What it is?

This refers to the source of water. The main feature is that the liquid spontaneously bursts upward with powerful pressure. In some cases this source is artificial, and in most cases it is natural. The occurrence of water is located at great depths in aquiferous earth layers. When this horizon is opened, the liquid easily rises to the top.

Designation of the term “artesian well”

This phrase is often found on bottles of mineral and drinking water. Everyone seems to have a rough idea of what it is, but they can’t explain it specifically.

Today there are two explanations of this term and both of them deserve the right to exist:

- An artesian well is a deep hole in the soil from which a stream of water spontaneously bursts out under powerful pressure. Most often, such a well is of natural origin, but there are also artificially created specimens.

- An exclusively man-made well that reaches the limestone aquifers of the earth. In these layers, water is constantly subjected to pressure, and when they are opened, it easily comes out.

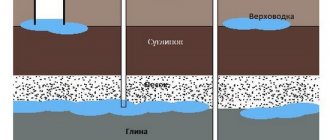

Layout of aquifers

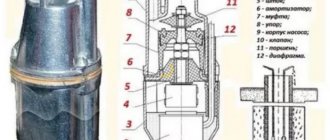

Device/design

An artesian well is a special drill hole in the ground that penetrates through soil layers and is divided into:

- paramount;

- minor;

- tertiary.

The depth of the horizon is around 200 meters. The level may be lower, it all depends on the level of clean water. 4 technologies are used:

- Classic option.

- Telescopic.

- Conductor.

- With double casing.

Device contents:

- Casing string.

- Header.

- Caisson.

- Production column.

- Pump.

Recommendations and operating rules

The service life of the well directly depends on compliance with the operating instructions, which are attached to the AS along with the passport. Please read it carefully before use. The main recommendations are as follows:

- Replace cleaning filters in a timely manner;

- carry out an annual analysis of the chemical composition of water, and if it changes, adjust the filter system;

- if the pressure decreases during water withdrawal, you need to call specialists without taking any independent measures;

- If an emergency occurs, contact the appropriate service to resolve the problem.

Positive and negative characteristics

pros:

- High quality water. Melt water, various contaminants with waste, fertilizers, etc. do not reach the water intake of an artesian well. According to the requirements of SNiP, drilling such a source is allowed at a distance of at least 300 meters from industrial enterprises, gas stations and similar objects that are potentially a source of pollution. With all this, the mouth can be easily protected from various contaminants.

- Stable pressure. Regardless of the time of year, there is a constant and stable level of water yield. Due to this, one source can provide water to several houses at once. On average, an artesian well produces up to 50 liters per hour.

- Water drilling can be done at any time of the year.

- Possibility to drill in any area of the house.

- There is no need to clean the source all the time.

- Service life up to 50 years.

Minuses:

- Drilling an artesian by hand is not so easy. There may be boulders and other obstacles.

- If a well is installed under a house, then difficulties arise due to the limited area. Because of this, achieving the required depth in such conditions can be difficult.

- Requires serious financial investments, as a large amount of equipment is used.

- It is necessary to purchase expensive and complex mechanisms, such as a filter system, to reduce the level of mineralization of water.

- A mandatory requirement is that the source be licensed by government agencies. Permits are also required.

- The head must be insulated. The best solution is to make a caisson. Will require additional costs.

What does the cost depend on?

To drill a well for water from an artesian aquifer, on average it takes 5-7 days. The cost of an artesian well for limestone, carried out on a turnkey basis, exceeds the cost of a source from a shallow, non-confined sandy horizon.

The high cost is justified by long service life and gradual payback. The following reasons influence the final price :

- Due to the great depth, drilling is characterized by increased complexity; heavy drilling equipment is used.

- A deep source requires a larger mine diameter and more casing pipes. This increases the cost of drilling and payment for drilling work.

- Deep burial requires the use of high-quality materials that can last for decades.

- The estimate increases if there is a need for additional work. Thus, when casing a well, annular cementation is sometimes carried out.

PVC casing pipes Source o-trubah.ru

What is the performance

On average it is 3 m3/hour. The volume is about 50 liters. A sufficient standard to provide water from one well to three cottages at once.

Good to know! High productivity is explained by the fact that it has minimal hydraulic resistance, due to the porous structure of limestone.

↑ How long should the casing be?

Rice.

7 Before you, (Fig. 7.), is a shortened version of the hydrogeochemical section.

(full version is in the article “Review of the hydrogeological and hydrogeochemical situation in the vicinity of Lake Kolpanskoye.”). On the right is the lithological column of well No. 050 (in the range of 0-7.5 m - glacial deposits; 7.5-16.2 m - variegated sandstones; 16.2-18.5 m - siltstones with clay interlayers; aquifers are marked in blue). The contents of elements that determine the chemical composition of water are shown in the center. On the left, numbers in circles indicate the numbers of aquifers.

If you drill a well 7.5 m deep and install 7.3 m pipes, you will get iron-free, fairly hard water, enriched with oxygen and magnesium. (Aquifer (1)).

If you drill a well 9.2 m deep and install 9.0 m pipes, you will get iron-free, soft, oxygen-enriched water with a high content of nitrates. And this is an indicator of sewage pollution. (Aquifer (2)).

If you drill a well 12.2 m deep and install 12.0 m pipes, you will get iron-free, very hard water with a moderate oxygen content and a high nitrate content. Apparently, sewage also gets into this layer. (Aquifer (3)).

If you drill a well 13.2 m deep and install 13.0 m pipes, you will get ferrous-manganese (exceeding the maximum permissible concentration for iron by 9 times, for manganese by 2 times), depleted in oxygen, and quite hard water. (Aquifer (4)). Please note: the separation between waters is only 1 meter

. Such water quickly turns yellow in air with the formation of brown sediment.

