When installing pipeline lines made of various types of materials, connecting plumbing fixtures and carrying out other work that requires sealing threaded connections, modern materials are increasingly used, one of them is the popular fluoroplastic sealant FUM. Its use has its own subtleties - in order to obtain a reliable sealed connection, you need to know how to correctly wind FUM tape onto the thread.

In the retail chain you can find several types of FUM tapes designed for use in various conditions, where they will work with maximum efficiency. Each variety differs in color, physical and technical properties, so when choosing, you should pay attention to this and purchase a product for a specific type of installation work.

Rice. 1 Examples of using FUM on fittings

Where is it used?

Due to its properties and characteristics, FUM tape is used in most situations where sealing treatment is required.

- Water pipes . The most important thing that FUM tape is used for is sealing water connections. The material is water-repellent, which makes it almost indispensable for fastening water pipes and parts during the assembly and installation of equipment.

- Gas pipeline . The film can be made gas-tight, and it can be used to install gas appliances and meters. However, not every FUM tape is suitable for this purpose; you need to purchase a specialized tape for gas.

- Technique . The material is characterized by resistance to various types of influences, therefore it is actively used to repair internal mechanisms of cars and various technical devices.

Heating pipes fastened with tape Source re-st.ru

Anaerobic gel sealants sanitary gel

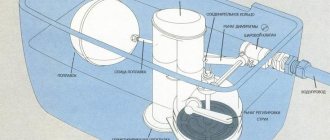

Another modern material for sealing pipe threads is sanitary gel. Reliable compaction occurs due to the polymer component of the gel. After hardening, sanitary gel does not shrink or expand, is resistant to temperature changes (from -60 to +150) and pressure surges, and has proven itself in various environments: water, natural and liquefied gas, heating antifreeze.

How to seal a plumbing connection: flax, fum tape, anaerobic sealant - a specialist decides

Sanitary gel is produced in three types:

- In green tubes - easy dismantling.

- In blue - medium dismantling.

- In red (Stop Master Gel) – dismantling with heating.

Installation using sanitary gel is simple: shake the tube and apply the gel in a thick layer around the entire circumference of the thread, distribute it evenly (with a brush, a special spatula), and assemble the structure. Excess gel is removed with a rag. Polymerization of the gel occurs in 15–20 minutes.

Pros and cons of using

The main advantage of choosing tape is its availability. FUM is sold at a low price, cheaper than flax tow and most other sealants used in plumbing.

The material is characterized by ease of installation. With proper skill, winding the tape occurs in a matter of seconds, but for this you should practice winding it on connections of different diameters for some time.

An important advantage of using tape is that the parts fastened with it can be easily disassembled. The connections do not freeze tightly; they can be disassembled even years after installation.

The main disadvantage of the material is that it is not the most reliable of seals, therefore, as a rule, it is not used for industrial installation. However, for household repairs the hermetic properties of FUM are quite sufficient.

Another disadvantage is that the tape often protrudes outward from the joints, so the pipes may look sloppy because of this.

Tape on thread Source sdelairukami.ru

Types of tape: choosing the right one

The first secret you need to know in order to use fluoroplastic sealant correctly: there are three types of tape. Each of them is designed for specific types of pipeline. Here is their brief description:

- To achieve tightness of threaded connections of pipes in which aggressive liquids will flow, use FUM-1 film. It is coated with a special lubricant that improves the quality of sealing and facilitates assembly.

- FUM-2 material is intended for systems through which oxidizers are supplied. It contains no lubricant.

- If the environment does not contain oxidizing agents, alkalis or other aggressive substances, FUM-3 film is suitable. It is also available without lubrication.

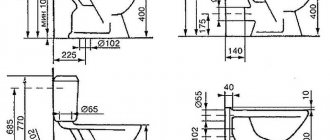

Just as important as the type of material is the width of the strip. It must strictly correspond to the width of the thread. Therefore, all three varieties are available in several different sizes.

If the type of film or strip size is chosen incorrectly, it will be very difficult to make the threads impenetrable.

Specifications

Let's consider the technical characteristics of the FUM tape, which determine its properties:

- the material is characterized by resistance to damage;

- has plasticity;

- retains its properties for a long time and does not need regular replacement;

- is environmentally friendly and does not emit harmful substances;

- heat-resistant, able to withstand a wide range of temperatures;

- the thickness is only two tenths of a millimeter;

- has dielectric properties and gas impermeability;

- elastic, capable of stretching almost twice its original length.

