Each multi-storey building is equipped with its own sewerage system. Its function is to drain sewage and other wastewater into a city-wide highway or other treatment facility. To prevent the spread of unpleasant odors indoors, use a vent pipe.

This device, which is a continuation of the riser, is carried through the roof to the outside of the building. It removes gases from the sewer circuit and stabilizes the pressure in it.

In this article you will learn a lot of useful information about this device and can see its photos.

General information

The mass of sewage that arises during the flushing of wastewater into the system, entering the main line, acts like a pump. Before the drain, the pressure indicator increases, and after them it decreases.

If the ventilation section of the line is not provided during use, the water seal will fail. Air mass is sucked through the drain hole of plumbing fixtures. The effect allows gases to enter the building.

This problem happens with devices with a weak water seal. But sometimes a breakdown occurs in several areas at once. It is accompanied by characteristic gurgling sounds appearing in the drain holes.

If the line is equipped with a ventilation section, air enters the line absolutely freely.

Due to this, the pressure indicator stabilizes. There is no failure of the water seals. Accordingly, the smell of sewage does not penetrate into the room.

Why is sewer ventilation needed?

Let's imagine that the sewer system of the house is equipped in the simplest way: all toilets, sinks, bathtubs and bidets are connected to the septic tank by pipes through a common riser. How does such a system work?

When a toilet is flushed, feces end up in the drain and then into the septic tank. The septic tank is not airtight, so the air displaced by feces is released into the atmosphere on the street, and unpleasant-smelling gases are reliably cut off by water in the water seal.

However, this only happens if the volume of flushed liquid is small and does not fill the entire lumen of the riser.

If the volume of liquid is large (for example, when water is released from baths on two or three floors at the same time), a piston of liquid is formed in the riser, descending downwards.

As with any piston pump, this will cause a vacuum of air above the piston and suck water from all water seals of plumbing fixtures into the riser and then into the septic tank.

After such a drain, polluted air with an unpleasant odor freely penetrates through all plumbing fixtures into all bathrooms at once.

This effect is most pronounced when the contents of the septic tank are quickly pumped out into a sewage disposal machine.

The problem is not limited to an unpleasant smell in the house. When feces decompose in a septic tank, gases that are dangerous to humans are formed: hydrogen sulfide and methane.

Thus, ventilation of sewer risers must constantly remove gases from the system into the atmosphere and reliably block their penetration into the room when draining and pumping out the contents of the septic tank.

Design standards

The design in question is a continuation of the riser. Therefore, it is constructed from the same channels. Their most popular cross-section is 110 mm. A “fungus” is mounted on top of the structure. It is needed to prevent rain or snow from entering the riser. In general terms, the basic standards are specified in SNiP 2.04.01-85.

To properly install a fan channel, follow these rules:

- choose the diameter of the device not less than the cross-sectional size of the riser;

- the part is mounted on the roof at a height of no less than thirty centimeters from the ridge;

- it is prohibited to connect a ventilated sewer structure with other ventilation systems in the house;

- the part is located away from windows;

- part of the channel passing through the attic must be insulated;

- It is strictly forbidden to install the structure under the roof overhang, as this will lead to its breakdown in the winter.

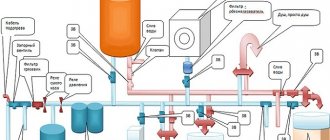

To install a fan channel, prepare its diagram. Below you can see a general example of it.

Check out the parts of the diagram:

- A - section 100 mm (toilet and bidet);

- B - size 50 mm (washing machine, sink, bathtub, shower);

- C - section 50 mm (dishwasher and sink).

You can prepare a fan structure project on your own.

To cope with the task you need to have minimal engineering knowledge and carefully study the requirements of SNiP 2.04.01-85. Below we will talk in more detail about what needs to be taken into account at the project preparation stage. The slope indicator of the internal sewerage system, according to SNiP 2.04.01-85, should be:

- for channels with a cross section of 50 mm - three centimeters per meter;

- for structures 85-100 mm - two centimeters per meter.

The slope value for branches up to one and a half meters in size is fifteen centimeters per meter. The channels must be installed straight. There should be no slope of the horizontal part. The directions of the channels can be changed using special fittings.

To combine several risers, it is allowed to use one fan riser. Change the direction of the channels above the area where the last plumbing fixture connected to the riser is located.

