A check valve is a type of pipeline fitting, the purpose of which is to prevent a change in the direction of fluid movement in the pipeline. The device automatically allows flow in one direction and stops flowing in the opposite direction. Refers to direct-acting protective pipeline fittings.

Before purchasing a 110 or 50 mm sewer check valve, it is important to understand the features of different types of locking mechanisms and their operating principles. It is also recommended to find out all the information about the existing sewer system.

Installation is quite simple; additional equipment is usually not required. It is important to purchase the device from trusted sales outlets, and also make sure that there is a warranty from the manufacturer.

Types of valves

There are different types of these devices. They differ in the features of their work. Let's look at them.

- Automatic - in demand for use in small private households. The device will not cope with significant loads.

- The kinetic valve functions correctly at low pressure. This device protects against air accumulation during drains.

- A combined option is a device that combines two types.

The pipeline can be installed in any direction. And for each case there is a separate option. When installing an air valve on a sewer, the diameter of the pipes must be selected correctly. This factor affects the separation:

- The receiving aerator has a diameter of 20 cm. The device is equipped with a filter that retains solid suspensions. This option is mounted on a horizontal highway.

- Ball devices are fixed to pipes with a small diameter. The device uses a ball part as a shutter.

- Inter-flange devices are characterized by compactness and low weight. Products are available as walk-through or corner. The shutter is represented by a special plate.

It is worth classifying products according to the method of fastening. The devices can be installed by welding. This option is not suitable for residential premises. For pipes with a small diameter, fasteners with couplings are suitable.

If the valve does not have a fastening element, it is clamped between the flanges. Fixation through flanges using a seal is also often used.

Existing types: characteristics, features

Fan valves may also be called aerators or air valves. They are divided mainly by their size, since depending on the installation location, an aerator of different sizes may be required.

There are two types of valves most commonly used:

- sewer aerator with a diameter of 110 mm - used for a centralized sewer riser,

- valve with a diameter of 50 mm - for connection with various plumbing fixtures.

Depending on the type of installation and characteristics, air valves can be of the following types.

- Air automatic. They are used mainly in private sector homes, as they have low throughput. They only work to release air.

2. Anti-vacuum. Recommended for use in all types of pipes. Can provide air inlet and outlet.

What is a check valve for sewerage 110 mm and other sizes

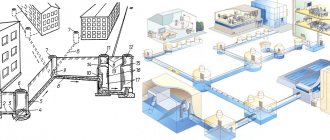

A check valve is a type of shut-off valve. It is installed in the lumen of the pipeline to block the reverse flow of liquid in case of clogging of the system. The device is installed in the basement on a horizontal section of the general sewer at the junction of the pipes. It can also be installed at a 90º turn in the pipeline.

To achieve maximum safety, a 50 mm sewer check valve can also be mounted on branches to plumbing fixtures on the first and second floors of an apartment building. This enhanced measure is justified by the fact that fecal water, when flowing back, can only rise above the first floor. Further, the accumulated mass is able to independently push through the plug formed in the pipe.

The check valve can be installed where the pipeline turns 90º

For the private sector, a check valve is installed before discharge into the sewer well (for each house separately - on the inside of the foundation). Such a device is also intended for an autonomous system, where wastewater accumulates in a drainage pit or in a septic tank. In this case, you should worry about how to fill the sewer cover with your own hands.

The check valve is characterized by simplicity of design, reliability, efficiency, durability, easy installation and convenient maintenance.

How to install it yourself

At the time of design, the risk of flooding should already be included in the system, so during this period it is necessary to work out the installation of the valve. Installation takes place in several stages.

Installation of a check valve can be done both on an external system and on an internal one.

The first stage is choosing an installation location

The location for installing the throttle must be easily accessible. The equipment must not be installed in the wall or floor, covered or cluttered.

Each device has a cover for cleaning and repair, so access to it is required at all times. If the sewerage system runs in the floor or concrete base, the locking mechanism is mounted in the pipe, and its upper part remains on the surface.

If the depth of the gasket is large and the headband is out of sight, we make a removable cover in the floor for inspection.

