Water in pressure pipelines for heating and water supply always flows in one direction. If for some reason it suddenly moves through the pipes in the opposite direction, the system stops working normally. Simply put, a water supply failure occurs with all the ensuing consequences. To prevent such failures, circuits use a check valve - a simple device that allows water to flow in only one direction. For those who are planning to install a pipeline in a country house, apartment or dacha with their own hands, the editors of the Yanashl website offer a review of “The best check valves for water for 2021”, compiled according to customer opinions and expert assessments.

What is this device and what is it for?

This is one of the types of shut-off valves. It looks like a small piece of pipe, as can be seen from the photo of the check valve for water. The purpose of this device is to prevent the flow from moving in reverse and thereby preventing a drop in water pressure.

In home garden water supply systems, the valve is designed for the pump to hold water in the suction device.

Expert advice on product selection

It is better to choose a check valve for a sewer, water supply or heating system in a specialized store rather than in the market. What matters is quality, reliability, tightness, and long service life.

Installed valve on a pipe. Source osn.by

You should inquire about the guarantee of trouble-free operation of the product from the manufacturer. Quality products will always have it.

A disc valve with a coupling fastening is suitable for metal-plastic pipes, and a rotary type of product is suitable for the heating system. It is necessary to select a water valve in accordance with the parameters of the installed system, the contamination of the flowing medium, the method of fastening and the required size.

The placement of the device must take into account the direction of flow. There must be special requirements for tightness so that there is no leakage of liquid when the valve is closed.

A valve with a large diameter may knock during operation. If the product has an inappropriate or too large diameter, a rattling sound will periodically appear when installed near the pump.

The valve body must be protected from mechanical damage in the form of stretching, bending, scratches and compression. The paint-and-varnish coating of the housing protects the device from corrosion.

The flanges must be parallel to each other during installation. The connecting bolts must be installed from the flange side crosswise, diagonally.

The factory arrow on the body must coincide with the direction of water flow, according to the technological diagram.

Valves for water Source chastnyjdom.ru

If you install a strainer in front of the valve, this will extend its service life.

Important! It is better to leave the choice of product to a specialist.

What does this valve consist of?

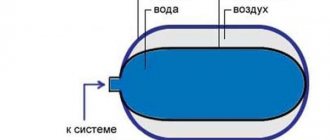

In addition to the body, the valve contains a small spring, a shutter, and a seal. Depending on the material from which the element is made, the modification of the device, manufacturers supplement check valves with springs, levers, bearings, and other auxiliary elements.

Design Features

The design of any check valve is not replete with complex parts. Regardless of the type of device, it consists of three required elements:

- Plastic or metal shutter with a silicone or rubber seal.

- A spring that ensures the shutter moves. Despite its small size, it performs a very important function, therefore, as a rule, it is made from high-quality steel.

- Device body.

To avoid the negative effects of aggressive chemical media (mineral salts, sulfur compounds, manganese, iron, etc.), dissolved in varying concentrations in any aquatic environment, the surface of the valve is subjected to additional protection. The protective layer is applied to the part using the galvanic method.

Some valve models can be equipped with additional elements to simplify the installation of the water supply network: a Mayevsky tap to allow air to bleed from the system, as well as a drainage hole to easily drain liquid accumulated in the pipe.

We recommend that you familiarize yourself with: Features of the faucet axle-box design for a mixer, independent replacement and repair of the device

Types of check valves

Experts subdivide these devices not depending on the diameters of the check valves for water, but by the type of shut-off element in them. So, valves can be:

- Disc-shaped.

- Disk.

- Ball.

- Bivalve.

The ball valve is considered quite reliable. The system is based on the fact that the ball moves inside the valve and closes the seat when necessary. However, it does not always fit tightly enough, which creates a pressure problem.

Poppet valves are divided into lift and rotary valves. The latter function under the influence of water. Lifting ones are equipped with a spring-loaded rod, which, under water pressure, presses the spring and the lock comes up.

The disc return element is the most popular and recommended by experts. It is also called spring. The valve is small in size with a simple and reliable latch system. The disk stands across the flow, which presses the spring when pressure appears.

The shutter of a leaf or double leaf valve consists of a pair of flaps mounted on the same axis. The petals are held in place by a spring, but as soon as water hits it, it pushes them out. With such a system, water circulation is reduced, which creates high voltage in the hydraulics.