If you drill a well 16.2 m deep and install 15.4 m pipes, you will get ammonia, ferromanganese (exceeding the maximum permissible concentration for iron by 3 times, for manganese by 2.5 times), oxygen-depleted, medium-hard water. In addition, it contains the strongest reducing agent hydrazine (N2H4), 7 times higher than the maximum permissible concentration. For reference: the lethal dose of hydrazine is 200 mcg.⁄l. (Aquifer (5)). Such water has an unpleasant odor and quickly turns yellow when exposed to air with the formation of a reddish-brown precipitate.

If you drill a well 18.6 m deep and install 18.2 m pipes, you will get iron-free, moderately hard water with moderate oxygen and magnesium content. (Aquifer (6)).

As shown in the figure, the best water in the studied interval is the water of the aquifer (6).

We made exactly this water by installing an 18.2 m casing pipe, carefully “rubbing” it with a carbide bit into the covering crust of the aquifer, thereby preventing the influx of ammonia-iron-manganese, hydrazine-containing water.

Now imagine that other drillers arrived, knowing nothing about water, and they built the well “like everyone else.” They drilled 10 meters with augers, and threw a rusty pipe there and another 6 meters of “sump” so that the water could settle better. They threw all sorts of rubbish into the gap around the pipe and squashed it down with a shovel. They asked for a lot of money - 2500 rubles multiplied by 16 meters. And they disappeared into the distance without a trace. And no one saw them again.

We're not kidding, this is how 90% of drilling companies operate.

Now let’s return to Fig. 7 and analyze the results of such “work”.

So: the well bore was drilled to a depth of 10 meters with an auger, therefore the bore diameter is 150 mm. A pipe of the appropriate length with a diameter of 127 mm is installed inside. Therefore, the side gap is 150-127 = 23mm. Since annular cementation was not carried out, and the wellbore crossed 2 aquifers (at levels 7.5 and 9 m), an influx of water, mainly from the aquifer (2), cannot be excluded. That is, waters enriched with nitrates, apparently of sewer origin.

Then an open shaft was drilled - a “sump”, with a diameter of 98 mm, which crossed the aquifer (3), containing very hard water enriched with nitrates; aquifer (4) containing ferruginous-manganese waters; and an aquifer (5) containing ammonia-ferruginous-manganese waters enriched with hydrazine.

As a result, from the outlet of the pump, we will have foul-smelling water that quickly turns yellow in the air, exceeding the maximum permissible concentration for iron by 5 times; for manganese – 2 times; for hydrazine – 3 times, with a carbonate hardness of about 1g⁄l.; and inflow of nitrate-containing sewage water.

All the fun – 40,000 rubles!

And when you present a claim to drillers with twenty-two years of experience, they will throw up their hands and say: “This is the water!”

Gradually you will get used to this water, having invested a lot of money in water treatment. Your neighbors will find cheaper drillers, for example, for 2400, who will hang the pipe on a welded scrap. Then a “new Russian” will appear, for whom a well will be made deeper and cheaper, say at 1800, using Euro technology, lined with an environmentally friendly plastic pipe. And they will ditch the last good water. In Fig. 7 - aquifer (6).

And a legend will develop that there was no good water in your area, and no.

We're not kidding. This has already happened in the Volosovsky district in the villages of Ozera, Pyataya Gora, Selo, Dontso, Kargalozy, Glumitsy. And many more places.

From the above, the conclusion is: “You shouldn’t be chasing cheapness, priest!” "The Tale of the Priest and His Worker Balda." A.S. Pushkin.

Water quality

According to GOST, there are certain standards. Iron levels should not exceed 1 mg per liter. Sulfates per liter no more than 500 mg. As for its hardness, this figure should not exceed 7 mEq/g.

As the level of the water horizon drops, the fluorine and mineral content in its composition increases. As a consequence, it is recommended to choose a location where the aquifer is as high as possible.

On the other hand, Jurassic clay brings iron into the water; because of this factor, they are looking for an area with the deepest water intake location.

Despite the high quality of the liquid, it needs to be cleaned. The goal is to reduce:

- Iron levels.

- Level of mineralization.

- Rigidity and so on.

Important! If you follow the technology during the drilling process and install equipment, you will be able to significantly reduce the level of various impurities.

↑ Properly made wells

Properly made wells do not “float”, do not “silt up”, pumps do not get stuck in them, and groundwater, overlying formation and sewage water do not get into them. They are durable. Their service life is 40 years or more. You forget about the well - you just always have water in your house.

Unfortunately, that glorious generation of hydrogeologists and drillers who made WATER, not wells, has passed away. Do you feel the difference?

A generation has come whose main goal is to cut money and “spoil” clients with all sorts of “sands,” “limestones,” and other “artesian waters.”

It is a deep misconception to think that everyone makes wells the same way.

Therefore, this is important information for visitors to our website and potential customers, and for employees of drilling companies - a short educational program (which means eliminating illiteracy).

Kinds

There are five designs:

- Regular.

- With double casing.

- With a conductor.

- On limestone.

- Telescopic.

Regular

The depth of the source reaches the upper waterproof layer when drilling a hole. After this, the diameter of the drilling rig and casing are reduced. Drilling is carried out right up to the water. The deep pump is installed at a distance of 10 meters from the static level; it can be installed one meter from the pit.

With double casing

This type of device consists of using casing pipes with different diameters. The first of them is located near the boundary of the formation with limestone. The second casing is located directly in the formation and reaches the aquifer.

The second casing has perforation. Liquid passes through it. A deep water lift pump is installed in the pipe located below. This technology is used in cases where there is not enough pressure in the aquifer, and the horizon has sandy lenses and layers of clay.

With conductor

By conductor we mean a pipe that has a large diameter, unlike the casing. A conductor is installed in cases where the top layer has quicksand. Due to it, the casing pipe of a smaller diameter is protected from the pressure created by the quicksand.

Let's understand the terminology: what does the name mean?

