In home utilities, the working medium is water. It contains dissolved salts. Because of them, the ball valve, which is installed everywhere in plumbing and heating systems, can jam. Dissolved salts in water are the most common cause of acidification of pipeline fittings. If such a situation occurs, owners of apartments and private houses are forced to decide how to open or close the ball valve. Less often, jamming occurs due to clogging of the shut-off valves with some debris. For example, metal shavings from used pipelines.

Ball valve design

A ball valve is a pipeline fitting with a polished shut-off element in the form of a sphere. The design features of the device do not allow adjustment of the flow of the working medium. Therefore, there are only two operating positions for the ball valve - open or closed.

A high-quality locking device is made with a collapsible brass body. One of its parts is the housing nut (coupling). For less durable similar products, the housing is made of silumin or zinc alloy (ZAM). These are fragile white materials.

Important! Manufacturers produce chrome-plated ball valves. Devices in this design are also white.

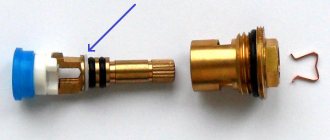

The locking device body is expanded in the middle part. There are two sealing fluoroplastic seats with a freely rotating valve in the form of a ball, cut off on two opposite sides. A spherical plug with one through hole is fixed to the rod. It is perpendicular to the axis of the pipeline and connected to a handle in the form of a lever or butterfly. The design may also contain a special nut that presses the oil seal and regulates the rod seal. It is located under the handle.

Practical advice

To avoid getting into a situation where the faucet is coked by lime or metal deposits, you need to turn it on 1-2 times a month, turning the valve to the maximum level.

Use only high-quality locking hardware from trusted manufacturers. Do not skimp on items such as ball valves, because their breakdown can be very expensive.

If you doubt your plumbing abilities, keep the phone number of a familiar plumber ready, who can help you out in difficult times and replace a faulty ball valve without fatal consequences.

Determining Ball Valve Position

To determine whether a ball valve is open or closed, you need to pay attention to the position of the handle. When it is perpendicular to the axis of the device, then the passage in the shut-off valve is blocked for the working medium. If the handle is parallel to the pipeline, the ball valve is in the open position.

If there is no lever or butterfly, it is recommended to pay attention to the darts of the stem. Their parallel arrangement relative to the pipeline indicates that the fittings are open and capable of passing the working medium. The product will be closed if the darts are perpendicular to its axis.

Main settings

Shut-off valves are an essential element of a gas pipeline, which is used both on external pipelines and on internal systems; only the diameter and size differ. For domestic gas pipelines in an apartment or private house, a gas ball valve with a diameter of 2-1/2 inches is used.

A separate valve is installed for each source of consumption - if a boiler and a gas stove are installed in the house, there must be at least 2 taps.

Shut-off valves on the gas pipeline in the apartment

If bottled (liquefied) gas is used, shut-off valves are not required. The cylinders already have a valve installed that regulates the fuel supply.

When choosing the best option, you need to consider several factors. There are 2 types of valves:

- Cork products. The design contains a conical part and a flywheel, which brings the first into operation. The plug is equipped with a hole; when connected to the pipe connector, it facilitates the flow of fuel to the equipment. The oil seal in this case is used as a seal.

- Gas ball valve. Here all the work is done by a metal ball, which plays the role of a locking part. The ball has a passage hole for venting gas to the equipment. This happens by turning the flywheel. The devices are considered the most reliable, which is why they are most often used in domestic conditions.

Ball valve 3/4 inch diameter

A plug valve is characterized by a loose connection and a shorter service life. Today they are no longer used.

It should be noted that the second version of the gas valve is divided into subtypes according to the fixation method:

It is used for household gas pipelines and has a small diameter. The connection to the pipe is made through a thread. The crane is collapsible.

Scope of application – pipelines of increased diameter. The connection is established by assembling the flanges with bolts. Collapsible design.

Used for large pipelines with a diameter of up to 70 mm. Welded to the main line, dismantling is not allowed. Can only be used once.

With a threaded and flanged connection, you can easily replace the gas tap in your apartment with a new one or remove and install it back several times. The welded valve is installed only once.

VIDEO: Ball valve design

What to consider when buying a gas tap

To buy a high-quality standard or corner gas valve, you need to pay attention to the following nuances:

- The cut size of the piping system, hoses and threaded areas. The gas supply pipe has a certain diameter; a valve must be selected taking this into account. This is done to ensure that the device hermetically closes all gaps. Otherwise, you will need to purchase additional adapters and adapters.

- Material. Cast iron products have the longest service life, so they are recommended by experts. In addition to these options, manufacturers offer polyethylene gas taps, zinc, and silumin.