The second stage is choosing a device

Locks are classified differently, some are installed outdoors, in a well, others can only be installed indoors. It is necessary to choose the most suitable one for the installation conditions. If there is an error at this point, the shutter may subsequently collapse or crack.

Tools:

- Grinder with cutting disc.

- A sharp, hard knife for chamfering.

- Oil, lubrication paste.

- Hammer and flat board.

- At the installation site, we clear the work area.

- We measure the length of the device so that it fits into the prepared space.

- Lubricate the end of the pipe generously with motor oil or plumbing paste.

- The O-ring should also be treated.

- Before inserting the firecracker into the pipe, having made the socket, we will turn the device several times (if possible).

- With a little effort, but sharply we stick the pipe into the throttle.

- Then we check to see if the rubber band in the device has pulled up.

- On the reverse side we continue assembling the sewerage system.

Valve operating principle

Each check valve model is designed to block the reverse flow of drains.

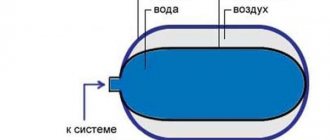

The closing mechanism is made in the form of a plate or ball. Models with a ball valve are more popular. The valve body has an inlet and an outlet. Inside the case there is a chamber with a locking mechanism. Due to the different diameters, pressure is generated in the nozzles, and the ball allows liquid to flow unhindered; as soon as the direction of movement of the drains changes, the ball completely blocks the flow.

The "plate" works on the same principle. When there is pressure, it rises freely, when the pressure changes, it falls and stops the movement of the liquid.

Overlapping plates are used in models with large diameters. The 110mm sewer check valve belongs to this category.

Each valve is equipped with a cover that is tightly bolted on. If necessary, it can be easily dismantled - this is required for cleaning the device and monitoring its operation.

Review of manufacturers

The most famous manufacturers of check valves:

- VIEGA/Germany . Devices for external sewerage made of polypropylene. The valve has two dampers, one of which has a manual locking system.

- CAPRICORN/Poland. Single valves for internal sewerage. Manufacturing material – polypropylene.

- McAlpine /Scotland. Plastic models for internal wiring. They are small in size.

- Polytron/Russia. Valves for outdoor installation with an emergency locking handle. Made from polypropylene.

Check valve device

In the store you can find two similar valves - regular and fan. These are completely different devices, each of them is designed for a specific concentration of wastewater. A conventional check valve consists of two pipes of different diameters. The inlet pipe is always smaller than the outlet pipe.

Between them there is a chamber with an air-filled ball or spring. If the liquid changes direction to the opposite, the ball (spring) will press on the membrane, which will close the inlet opening.

There is also a special inspection hatch in the device body. If clogged, you can open the hatch and clean the valve. The hatch cover is equipped with a gasket that makes it airtight.

Video: check valve - sewer protection

Installation of 110 mm check valves made of different materials on the sewer system

Currently, as evidenced by reviews from owners, a 110 mm sewer check valve is most often chosen in a plastic version. This is due to the fact that the drainage system is mounted from this material. Installation of the product does not cause any difficulties.

Check valves for sewerage are most often made of plastic.

Once the location for installing the valve has been selected, a section of the pipeline should be cut, the length of which must match the dimensions of the shut-off device with an allowance of 5 cm. The pipe sections must be processed with a file. A valve with a socket connection is placed on a section of pipeline. The same procedure is performed on the exhaust manifold side. The connection is sealed using sealing elements of the locking device.

Helpful advice! To ensure the most reliable connection, the edges of the pipes are recommended to be treated with sealant before installation in the socket.

When using a plastic check valve for a 110 mm sewer pipe for a cast iron or steel pipe, you must additionally purchase two adapters. The sequence of work is the same as when installing a shut-off element on plastic pipes. Using a grinder, a space is cut out on the manifold for mounting the locking element. The edges are processed with a sanding machine.

An adapter is put on a piece of pipe, then a check valve, after that another adapter, which is attached at the other end to the pipe by means of a socket connection using tow. To make the system reliable, the seams are treated with silicone.

Check valves can be made of cast iron and steel

Important! The cast iron check valve is mounted using bolted joints by tightening the mounting plates and sealing rubber bands.

