Settling tanks are artificial reservoirs or natural reservoirs in which suspended impurities contained in them are separated, floated or deposited from industrial and domestic wastewater under the influence of gravity or using reagents. A sewer settling tank can be used as a filter for preliminary and final wastewater treatment in a drainage system.

The primary stage is the separation of mechanical impurities or suspended particles and the beginning of biological wastewater treatment. In biocoagulator settling tanks, activated sludge is mixed with source water, colloidal and finely dispersed impurities are separated. Secondary settling tanks of treatment facilities, final treatment devices, are called environmental protection ones, since after them the clarified water is discharged into natural reservoirs.

Simple type device

The sump tank can be in the shape of a rectangular or round well.

that flows through it flows slowly, allowing sediment to form.

It is not removed until it rots (six months, a year).

The rotting process is accompanied by fermentation and the release of gases, which lift heavy particles upward, forming a crust (sometimes 0.5 m thick).

Types by nature of work

There are different types of settling tanks. They differ in the nature of their work:

- static,

- dynamic.

Static

They are standard reinforced concrete tanks . A static settling tank is used when water flows periodically and its consumption is insignificant.

For cleaning, taps or siphon tubes are used, which are located above the level of impurities. Unloading of settled particles is carried out manually or using special drain devices.

Attention. The advantages of this type include versatility. Additionally, it can be used as a storage or buffer tank.

Dynamic

Used for mechanical water purification. Used for high flow rates of waste liquid. The action is based on the constant movement of water in the process of purifying impurities.

Depending on the direction of water, the dynamic settling tank is divided into three types:

- horizontal;

- vertical;

- radial.

The choice of settling tank type is influenced by:

- terrain conditions;

- concentration;

- quality of undissolved impurities in water;

- groundwater level.

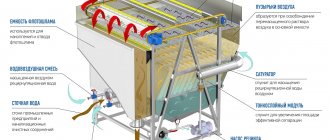

Horizontal

The most common type. It features a rectangular tank shape. Divided into several compartments using longitudinal partitions.

Settled particles in a rectangular settling tank are removed using a transverse tray or a special scraper, which are installed at a certain level.

If coagulation purification of wastewater occurs, the device is equipped with flocculation chambers. The structure has a high lightening effect. The disadvantages of the horizontal view include: not a cheap price for installation work and the presence of zones where precipitation stagnates.

Vertical

The shape resembles a square or cylindrical tank with a conical bottom. The movement of water occurs from bottom to top. The shape of the bottom allows impurities to easily sink to the bottom and be easily removed during further cleaning.

The efficiency of such a settling tank is 10-20% lower than that of a horizontal or radial one.

The advantage of the structure is its ease of operation and design . Disadvantages include greater depth. It increases the cost of installing structures in places with weak soil and high groundwater levels.

Radial

This type of sedimentation tank is a round tank. The movement of wastewater occurs in a radial manner, from the central part to the periphery. This allows you to increase the speed of water movement, which varies from high in the central part to low in the peripheral part.

Particles located on the surface are removed by a suspension device located on a rotating truss. Particles are collected in a collection tray or receiving hopper .

Among the advantages of radial settling tanks are low specific material consumption and ease of operation. The disadvantage is the high gradient velocity in the center, which reduces the volumetric utilization rate.

Projects

Russia, Moscow LLC "Alfa Stroy"

Equipment supply

Implemented

Russia, Murmansk, Shipyard

Equipment supply Design Commissioning works

Implemented

Differences in purpose

Depending on the purpose in the technological scheme, settling tanks are of two types:

- Primary. Installed before the physico-chemical or biological purification process. Excessive amounts of suspended solids and mechanical impurities (sand) are removed.

- Secondary. Installed after biological treatment at the end of the process flow. They are used to retain activated sludge that comes along with purified water. As well as biological film.

Biological cleaning method

This method is carried out using the vital activity of microorganisms that oxidize organic compounds . Microorganisms feed on pollution, their mass increases, they actively reproduce and renew biological mass.

The microorganisms themselves carry out aerobic and anaerobic processes, the difference of which is that the first process requires a good ventilation system, while the second requires the absence of oxygen.

This method of wastewater treatment is most often carried out in biological ponds, which have shallow depths and there are no underwater currents, or in filtration fields that are specially equipped for a dosed flow of contaminated water. For this type of purification, biofilters, aeration tanks and SBR systems are most often used.

The advantage of such devices is that they are not affected by the weather, because the conditions necessary for the life of bacteria are maintained artificially.

For the anaerobic process, they have digesters. They are good because they do not require additional aeration of the water, however, as a result of the oxidation of organic compounds, methane is released, the removal of which requires close attention.

The method of biological wastewater treatment can remove about 98% of contaminants, and they are designed for 5-8 people, which will be an excellent option for a summer residence.

Types by method of sludge unloading

There are several ways to unload sediment. Each of them has its own characteristics:

- With scraper mechanisms. The action process is chain transmission. To clean heavy particles, a scraper device is used that moves along the bottom of the settling tank. Impurities located on the surface are also sent to a special chute.

- Pumps. A suction pipe is inserted into the lowest part of the sump. Pumping occurs periodically as sediment accumulates.

