The casing pipe is part of a hydraulic structure. It should be characterized by high strength, which will allow the well to be operated for a long period. When choosing such a product, special attention should be paid to the material. This is due to the fact that it will be difficult to replace the pipe in the future. When it deforms, the function of the facility’s water supply system is disrupted.

Types of casing pipes for wells.

Casing pipe: properties and purpose

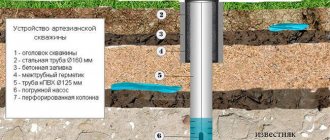

A water well for a private house is a small-diameter vertical channel drilled in the ground using a special installation. Its depth often reaches several tens or even hundreds of meters. To prevent the destructive effects of natural factors on its walls and preserve the original quality of water extracted from deep layers, a special casing pipe is used for the well.

From the technical side, it performs the following number of functions:

- Prevents wall collapse and ensures the safety of water intake parameters throughout the entire period of operation.

- Eliminates the penetration of ground and surface flows into the watercourse due to the complete sealing of the tunnel.

- Prevents contamination and destruction of equipment from silt, soil particles, suspended particles, and aggressive substances.

- Maintains the original diameter of the well and protects it from ground displacements.

- Provides resistance to the pressure of soil masses.

Diagram of a well with casing Source housecomputer.ru

If drilling is carried out in hard rock or to a shallow depth with a guarantee of maintaining the original parameters of the channel, then a well without casing is allowed. However, most often a pipe string is still installed. Moreover, it can be either single or double.

In the first case, the casing simultaneously plays the role of both a protective contour and a working artery - through which water is directly drawn. The second option is when a separate pipe is installed inside the protective circuit. As a rule, such a need arises when quicksand is detected at the drilling site or there is a high probability of upper runoff entering the well, as well as wall collapse.

Selection rules

There are two types of criteria, consideration of which allows you to accurately decide which pipe is best to use for a water well, these are:

- Technical.

- Operational.

Factors of the first category include:

- Diameter.

- Method of connecting pipe sections.

- Type of material.

Choosing the diameter of the casing pipe Source ytimg.com

The diameter of the casing pipe for a well is calculated using a special formula, taking into account a number of parameters. It is generally accepted that along the internal contour its value should be at least 110 mm. This is due to two reasons - optimal water intake conditions and the selection of submersible pumping equipment of suitable dimensions.

The well will have better performance characteristics when the pipe segments are fastened with a threaded connection. It will ensure maximum tightness, strength and durability of the casing. In most cases, the installation company decides what diameter the installed pipe string should be and what type of connection is required for it in a particular case.

Factors of the operational category of criteria for choosing a pipe for casing:

- Inertness of the material relative to aggressive environments.

- Resistance to external compression of soil masses.

- Endurance relative to mechanical loads - to ensure integrity during transportation and installation.

- Increased resistance to corrosion.

- Long service life.

- Optimal cost.

Three modern materials meet the requirements: steel, plastic and asbestos cement.

Note! Which pipes are best to use for a water well must be decided in advance - before searching for an installer. Typically, a company works with only one material and has in its arsenal special equipment and proven technology for a specific type of pipe.

Casing pipe with thread Source vostokpipe.ru

See also: Catalog of companies that specialize in water supply, sewerage and related work

For the oil and gas industry

The main area of use for casing pipes is the oil and gas industry. For oil or gas wells, large diameter metal casing pipes are typically used (the material typically used is a strong variety of steel). This choice is determined by the fact that plastic shows rather poor performance in terms of strength when working at great depths.

Oil and gas casing pipes are usually 10 to 15 meters long. Special threaded parts are used to connect to each other - this allows you to obtain durable structures with a high degree of sealing, which avoids leaks in case of wear. At great depths at pressures of more than 30 MPa, each element must be equipped with a rubber seal.

Please note that according to GOST, pipes of various diameters must have a certain wall thickness to ensure reliable and safe operation in the well (there is a possibility of damage to individual elements under the influence of excess pressure that is naturally formed in the well).

Table of correspondence between wall thickness and diameter:

| Diameter in centimeters | Wall thickness in centimeters |

| 42,5 | from 1 to 1.5 |

| 32,5 | from 0.9 to 1.3 |

| 19,5 | from 0.8 to 1.2 |

| 12,5 | from 0.6 to 1.1 |

Types of pipe material

Those who first encountered such a water supply to their home from deep sources often have the question of which pipe is better for a well - steel or plastic. However, in reality, there is also a third option - asbestos-cement. Let us analyze the features of application, their positive and negative properties in more detail.

Steel

Steel alloy is the most common casing material. Most companies offer rolled steel pipes for casing formation. The main reason is that its service life is similar to the period of operation of the well itself. However, due to the wide variety of ferrous metal products, some companies offer an alternative.