Recommendations

- When inserting into a finished system, it should be taken into account that the diameter of the product’s nozzles must match the diameter of the pipes; otherwise, installation will have to be carried out with adapters.

- Many valve models are equipped with a mechanical shutter that allows manual shutoff, which is sometimes necessary.

- To install the product in the desired direction, you just need to look at the arrow on the body; it points in which direction the drains should move.

- A prerequisite for installation is the tightness of the connecting seams.

Shut-off valves with a diameter of 110 mm are suitable for almost all types of sewer pipes. This size is standard.

Check valve 110 mm consists of:

- Plastic or metal housing

- Overlapping mechanism in the form of a plate

- A spring that is compressed when pressure is applied, and which expands when pressure is dropped to press the disc tightly.

- Lever for manual control.

Important for installation:

- The valve must be freely accessible for maintenance.

- Number of protective mechanisms.

Possible causes of sewer blockage

The occurrence of fecal backflow can be caused by several reasons. The first lies in the improper operation of the sewer system, where plastic bags, intimate hygiene products and other things that block the cross-section of the pipe may unintentionally end up.

Non-return valves make it possible to freely drain wastewater when the level in the drainage channel drops

In this case, you will need to think about how to break through the sewer at home. The most effective method is to use a cable to clean pipes.

During long-term operation, deposits appear on the inner walls of pipes, which gradually grow, reducing the clearance of the pipeline. The settled sediment forms a rough surface on which solid particles accumulate, resulting in the formation of a plug. A good result for removing blockages is the use of chemicals that dissolve deposits inside the drain.

Another possible cause of clogging of the sewer system is an incorrect slope of the collector, which occurs as a result of improperly performed installation work. Here it should be understood that a traffic jam can form both with a strong and with an insufficient slope. To prevent solid contaminated particles from accumulating on the inner walls of the pipeline, water must move through it at a certain speed. This problem can be eliminated only by completely reworking the system.

During long-term operation, deposits appear on the inner walls of pipes, which gradually grow

A common cause of clogged sewer drains is the presence of a large number of outlets located at an angle of 90°. This configuration of the system contributes to a sharp change in the speed of movement of wastewater. Large suspensions can immediately linger, forming a plug.

Where should a check valve be installed?

The internal sewage system of an apartment can be equipped with one or several check valves. Usually one device is used, which is placed in front of the riser.

Due to the fact that the riser often becomes clogged at the very bottom (in the basement), the first floor apartments will be flooded with sewage. Therefore, it is impossible to install one valve on a common riser. Check valves of smaller diameter are placed directly in front of plumbing fixtures.

Private houses are equipped with valves when there is a risk that the septic tank may overflow with melt or groundwater. However, unlike an apartment, here you can get by with just one device, installing it inside the house or outside. If you install the valve on the street, it will be located between the treatment plant and the house, that is, in the area of the external sewerage system.

It is recommended to install a non-return valve on the sewer if:

- your apartment is located on the first floor of a multi-storey building;

- you live on the second floor, if the residents of the first floor took care of installing the valve, if clogged the drains will be able to reach you;

- you live in a country house on an area with a high groundwater level.

Residents on floors 3 and above do not need to use this device. Since the wastewater simply cannot rise to such a height. At this level, the liquid will squeeze out the blockage with its mass.

The occurrence of blockages

List of reasons

- Wear and tear of sewer pipes (poor flow capacity)

- Ingress of large debris

- Residents doing renovations flush waste construction materials down the toilet.

What to do?

When there is a blockage in the sewer riser, the reason is no longer important. Apartments on the first two floors suffer. The sewer column rarely rises higher.

The speed at which our emergency services work is needless to say. By the time they get there, they will identify and eliminate the cause. The entire home may be filled with sewage. To put it mildly, this will cause discomfort.

It is generally accepted that the culprit is large debris, but in fact it only reduces the throughput, but subsequent discharges of sewage lead to the final blockage of the system, which is the reason for the rise of the column. As you know, water will always find a hole and the toilet will be the first one in its path.

According to the same scheme, a traffic jam is formed in an incorrectly designed and installed system. It is enough to disturb the angle of the pipe, and a quick blockage is guaranteed.