There is hardly a person who has never heard of an artesian well and that this is one of the best water supply options. An artesian well is a circular opening drilled to reach aquifers with certain properties.

Some underground aquifers lie between impervious layers. Interstratal waters can be non-pressure and pressure; the latter are called artesian. The name comes from the historical region of Artois in northeastern France. Here, since the 12th century, for the first time in Europe, they learned to build gushing wells.

Artesian layers are located in certain geological structures (in depressions, bends, troughs). The depth at which artesian water lies depends on specific geological conditions. Aquifers are formed at different depths, from 100 to 1000 m; for domestic use, sources with a depth of no more than 150-200 m are most often developed.

Diagram of an artesian well Source strojdvor.ru

An artesian aquifer is composed of sedimentary rock: limestone, sand, dolomite or gravel. Water fills voids, cavities and cracks in loose material. The aquifer is enclosed between impermeable layers (usually clay), so the water in it is under pressure.

An artesian aquifer is composed of sedimentary rock: limestone, sand, dolomite or gravel. Water fills voids, cavities and cracks in loose material. The aquifer is enclosed between impermeable layers (usually clay), so the water in it is under pressure.

Determining the location for artesian wells in the country

Consider these points:

- The specific location of the source.

- The location where equipment will be installed on site.

- The area where process water will be drained.

- Determination of the working area.

The site must be at least 4 by 9 meters in size. This is explained by the need to install special drilling equipment. If a machine is used, its mast height is up to 10 meters. Therefore, there should be no electrical wires in this location.

A map of your region can help you find out exactly where to drill. Moreover, there are standards for distance from certain objects:

- From industrial enterprises and other potentially hazardous pollution sites at a distance of no closer than 300 m.

- Closer than 200 m from sewers, burial grounds, landfills.

- No closer than 30 m from houses and other buildings.

Advice! It is extremely important to study the area and make sure that there are no communications running underground.

Documenting

If you need to obtain permission for an artesian well, then be prepared to fulfill several requirements:

- All buildings and trees should be no closer than 30 m to the well.

- Sources of biological pollution should be located no closer than 200 m. These are barnyards, farms, sewage basins, etc.

- Chemical plants, gas stations, auto repair shops - within a radius of 300 m.

- A distance of at least one hundred meters is allowed between two artesian wells.

To increase your chances of a positive outcome when applying for drilling, you can fence the area with some kind of fence with a radius of at least 30 m.

Application documents

- A document confirming ownership of the plot.

- Lease agreement if the site is not owned.

- Cadastral plan of the site.

- General plan for the development of this site.

- Situational plan.

After an artesian well is installed on a summer cottage or in a private household, it must be registered as an official source of water. For this purpose the following documents are submitted:

- Well design for expert assessment.

- Confirmation of the arrangement of the sanitary zone.

- Confirmation of the suitability of water for consumption.

Tools for DIY digging

Equipment depends on soil type. For example, the rotary method is used for limestone. A special installation rotates the drilling elements.

A bit is used in the construction of a telescopic well. As the drill goes deeper, a smaller diameter bit is used.

A tripod is used if drilling is done with your own hands. An electric drive is installed on it to automate the process. In this case, a special rod with a drilling head is used. If the soil is relatively soft, a spoon drill is used.

Drilling depth and subsoil law

The legislation of the Russian Federation (Law “On Subsoil” 2395-1 dated February 21, 1992) classifies groundwater as a mineral resource, which obliges it to obtain a license for the right to use it on its own sites.

Article 19 of this Law indicates that this document must be obtained when consuming groundwater in a volume of more than 100 m3/day. At lower productivity, a permit for the construction of a source is not required. The upper limit of permissible water withdrawal is 500 m3/day.

In a number of regions of the country, groundwater is included in the register of centralized horizons. For such sources, a permit is issued regardless of the productivity of the wells. This issue requires clarification from local authorities.

In addition to the permitted flow rate of wells, legislation (Article 10) also determines the service life. The license is issued for 25 years only. After this, the possibility of extending the document is possible with the creation of a special commission.

Read more about how to obtain a license for an artesian well in our article here.

Types of drilling

Depending on the composition of the soil and the level of water intake, different technologies are used.

Clay soils

A coil is used with a minimum amount of pebbles and gravel in the soil, mainly in loam and clay soil. Its design includes a head, a rod and a spiral coil, at the bottom of which there is a blade. It gradually cuts off the rock and goes deeper into the soil.

Hard rocks

In such conditions, a drill bit is used. It should be made from strong grades of steel. There are I-beams, crosses and chisels; some have a 90-degree sharpening angle. You can go through a small boulder with a pyramidal chisel; it crushes or moves it.

What does the cost consist of?

The total cost of turnkey well drilling is influenced by many factors, including:

- Fare.

- Type and used drilling technology.

- Materials for casing and pipes.

- Pumping to clean water.

- Project and passport with included source characteristics.

Equipping a well is not a cheap task and can take a lot of time. Therefore, it made sense to unite several farms and choose a site accessible to all participants.

How to drill a well on limestone with your own hands

- A hole is drilled using an auger.

- The pit must be equipped with a casing pipe. It is selected based on the soil layer: plastic or steel.

- Next, the casing is clogged. The casing should be one meter or more into the clay soil layer. This prevents the penetration of groundwater.

- To get into the limestone layer, drilling continues through the casing. The diameter of the pit in limestone will be smaller. You can use hydraulic drilling technology using a special hydraulic device or, for example, a pneumatic hammer, auger, etc. The main task is to penetrate the interlayer layer.

- When the required depth is reached, all rock should be removed from the pit.

- Next, a plastic pipe is lowered, which will protect the limestone walls from erosion. The result is a two-pipe well. The bottom of the pipe should be perforated so that liquid can penetrate through it.

After this, installation of ground equipment is carried out.

Sequence of drilling work

- Loosening the rock.

- Collecting cuttings from a well.

- Insertion of casing pipes.