Method of winding flax on a thread

Before starting work on winding plumbing flax onto a threaded connection, it is necessary to carry out some preparatory work.

The threaded part is prepared for flax winding

Thread preparation

If you decide to seal the connected parts of your water supply using this method, you must first prepare the thread itself. The fact is that flax wound on a regular thread will bunch up with a screwed nut. There will be practically no residue left in the threaded connection itself. The work will be done poorly, and such a connection is doomed to leak in the very near future. In order for the flax fibers to be attached to the threads, it is necessary to make notches on them. Notches on threaded threads can be made with any available tool - a chisel, a sharp screwdriver, a file, or, if the place of work allows, even a hacksaw. The notches are made longitudinally, across the threads on the pipe. The main thing is that the notches have sharp, not smoothed edges.

You should also know that the top of the pipe thread must be rounded. Inch threads for pipe connections are cut this way, with a 55-degree angle at the top. If this requirement is not met, the 60-degree thread will tear the winding. Manufacturers of pipes, fittings, taps and other elements make threads taking into account all these requirements, in addition, they apply the necessary notches at the production stage. Such products can be considered fully prepared for winding tow.

How to wind

First, we separate a small strand from the entire mass of tow. There is no need to choose a very thick bunch; try to take the optimal amount of material at once. The winding should not be very thin; such a connection will not be tight. However, a layer of flax that is too thick will clump together when the nut is tightened, which will also lead to defects.

If there are lumps or other impurities in the strands, they must be removed. Next, you can either twist the strand or weave it into a braid. You can even fluff up the bundle of material before winding. There are some tricks when winding flax on a thread:

- If you twist or braid a braid, before use you can apply the selected sealant (special sealing paste, lithol, paint, etc.) to it. Or use the tow as is, then the sealant is simply applied to the threads. During the process, you will choose the option that is most suitable for you. This will not affect the final result.

- It is necessary to wind plumbing flax in the direction opposite to the direction of the thread turns. For example, with a left-hand thread, flax fibers are wound clockwise, and with a right-hand thread, vice versa.

- You need to start work from the point where the thread exits. The strand is taken in the right hand (instructions are given for right-handed people) and applied to the pipe. With the thumb of your left hand, press the edge of the fibers to the place where the thread exits the pipe. Next, with the first turn of tow, they try to wrap the end of the strand to the pipe, making a so-called “lock”. Then, turn by turn, flax is wound onto the threaded part. This must be done without gaps between the fibers, as tightly as possible, moving towards the start of the thread. Closer to the edge of the pipe, the thickness of the wound tow must be reduced. This will allow the nut to fit into the threaded part more easily.

- When the winding is completed, the excess tow is separated, its tip is glued with sealant, and then the winding is smoothed flush with the thread.

This is what proper flax winding should look like

The ideal option is the case when the maximum force applied to the nut falls on the last 2-3 turns of the thread, and when fully tightened, some of the turns remain outside. If the nut is screwed on by hand, then the winding is made too thin. You either need to add tow on top of it, or do it all over again.

After installation work, the plumbing tow protruding from under the nuts can be cut off or smoothed at the junction. After completing the installation work, connections made of ferrous metals must be painted over to protect against corrosion.

Plumbing flax, when used correctly, can provide the most hermetically sealed connection of any elements of water supply systems for cold and hot water, regardless of their internal pressure and temperature. However, the work should be carried out carefully, and if there is the slightest suspicion of a defect, it should be completely redone. This will give you confidence in the durability and reliability of the connections.

Using FUM for water connections

The use of sealed film for water connections has certain advantages compared, for example, with the use of flax tow and sealant

Taped water connections Source userapi.com

See also: Catalog of companies that specialize in water supply and sewerage work.

When using sealant, depending on its type, the connection can be sealed almost tightly, and if dismantling is necessary, the pipes will take a long time to disassemble.

The advantage of using FUM tape for water is that it does not interfere with the dismantling of pipes, is sufficiently waterproof and is easier to use. It can also be used together with flax as an additional sealant.

Material properties

The main advantage of fluoroplastic is its high plasticity.