- Integrity. Since tension gas valves are sold in large quantities, during transportation they may receive various defects in the form of chips and cracks. Factory defects in the form of sagging are also common. This informs about non-compliance with government regulations during the production process.

- Manufacturer. To avoid falling for a low-quality fake, it is recommended to give preference to well-known brands. Responsible manufacturers include the Polish company Broen Ballomax, the German company Dungs and Bugatti.

VIDEO: How to spot fake Bugatti taps

Installation of shut-off valves

Depending on the type of locking element, you can install it yourself without the involvement of specialists. To do this, you need to study in detail how to change the gas tap in an apartment and prepare all the necessary tools.

Ball valve installation and repair diagram

To work you will need:

- new threaded type gas valve;

- 2 wrenches - one for screwing in, the second for holding the pipe in a stationary position;

- graphite lubricant for gas valves;

- linen thread;

- stub.

- Before changing the gas valve, you must first shut off the gas supply to the kitchen, boiler room or other room where work is planned. Turn the valve lever to the closed position.

- Unscrew the tap from the outlet pipe. If the actions are difficult to carry out, you need to treat the joint area with WD40. This component will ensure smooth running. If the house has a welded element, then it is cut off using a grinder, after which a new thread is created on the pipe.

- At the time of completion of dismantling, the pipe should be quickly closed with a plug. If the work is done together with a partner, you can do without the locking part and ask to cover the exit with your hand.

- The threaded part is wrapped with flax thread to improve sealing, and then lubricated with graphite.

- Next, a new gas valve is screwed on.

During installation work, open windows and doors in the room, and turn off electrical equipment. The best option would be to turn off the electric meter before installation. This will provide a safe environment for this task.

How to check a joint for leaks

The final stage of installing a gas tap is to check its connection for leaks. To do this, prepare a concentrated soap solution to lubricate the gas valve on the boiler, or more precisely, the area where it is fixed to the pipe.

Be sure to check for leaks before starting

The soap must be as foamy as possible, otherwise it will be impossible to detect a leak if it occurs.

Next, open the valve so that gas begins to flow from the gas pipeline and carefully observe the process. If the element itself or the junction allows fuel to pass through, the soap solution will begin to foam. Here you will need to turn off the gas supply, remove the shut-off part and install it again.

A few words in conclusion

Experts do not recommend using welded type cranes. Despite the fairly robust design, if a mistake is made, welding can leak gas, and to solve the problem, you will need to carry out the work again, but with a new valve. Therefore, it is better to give preference to threaded variations.

Remember! Carrying out self-installation is considered a very risky and unsafe activity. If you do not have the necessary experience, it is recommended to turn to gas workers, especially since the price for their services is reasonable - 300-500 rubles.

VIDEO: How to replace a gas tap

Source

Ball valve repair

When the ball valve does not shut off the water due to acidification, in no case should you try to turn the handle of the device using physical force. It is also not recommended to use additional pliers. It’s good if, as a result of excessive pressure, only the lever or butterfly breaks. After all, handles are usually made of aluminum alloy or silumin. One of the internal parts of the product's locking mechanism may also break. For example, a plug in the shape of a sphere or a stem of a polished ball. In the worst case scenario, a crack will appear on the body, due to which the shut-off valve will simply fall apart.

To repair a ball valve, you must first remove the handle of the product. It is secured with a nut that needs to be unscrewed. After removing the butterfly or lever on some models of this type of shut-off valve, it will be possible to loosen the pressure on the fluoroplastic rod seal (oil seal). It is recommended to turn the clamping nut only half a turn.

The next step is to use an adjustable wrench. With its help, a rod is clamped, which has two parallel flat sides. They are used to install the adjustable wrench. After this, the locking mechanism of the valve must be rotated in different directions. This action must be performed slowly and carefully, having first found out in which direction the tap closes.

When turning the rod, you do not need to exert much effort. It is recommended to gradually increase the amplitude of movement of the locking mechanism. The functionality of the ball valve will be considered restored when it completely opens and closes smoothly.

Now you know, if the tap does not close, what to do in such a situation. However, this option for restoring the functionality of shut-off valves is used when the situation is not running. The disadvantage of this method is the possible appearance of scratches on the fluoroplastic sealing material. They are formed due to salt deposits. Once they appear, there is a high probability that the device will not fully cover the working environment.

Once the water ball valve repair is completed, you must remember to tighten the gland seal nut. When such an element is missing in the design, you should try to unscrew the locking device in the usual way. If in this case water drops appear from under the rod, then the ball valve will have to be completely replaced.

The restored functionality of the product is checked by opening and closing it. To do this, first put the handle on the faucet, and then turn the rod from one stop to the other. Finally, all the nuts are tightened.