- Installation of water pumping equipment.

Further arrangement

Ready-made water supply system from an artesian well

After drilling a well, a number of mandatory works need to be carried out:

- Installation of a caisson made of plastic, concrete or steel.

- Installation of a deep-well pump.

- Installation and adjustment of electrical wiring and equipment.

- Installation of an automatic unit and hydraulic accumulator.

- Laying pipes to water intake points.

- Design of the appearance of the well. There is complete scope for imagination; you can decorate it as a beautiful well or gazebo.

Our other article describes in detail how to drill a well on a site with your own hands in the sand and what you will need for this.

A comparison of wells and boreholes according to various parameters is presented in this site material.

Several methods for making borehole caissons are here https://okanalizacii.ru/vodosnabzhenie/skvazhina/kesson-dlya-skvazhiny-svoimi-rukami.html

What to do if the pit fails

Determine the cause of the problem. Breakdowns can be repairable or irreparable. For example, an unresolved breakdown is caused by poor pipe insulation, poor-quality pipe connections, incorrect choice of filter, etc. If you carry out the drilling process correctly and follow the equipment installation diagram, these problems can be avoided.

In some cases, it is possible to fix the problem. For example, cleaning the filter by pumping water to clean it can help. Sometimes it is better to contact specialists who can quickly determine the cause.

↑ Selecting a well location

When choosing a well location, we recommend proceeding from the following considerations:

- According to the “requirements for choosing the location of water intake structures for non-centralized water supply” set out in SanPiN 2.1.4.1175-02, the distance between the well and sources of pollution (which will include not only your septic tank, but also the cesspool of your neighbor’s grandmother) must be at least 50 m.

Since such standards are being developed somewhere on the Moon, and in living conditions on 6 acres are impossible in principle, we advise you to ensure the maximum possible separation between the well and sources of potential pollution. - If your site has a natural slope, it is better to place the well at a higher level than the septic tank.

- The well should not be placed closer than 3-4m from the foundation, much less inside a building under construction.

This precaution is due to the fact that there have been cases when rain and melt water washed the soil from the outside of the casing and was absorbed by the first aquifer from the surface. As a result, soil was removed, up to the formation of a sinkhole with a diameter of 3 to 5 m or more. And if on the street the development of this process is easy to notice and prevent by making an additional clay barrier, then indoors, under a concrete screed, you will not see it, until the house bursts at the seams. And although the probability of this event is small, it is still not worth the risk. - There should always be access to the well.

Life is life. Whether you dropped a pump, quarreled with good neighbors and they threw stones, gymnastic dumbbells, or some other nasty thing into the well, or whether the aquifer has become polluted, the well needs to be cleaned or deepened. It is not always possible to do these operations manually. But you can’t drive the car. The owner managed to build a garage for 5 cars, and the owner built flower slides with thujas. So what should I do? Drilling a new well? So it is better to provide access to the well in advance.

Drilling a well manually in questions and answers.

Which well to choose, regular deep or Abyssinian?

To make a choice, you need to know how they differ.

The Abyssinian well is drilled with a small diameter drill of approximately 60-90mm. The casing pipe for it is most often 40-70 mm in outer diameter. In an Abyssinian well, the pump is located on the surface of the earth. Modern surface pumps can lift water that is at a maximum depth of 8 meters.

For example, if you have drilled a well and the water level is deeper than 8 meters, then it is impossible to lift this water with a surface pump. The water surface is the distance from the ground level to the surface of the water in the well.

But if you dig a well 1-2 meters deep and install a surface pump at its bottom, you can raise water from a depth of 9-10 meters.

An ordinary deep well does not have this drawback, since its submersible pump is located at a depth below the water surface.

The diagram shows a regular deep and an Abyssinian well.

Therefore, if the water surface is deeper than 7-8 m, then you will have to choose a regular well.

The question immediately arises of how to preliminarily determine the depth of the water surface.

If you have neighbors who have a well drilled, you can ask them at what level the water level is. As a rule, on neighboring land plots the aquifers are the same and the water table level will also be the same. Exceptions occur in rare cases and are related to the geology of the site.

If there are no such neighbors, then you will have to drill. There may be two options here:

1. drill for an Abyssinian well and if the water surface is below 8m, then drill it for a regular one.

2. Immediately drill a regular well with a cutter with a diameter of 160 mm under a casing pipe with a diameter of 125 mm. Its diameter should be at least a quarter wider than the diameter of the casing pipe.

Before you start drilling, you need to understand that it will be much easier to drill an Abyssinian well than a regular one, since the diameters of their holes differ significantly. In addition, the cost of materials for an Abyssinian well is less than for a conventional one. But there are also disadvantages. An Abyssinian well has a much smaller filter surface area than a regular well, so the Abyssinian filter will clog more often. It also has approximately 2 times lower flow rate (the amount of water that a well can produce per hour) compared to a conventional well.

What to do if quicksand is exposed during drilling.

Quicksand is soil saturated with water (usually sand or sandy loam), which is capable of liquefying under mechanical influence on it, when it is opened by pits and other workings. We can also say about quicksand that it is a sealed volume in the thickness of the soil, in which fine and dusty sands saturated with water are under pressure. Its thickness varies from 2 to 10 m. Silty sands and sandy loams, saturated with water and containing large quantities of very small particles (clay and colloidal), which begin to play the role of a lubricant between large particles of soil, often exhibit quicksand properties. Due to the presence of clay and smaller colloidal particles, these soils have hydrophilic properties and weakly release water. Wikipedia

If during the drilling process the so-called slurry is removed - it can be sand mixed with water and clay and the well is not deepened, then it means they have drilled to quicksand. Quicksand constantly fills the drill shaft and prevents it from being deepened.

To pass the quicksand, you can try the following options:

- Wash the quicksand with bentonite or glue.