In addition, the material is durable, non-toxic, chemically inert, and thermally resistant. FUM tape is capable of operating at pressures up to 40 MPa (relevant for antler baths).

The temperature range is minus 60 – plus 200 degrees.

When heated above 260 degrees, the structure of the material begins to deteriorate, and highly volatile fluoride compounds are released.

Average material characteristics:

- thickness 0.04 - 0.2 millimeters;

- width – 10, 15, 20, 60 millimeters;

- fracture tension 40 – 60 kg/cm2;

- lubricant content 0.3 – 20%;

- 100% elongation before breaking.

Using FUM for a gas pipeline

To fasten gas pipeline parts and install gas equipment, you should use only special FUM tape for gas. It must be supplied with a certificate of conformity confirming its suitability for use on gas pipes.

The special film for gas is yellow. It is made wider - up to two centimeters in width.

Yellow FUM tape for gas Source megastroy.com

The use of the material is possible only when sealing can only be achieved using a sealant. In the case of rubber hoses, as well as metal hoses, the sealing function is provided by a special gasket. In this case, the additional seal will not add tightness to the connection, and may even break it, as it will interfere with the tight fit of the gasket.

Precautionary measures

- It is not recommended to wind the seal using two or more pieces - this will compromise the tightness and strength of the connection.

- The tape on the thread should not be partially unwound, since if it is applied again, the connection will lose reliability. If winding is unsuccessful, the material should be removed completely and the process repeated.

- If, when connecting the elements, too much tension is created, which can lead to breakage, the tape will not be loosened. In this case, you also need to apply the seal again, removing the old section.

FUM tape is a material that is sufficiently reliable when sealing threaded connections. Its correct use will ensure the tightness of any pipeline even for a person who does not have extensive experience in plumbing work.

- Author: Vladimir Doneshko

Rate this article:

- 5

- 4

- 3

- 2

- 1

(19 votes, average: 2.9 out of 5)

Share with your friends!

How to wind tape

In fact, to figure out how to properly wind FUM tape onto a thread, you do not need to have any special skills. However, certain operating features should be taken into account in order to protect connections from leaks.

Before winding FUM tape, you must first thoroughly clean the parts. All joints must be treated with a solvent and dried to prevent debris from getting under the tape.

Winding tape onto a thread Source sovet-ingenera.com

Sequence of winding fum tape

For those who want to learn how to wind fum tape correctly, there is a certain algorithm of actions, the implementation of which will ensure a reliable connection:

- First of all, you need to select the desired width and thickness of the tape. For example, if parts of the water supply system have significant wear, then the tape must be selected with a greater thickness, up to 0.2 mm.

- Next, you need to thoroughly clean the parts being joined so that there are no residues left from previous tapes, tow, paint, rust residues, etc.

- Then you should carefully wind the tape onto the part with a smaller diameter, that is, on the one that will be screwed in (or onto which the second element of the threaded connection will be screwed).

- You need to wind the tape strictly clockwise, since according to our standards, almost all threaded connections (in general, everything in plumbing) have a right-hand thread. This is done so that when screwing the joining parts, the fum tape does not fold, but continues to wind together with the part. Understanding how to properly wind fum tape is quite simple. If you want, you can learn this in 30 minutes.

Using these basic rules, you will easily understand how to properly wind fum tape for threaded water pipe connections

It is worth paying special attention to the fact that the tightening force must be selected carefully. This is especially true for plumbing parts made of bronze and other soft metals and alloys. The main thing is not to over-tighten! The final result depends on how to wind the fum tape correctly.

The main parameter here is the skill of the repairman, but for beginners it is enough to simply tighten it without putting much effort. After starting the water, you need to check the connection and tighten it if necessary. If the water is still leaking, and tightening it further is risky, then you need to turn off the water, unscrew the connection and add a couple of turns of the tape

The main thing is not to over-tighten! The final result depends on how to wind the fum tape correctly. The main parameter here is the skill of the repairman, but for beginners it is enough to simply tighten it without putting much effort. After starting the water, you need to check the connection and tighten it if necessary. If the water is still leaking, and tightening it further is risky, then you need to turn off the water, unscrew the connection and add a couple of turns of the tape.

Things to consider

When working with tape, it is necessary to take into account some of its characteristic features.

- The tape is quite slippery, so you need to wind it carefully so that the strips do not move out of bounds. It is advisable not to allow the edge to fall out into the inside of the connection.

