Septic tanks of low and medium price categories do not fully filter sewage - in this form it is impossible to drain the purified liquid into the ground or ditch; additional treatment is required. Traditional methods are a drainage well and a filtration field - objects that require a lot of time and effort to equip (the costs are comparable to those when installing a septic tank). But modern industry has a good solution to this problem - infiltrators for septic tanks. These post-treatment devices will be discussed in this article.

Infiltrator for septic tanks

Infiltrator

Infiltrator for a septic tank - device and principle of operation

You may be interested in information - septic tank microbe official website of the manufacturer

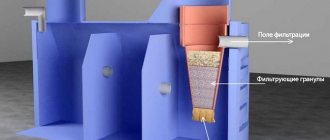

As was written earlier, the function of the infiltrator is the final purification of wastewater passing through the septic tank (Termite). Essentially, the device performs the same task as a filtration field or drainage well, but is more compact, cheaper and easier to install. The infiltrator is designed as follows.

- The case is made of thick and durable plastic. It has a relatively elongated rectangular shape, resembling a trapezoid in cross-section. The housing also plays the role of an infiltrator cover and is equipped with stiffening ribs designed to strengthen the structure and protect it from pressure (earth from the outside and water from the inside).

- Inlet pipe - through it, water from the septic tank enters the infiltrator.

- Ventilation pipe - necessary for the flow of air into the infiltrator. Why this is needed will be discussed below.

- A cushion of crushed stone - the water entering the infiltrator undergoes final purification, seeping through this cushion into the ground.

Important! When installing a row of several infiltrators, an overflow pipe is installed instead of a ventilation pipe in all products except the last one. With its help, aftertreatment devices are connected to each other along a chain.

The design of the infiltrator and the principle of its operation

An example of using several infiltrators. You can see a branching pipe coming from the septic tank, overflow pipes and a ventilation device

Let us present the principle of operation of any infiltrator in the form of separate stages.

Stage 1. Water flows from the septic tank into the infiltrator pipe.

Stage 2. Through the pipe it enters the infiltrator housing.

Stage 3. Upon contact with oxygen, which enters inside along with air through ventilation, the process of oxidation and breakdown of organic substances that were not previously screened out in the septic tank occurs.

You may be interested in information: septic tanks for a summer residence without pumping, budget

Stage 4. Partially the products of these reactions escape into the atmosphere through ventilation. The rest, along with the water, fall into the crushed stone layer.

Stage 5. The remaining substances that polluted the drains are filtered out on the crushed stone bed. Purified water goes into the ground without harming the environment or poisoning nearby reservoirs and wells.

The principle of operation of a septic tank with an infiltrator

Infiltrator installation process

Features of gas connections

When connecting gas stoves, water heaters and other types of equipment, flexible hoses are also used. Unlike water models, they are yellow and are not tested for environmental safety. For fixation, end steel or aluminum reinforcement is used. There are the following types of devices for connecting gas appliances:

- PVC hoses reinforced with polyester thread;

- made of synthetic rubber with stainless steel braid;

- bellows, made in the form of a corrugated stainless steel tube.

The Santekhkomplekt holding offers engineering equipment, fittings, plumbing fixtures and devices for connecting them to communications. The assortment is represented by products and materials from well-known foreign and domestic manufacturers. Discounts apply for bulk purchases, and product quality is confirmed by standard certificates. For information support and assistance, each client is assigned a personal manager. The ability to arrange delivery within Moscow and to other regions of the Russian Federation allows you to quickly receive the purchased goods without unnecessary hassle.

Drainage is a drainage and drainage measure to remove excess groundwater.

If water does not leave the site for a long time, the soil becomes gleyed, if shrubs and trees quickly disappear (get wet), you need to urgently take action and drain the site.

How to choose an infiltrator for a septic tank

The selection of an infiltrator for a septic tank is carried out according to the following criteria:

- the type of soil on the site and its water permeability;

- infiltrator volume;

- permissible load;

- quality of execution;

- dimensions and weight;

- price.