The old sewer system itself is potentially dangerous. She served her purpose a long time ago. The internal diameter of the pipes is greatly narrowed; a plastic bag is enough for an accident to occur.

In private homes, such overflows can be caused not only by disruption of the sewage system, but also by a sharply rising groundwater level.

Check valve with electric motor

This modern analogue of a check valve runs on electricity; in case of frequent power outages, there are models with batteries. In this device, the locking membrane is always completely open, which prevents the formation of dirt build-ups on it, which prevent it from closing completely if necessary.

The device operates as follows:

- the liquid begins to move in the opposite direction and fills the pipes;

- when the pipe is filled to 70% of its volume, the probe installed inside sends a signal to the electrical unit;

- sound and light alarms are triggered, notifying you of trouble;

- the damper closes automatically.

Step-by-step installation instructions

Most air valves are produced by manufacturers to connect to DN110 pipes. If the connecting size of the device does not correspond to the size of the pipe, a special adapter is used. For pipes DN50 or DN75, aerators with the corresponding diameter of the connecting outlet or equipped with a reducing insert are used.

It must be remembered that a valve designed for pipes with a diameter less than 110 mm can be installed for a maximum of two plumbing points.

In areas of transition from a pipe of a larger diameter to a valve with a smaller diameter, reducer inserts and various adapters are used. To install the aerator on a cast iron pipe, there are also special adapters that ensure a reliable joint between the plastic and the metal.

At the beginning of the work, the installation location of the valve is determined, taking into account the installation rules and its accessibility for further maintenance.

Next, perform the following steps:

- The water supply in the house is turned off.

- If the installation is carried out on a previously installed pipeline, then a tie-in is made and a special adapter is installed.

Most aerator models have a bell-type connection.

The assembly of such connections is carried out in the following sequence:

- The outer surface of the smooth part and the surface inside the socket are cleaned of dust.

- Wipe the sealing ring from possible contamination and place it in the socket groove.

- The surfaces that come into contact during connection are lubricated to reduce friction. To do this, use a silicone-based sealant or soap solution, glycerin.

- Place the smooth end of the valve into the socket up to the mark. The quality of the connection is checked by rotating the parts relative to each other, followed by returning to their original position.

If necessary, the area with the connected vacuum valve is secured with a clamp. Upon completion of work, it is necessary to check the joints for leaks.

The surfaces that come into contact during connection are lubricated to reduce friction. To do this, use a silicone-based sealant or soap solution, glycerin

For hidden installation, special models of vacuum valves are used. If the riser is hidden in a fine or protective box, then measures must be taken to ensure the flow of air into the sewer valve. To do this, a ventilation hole is made according to the size of the aerator mesh.

The aerator body is buried in the wall, the fastening element is adjusted so that its outer edge is flush with the wall surface. The only visible element remains the decorative grille, which can be attached using self-tapping screws or inserted manually. For aesthetic reasons, it is available in the most popular color options - white, gray, black and chrome.

Some valve models can be used as drain cleaning holes. To do this, remove the decorative cover, take out the internal mechanism of the fan valve and insert the cable inside.

Design and operating conditions of the device

The body of the vent valve for sewerage installations is made of propylene. The internal mechanism can be equipped with a rubber membrane or rod that allows air to pass into the system without releasing it back into the premises. The rod valve is considered more reliable, since its working part wears out more slowly.

When choosing a valve, pay attention to the following characteristics:

- for open or closed installation;

- required diameter of the connecting outlet;

- with a regular or double thermally insulated riser wall;

- what kind of locking mechanism is used - membrane or rod;

- for vertical or horizontal (T-connection) connection.

Vacuum valves for sewerage are subject to strict requirements, each of them is tested for tightness and reliability - during operation they can withstand more than 800 thousand operation cycles without loss of performance.

The vacuum valve device is simple. This ensures its reliable operation, designed for hundreds of thousands of opening and closing cycles

Reviews

Vacuum valves have proven themselves well among consumers. The advantage of these devices is their versatility and ease of use. Vacuum valves from companies such as Ostendorf and McAlpine deserve special attention.