How the tape should be positioned on the thread Source abro-ind.ru

- Once the film has already been wound, it cannot be unwound and re-wound - this will break the tightness. Try to process it carefully right away, otherwise you will end up wasting a lot of material.

- Also, the tightness will be broken if there is a need to loosen the connection. In this case, you will also have to rewind the material.

Where is the best and highest quality pipe winding sold?

Our website presents a wide range of windings. The price is indicated in the catalogue, where you can also arrange delivery of windings for water supply, heating and gas devices.

Since 2004, it has been successfully operating in the plumbing equipment market. The company supplies engineering heating and water supply systems of its own brands AQUAPIPE, AQUALINE, AQUALINK.

The products fully comply with international standards and are manufactured using high-tech equipment. In production, not only intermediate and final control of products is carried out, but also components and raw materials are checked, which makes the product fully comply with the specified characteristics.

For all questions related to pipe windings, which you can buy at SantekhStandard, please call:

When repairing a pipeline, the main requirement is the tightness of the connections. The functionality and trouble-free operation of plumbing, heating, gas and other systems depend on them. How is tightness achieved?

Most often, when installing and repairing a water supply system, a threaded connection is used - it is inexpensive, fast and practical. With just a wrench on hand, a plumber can easily disassemble and reassemble the system and replace a failed unit. But the thread does not guarantee that the connection will be perfect; some other sealing component is needed.

Other seal options

Of course, FUM tape is not the only existing option for sealing joints. Among others, linen tow should be highlighted, along with which various types of sealants, as well as plumbing thread, are used to fasten pipe parts. Let's consider their advantages and disadvantages in comparison with FUM.

Flax tow

Linen is also one of the most popular materials. Just like FUM, it is customary to wrap tow in a dense layer.

It is important to wind the tow carefully and tightly, filling the thread completely along the turns. The outside of the fibers is additionally coated with paint or sealant. This leads to the main disadvantage of this material. It should be borne in mind that if paint is used, the connections cannot be dismantled and the pipes will be unsuitable for repair.

Flax tow Source ytimg.com

Also, the disadvantage of this material is its relative fragility. Unlike tape, flax is subject to gradual decomposition under the influence of moisture.

The main advantages of tow in comparison with FUM are:

- Adjustability. After winding and securing the connection, it is possible to unscrew it at a slight angle without loss of tightness and the need to replace the sealing material.

- Reliable sealing, high degree of tightness and ability to absorb liquid.

- High resistance to various types of physical influences.

- Easy to disassemble the connection.

If you have to choose what is better to use – ribbon or linen tow, then there is no definite answer. As a rule, it is recommended to use tow for intermediate pipeline connections. The tape is more suitable for securing taps, meters and mixers.

Sealants

When using flax tow, for a better fit and seal, the joint is additionally treated with a liquid sealant.

Liquid sealants Source ad-cd.net

Technical parameters and brands

Industrially produced fluoroplastic tapes and films are regulated by GOST 24222-80; the PN brand (non-oriented cushioning material) is used as an insulating sealing material; in accordance with the PN standard, opaque matte products from milky to light gray are used.

Tape sealing material made from the PN brand has the following parameters:

- It has excellent chemical resistance to aggressive substances and does not dissolve even in aqua regia - a mixture of concentrated nitric and hydrochloric acids.

- The produced film does not lose parameters in the temperature range from -269 °C to +260 °C, and is a low-flammable material with an ignition threshold of 520 °C.

- When heated above 260 °C, the polymer releases volatile toxic fluorine compounds.

- The material is gas-tight and an excellent dielectric - electrical strength 65 kV/mm.

- The tensile strength of the film in the longitudinal direction is 19.1 MPa or 191 kgf/cm2.

- The film has high elasticity, its relative elongation to break at any thickness is 185%.

- The material has no pores and has a low coefficient of friction.

- According to the above standard, the thickness of the PN film lies in the range from 0.2 to 3 mm, and the width is 40 - 120 mm.

Also, for fluoroplastic tape of grade 4D, made by rolling out a rope, the technical specifications of TU 6-05-1388-86 are adopted, which indicate:

- Scope of application: threaded connections of pipelines made of all types of materials operating in temperature conditions from -60 °C to +200 °C;

- Working medium pressure: up to 9.8 MPa (98 kgf/cm2), maximum permissible values - 41.2 MPa (412 kgf/cm2).