Choosing an infiltrator for septic tanks

Now let's look at these criteria in more detail. Let's start with the type of soil and the degree of its permeability. This criterion does not relate directly to the design of infiltrators, but it is very important, as it affects the number of devices that need to be purchased. Sandy soils absorb and pass water well, so you don’t need too many infiltrators - on average, one or two products are enough for a family of 3-4 people. A completely different situation is observed in the area with clays and loams - there the water permeability rates are low, therefore, for the effective operation of the entire treatment system, more infiltrators will be required. The classification of soils and filtration coefficients for its various types can be found in the tables below.

Diagram of a septic tank with two infiltrators

Table. Classification of soils according to the degree of water permeability.

| Type of soil | Filtration coefficient for a given soil, kf, m/day. |

| Very highly permeable | More than 30 |

| Highly permeable | From 3 to 30 |

| Waterproof | From 0.3 to 3 |

| Poorly permeable | From 0.005 to 0.3 |

| Virtually waterproof | Less than 0.005 |

Table. Indicators of filtration coefficient for various types of soil.

| Soil type | Filtration coefficient, kf, m/day. |

| Gravel | From 100 to 200, depending on the faction |

| Sand and gravel | From 75 to 150 |

| Coarse sand | From 25 to 75 |

| Sand medium-grained | From 10 to 25 |

| Fine sand | From 2 to 10 |

| Slightly decomposed peat | From 1 to 4.5 |

| Peat is highly decomposed | From 0.01 to 0.15 |

| Sandy loam | From 0.2 to 0.7 |

| Loam | From 0.005 to 0.4 |

| Clay | Less than 0.005 |

The second most important criterion for choosing an infiltrator is internal volume. The larger it is, the more productive the product is. When searching for or purchasing infiltrators, be sure to take this characteristic into account. For areas with loam, the total volume of post-treatment devices should be three times the productivity of the septic tank, measured in liters per day.

The photo shows Triton 400, one of the most popular infiltrator models. Behind it is the septic tank “Tank”

The durability of the infiltrator and its resistance to pressure from above, from the sides or from the inside directly depend on the permissible load and quality of workmanship. When purchasing a post-treatment device, be sure to pay attention to the thickness of the plastic - it should be uniform. Also, when purchasing, take a close look at the case for defects and weak points.

The next criterion is size and weight. These characteristics directly determine how convenient the infiltrator will be to transport, carry and install, as well as how large a pit needs to be dug to install the product.

Addition to the septic tank - infiltrator

And the last thing is the cost of the post-treatment device. Be especially careful with infiltrators that are sold at a greatly reduced price - they may be defective. If the cost of the product seems too high to you, check with the seller what qualities and distinctive advantages of the infiltrator it is due to.

Video - Installation of a septic tank “Tank-2” with an infiltrator and a drainage well

Recommendations for selection

When choosing an infiltrator, you need to pay attention to the material from which it is made. It should not corrode or interact with chemicals that may enter with wastewater. Most manufacturers use cross-linked polyethylene for infiltrators.

The infiltrator body must be durable and free of cracks. The device will have to withstand soil and water pressure when it is completely filled with it.

The main characteristics of the infiltrator are its capacity and size. Since the maximum possible volley discharge of water from the septic tank and the filtration rate depend on these parameters.

When choosing an infiltrator, it should be taken into account that the actual capacity of all installed infiltrators together must be at least 3 times greater than the productivity of the septic tank.

If the septic tank is 500 liters, then the infiltrators should have a volume of 1500 liters. At the same time, the required capacity of such devices must always be calculated with a margin. The type of soil also has a significant influence on the number of infiltrators. For example, loam is much less permeable to water than sandy soil. Therefore, when making calculations on the volume and number of devices, you should definitely take this characteristic into account.