- Hydroflush. It is a hydromechanical system. They consist of flushing pipelines with sprays, which are located in trays along the bottom of the sump.

The mode and method of sludge unloading affects the efficiency of clarification.

Settlement ponds

Pond settling is the simplest method of wastewater treatment. Under the influence of attraction, dispersed components settle to the bottom or float to the surface.

Typically, treatment ponds have several parts. But this cleaning method has many disadvantages.

This:

- the need for a large area;

- high price;

- air pollution by evaporating volatile gases;

- the influence of wind on the quality of cleaning;

- high labor intensity when collecting oil and sediment from large areas.

Thin-layer varieties

To increase the efficiency of settling, thin-layer sedimentation tanks are used. The structure has a shallow depth, which makes it possible to reduce the size, since the settling process occurs quickly.

Among the advantages of use:

- has compact dimensions;

- reduces installation costs;

- increases the speed of wastewater purification.

There are two types of thin-layer sedimentation tanks:

- Lamellar. It consists of a series of plates between which water moves. There are three types: cross-flow, direct-flow, counter-flow. The first type has a cross flow of water. In a direct flow, the movement of the separated sediment and purified water has the same direction. In countercurrent form, purified wastewater moves in the opposite direction of the precipitated impurities.

- Tubular. They are a pipe with a small diameter and a length of about a meter. They differ in the angle of inclination: small, steep. The small angle of inclination allows you to perform one cycle, consisting of clarification and washing. It is used to purify liquids with a small amount of impurities. The steep slope allows not only clarified water to drain, but also settled sediment to slide off. This eliminates the need for flushing the pipe.

The effectiveness of plate and tubular types is the same.

Continuous settling tank with conical shelves

In addition to multi-tier settling tanks, a large settling surface is also achieved in continuous settling tanks with conical shelves (Figure 6), used, for example, for settling carbonated juices from sugar factories. The separated suspension is fed through fitting 1 and distributed through channels between conical shelves 2 (through one), on the surface of which solid particles are deposited. The settled particles slide along inclined shelves to the walls of the housing and then move down to fitting 3 to remove sludge. The clarified liquid is discharged through channels 4 between two overlying shelves and removed from the apparatus through fitting 5. The advantage of settling tanks of this type is the absence of moving parts and ease of maintenance.

1 – fitting for supplying the separated suspension; 2 – conical shelves; 3 – fitting for draining sludge; 4 – channels for draining clarified liquid; 5 – fitting for removing clarified liquid. Figure 6 – Continuous settling tank with conical shelves

How to make equipment yourself

You can make a wastewater treatment facility yourself. The following types of materials are used:

- iron;

- plastic;

- concrete.

The simplest design is considered to be a single-chamber settling tank. To assemble it you will need reinforced concrete rings with a diameter of 1.0 m.

The well cover will be collapsible, using a steel pipe as natural ventilation. It must be covered with kuzbaslak. The tray of the outgoing pipe is located 0.02 m lower than that inside the liquid, and the outgoing pipe is 0.05 m higher.

The internal part of the structure is finished with cement mortar (1:2), the thickness of which is 1.5 cm (with grout).

Wastewater consumption in three times the amount is the main parameter of the capacity of the structure. An approximate calculation scheme for a single-chamber settling tank when using wastewater up to 0.5 m3 per day:

- capacity is 1.5 m3;

- reinforced concrete rings with a diameter of 1.0 m;

- The depth of the well reaches 2.95 m.

Installation process:

A suitable location is selected.- A hole of the required size is dug.

- The selected tank is lowered into the pit.

- Connects to a drainage well.

- Pipes are being laid.

- Leak tightness is checked.

- Buries himself.

The structure is easy to use. Cleaning is carried out once or twice a year. After which a small amount of sediment should remain in the settling tank for fermentation of the incoming wastewater.

Attention . The structure must be airtight.

We invite you to watch a video that clearly shows the process of installing a sump pump with your own hands.

Model range and technical characteristics of settling tanks

| Name | Productivity, m3/h | Length*, mm | Width, mm | Height, mm |

| PVO-ON-1 | 1 | 1517 | 606 | 1715 |

| PVO-ON-2.5 | 2,5 | 1720 | 1088 | 1715 |

| PVO-ON-5 | 5 | 2285 | 1080 | 2400 |

| PVO-ON-10 | 10 | 2295 | 2088 | 2400 |

| PVO-ON-15 | 15 | 2780 | 2088 | 2400 |

| PVO-ON-20 | 20 | 3790 | 2088 | 2400 |

| PVO-ON-25 | 25 | 4260 | 2088 | 2400 |

| PVO-ON-30 | 30 | 4700 | 2088 | 2400 |

| PVO-ON-40 | 40 | 6500 | 2088 | 2400 |

| PVO-ON-50 | 50 | 8620 | 2088 | 2400 |

| PVO-ON-65 | 65 | 9600 | 2088 | 2400 |

| PVO-ON-80 | 80 | 13200 | 2088 | 2400 |

| PVO-ON-100 | 100 | 8620 | 4380 | 2400 |

*Dimensions are for reference only, as the manufacturer is constantly improving the design.