- Drill the well to a larger diameter to the quicksand and drive the conductor. This is a metal pipe that is one or two sizes larger than the casing pipe. It is important that the conductor completely covers the quicksand and enters its end into solid ground. If this is not done, the conductor may turn into quicksand, since he is in constant motion. After this, you can continue drilling through the conductor using a bailer or hydraulic drilling.

Drilling diagram with conductor.

Why is it necessary to flush a well?

Washing a well is washing it with a special adhesive solution, which glues and strengthens the walls of the well and prevents them from crumbling and collapsing.

The solution is prepared using water and bentonite, which can be purchased at a hardware store.

Bentonite is a natural, non-toxic material that swells in water to form a dense gel. In confined spaces, this gel does not allow water to pass through.

Approximately 25 kg of bentonite per ton of water is diluted. After this, the resulting solution should sit for at least 2 hours, and preferably 12 hours. During this time, the bentonite will swell and the solution will resemble jelly.

As a replacement for bentonite, you can use ordinary CMC wallpaper glue. It costs an order of magnitude cheaper. Dilute it with approximately 20 liters of water per 4 plastic cups of glue. If during the work the glue begins to curl up and turn into a paste, then ordinary soda can be added to the solution. This will prevent the glue from curling.

You can also mix water with fatty clay and create a jelly solution. This solution also works well.

Cases when well cleaning is necessary:

- If a well is drilled in sand, then it must be washed along its entire length. If the hydrodrilling method is used, then the drilling fluid should be prepared from the very beginning of drilling. If the auger drilling method is used, then it must be flushed after changing each rod.

- If a well was drilled in clay and reached a sandy aquifer, then the well must be flushed before removing the drill and installing the casing. While drilling is taking place in clay, it is not necessary to wash out.

- If you need to pass quicksand.

- If it is necessary to pass through an unnecessary water carrier, for example, a perch. In this case, this aquifer must be sealed and prevent the drilling fluid from escaping into this aquifer. The density of the drilling fluid should depend on the rate of outflow of the solution into the aquifer. The stronger the outflow, the thicker the solution should be and, therefore, the longer it will take to flush the wellbore.

How to understand that an aquifer has been found.

There may be more than one aquifer. Therefore, if water is needed for technical needs or for irrigation, then you can stop at the first layer. Such a layer can be at a depth of 4 meters. Water taken from this layer is usually not pure, but there may be exceptions. This water is called perched water.

Verkhodka is groundwater that accumulates above temporary support (frozen soil, etc.). They lie near the surface (above the groundwater horizon), are prone to sharp fluctuations, and are easily polluted. Wikipedia

If water is needed for general use, then it is better to drill deeper.

It is not difficult to understand that you have reached an aquifer.

If the hydrodrilling method is used, the drilling fluid will begin to flow into the well. This will be clearly visible by the drop in water level in the technical pits. That is, the aquifer will absorb the water that is poured into it. At the rate at which the water carrier consumes water, at the same rate it releases it. In 95% of cases it will be an aquifer, in 5% of cases it will be a crack in the ground or a void. If water goes into the well very quickly, then it may be a void in the ground.

If the auger drilling method is used, then you can understand that you have reached the aquifer by the wet soil being removed and its type.

Good aquifers are found in coarse sands, limestones, sand and gravel, or gravel. Sometimes there is water in loam, but very rarely. Therefore, one of the signs of an aquifer will be coarse sand or other aquifer-bearing rocks.

The end of a sand aquifer can be determined when the drill hits something harder than sand, most likely limestone or clay. If the coarse sand runs out and another rock starts, it means the aquifer has ended.

Once the aquifer has been found, it is necessary to install a casing pipe with a filter.

Why is well backflushing done?

Backflushing is done immediately after the casing is installed. It is necessary to unseal the water-bearing channels of the well and wash sand and small stones out of it. Essentially, this is hydraulic fracturing (creating voids in the well).

Backwashing also flushes water-bearing channels that were previously sealed with bentonite or glue. Moreover, if the water carrier was sealed in loam, then it will take longer to erode than a water carrier in sand.

It is best to wash with a high-capacity motor pump (from 1000 liters per minute) with water in a volume of 2-3 m3. In order to perform backwashing, a head with a fitting is placed on the casing pipe, to which the hose from the pump is connected. Water under pressure is fed into the casing, exits the filter into the well and rises to the surface of the earth between the casing and the walls of the well.

A pressurized water supply hose is connected to the blue plastic casing.

How to pump a well.

Pump the well immediately after backflushing.

Pumping a well is a long-term pumping of water with a pump in order to flush water-bearing channels, clarify the water and increase the productivity of the well. Pumping can be continuous for 2-48 hours.

This action allows you to clean the well water from small rock particles dissolved in it. Therefore, you need to pump until the water becomes clear. Also, in order to increase the productivity of a well, it is practiced to pump it for a long time for a day or more.

All small particles that pass through the filter are pumped out of the well, while the rest accumulate at its bottom. Therefore, it is better to use an inexpensive pump for pumping, as it can easily clog. If a well was drilled in the warm season, then you can understand what kind of water flows from it by its temperature. The water from the well will be noticeably colder than the water that was previously backwashed.

Well filling.

Filling the space between the casing pipe and the walls of the well is carried out in order to protect the well from various contaminants entering it from the surface of the earth.

In order not to clog the water-bearing channels, sprinkling is carried out only after backwashing and subsequent pumping. Also, sprinkling is done only under water pressure, so as not to clog the casing filter. Therefore, before sprinkling, a pump is connected to the casing pipe and water is pumped into it. Everything is the same as for backwashing.

The well is filled with sand or crushed stone above the height of the casing filter, and then covered with clay.

How to determine the water level in a well.

Everything is very simple. You need to take a regular rope with a narrow weight. For example, you can attach a regular wrench to it.