Infiltrator for septic tank - step-by-step installation

This section of the article provides step-by-step instructions for the installation process of an infiltrator, which was installed for a Termit 3 septic tank for one of the private households.

Recommendations for installing an infiltrator

Step 1. Determine the location of the infiltrator. It must meet the same distance requirements from wells and bodies of water as other local treatment facilities. In addition, the infiltrator should be located from the septic tank itself at a distance of 2 to 10 meters.

Step 2. Mark the area of land where the foundation pit for the infiltrator will be built. This pit should be slightly larger in length and width than the device itself.

Step 3: Either by hand or using an excavator, begin digging the pit. The depth should reach 1.5-1.75 meters, depending on the thickness of the future sand and gravel cushion. Since the infiltrator is usually installed simultaneously with the septic tank, take advantage of the power of construction equipment, if one is used to perform the main task of installing the VOC.

Digging a pit using special equipment

Important! In the case where the site is characterized by very high groundwater, it makes sense to install an infiltrator and crushed stone bed near the surface of the earth or directly on it. In such a situation, instead of a pit, an embankment is created.

Step 4. Level the walls and bottom of the pit.

The walls and bottom of the pit need to be leveled

Step 5. Make a trench for the pipe connecting the septic tank and infiltrator to each other.

Step 6. Line the walls of the pit with geotextiles, lay the edges on the surface of the earth near the pit. If the infiltrator leaks, the material will not allow water from the septic tank to go into the ground without passing through the crushed stone layer.

The walls of the pit are lined with geotextiles

Important! It is not advisable to lay geotextiles directly on the bottom of the pit - in this case, the flow of water into the ground after post-treatment will be difficult, and the material itself will silt. As a result, the efficiency of the infiltrator will drop sharply.

Step 7. Fill the bottom of the pit with medium-fraction crushed stone. Calculate the amount of crushed stone so that you get a layer 40 or more centimeters thick.

The bottom is covered with crushed stone

Step 8. Level the layer of crushed stone. If necessary, check the building level readings.

Step 9. Place the infiltrator itself on a bed of crushed stone, level it in height, connect the ventilation and the pipe connecting the device to the septic tank. Check the tightness of the connections, and if necessary, do a test run of the local treatment system.

The infiltrator is installed on a crushed stone bed

Another photo of the installed and connected infiltrator

Step 10. Cover the top of the infiltrator with geotextile.

The device is covered with geotextiles

Step 11. Place thermal insulation on the top of the septic tank body. In this case, Penoplex boards are used.

Laying thermal insulation material

Step 12. Place a layer of sand around and above the infiltrator and compact it well. The layer thickness should be approximately 50 cm. Then completely fill it with soil.

Backfilling the infiltrator

At this point, the installation process of the infiltrator can be considered complete. Most devices from a variety of manufacturers are installed using a similar principle. If the infiltrator and the septic tank itself were installed correctly, then in the end you will get an effective local treatment facility that will cope with your sewage waste for several decades.

Advantages

You can use different types of devices for additional purification of water that has already settled well in the septic tank. However, for private households, the most profitable option is an infiltrator. Externally, this device looks like a plastic box with no bottom. Its advantages:

- the possibility of removing wastewater to a shallow depth allows the use of soil post-treatment even when the soil water is shallow;

- the minimal weight of the plastic structure makes it easy to install yourself;

- the ability to organize high-quality post-treatment in a small area, so one infiltrator can replace 35 meters of drains in filtration fields;

- the design copes well with uneven flow of wastewater;

- the affordable cost of the structure and the ability to install it yourself allows you to reduce construction costs.

Types of filter structures

There are two types of well filtration structures that work on the same principle and are installed in a similar way. Their differences lie in the area of application. The former are used in the drainage and stormwater systems, the latter in the sewer system.