Frequent errors and problems during installation

The valve may fail due to errors and shortcomings during its installation. Therefore, it is recommended to follow the instructions specified in the description during the installation process. It is necessary to carry out a technical inspection of the device at least once a month to identify problems. When operating shut-off valves, the following problems may arise:

- If during installation you forgot to remove the plug or valve lock, then there may be a lack of flow. A plug remaining in the tee can cause the pressure in the area before the valve to be less than the pressure in the area after it. This results in the device being unable to pass liquid. To eliminate this malfunction, it is recommended to dismantle the structure and remove the plug.

- In contaminated water, solid mechanical particles can damage the valve or get stuck between the seat and the plate. This leads to the fact that the valve will not seal the passage. To fix this problem, you need to dismantle the device, carry out cleaning procedures and reinstall it. Before doing this, it is recommended to try to wash off this particle with a stream of water. To do this, you can close and open the shut-off valve closest to the valve several times.

- An unsuccessfully selected valve leads to knocking noise. This happens due to the larger valve diameter. This problem can only be solved by purchasing a new device with a smaller diameter or reinstalling the existing one in a more suitable location on the pipeline. Please note that knocking may also occur due to the fact that the device is installed too close to the central pump. High flow turbulence also contributes to tapping in the device.

- A broken threaded coupling is another consequence of non-compliance with instructions during the installation process. This occurs if the valve is under stress from the pipelines, or if too much sealing material was used during its installation. In this case, it is recommended to replace the device.

Where is it recommended to use check valves?

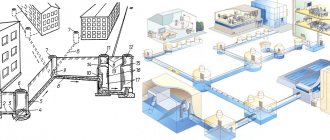

These elements are required to be used in the water supply system. In addition, they are indispensable in sewer lines, heating devices, pipes near water meters, in pipe branches in water heating devices, and plumbing units. Shut-off valves in the heating system eliminate the supply of reverse flow, which is important during the operation of water heating devices.

Why is the device needed?

A sewer check valve is a device that is designed specifically to prevent leaks and backflow of water due to clogged sewer lines. Sometimes even a package that accidentally gets into the pipeline leads to blockages and flooding of the apartment.

To protect the room from the reverse movement of sewer system waste, a special valve is installed that operates automatically. A similar mechanism is used not only in offices, cottages, residential buildings and industrial premises, but also in heating and water supply systems (for the pump).

Their operating principle is quite simple: if the waste liquid begins to move in the opposite direction, the locking mechanism stops this movement, as a result of which flooding does not occur.

In most cases, the need to install the device arises in the following situations:

- regular entry of debris and large objects into the sewer system, as well as other violations of operating rules;

- a long period of use of the pipeline, during which a layer of grease with dirt particles has formed on the inner surface. This significantly increases the likelihood of clogging;

- the slope of the sewer pipeline is too large or small, because to ensure free gravity flow of liquid, it is important that a certain speed of movement of the wastewater be maintained;

- bends located at a perpendicular angle to the sewer pipe. As a result, the speed of water movement changes sharply and a water blockage may occur.

If in a multi-storey building with a single riser, residents of first-floor apartments installed a check valve for the sewer system at 50 or 110 millimeters, then flooding with drainage can occur even on the 2nd floor. The liquid will not get further up, because... pressure will most likely cause the blockage to clear.

In country houses, similar locking mechanisms are also often installed. However, then it is recommended to install them on the street, after collecting all the branches of the sewer pipes into a single one.

Main tasks of the device

It stabilizes the pressure in the system, protects against water hammer, and prevents reverse fluid circulation. If the valve is installed in a submersible pump in front of a well in a summer cottage, it allows the pump to operate without failures or breakdowns.

Purpose and scope of application

The key purpose of a check valve is to protect the pump from damage. When the pump is not working, water can return to the well again, spinning the pump impeller in the opposite direction, which contributes to wear and tear of the pump. And with shut-off equipment installed, water cannot flow back into the well, since the valve plate closes under the action of a spring.

It is recommended to install the valve in the following locations:

- In front of the water heater. The water heated in the boiler has high pressure and can return to the pipeline. However, a valve installed in front of it prevents this.

- On metering devices. Constant pressure surges in the flowing fluid can damage measuring instruments. A valve installed on the meter will help protect it from damage. This device also prevents the meter impeller from rotating in the opposite direction.

- After the submersible pump. Autonomous water supply systems involve the installation of a submersible pump in a well. A valve installed after the pumping equipment prevents the outflow of liquid from the system back into the well if for some reason the pump stops working.