You lower the rope and listen. When you hear the sound of a “gurgle,” this is the beginning of the water column, that is, the level of the mirror. Tie a knot in the rope and lower it further. If the rope weakens, it means it has reached the bottom of the well. Tie a second knot. Pull out the rope and measure the distance between the knots, this will be the height of the water column.

You also need to understand that the water level may change according to the season or with active pumping of water. Therefore, the level of the water column in the well should be as high as possible. Preferably at least 2m.

What to do if clay sticks heavily to the walls of the drill shaft and drill rod?

Red-brown clay tends to swell and stick strongly. In this case, ordinary soda helps well, as it makes the clay inactive. Soda must be added to the drilling fluid. As a result, the clay stops sticking to the tool and the walls of the drill hole.

Does the water surface level depend on the depth of the well?

A well is drilled to find a source of water - an aquifer. It may end up at a fairly large depth, for example, 25m. But this does not mean that water will need to be raised from such a depth. After the well has reached the aquifer, water fills its trunk and rises along it to a certain level, for example, 10 m from the level of the earth's surface. This level is called the water mirror. The exception is artesian wells, where water is under pressure in the ground and when such an aquifer is opened, water can spontaneously flow to the surface of the earth.

What pipes to use as casing.

Metal or plastic pipes are used as casing pipes. Since metal pipes are quite expensive, plastic casing pipes are most often chosen for wells. Special blue HDPE (low-density polyethylene) plastic casing pipes for wells are available for sale. These pipes are made of food-grade plastic and are chemically safe for humans. It is strictly forbidden to use ordinary yellow or gray PVC sewer pipes for the well.

HDPE casing pipes

Pipe with slot filter. Filter length 3 meters.

When purchasing plastic casing pipe, try not to purchase black pipes. As a rule, such pipes are made from recycled materials. And no one can guarantee that secondary raw materials will not contain potentially hazardous substances.

Which pump to choose for a well?

A deep-screw pump is best suited. The main thing is not to use a vibration pump. Due to constant vibrations, the soil around the well is compacted and the water channels are closed. As a result, the well's flow rate may decrease until it completely dries out. Also, due to constant vibrations, the water in the well will be cloudy.

If the water surface is at a depth of 7-8 meters, then you can install a centrifugal pump on the surface of the earth.

What equipment is used to construct a well?

Caisson

Here you can repeat almost everything that was said above about pipes. Plastic caissons often burst as a result of compression by soil, and due to the fact that they weigh little, they sometimes “float” (pushed out by groundwater). If the seal is broken, not only groundwater, but also rainwater may come out of the tap. The metal caisson remains intact even with severe deformation.

When choosing, pay attention to the quality of waterproofing of the metal structure. The durability of the caisson depends on it.

Well pump

The standard pump diameter is 4 inches. There are also 3-inch models, but they are more expensive for the same performance and pressure. But many well-known manufacturers simply don’t make them.

When purchasing a pump, you can save on the brand. There is a lot of high-quality pumping equipment from “unpromoted” brands on the market. To understand the market situation, compare prices for pumps with similar characteristics from different manufacturers. And don’t forget to discuss this issue with the contractor in advance.

And finally, the most important point!

Methods for drilling a well manually.

Hydro drilling.

To drill using this method, you will need drill rods with a cutter, a water supply hose and a water pump.

The essence of the method is that drilling occurs using a drill with a cutter and a stream of water. To drill, just twist the rod in different directions, first in one direction and then in the other direction. Full rotation of the drill is not required. As the rod rotates, the drill cutter loosens the rock, and the water that comes out of the rod in the drilling zone lifts the eroded rock up out of the well.

Hydro drilling of a well.

The upper part of the drill string with removable handles and an attached hose through which water is supplied to the drill shaft.

The disadvantage of this type of drilling is that it cannot be used to penetrate clastic rocks such as pebbles or simply rocks rich in stones. During the drilling process, soft rock is washed away, and stones remain at the bottom of the well, where they accumulate and interfere with drilling.

The advantage is that there is no need to remove the drill from the wellbore to remove loose rock.

Drill rods are made 1.5-2 m long from a water pipe with a nominal bore of 25 mm and an outer diameter of 32 mm. The rods are connected using threaded couplings. The rods have regular pipe threads cut on both sides. The coupling is partially screwed onto the rod on one side and scalded.

Drill rod with welded coupling.

Connection of drill rods.

The drill bit must be made of durable and thick metal. An old leaf spring from a truck will work best. These springs are made of 75G steel and they are hardened, which gives the metal special abrasion resistance.

The cutter, as a rule, is made with three blades or two blades. It is necessary to make notches on the edges of the cutter. These notches perform the function of a rock crusher and with them the drill rotates more easily.

Drill rod cutter.

For hydrodrilling, you need to organize two pits for water: one of them is larger (it should be located close to the drilling site) and the second is smaller. The pits will serve as water reservoirs. In the first pit, the washed rock will settle and settle to the bottom, and from the second pit, water should be taken by a pump and supplied inside the drill rod. This way the water will flow in a vicious circle. The first pit must be periodically cleared of washed-out rock and, at the same time, this rock must be inspected in order to search for coarse-grained aquifer sand.

To reduce the amount of water that goes into the soil of the pits, their bottom can be covered with polyethylene.

The photo shows technical pits for hydraulic drilling.

A drill rod with handles held above the edge of the drill hole by a special catcher.

Hydraulic drilling scheme.

Auger drilling.

To drill a well with an auger, special auger rods are required.

This type of drilling has both its advantages and disadvantages. Augers allow you to drill into rocks saturated with stones, but in order to lift loosened soil to the surface of the earth, you need to periodically remove the entire drill string from the wellbore. And the deeper the well, the harder it is to remove the drill string. Therefore, when drilling deep wells, it is necessary to manufacture a lifting mechanism.

For manual auger drilling, it is enough to make the first rod with the auger. It makes no sense to make the remaining rods with augers. You can make a rod with an auger yourself or use some other auger, for example, from an old fishing drill.