To connect 2-3 channels, use a tee. It is mounted at an angle from forty-five to one hundred thirty-five degrees. It is necessary to change the direction of the channel only by means of a special bend placed at an angle of one hundred and thirty-five degrees.

It is advisable to place the lower part of the fan structure in a warm place, and the upper part in a cold place. This will make the traction level optimal.

The cost of installing a ventilated duct in a multi-story building depends on many factors. First of all, it depends on the quantity of materials needed, their quality, and the complexity of installation. Installation of a fan structure costs on average 5-7 US dollars per linear meter. The cost of performing the work may include the creation of grooves, installation of clamps and dismantling of old structures.

Fan channels may need to be cleaned if dirt or precipitation has entered them. It's easy to prevent this. As we already wrote above, part of the structure on the roof needs to be equipped with a special fungus.

Arrangement of internal sewerage

Based on the purpose of the building, the construction of internal sewerage is provided:

- sanitary - collection and disposal of household liquids coming from plumbing household appliances (sinks, toilets, bathtubs, etc.);

- industrial - collection and disposal of industrial wastewater;

- drainage – collection and disposal of precipitation products.

Internal domestic sewerage is characterized by the installation of gravity pipelines, usually closed.

Layout of internal sewerage in the basement of the building. According to norms and standards, open installation of sewer pipes is allowed here

Industrial wastewater can be discharged through open tray systems if the wastewater does not emit harmful gases, vapors or leave unpleasant odors. It is recommended to lay sections of any sewerage system strictly straight with a given slope.

Standards for laying and installing lines

Outlet pipelines are connected to risers using oblique crosses and tees. If drain pipes from several plumbing fixtures located at the same level are connected, only oblique crosses should be used.

It is not permissible to use straight crosses for drainage, provided they are placed along a horizontal axis.

Non-pressure (pressure) internal sewerage lines must be made using pipes and fittings with a service life of at least 25 years. Technical fittings must ensure stability of hydraulic resistance throughout the entire service life of the system.

It is recommended to use sewer pipes and connecting fittings made of polymers.

Sewer riser hidden in a box. According to standards and rules, the box must be made of non-combustible materials. The exception is the material of the removable front panel of the box - moderately flammable is allowed

Thus, the laying of sewer lines from polymer pipes is carried out according to the following standards:

- hidden installation of risers (in shafts, boxes) with front panel equipment;

- the material of the shafts and boxes is non-flammable;

- the material of the front panel of the box shafts corresponds to the flammability group “G2”;

- open laying of polymer pipes is carried out in the basements of buildings;

- the section of the riser rising 80-100 mm above the floor slab is insulated and cemented with a 20-30 mm layer of mortar.

It is prohibited to carry out hidden (open) installation of sewerage inside walls, inside the floor structure, or under the ceiling of residential premises for any purpose.

It is possible to introduce several sewerage systems into the structure of multifunctional buildings for the drainage of liquids with varying degrees of environmental aggressiveness.

Separation of domestic and industrial sewerage systems is mandatory provided that outgoing industrial wastewater requires treatment, treatment and subsequent organization of recycled water supply.

Ventilated risers: calculation and installation

It is necessary to provide for the creation of ventilated risers connected to the points of sewer lines located along the upper horizon. Ventilated sewer risers should be led outside through a passage through the roof of buildings.

On buildings with flat and pitched roofs that are not in use, the vent pipe is installed, raising it above the roof level by at least 200 mm. In this case, the exit point of the ventilated riser pipe should be at least 4 m away from nearby windows.

In the foreground is the outlet of the air exhaust ventilation system, and a little further there are two outlets of ventilated sewer risers

On exploited roofs, the outlet of the ventilated riser must rise above the roof by at least 3 m and combine at least 4 separate risers. It is permissible to raise each individual riser below the level of the roof being used, but in this case a non-return ventilation valve should be installed that allows air to pass only inside the pipe.

The valve must be installed at the level of plumbing fixtures located at the highest level of the sewerage system.

The estimated number of ventilated risers (air exchange rate) is determined by the formula:

N=kW/Q,

Where:

- N – number of risers;

- k – air exchange rate per riser, l/day (norm for calculation is 80-100);

- W – volume of the sewer network, m3;

- Q – daily volume of dirty air at the outlet of the riser, m3 (320 for calculation).

The minimum possible depth of sewer pipes should be determined taking into account the existing permanent and temporary loads. If there is a risk of damage to pipelines from mechanical stress, they should be protected.

In areas where there is a risk of the external temperature decreasing to negative values, insulation should be used.