Rice.

5 Application area and dimensional parameters of produced FUMs FUM tape is produced in the following brands:

1 - for industrial working environments, as well as for equipment with chemically active substances - acids, high concentration alkalis, their mixtures and solutions. They are made of the first and highest grades, used with vaseline oils (17-20%) as a lubricant.

2 is a lubricant-free fluoroplastic sealant designed to isolate joints of oxygen-conducting systems or those with other active oxidizing agents.

3 - extreme sections of the first two tapes and the SKL film (wet calendered tape made of fluoroplastic F-4), for use in industrial pipelines, the working fluid of which is industrial components and chemically active substances in the form of concentrated acids, alkalis and their combinations in different proportions .

The main physical characteristics of FUM 1-3 used in the construction industry according to TU 6-05-1388-86:

- tensile strength, MPa: 6.86 and 4.9 for FUM-1 and 2.94 for FUM-3;

- elongation at break, %: 95, 80 for FUM-1 and 40 for FUM-3;

- thickness, mm: 0.1 -0.14 for FUM-1 and 0.12 for FUM-3;

- width, mm: 10 - 60 for the FUM group and 3 - 25 for FUM-3.

Rice. 6 Example of incorrect winding - large layer and channel overlap

Briefly about the main thing

FUM tape is one of the popular and effective sealing options. It is affordable, easy to use, and does not create problems during subsequent repairs.

There are several simple rules on how to wind FUM tape onto a thread:

- the winding area must be cleaned;

- the tape is wound along the thread - how the nut will move along it;

- When winding the tape, you need to tighten it a little;

- Usually four layers are enough, but sometimes more are required;

- After winding the tape, the thread relief should be palpable.

Ratings 0

Read later

Advantages and disadvantages

The advantages of the winding include:

- The first difference from tow is that fumlenta does not absorb water. Therefore, the joining does not require additional sealing in the form of paint or putty;

- Ease of use - the seal is packaged in small reels, from which it is easy to screw directly onto the thread;

- Aesthetic processing - the material does not protrude beyond the edges, as happens with tow. In addition, the tape is produced in colors that match the colors of plastic pipes and blends into the general background;

- Linen tow becomes unusable over time and requires replacement, but fluoroplastic does not collapse and lasts as long as a fitting or siphon;

- Easy dismantling in case of replacement of the structure. The winding is simply removed without additional stripping;

- After winding the seal, no significant effort is required to connect the parts;

- Widespread - it can always be purchased in several widths and thicknesses in any construction market.

There are minor disadvantages:

- Not suitable for triangular metal steel threads, as the material may be damaged by sharp edges and will not function as a sealant;

- The excess winding is not compacted like traditional tow, so you need to dose the winding turns. Usually this is 3-10 revolutions;

- The seal is not suitable for equipment that produces vibration during operation. During operation, shaking deprives the fluoroplastic of its inherent properties, breaking the tightness.

Processing agents

Some special compounds may complicate the dismantling of connections, the need for which arises when a leak occurs, when connecting new elements, or when replacing certain parts. Paint and silicone contribute to the gluing of elements and, as a result, difficulty in separation, in some cases it becomes impossible. In the absence of accompanying means or improper winding, similar problems appear on steel parts caused by the occurrence of corrosion damage at the connection.

Linen tow should be wound only in accordance with established rules. To begin with, it is treated with a suitable product, and the thread for it is also prepared. The winding direction should follow the thread turns. Then the remaining part is taken out beyond its limits and stretched, at this time the connection is screwed on and tightened. How much flax should I wrap on the thread? This can be determined by the tightness of the fitting being screwed onto it.

What sealants does the building materials market offer?

There are several types of sealing materials that differ in cost, ease of use and reliability of use:

- FUM tape (fluoroplastic sealing material)

- Sealing thread

- Linen thread

Among all the FUM proposals, tape is quite difficult to use, sealing thread has good qualities, but is too expensive, and only flax is an impeccable product that has proven itself over many decades.

How to properly wind flax on a thread?

To ensure a strong and tight connection, the threaded areas must be cleaned of rust using fine-grained sandpaper

At this stage it is important not to damage the threads. Then you should check whether there are notches on the thread - with them, the laid flax threads are fixed and do not move when connecting the parts. If there are no notches, they can be applied with a file or a plumbing wrench.