Absorption well in the drainage system

In this case, drainage absorption wells are the end point of a complex drainage system of the site, where groundwater or rainwater flows through a pipeline, so that later, after passing through a natural filter, it goes into the ground. Its main purpose is to remove water from the house and clean it from silt and sand.

The diagram shows the organization of storm and drainage sewerage for a site with a storage tank. In soils with high absorption capacity, instead of a collector, a filtration well is installed

The diameter of such wells, as a rule, is no more than one and a half, and the depth is up to two meters. It is allowed to drain both systems into one well. The filter container is installed at the lowest point of the site so that water flows into it by natural gravity.

Filtration structure in the sewer system

In the sewerage system of the site, absorption wells are used for post-treatment of wastewater coming from a hermetically sealed reservoir in which the wastewater undergoes primary biological treatment. The tank is made of concrete rings, brick or rubble stone, or a ready-made septic tank is used.

Scheme of installing a filtration well with a septic tank, in which sewage waste undergoes primary treatment, and then flows through a pipe into an absorption tank and through a filter system goes into the soil

The principle of operation of the system is as follows: wastewater from the house sewer enters a sealed container, where it is oxidized for two to three days under the influence of anaerobic bacteria living in airless space.

Then the wastewater enters the filtration well, where other bacteria - aerobes - are already present. Their vital activity is activated under the influence of oxygen.

As a result of double purification, the liquid entering the soil from the absorption well is almost completely free of harmful microorganisms and organic substances.

Wastewater disposal can be organized in two ways:

- Separate. Water from the kitchen, bath, and washing machines goes into the septic tank, and sewage with feces goes into the cesspool.

- Joint. All household waste goes into a septic tank or storage tank.

As a rule, in the first case, gray wastewater is sent to different sewerage facilities. For example, fecal waste - into a storage well with subsequent pumping and removal, gray domestic wastewater from kitchen sinks, bathtubs, washbasins, etc. devices - into absorption wells.

In the second case, you need a septic tank consisting of at least two chambers, each of which carries out its own cleaning stage sequentially. Fecal matter settles in the first chamber, from where it is periodically pumped out using a sewer truck.

A single-chamber septic tank is usually installed in individual households that have a separate sewage system.

Liquid waste without suspended particles with a minimum amount of impurities enters the second chamber, where it is further purified. After this, the water passes through the pipes into a filtration well, from where, after passing through a natural filter, it goes into the soil.

The second option of the joint scheme is complete pumping and removal of wastewater.

Stages of wastewater filtration

Wastewater filtration is carried out in stages. Consider these processes:

- First, the liquid settles (in the first section). The membrane partition of the septic tank prevents foam and accumulated gases from penetrating further into the system.

- The wastewater that continues to flow leads to pressure on the existing liquid, as a result of which the part that has undergone primary treatment overflows into the second zone of the septic tank. Under the influence of reagents, impurities are broken down.

- Further, in the following zones, suspended impurities obtained after a chemical reaction with reagents precipitate, and the purified water then goes through pipes to the distribution well.

Bacteria for septic tank

To increase the operating efficiency of the septic tank, products containing anaerobic bacteria are added to it. The essence of their action is that they break down the thick wastewater contained in the septic tank and prevent it from forming sludge.

The septic tank must have a hatch. Since anaerobic bacteria do not act 100%, undissolved particles will remain inside the septic tank in any case, and a hatch will be necessary in order to pump these particles out through it. It is necessary that the hatch can be safely accessed by a sewer truck. In this case, the hatch must be tightly closed, otherwise, if large insoluble residues or large amounts of water after heavy rains, as well as toxic impurities, get into it, the service life of the septic tank and drainage may be significantly reduced, as a result of which the causes of clogging may become more serious .

How many of these elements are needed?

Photo: installation of infiltrators

The quantity depends on the brand of equipment. For example, one Tank-1 septic tank requires two Triton-400s. And provided that the soil base is peat or sand, then you can get by with one additional device. Also, when choosing, you need to take into account the required power, soil and other existing terrain features.