Laying sewer pipes in a system made without a standard calculation is allowed with a slope calculated according to the formula:

1/D,

where D is the diameter of the pipes used.

For networks inside residential (domestic) premises, the laying depth of sewer pipelines must be at least 100 mm from the top of the pipe to the floor level. It is unacceptable to change the slope in sections of horizontal branch pipelines.

Inside buildings, the installation of plumbing fixtures (wastewater receivers) is required. The number of such devices is determined by the architectural and construction design of the facility. All plumbing fixtures must be equipped with water seals (siphons) - devices that block the exit of the sewer gas environment into the premises.

Installation errors and repairs

When installing ventilation ducts, inexperienced craftsmen make mistakes. They are usually associated with the desire to get the job done quickly.

The most common mistakes are:

- The outlet of the fan channel is not on the roof, but in the attic. Over time, gases will accumulate in large volumes. Finding no way out into the atmosphere, they will begin to penetrate other rooms of the building.

- Installation of the device on the outside of load-bearing walls. This will lead to condensation and subsequent troubles.

- The use of decorative fungus on the upper part of the channel leads to a decrease in traction. As a result, the device does not perform its function. This leads to the spread of gases inside the building.

Repair of fan structures often involves replacing old cast iron channels with new polymer ones. It is advisable to perform this procedure under the guidance of an experienced specialist. Cast iron products are quite heavy. Moreover, they are characterized by a fragile structure. Careless handling will cause them to break. You need to be very careful when working with cast iron parts. Otherwise, you can cause damage to any elements of the structure and your own body.

If you need to replace ducts in a multi-story building on the ground floor, choose only high-quality replacement products. It is important that new polymer structures can withstand the existing pressure in the system.

To carry out repair work, you need various tools. You will need a drill, an angle grinder and a sledgehammer. To solve the problem, you may also need other tools. Since replacing cast iron products is a rather complex and time-consuming operation. After dismantling the old channels, install new ones. You already know how to do this.

Requirements for a ventilated valve (aerator)

The installation of ventilated valves to allow air into the system (Figure 5), which guarantees normal operation of the sewer system, is carried out on the basis of appropriate calculations. The throughput of the aerator must correspond to the specified design parameters for the throughput of the riser. In turn, the fluid flow through the riser depends on its diameter, type (ventilated/non-ventilated) and height. The calculations also take into account the diameter of the dictating floor drain (with the highest waste flow), the angle of liquid entry through it, the height of the water seals and other initial data.

Figure 5. Operating principle of an aerator - air valve for sewerage: 1. In the operating position, the valve is closed - air from the sewerage does not enter the room. 2. When a vacuum occurs in the sewer riser, the aerator valve opens, the missing amount of air comes from the room, preventing the water seal from breaking.

In a simplified form, you can coordinate the flow parameters of the aerator and ventilated riser using tabular selections. Initially, you should refer to Appendix “B” of SP 40-107-2003 for the installation of internal sewerage from polypropylene pipes. It is to this that SP 30.13330.2012 refers to determine the characteristics of the aerator.

The largest valve with a live air flow cross-sectional area of 3170 mm2 ( Important! Look in the store not at the outer diameter, but at the size of its opening, roughly), if the design conditions are met, it is capable of compensating for decompression in risers ∅110 mm, the maximum throughput of which is indicated in table 1.

Table 1. Capacity of a riser made of polypropylene pipes ∅110 mm, equipped with a ventilation valve with a clear cross-sectional area of the air flow of 3170 mm2 and 1650 mm2.

| Diameter of floor outlet, mm | Angle of liquid entry into the riser, ° | Riser capacity, l/s | |

| 1650 mm2 | 3170 mm2 | ||

| 50 | 45.0 60.0 87.5 | 5.85 5.10 3.75 | 7.7 6.8 4.54 |

| 110 | 45.0 60.0 87.5 | 4.14 3.64 2.53 | 5.44 4.8 3.2 |

Next, you should find out the flow parameters of the sewerage system with similar initial data. For ventilated risers, they can be gleaned from tables 6-9 (SP 30.13330.2012).