Casing steel pipes Source geolog.ru

To the natural question of the average consumer, what kind of steel pipes are used for a well, the answer is the following number of options:

- Cast iron.

- Enameled.

- Galvanized.

- Stainless.

- Metal-plastic.

The advantages of steel pipes include:

- Resistance to damage during installation and transportation.

- Not subject to soil compression.

- More than half a century of service life.

- Possibility of clearing a channel when clogged with silt using drilling technologies.

- Preservation of original parameters until the end of operation.

- Maximum well depth.

Among their disadvantages are:

- Susceptibility to corrosion.

- Penetration of rust into the water supply.

- High price.

Alternative options do not have some disadvantages - for example, they do not rust. However, the natural price for this is a significant increase in the cost of the project.

Casing metal-plastic pipes Source remoskop.ru

Selection by diameter

The diameter of the casing pipe for a water well is the most important characteristic, without which the drilling procedure will not begin. Its value directly depends on water consumption at peak consumption - that is, when all possible consumers are involved in the facility:

- Kitchen faucet.

- Shower.

- Washing machine and dishwasher.

- Bathroom.

- Garden watering system, etc.

According to regulatory data, the minimum water supply from a domestic well is approximately 700 liters per hour. Further, if we assume that at peak load 5000 liters of water per hour are required, then in accordance with the manufacturers’ recommendations it is necessary to install pumping equipment with a working diameter of 10 cm.

To calculate the internal diameter of the casing pipe, it is necessary to add twice the distance from the casing walls to the working diameter of the pump. If we assume that it is equal to 5 mm (the diameter of the pump should be slightly less than the internal diameter of the casing), then it turns out = 100 + 5x2 = 110 mm. And this is only the internal value of the parameter. The outer diameter of the pipe for a water well will be obtained by adding to it twice the wall thickness of the pipe itself. If it is, for example, 6 mm, then it turns out = 110 + 6x2 = 122 mm. The hole of the channel being drilled is always slightly larger than the diameter of the casing.

Casing technology

Well casing is carried out using a drilling rig using the following technology:

- At the initial stage, a channel is drilled that is larger than the diameter required - to a depth of at least 5 meters.

- Next, a smaller drill is installed, and drilling continues until the aquifer is reached.

- When water appears in the tunnel, hermetically connected pipe segments are installed.

- Once the required depth is reached, the pumping equipment is immersed.

- The well is being adjusted and tested.

Important! The drilling procedure should proceed evenly, and the casing should descend unhindered. Otherwise, the well pipe will be subject to overstress during installation, which will subsequently lead to rupture of the material and clogging of the well.

Column made of metal + uPVC: pros and cons

The combination of metal and plastic is an excellent option. This design realizes the advantages of the two options and mitigates their disadvantages. The metal contour enhances the strength of the structure. The plastic casing prevents the liquid from touching the metal, protecting it from corrosion.

Double well casing technology:

- Preparing a shaft size for external casing.

- Assembling the external structure with threaded locks.

- Immersion of the production pipe into the external circuit.

The disadvantage of double casing is the high installation cost. This scheme is not used when the budget is limited. Installing a double casing requires more time than installing a single pipe structure.

Briefly about the main thing

The casing pipe in a well performs the following number of tasks:

- Keeps walls from collapsing.

- Protects against external water flowing into the well.

- Prevents it from clogging.

- Protects the well from destruction and compression by soil masses.

When deciding which casing pipes are better for a well - plastic, asbestos-cement or steel, it is necessary to proceed from the drilling depth, operating conditions and cost of work. When choosing a casing pipe, you should take into account not only the type of material and its properties, but also the way its segments are connected and the diameter, calculated according to the peak flow rate of water consumption. The casing procedure is carried out by specialized companies using special equipment according to the developed technology plan.

Ratings 0

Double column: metal + uPVC

You don’t have to choose which is better, plastic or metal, but use both materials at once. In this option, a plastic contour with a smaller size is installed inside the steel contour. This scheme is rarely used in the Moscow region.

What tasks does each of the structural elements perform:

- The outer contour takes mechanical loads caused by soil movements.

- The inner circuit protects the outer from corrosion. It prevents liquid from touching the metal walls.

Steel is used to make the outer contour. The internal contour can be made of HDPE or uPVC. Aqualux+ engineers recommend uPVC plastic pipes because they are more hygienic.

Buden is interested: The cost of a meter of drilling with a steel pipe ⌀ 133 mm and uPVC ⌀ 113 mm.

Figure 3: Casing pipe steel ⌀ 133 mm and uPVC ⌀ 113 mm.