150-1000 mm. Country of origin: Serbia.

Peshtan pipes as an alternative to Pragma pipes

Pipes of the Peshtan brand are produced in Serbia and are considered an analogue of Pragma pipes. The pipe is presented in the form of a corrugated propylene pipe. Pipes are used for drainage of underground water flows and are used in a free-flow sewer system.

Features of Peshtan pipes.

Pipes have a number of advantages:

- 1. They have a high ring stiffness equal to SN8, this is due to the presence of a second layer of pipe. The pipe can be used at a depth of up to 10 m.

- 2.Easy to transport due to low weight.

- 3.The material eliminates the presence of corrosive and putrefactive processes and resists the negative effects of chemicals.

- 4.have a certain flexibility, although they are highly resistant to deformation. This advantage allows the use of Peshtan pipes without laying them in open trenches.

- 5. Service life reaches one hundred years.

- 6. There are no deposits from waste water left on the smooth walls, which reduces the abrasion process.

Peshtan pipes have a wide range of applications. They are installed in sewer networks of cottages, dachas, residential and non-residential premises, plants and factories.

Pipes produced by Peshtan are better suited than other brands for use in external sewerage networks and installation of water supply systems.

Specifications

The Korsis sewer structure is produced by co-extrusion. This is a PE product, the technical characteristics of which are determined based on the parameters of the outer diameter, nominal diameter, wall thickness, and profile width. The shape of the profile prevents its deformation.

There are two types of products on sale. They differ from each other by their ring stiffness class:

- 4 kN/m²;

- 8 kN/m².

Different rigidities allow the pipe to be laid at different depths. The black corrugated wall ensures its resistance to ultraviolet radiation. The white color on the inside makes it easy to diagnose its condition.

The pipe is produced in lengths of 6 and 12 meters. In terms of outer diameter, it varies in size from 110 to 1200 mm. It is possible to use the material with or without an already attached socket.

The outer and inner diameters of the product vary depending on the height of the corrugation, the thickness of its walls, the thickness of the walls of the inner layer, the pitch of the corrugation, and the width of its protrusion. For example, with an internal diameter of 110/91, the outer diameter is 110 mm, the corrugation height is 8.7 mm, the thickness of its walls is 0.45-0.5, the corrugation pitch is 12.6, and the protrusion width is 8.6 mm.

About the application and benefits of products (video)

General information

1.1. History of sewer pipes

Historically, sewers were open channels and structures made of stone, brick or wood, and pipes made of various metals were also used. At the end of the 19th century, sewer systems made of reinforced concrete pipes appeared. In the mid-20th century, a new solution was invented - polymer pipes, which made it possible to quickly build durable and reliable pipelines. In a short period of time, pipes made from polyvinyl chloride (PVC), polyethylene, polypropylene and their various derivatives were developed and used. These pipes are lightweight and easy to install and, moreover, are affordable. During the construction and operation of sewer networks, shortcomings of some materials were also noticed, for example, PVC did not always meet the necessary operational parameters, primarily due to increased fragility and low frost resistance, while polyethylene grades were constantly being improved.

At the moment, polyethylene has an optimal combination of physical and chemical properties: high chemical resistance, frost resistance, viscosity, durability, the ability to self-compensate for internal stresses and many others, which will be discussed below. In recent years, progress has been directed towards the creation of lighter types of pipes with high ring stiffness and a better stiffness/material consumption ratio compared to other materials.

Research was carried out on a wide variety of types of pipe wall profiles, which led to the creation, in particular, of CORSIS pipes.

Double-layer polyethylene pipes KORSIS are characterized by excellent resistance to the aggressive effects of wastewater and loads arising during installation and operation, ease of installation, durability, and excellent quality/price ratio.

1.2. Requirements for sewer pipelines.

Economic feasibility of application

Requirements usually applied to any sewer pipelines:

- good long-term hydraulic characteristics;

- resistance to external loads;

- long-term tightness of connections;

- optimal corrosion and chemical resistance;

- high resistance to abrasion;

- low overgrowth with various types of sediments;

- simple and quick installation;

- competitive price in comparison with other materials.

The material and type of pipe must comply with the conditions stipulated by the project. First of all, this relates to hydraulic characteristics, outer diameter and the value of the roughness coefficient. Resistance to chemical attack and abrasion must be assessed taking into account the properties of the wastewater. The tightness of the pipe system must be two-way: many of the problems found in existing sewers that cause damage to treatment plants are caused by groundwater infiltration at the connections. Lack of sealing is mainly due to improper installation of the pipe, although it may also be due to improper joint design or the type of seal used.

When analyzing the economic feasibility of using polyethylene pipes, it should be noted that it is much more important to make comparative estimates of the costs of laying a pipeline, but to consider the sewer pipeline as a whole, including in these estimates the future costs of maintenance and repair, as well as service life, preferably not less than 50 years old.

When designing sewer systems, primary considerations are typically given to issues of final cost (which refers to the total cost of material, installation and operation) and durability if properly maintained.

On this basis, the project developer, customer, contractor and maintenance service must optimize the project as a whole, consisting of: analysis of detailed construction plans, optimal choice of material, precise determination of the most economical and suitable installation methods, technically and economically efficient installation, and finally the correct mode operation.

The KORSIS polyethylene pipe best meets all the specified requirements.

Installation of inspection wells

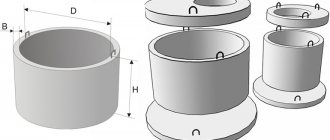

These independent structural elements are an integral part of the sewer system. Wells can be made of polyethylene or concrete. Polyethylene structures are divided into two main types.

The first type contains a monolithic cast element , which is connected to a vertical section of the pipe. To connect a sewer pipe to it, rubber seals in the form of rings are used, ensuring a waterproof connection.

The second type is different in that it consists of pipe sections welded together. The connection to the main elements occurs using couplings.

If a concrete well is installed, then it is necessary to ensure that the hole in the well corresponds as closely as possible to this indicator of the pipe. All connections are coated with cement mortar.

During the work, a support should be installed for the free end of the polyethylene pipe, which is intended to enter the well wall. First, the work of concreting the well is carried out and only after hardening the pipe is connected.

It is impossible to do two jobs at the same time, as this can cause deformation of the highway under the influence of heavy concrete masses.

Technical characteristics of polypropylene material

- Polypropylene melts at a temperature of 168ºC.

- Density is 910 per kg.

- The tensile strength is 25–28 MPa.

- The elongation limit at break is more than 200%.

- The material becomes brittle at 20ºC below zero.

- The bending modulus is taken to be 1250–1650 MPa.

- The hardness of the pipe material according to the Rockwell scale is assumed to be 55–75 α.

- Thermal conductivity coefficient is in the range of 0.17–0.23 W per meter.

- The coefficient of specific heat capacity at a temperature of 20ºС is 1.95 kJ per kg.

Abrasion testing is usually carried out using two systems. The first is to determine the amount of material that has been subjected to abrasion and wear after the advancement of abrasive particles. The second indicator indicates the time during which the particles were worn out under the specified conditions.

Abrasion by abrasives occurs due to friction during the rolling of certain abrasive particles, cutting off material components by them, if the flow consists of uneven, sharp and hard elements.

A number of studies conducted by specialists indicate that the mechanism of self-cleaning and deposition of microparticles on the walls of the pipe are directly related to the process of material abrasion.

Sewer underground and above-ground pipeline systems made of polyethylene with a ribbed outer surface are developing and are gradually replacing all other materials for drainage devices. Because of their high performance qualities, they are popular among builders.