Table 2. Capacity of ventilated risers made of polyvinyl chloride (PVC) pipes (SP 30.13330.2012 (Table 7)).

| Outer diameter of floor bends, mm | Angle of connection of floor branches to the riser, ° | Throughput, l/s, risers with pipe diameter, mm | |

| 50 | 110 | ||

| 50 | 45 60 87.5 | 1,10 1.03 0.69 | 8.22 7.24 4.83 |

| 110 | 45 60 87.5 | 1,10 1.03 0.69 | 5,85 5.37 3.58 |

This also takes into account the diameter of the floor outlet and the angle of its connection. From the tables it becomes clear that, for example, for some of the most popular PVC pipes today, Ø 110 mm with an outlet Ø 110mm/450 (outlet for connecting a toilet), the second throughput of the riser will be 5.85 l/s. This figure turns out to be slightly higher than with similar geometric parameters of a sewer system with an air valve (5.44 l/s (Table 1)).

Consequently , by removing the decompression pipe and installing a similar aerator, during a salvo discharge it is possible that a vacuum may occur with dehydration of the siphons.

Is a vent pipe needed in a one-story house?

All multi-storey buildings must be equipped with drainage channels. Without them, it is impossible to solve the problem of gas distribution. Sometimes the use of this element is also relevant for private houses.

If the building is located there are several plumbing units used simultaneously. If the riser has a cross-section of fifty millimeters, even a small mass of waste can break the water seal. Therefore, in this situation, a fan channel is also needed. If on the site of a private house the septic tank is located near the building, you need to equip it with the ventilation devices in question.

To quickly connect the washing machine to the drainage system, install a separate siphon with a channel for it. Ventilation of the riser will be required if the main line is constructed incorrectly.

Check valve

Installing a check valve on the drain pipe can improve the efficiency of the system, in particular, prevent the backflow of gases.

In addition, check valves reduce the risk of drain pipe clogging. Sewerage without a drain pipe equipped with a vacuum valve. will perform its functions, however, its ease of use and degree of reliability may be lower, so it is still recommended to use these elements together. In particular, with dry water in the siphon, the valve alone will not get rid of the smell.

Valve on pipe

Installation of the drain pipe is carried out at the stage of construction of the internal part of the sewer; it can be done with your own hands if you have minimal skills

It is only important to strictly follow the recommendations of specialists and the requirements of building codes and regulations. The use of modern materials significantly reduces the labor intensity of work

Pipe materials and diameters

Since the drain pipe in a private house is part of the system, it would be optimal to make it from the same material that was chosen for the rest of the pipelines. In some cases, a combination of materials is allowed, but experts believe that the efficiency of dissimilar systems is significantly lower.

To install the internal part of the sewer system in a private house, cast iron or plastic pipes are used.

- Cast iron pipes have the required durability, but if they have defects during processing or receive mechanical damage, they become susceptible to corrosion. In addition, the large weight of the products significantly complicates installation, not only from the point of view of increasing labor costs, but also from the point of view of fixing vertical sections of the pipeline.

- Plastic pipes are increasingly being used for the installation of internal sewerage systems. which, in addition to light weight, have a number of other advantages, including strength, durability, absolute immunity to corrosion and the presence of a smooth internal surface, which reduces the likelihood of deposits and blockages. Another advantage of plastic is a large selection of not only pipes of different diameters, but also the fittings necessary for the implementation of the developed scheme.

The choice of the diameter of the fan pipe is made taking into account the design features of the system. The main condition: the diameter of the drain pipe should not be less than the largest pipe (including pipes and bends) of the system.

Since in the vast majority of cases the largest sewer pipes are used to connect the toilet and have a diameter of 110 mm, the drain pipes are also installed with the same diameter.

Structural layout diagrams

Modern sewer network solutions based on polymer pipes can significantly extend the service life of the system and simplify installation work. Sewage in a private house without a drain pipe remains quite functional, especially in houses with a small number of appliances and people, the standard system copes with the flow of wastewater.

Typical location of vent risers in a private house

An unpleasant odor appears at times of heavy load, when most of the devices are activated at once. In such situations, many owners install additional aerators - ventilation valves; they compensate for the lack of air in the system. Installation of such equipment occurs at a level of 1–2.5 meters from the finished floor level.

The installed fan complex will provide a number of advantages:

- A working and independent ventilation system to remove odors from risers.

- Creating a high-quality restriction of water flow, with normalization of air pressure inside.

- Providing functionality for several bathrooms located on different levels in a private house.

Such points will allow the construction of the required riser, taking into account high-quality ventilation and ensuring long-lasting functionality. The resulting sewage system will allow for the use of several full bathrooms.