If there are no notches, they can be applied with a file or a plumbing wrench.

Proper winding of flax consists of several steps:

Check the tightness of the connection with a clean, flax-free thread to understand how thick the winding should be. Take a bunch of flax and separate a strand of sufficient thickness from it to obtain a tight connection. The flax hairs should be the same length, without lumps, straw or debris. Twist the strand into a loose rope of such thickness that it can fill one thread groove. Holding the end of the flax rope at the edge of the thread, wind it in the direction opposite to how the nut is tightened. Each subsequent turn should fit tightly to the previous one

Here it is important not to overdo it with the number of layers, there should be no more than two, otherwise the connection may burst when tightened or from hot water during operation. If the bundle turns out to be short, winding should be continued with the next bundle. Inspect the reverse side of the winding and make sure there are no bald spots. Apply a layer of special paste or silicone on top of the flax and tighten the connection until the paste hardens. The use of a sealing composition contributes to the durability of the connection, prevents rotting of the flax, and makes it easy to disassemble the structure in the future

Sealant should not be used as a sealant; such a connection is difficult to disassemble.

The use of a sealing composition contributes to the durability of the connection, prevents rotting of the flax, and makes it easy to disassemble the structure in the future. Sealant should not be used as a sealant; such a connection is difficult to disassemble.

Using a sealant when threading pipe systems is easy. This approach does not require the use of expensive equipment, and can be easily performed by both a professional and a home plumber.

1. Purpose of tow and how it works.2. Types of sealing materials.3. Method of sealing pipe threads with tow.

In plumbing work, tow is used to seal pipes and transitions connected by threads. It is made mainly from flax waste and is a coarse fiber of small size. If you wind the tow correctly, protection against leaks will be provided throughout the life of the pipeline. Answering the question of how to wind tow on a thread, it should be said that the quality of workmanship prevents the risk of a leak in the plumbing system. There is a gap between the threaded connections through which water freely flows out of the pipeline. If it contains properly laid plumbing tow, then the gap becomes smaller, and as water penetrates into such a connection, the flax swells and the leakage stops.

Flax paste effectiveness of the old method

Plumbing flax (or tow) was actively used in the Soviet years, but has not lost its popularity today, despite the wide variety of modern seals. To seal threaded connections, strands of flax were used in combination with red lead on drying oil or special oil paint. The main active ingredient of both formulations is lead. It is rarely found in modern analogues, and the sealant itself is not able to fully combat corrosion.

As an alternative, gray sealing pastes are used. Dry winding is strictly prohibited. The paste prevents flax from rotting and drying out, and plays an important role in water. Without its use on threaded connections with hot water and heating, the flax strand dries out, crumbles, and leaks appear. A black coating with traces of corrosion will form on the surface of the cold water pipeline and a leak will occur.

In direct contact with water temperatures above 90°C, tow shrinks and loses its properties, which is why it is so important to cover it with paste in order to increase the temperature barrier and the service life of the seal.

When choosing a high-quality material for sealing threaded connections, experts recommend choosing Unigarn flax and Unipak sealing paste. This seal can be easily dismantled and replaced if necessary.

Here are the main advantages of using sanitary flax with paste for hot water taps:

- 1. Possibility of winding on pipes of any design and diameter.

- 2. Winding on dirty, wet and old surfaces.

- 3. Adjustment (regulation) of connections at 45° and higher.

- 4. Ability to withstand temperatures up to 140°C, used for heating systems.

- 5. Long service life if the correct winding technique is followed.

- 6. Cheap material. The price of 100 g of flax does not exceed 100 rubles, a good paste costs 200–250 rubles. For home use, such a kit is enough for a large number of connections.

It is also necessary to remember that flax is a natural material, it does not contain harmful impurities, and is suitable for connecting threaded connections with drinking water.

The material also has its disadvantages:

- the paste stains your hands and leaves marks on white propylene pipes;

- inconvenient for winding on plastic and small threads;

- flax fibers get tangled and create inconvenience when working.

Working with plumbing flax requires skill and knowledge. The main thing is to attract the tow well, hide the ends of the strands, ensure complete closure of the threaded connection and do not skimp on the sealing paste.