Drilling a well with an auger.

Set of drill rods with auger.

Drilling using the percussion-rope method.

The operating principle of such drilling is that a round metal pipe is lowered into the wellbore under its own weight. Hitting the bottom of the well, it breaks the soil, stones and is filled with broken rock. Afterwards, the pipe is removed from the drill hole and cleaned of soil. This process is repeated many times.

The effectiveness of this drilling method directly depends on the height from which the drilling tool falls and its weight. Therefore, this projectile should be weighted. You can make it long and fill one part with concrete or lead, and leave the other part to receive soil.

The big advantage of this drilling method is that it allows you to penetrate rocks with stones. But there is also a drawback. If you do not use a winch to lift the projectile, you will have to expend great physical effort.

Homemade drilling rig for percussion-rope drilling.

For manual well drilling, two main types of tools are used:

- A driving glass is a pipe with sharpened edges and longitudinal slots for removing soil.

The pointed working edge should be slightly larger in diameter than the diameter of the pipe. To do this, the edge of the pipe is flared with a hammer.

This is necessary so that when using this tool, a hole is formed in the ground slightly larger than the diameter of the glass. This removes friction between the nozzle and the wellbore.

Basically, a glass is used to remove soil that may stick to its walls. Such soil can be clay and loam.

Hammer glass.

- The second tool is a bailer .

This tool is also made of a metal pipe and its working edge must be sharpened and flared. The difference from the glass is that the bailer does not have longitudinal holes for excavating soil, but there is a valve inside near the working edge. This design is due to the fact that the bailer is designed to remove extremely loose or waterlogged rock. For example, a mixture of clay and water is lifted very well by a bailer.

Bailer

Hammering the Abyssinian well with a needle.

The essence of the method is that a pipe with a diameter of 57 mm with a sharp end, which is also called a needle, is driven into the ground. Often a tip made from old scrap is welded onto the tip of the pipe. The needle consists of several pipes along the length, which are extended during the driving process using conventional welding.

During driving, the pipe pushes the soil apart with its tip and enters it. This method of drilling a well is suitable only for shallow wells, for example, for the Abyssinian.

Scheme of driving an Abyssinian well.

Plugging an Abyssinian well.

Making a pipe tip.

Making a pipe tip.

Slots are cut in the pipe in a checkerboard pattern using an angle grinder (grinder) in a thin circle at a distance of about half a meter from the tip. The number and size of the cracks will affect the ability of water to penetrate inside the pipe, so there should not be too few of them. The cutting wheel should be as thin as possible. These slits will act as a coarse filter. The length of such a filter must be at least two meters on the pipe. The slot filter should be located 50 cm from the pipe tip. Thus, this distance will act as a sump.

Manufacturing of slot filter.

To make it easier to plug the pipe, you can first walk a couple of meters with an ordinary garden drill, and only then proceed to plugging.

The driving process can be mechanized by using a hammer drill or jackhammer for this purpose.

To reduce friction between the pipe and the ground and make work easier, a small thickening is made in a circle immediately after the tip. The easiest way to make such a thickening is to weld around the pipe. If the pipe reaches stones that cannot be penetrated, you can always remove it and try to hammer the needle in another place.

This method of drilling a well has two significant disadvantages.

- The problem with driven wells is that the water carrier is searched for blindly, since there is no soil to be removed from the well. Therefore, to determine the aquifer, you need to pour water into the pipe after every meter of blockage and watch its absorption by the earth. As soon as good absorption has begun, the aquifer has been reached. One point is worth paying attention to here. Sometimes, when clogged, the holes in the pipe become clogged with clay and therefore it is worth paying attention to every, even small, absorption of water by the well. If there is absorption, then you need to first backflush and then pump the well.

If, after pumping the well, the volume of water that it can produce remains small, then the pipe should be driven deeper.

- After reaching the aquifer, it may turn out that the water surface will be established at a depth below 7-8 m. In this case, the surface pump simply will not be able to lift water from the well to the surface.

If the well has been pumped, then a HDPE pipe with a diameter of 32-25 mm with a filter is lowered into the well and a pump is connected to it.

Filter on the HDPE pipe.

The filter is wrapped in stainless steel mesh.

Another method of making a filter for a needle is practiced. To do this, the pipe is drilled with holes with a diameter of approximately 12-16 mm and a filter made of stainless galloon mesh p48-52 is put on top. The pipe must be fitted with a tip with a diameter larger than the diameter of the filter.

We recommend reading:

DIY well filter.

Filter with tip

Stages of manufacturing a filter for a needle well.

Equipment used

In order for a well to function normally, it must be properly equipped.

Typically, the following elements are used for this:

- casing pipe - can be made of metal, plastic or asbestos. Its main task is protection against wall collapse;

- A caisson is a pit near the casing. Made from plastic, metal, concrete or brick. It protects the well from freezing and also serves as a place to install all the necessary equipment. It is installed below ground level, insulated and covered with earth;

- submersible pump - a device for pumping out water and supplying it to the water supply system;

- head - serves to seal the upper part of the well under water. There are models made of plastic, steel and cast iron on the market. Another function of the head is to hang attachments. For example, steel lids can withstand weight up to 500 kg;

- hydraulic accumulator - a storage tank that serves to equalize pressure in the system, protects equipment from water hammer and prevents the submersible pump from turning on too often.

In addition, an external filtration system is used - it is selected based on a chemical analysis of the water and will be individual for each source.

Calculators for calculation

The cost of all work performed and materials used when constructing a water intake depends on many factors:

- the depth of the artesian layer of water on a given piece of land;

- complexity of the chosen design;

- the drilling technique used and the amount of special equipment and machinery used;

- power of installed pumping and electrical equipment;

- the number of pipes and other materials, depending on the length of the water pipeline laid to the consumer;

- external arrangement of the source.