Installation in front of the water heater Installation of the valve on metering devices Installation after the submersible pump

Valve installation rules

Installation of a check valve for water is required in front of the meter. It is placed on the pump at the beginning of the suction device, or before the pump itself. But whether it will stand horizontally or vertically depends on the manufacturer’s instructions.

In addition, you need to make sure that you have purchased the right valve, since various modifications of these devices are intended for sewerage, water supply, and heating systems.

It is important not only to choose the right element, depending on its purpose, but also to take a responsible approach to its installation. Be sure to do this during water circulation. It’s easy to determine: by the arrow marked on the valve. It is also important to consider maintenance or replacement of this valve, so it should be installed in an accessible location.

If the device is mounted on a boiler, the device must be disconnected from the power supply and the water must be turned off. It must first be removed from the container.

As for the plumbing, since the pressure in the cold and hot water supply systems is different, each pipeline will require its own valve. Experts advise installing a water purification filter in front of this element. Otherwise, the locking mechanism will quickly become clogged and fail.

It is important to ensure that the valve is exactly suitable for a particular pipe diameter and in no way reduces it. Otherwise, the pressure may increase significantly, which is dangerous for the operation of the system.

Why is the valve not working?

A sign that the check valve is broken - the system cannot maintain the accumulated pressure. Or rather, a broken valve is only one of the reasons. The second is a leak in the supply pipeline. So you'll have to check both options.

What does a water check valve look like in cross section?

If you look carefully at the check valve device, you will understand that there is nothing to break. Possible breakdowns include a wedge on the rod and debris that prevents the disc from pressing tightly. The locking plate may also be worn. The latter is incurable, we change it immediately. Wear also includes pressed grooves from the seat on the sealing ring. So having a seal is a mixed advantage. The rubber is pressed through and the valve begins to “etch”.

This is what a blockage looks like on a small diameter OK

If the stem is lopsided or jammed, in some cases you can correct it. As a rule, this does not last long, and it will jam again quite soon. If the locking plate is clogged, it can usually be cleaned. To prevent this situation from happening again, place a filter in front of the check valve. If it is already there, and the water is still too dirty, there are several options:

- install a second, smaller filter;

- or raise the end of the pipeline from the bottom level;

- clean or deepen the well or borehole.

If we are talking about a submersible pump of the “Kid” type, dampening the vibrations that occur during its operation will help reduce the amount of turbidity. There are different methods - from the use of springs in suspension, to rubberized suspension. This really helps. Another option is to place a barrel with a wide neck in the bottom of the well, and a pump in it. Less silt and sand will rise.

You can see this picture

Next note. If, after a long period of operation without breakdowns, the check valves begin to “fly” one after another, the water level may have changed and you need to move the suction point. The second option is that the pipes are clogged with sand or silt and the pipeline needs to be simply flushed. Well, check it for leaks. By the way, if the station does not gain pressure, then the problem is most likely not in the check valve, but in the bulb, its fastening, nipple, etc.

Selection and purchase

Before you decide where to buy a check valve for water, you need to inquire about the availability of a guarantee for quality work from the manufacturer. If there is none, it is not advisable to buy the element.

It is also worth paying attention to the permissible temperature of the working environment in which the valve will operate. From this we can conclude for which water supply systems it is intended (hot or cold water supply).

It is important to consider the type of connecting thread. Manufacturers produce valves with internal or external threads. Preference should be given to the element that is easier to install in a particular system.

The valve is easy to check. You need to blow in the direction of the lock to make it close. Moreover, it should not allow air to pass through.

Connection type

The locking device can be mounted in one of the following ways:

- With a flange connection type, the valve is connected to the section of the pipeline between the disks of two pipe flanges using fasteners and an O-ring. The advantage of this method is the ease and simplicity of disassembly in case you need to replace parts or repair a breakdown.

- With the coupling type of connection, the fittings are connected to the pipe using a fine-pitch thread located on the inside of the pipe. The outer side is shaped like a hexagon so that you can use a key. The advantage of this type of connection is that there is no need to use additional fasteners; among the disadvantages, one can note the laborious process of screwing the pipe onto the pipeline.

- With the wafer type of connection, the fittings are clamped between the flanges at the ends of the pipe sections. This connection has a high level of tightness.

- With a welded connection, the fitting pipes are mounted into the system by welding. This method is used in cases where the working medium is poisonous gases or liquids, since the welded connection ensures complete tightness of the system.