This is relevant when a private house has independent and multi-level options for placing wastewater disposal. There is only one way out in this situation - the craftsmen can install the system with one vent riser, the exhaust part of which will be combined. But the diameter of such a pipeline must correspond to the cross-section of the working riser or be 50 mm larger.

How to Determine What Installation Requires

The drain pipe is an optional, but highly desirable element of the sewer system, which perfectly stabilizes its operation. It is considered that installation is necessary for all houses with a height of more than one floor

However, when designing a sewer system, it is important to take into account other minor factors:

Diameter of sewer pipes. If the diameter of the sewer riser pipes is less than 110 mm, then sewer pipes must be installed, since to fill the full volume of the riser, it is enough to drain the toilet and bathtub at the same time.

If the septic tank is located in close proximity to the house. Even if the house is one-story, but the wastewater tank is too close to it, you need to protect yourself with the help of a vent valve. If the layout of your home means there will be multiple bathrooms or baths that could potentially be used at the same time, then it is best to reduce the risk of a vacuum in the system. If the house has plumbing fixtures that have a large volume of waste water, for example, a swimming pool, jacuzzi, large bathtub.

Remember that the amount of wastewater is affected not only by the number of plumbing fixtures, but also by the intensity of their use. If the building has two bathrooms located above each other, but only one family lives in it, then it is unlikely that a drain pipe will be needed, but it certainly will not be superfluous.

When designing sewer systems for private houses, it is necessary to take into account many factors, ranging from the number of floors and devices that drain water into the riser, ending with the diameter of the pipes. Fan pipes are divided into categories based on shape, diameter and material used to make them. The diameter of the drain pipe depends on the diameter of the sewer riser. Based on the material, they are divided into the following types:

- Metal. Traditionally, the communication elements of the sewer system were made of cast iron. This is a fairly strong, durable and relatively inexpensive alloy. The disadvantages of this material are heavy weight and low ductility.

- Plastic. Nowadays, cast iron fan pipes are gradually being replaced with plastic ones, since this material is much more plastic and easier to process. Plastic models are lighter, cheaper and much more practical than cast iron, so they have almost displaced cast iron from the plumbing market.

Please note! When installing or replacing a drain pipe, you can connect cast iron sections with plastic ones; the main thing is to choose the correct diameter of the pipes so that in no case is there a reduction in the cross-section in the system.

Functional sewerage system without sewerage units

Sewage in a private house without a drain pipe is carried out in one-story buildings with a usable basement, but the installation of a toilet and bathtub takes place only on the first floor, not far from the riser and discharge into the external sewer network.

Sewer water seal

In this case, the consumption of a washbasin or house cleaning system is not dictating; such an amount of wastewater from sanitary appliances occurs irregularly and is not capable of affecting the operation of the system.

A private home is often equipped with grease traps; the equipment reduces the concentration of fats and organics in wastewater. Installing such equipment requires regular flushing of pipes with hot water. Air valves will help compensate for the lack of oxygen.

The valve outlet is connected to the main pipeline from the washing with fittings; the difference in elevations protects the equipment from flooding during flushing of the pipeline.

Related video: Fan pipe for sewerage in a private house

https://youtube.com/watch?v=HkdNv_ydf8w

Selection of questions

- Mikhail, Lipetsk — What discs should I use for cutting metal?

- Ivan, Moscow - What is the GOST for rolled sheet steel?

- Maxim, Tver - Which racks for storing rolled metal products are better?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals without the use of abrasives mean?

- Valery, Moscow - How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

Design of water supply and sewerage

engaged in the design of engineering systems. One of the priority areas of our work is the development of projects for water supply and sewerage systems.

Individual water supply and sewerage in a house, apartment, office, restaurant... this is an opportunity to organize an engineering system that will work properly in any conditions. Our design is a high-quality and competently compiled package of documents that will easily allow you to quickly install the system.

Example of a water supply and sewerage project for a house

Back

Forward

Pipe materials

A sewer pipe for a sewer system in a private house with a height of two, three or four floors is a decisive factor; in its absence, the hydraulic valves of the upper sanitary fixtures must be calculated for additional load. In this calculation, it is necessary to take into account the second flow rate from the devices, the cross-section of the pipeline, local resistance and pipe material.

Depending on the temperature of the discharged water, as well as the requirements for the working strength of pipelines, specialists select and install the following pipes:

- Plastic, modern polymer or metal-plastic for the installation of gravity lines.

- Plastic, metal-plastic pipes of low noise series for pressure pipelines.