The cost of products of these brands varies from eight to twenty US dollars. This is quite expensive equipment. But it has excellent performance characteristics and durability. Reviews of devices from these manufacturers are very good. But for equipping large buildings it is better to use a fan riser.

Pros and cons of using a valve

The advantages of using a sewer aerator:

- the ability to prevent the appearance of an unpleasant odor inside the room (if the normal operation of the riser ventilation is disrupted);

- the ability to do without laying a vent pipe (which means not making an extra hole in the roof).

It should be noted that it is possible to use a valve on an unventilated riser, but this will only be effective in low-rise buildings. For multi-storey buildings, ventilation valves are considered an additional component to the pipe leading to the roof.

In principle, they can also be used separately, but only as a last resort . And in this case, an accurate calculation of both the number of devices and their throughput will be required (which should be done at the design stage of the building itself).

Design and principle of operation of the sewerage air valve

One of the obvious disadvantages of the sewer aerator is the possibility of it jamming. The movement of the rod (membrane) can worsen both from time (natural wear of parts) and from the ingress of some debris. The second option is unlikely, since foreign objects can only get inside when opening the lid.

Determining the installation location

It is important to know! The air valve for sewerage is usually mounted 20-30 cm above the main pipe. During installation work, do not allow dust, dirt or liquid to penetrate the membrane. For optimal performance, a systematic supply of oxygen is necessary.

For installation in an apartment, the device is mounted on a pipeline in a vertical position. This method will not provide ventilation to the riser, but will eliminate odors in a specific area.

It is recommended to install a sewer air valve in a private house. In this case, it is possible not to carry the fan structure through the roof. But some experts argue that it should be mounted only as an auxiliary part to the riser.

In private houses and apartments, plastic sewers are installed. Air elements are also made from polypropylene or PVC.

The valve must be installed:

- In high-rise buildings that are connected to wastewater treatment plants.

- In waste disposal areas.

- When connecting sewerage to sanitary facilities.

- In systems that can be connected horizontally.

Operating rules and common mistakes

- The aeration valve must be sealed. You can check it by simply filling it with water. There should be no leaks.

- The location of the aerator in the sewer network is strictly vertical. With a horizontal device, correct operation of the device is not guaranteed. The valve can be installed on a horizontal pipe section using adapters, but it itself has a vertical position.

- If necessary, access to the valve must always be open. It does not require regular maintenance, but must be easily accessible for cleaning and monitoring.

- During installation, it is necessary to take into account that air must flow freely to the aerator, since when a large amount of liquid is drained into the system, 25 times more air is entrained than the volume of water. The room should be well ventilated or have an exhaust hood.

- The aerator is installed at the highest point of the riser, above the connection level of the outermost drain point. For different connection options, different adapters, crosses, etc. are used.

- The valve installation can be hidden. To ensure that air flows well to it in this case, a ventilation hole is made in the pipe according to the size of the aerator mesh.

- Some models are used not only for air intake, but also for cleaning sewers. To do this, remove the valve cover, take out its mechanism and insert a metal cable inside.

How to clean, conduct an audit

The sewer system itself prevents the passage of clean water through it. Sometimes debris does not pass through the valve, getting stuck at the base of the plug cheeks. This problem often occurs if you do not monitor what goes into the drains.

Manufacturers of water seals have provided an inspection window in the device. It is located at the top of the shutter. Fastened with several bolts: three or four. Cleaning or inspection of unit components occurs through it.

We unscrew the bolts, first loosening each one. Remove the water seal cover. A round membrane and a chamber through which all the water passes will become visible. We remove all debris and large elements stuck in the chamber with a glove. We slam the plug several times, shaking it off. Now you need to rinse the device.

Clean water is poured inside the window. First, wash the chamber after the membrane, then the inlet compartment. After the inspection, we check the normal operation of the throttle by flushing the toilet or turning on the water in the sink. All this without closing the viewing window lid. You can see how everything works. Only after this close the lid and tighten the bolts. The rubber band also needs to be washed and returned to its place.

Important: you cannot immediately pull out all the pins and remove the cover. Residues of waste water can suddenly rush through the window.