Lubricant to make the task easier

In case the parts are stuck tightly and do not want to turn, lubricant will come in handy. You need to lubricate the clamping nut with it and wait a couple of minutes. It is best to use special silicone grease for these purposes. If it is not there, you can use VD-40.

At the end I will add: before starting to “reanimate” the tap, it is better to turn off the water, if possible. When designing a crane, there is always a risk that it will permanently break. Personally, I do not recommend dealing with old, completely rusted taps, or with cheap Chinese ones. It is better to replace them immediately.

Combined split type couplings (American)

They are products for joining plastic and metal pipes. Moreover, the design of such couplings allows for subsequent separation of the joined sections without their deformation. American cables are very convenient to use for connecting consumers that require periodic maintenance (heating radiators, electric water heaters, etc.).

The process of connecting and disconnecting in such couplings is carried out through a threaded connection on the metal section of the coupling (using a key). Moreover, just like the MRV and MRN couplings, the “Americans” can also be equipped with various types of threads (internal and external).

The technical characteristics of dismountable couplings are +95⁰С and 2.0 MPa.

The standard range of diameters of American collapsible couplings is represented by the following values:

20×0.5; 20x0.75; 20x1; 25x0.5; 25x0.75; 25x1; 32x0.75; 32x1; 32x1.25; 40x1.25; 50x1.5; 63x2; 75x2.5; 90x3; 110x4,

where the first value is the diameter of the workpiece (for soldering to a polypropylene pipe), the second value is the nominal value of the external or internal pipe thread in inches.

Use of solvent

After unscrewing the top nut and removing the handle, it is recommended to pour in any rust solvent, which can be WD-40, kerosene or diesel fuel. Then one of the hammers should be installed on one side of the nut, and with the other, apply several blows to the opposite part of the fastener, and then change the position of the tool.

Tapping should be replaced by refilling the solvent, and then unscrew the nut with a suitable size spanner. If necessary, all of the above activities will need to be repeated.

Working with rusted parts, including taps, is very difficult, so replacing or repairing them will require some tricks and simple but effective methods to make unscrewing easier.

Gentlemen, help! At the dacha, the well is an inch pipe. A hand pump is screwed onto the pipe. The pump has not been removed for several years. Now it is broken and needs to be replaced. However, the thread is rusty and the pump cannot be unscrewed by any force. Tell me if there are any techniques and technologies to unscrew a rusted threaded connection. Thank you

Try soaking the joint in WD-40. Sold at any auto parts store.

+1 is better than LM-40

Exposure to fire (a blowtorch, or even a candle) for several minutes, and a longer wrench should help.

Tap, heat, WD-40 or kerosene

Pepsi-Cola or Sprite. Seriously. I unscrewed one old faucet.

a blowtorch in your hands and heat until the paint or tow in the thread burns, then sprinkle with liquid oil (I use transformer oil) or better yet, make a compress out of it at night.

When I worked at a drilling rig, I learned how to unscrew the threaded coupling on a drill string pipe (the diameters are different, up to 500 mm, they are tightened at the factory on a special machine, with a force, as the driller told me - 3-5 tons). You hit with a sledgehammer, but so as not to flatten , with sense and understanding, preferably around, until it doesn’t work by hand. When I unscrewed the 180 (I don’t remember exactly) coupling for the first time, I was surprised for a long time - it’s necessary, with a simple sledgehammer you can unscrew the Counterweight to the opposite side and hit it in a circle with a hammer, the main thing is not the force of the impact, but the shaking of the threaded part. Otherwise, heating is not always suitable, sometimes it’s simply impossible.

the neighbors will be happy. The lower floors will be especially lucky, and whoever turns on the water first will then be lucky. full meshes on the faucets will be

2Alex___dr oh, well then you can use a sledgehammer

Nope, you can’t use a sledgehammer on an inch pipe, I was talking about the 180th. And the inch one is only the head, it’s a bone! (With)

I bought a compact burner at a hunting store with a replaceable small bologna, it’s very convenient and costs pennies

orinbasar It won't warm up. I was dismantling a 25-year-old 1″ riser with a long steel coupling - I couldn’t tear it off with any effort. Rothenberger heated it with a small burner until the end of the tank, then together with his father (120 kg + 93 of mine) they jumped on the “3rd number” with a pipe - zero emotions. Only the key (the powerful Leningrad key) was bent. I had to cut it.

in my humble opinion

The main thing is to pull the nut off, you don’t need to pull it, you need a jerk and lm)

The main thing was to tear off the long (100mm) steel coupling. The locknut is nonsense.

Yes. Teach me more