Traditionally, when preliminary calculating the cost of upcoming work, 1 linear meter of penetration is taken as a unit of measurement. The price of such a unit can range from 2000 to 4000 rubles. The total estimated cost for arrangement of a source of drinking water can vary between 150,000-300,000 rubles.

To independently calculate the approximate cost of a well, you can use an online calculator. You need to enter the initial technical data into it. In this case, excavation work and the cost of the highway from source to consumer are not taken into account.

Conclusions and useful video on the topic

The video will clearly present the process of drilling a well manually with the installation of casing and a filter in the casing pipe:

Each type of water well has its own advantages and disadvantages.

Now that you have an idea of the type of wells, their design and construction methods, it will be easier for you to make a choice in favor of one design or another, based on the characteristics of your site and your own financial capabilities.

If you have ever drilled a well with your own hands, tell us how difficult or simple the process was. Please write comments in the block below. Ask questions, share your impressions, post pictures related to the topic of the article.

The principle of operation of an artesian well

Groundwater accumulated between waterproof layers rushes up the trunk when the top layer is opened. The action of an artesian well is based on the principle of communicating vessels. The well operates under certain conditions:

- the well is installed in a lowland;

- a loose porous layer, saturated with liquid, sandwiched between two waterproof layers.

A significant volume of water accumulates in a confined space and has no way out. An artificial hole made through several types of soil allows water to rise to a certain height under the influence of pressure.

The action of an artesian well

Therefore, despite the considerable depth of the well, water intake is carried out at a higher level, usually on a sandy horizon. The amount of lift depends on the amount of liquid in the underground pool. In some wells, water pours out like a fountain, while in others it simply rises to half the well. After water intake, the level is restored spontaneously.

Advice. The productivity of a well is proportional to its diameter and cost. The larger the diameter, the more significant the productivity of the well and the higher the cost of drilling it.

Which filter and where to use

The next step after installing the casing is installing the filter. The filter itself can be mesh, perforated or slotted, which is selected taking into account the properties of the aquifer. It takes into account which layer the water passes through, the size of the particles, and their composition.

Each type of filter has its own nuances. So, synthetic mesh can often become clogged, and perforated metal can add iron. Slotted ones are most often used. The cost of filters varies depending on the wall thickness, diameter, and material from which it is made. Metal ones are more durable, stronger, but also more expensive than PVC.

The filter is installed directly at the level of the aquifer. There is no need to place it deeper - the water will wash out, collapse the rock to the filter and it will be difficult to clean. You should not install the filter above the aquifer, so as not to block and ruin the well. One of the consequences of an incorrectly installed filter is cloudy water, which is then difficult to get rid of.

Soil and drill selection

In order for drilling to proceed without problems, it is necessary to know the characteristics of the soil in the well. This will help you choose the right drill.

Homogeneous soil throughout the entire well is extremely rare. Most often, sandy and clayey soils alternate, as well as the so-called hard soil, which is compressed rocks of various genesis.

- It is better to use a spoon drill to go through the sand layer. Constantly adding water to the well reduces soil compaction and facilitates the drilling process.

- When passing through hard soil, a drill bit is used. It is usually used in two versions - cross and flat. Each of them is designed for one purpose - to break and loosen hard rocks.

- When going through a layer of clay, it is better to use a spiral drill, also called a coil drill. In this case, the spiral pitch should not be greater than the diameter of the drill. At the bottom, such a drill should have a size of 45 - 85 mm, the blade size should be in the range of 258-290 mm.

- Soils with large stones such as pebbles are passed with alternating drills. It is better to use a bailer and a chisel for this purpose.

Work technology

Before starting construction work, you must obtain a permit and prepare the necessary documents:

- Title deeds and land plot plans. Among them should be situational, cadastral and general.

- Water consumption is calculated. The calculation must be agreed upon with the Water Resources Committee.

- In order to arrange a sanitary zone at the well construction site, the consent of Rospotrebnadzor is obtained.

- Permission must be obtained to carry out design work. These issues are dealt with by the Center for State Monitoring of Subsoil Conditions.

All received papers are sent to the Subsoil Use Department. Based on these documents, a license for the construction of nuclear power plants is issued.

The next stage is concluding an agreement with the design organization. When the construction and installation of the well is completed, the AS must be registered.

Stages of work

Construction work on the arrangement of an artesian spring can be divided into several stages:

- Determination of the depth of the aquifer.

- Search and preparation of a site for construction.

- Delivery of construction and drilling equipment to the site.

- Work on loosening the soil and its extraction.

- Pipe installation.

- Installation of pumping equipment.

- Connection of water main and equipment.

Technology selection

The main stage of NPP construction is drilling. It is performed using specialized equipment. Different operating principles can be used; soil extraction is carried out using the following technologies:

- Auger. This method is best suited for constructing a well on light sandy soils. In this case, the main working tool is a screw - an axis equipped with a solid helical surface. The advantages of this technology include the speed of work and relatively low cost. However, auger drilling can only be used to create shallow sources. If the artesian aquifer is located deep, then it is worth choosing a different technology.

- Rotary. The process takes place using a drill bit. Unlike an auger, this tool has increased strength and copes not only with loose soils, but also with any hard rocks, such as boulders. The disadvantage is the higher cost of performing the work.

Drilling

Drilling work is carried out in several stages:

- Drilling equipment is placed on the site.

- The rock is loosened according to the selected technology.

- Sludge is removed from the well - soil that was formed during the operation of special equipment.

- A casing pipe (or several pipes, depending on which design scheme was chosen) is inserted.

- Assembling equipment for an artesian well.

Well development

The work of installing a well is not limited to drilling; it is equally important to properly install the plant and start it up. This work is carried out in stages:

- Install the caisson. It can be made of steel, concrete or plastic.

- The submersible pump is being installed.

- Electrical wiring and additional equipment are being adjusted.

- Install the pump accumulator and automatic unit.

- The water intake points and the source are connected by a pipeline.

- Carry out decoration.