In the modern world, most summer residents and residents of country villages prefer to use various water devices for their purposes. Today there is not a single country or suburban area that would not be equipped with some type of water pump. One of these types is deep. This device easily allows you to pump clean and fresh water from an underground well, while it is very convenient and practical. Naturally, this device is selected strictly individually for each site, taking into account all climatic and budgetary features. You can do the installation yourself, but it is preferable to entrust this serious matter to a professional technician, since he can definitely guarantee a 100% positive result.

Operating principle

Today it is known that all deep-well pumps have a huge number of different characteristics. Each of them differs from the other in some special feature or nuance. Undoubtedly, the entire installation of this device is located below the surface of the water. And it is from the pump itself that the wire and pipe for supplying water run in a dense insulated winding. In the standard assembly of any device you can usually see a motor and a filter. And the liquid suction itself is carried out from below or from above the installation. A mechanism with bottom suction can easily filter sand or silt from the waters of an underwater river. Deep well pumps consist of two components:

- Pumping part with several stages;

- Motor part. It can be either built-in or external.

Criterias of choice

When choosing a submersible pump for a well, first of all, they proceed from the main parameter of the source - the volume of supply (flow rate); if official drilling was carried out, this indicator is indicated in the passport for the well.

It should be noted that the flow rate depends on the electric pump used, so if it suits the owners, you should choose a unit with the same value. In addition, the passport provides figures for the static and dynamic level, the height of the casing and its diameter.

When carrying out drilling operations independently, determining the flow rate is not difficult - the water raised by the pump is poured into a container of known volume and the time for filling it is counted.

Surface or submersible

Due to the short distance of the aquifer from the surface of the earth and the small diameter of the casing pipes in an Abyssinian or home-made well, surface-type units are used, the suction depth of which does not exceed 9 m. Also, surface pumps into a water well can be used in artesian or sandy sources, if they static and dynamic level less than 9 m.

Typically, external water intake equipment is located in a single block called a pumping station; it includes a surface centrifugal electric pump, automation elements (relays), control devices (pressure gauge) and an expansion tank (hydraulic accumulator).

Due to the high noise during operation, the selected surface station must be placed in the basement of the house or a coffered pit; the advantages include easy access to the equipment at any convenient time.

Deep centrifugal pump for a well - design using the example of Pedrollo

Submersible pumps are used in cases where the water surface is located at a great depth; compared to surface models, they have higher characteristics, allowing several houses to be supplied with water from a high-performance artesian well, even in domestic use. They are more difficult to install and immerse in the well; this requires special heads and adapters. Since the well pump is out of sight, maintenance and monitoring of its operation is difficult.

In the absence of washing water, the submersible pump fails; if the system does not have an idle relay installed or the unit does not contain built-in protection against winding overheating, any drop in the water level below the water suction holes of the filter will lead to burnout of the electric motor.

Pump performance - determination method

As noted earlier, surface models are more effective when used at small distances of the water surface from the surface of the earth; such pumping equipment is better suited to independently constructed wells. When drilling wells yourself, there is no data on the speed at which the source is filled with water, but based on this information, the desired model of the future pump is selected. In this case, you cannot cope without an electric pump that takes water from the source, so you will have to temporarily borrow or rent it.

Vibrating submersible pump for a well - device and appearance

When determining the flow rate of a source with a surface electric pump, it is placed as close as possible to the well and the pressure pipe is immersed in water; at the output of the electric pump, the water is poured into a container of known volume, while measuring the time of its filling.

Let's say an ordinary 20 liter canister is filled in 60 seconds, converting this time into hours, we get a flow rate of 1200 liters per hour, which corresponds to the standard counting units of 1.2 cubic meters per hour. If after some time (1 hour) the water in the source drops below the level of the suction pipe and does not appear at the outlet, the electric pump is turned off and the well is given time to replenish its water reserves. A shut-off valve is installed at the outlet of the pipe from the pump and after some time the electric pump is turned on again, reducing the water flow with a tap, the presence of which is also monitored for an hour.

Thus, by means of several experimental intakes of different volumes of water, the amount of liquid per hour that can be pumped out by a well pump is determined; the technique can also be used in the case of determining the flow rate of a well with a submersible electric pump.

Lifting height - what factors to consider

A water pump in a water supply system must perform three tasks: lift water from a source, deliver it through pipes to the consumer, overcoming their hydraulic resistance, and provide the system with a given pressure for the operation of automation and home appliances (washing machines and dishwashers). It is these components that make up the formula for calculating water pressure, which will be discussed below.

Screw deep well pump - device

Immersion depth

The depth of immersion under the water surface is a passport parameter taken into account when installing a submersible electric pump; surface types are located on the ground and the data is not included in their technical characteristics. To determine the immersion depth that the selected unit should have, the static and dynamic levels are measured.

The static level is the distance from the surface of the earth to the water surface in a calm state of the source, the dynamic level is determined when an electric pump operates at depth for an hour, it is also equal to the distance from the surface of the earth to the water surface.

All measurements of water levels are made using a long dry rope with a weight, it is lowered into the well until a splash sound is heard and then the distance between the edge of the wet area and the surface of the earth is measured.

The selected submersible model must have a immersion depth in its passport specifications equal to the distance between the static and dynamic levels with a margin of 3–5 meters. This will allow the electric pump to be located far enough from the silted well bottom when using sand wells and thus improve the quality of the water taken.

Also, when the water level drops in dry weather or when the source silts up, a reserve of several meters will ensure uninterrupted operation of the electric pump. Another advantage of placing the electric pump further away from the bottom is saving money on materials and choosing a cheaper model with fewer technical requirements.

Casing parameters

Well diameter

The borehole diameter plays an important role in determining the dimensional parameters of the selected unit; it must fit into the channel with a small gap between the pipe walls. The standard diameter of manufactured submersible electric pumps is about 75 or 100 mm; for these sizes, taking into account the wall thickness, casing columns with an outer diameter of 90, 113 and 125 mm are suitable.

Centrifugal deep well pumps

Devices of this type are usually used to lift water for quite a long time without seasonal breaks. Such a jaw mechanism has two components - a hydraulic device and an electric motor. They are good for summer residents to use on their plots, since they do not take up much space, are convenient and easy to use, are also simple in structure, and most importantly, they are affordable to many from a financial point of view.

Bottom line

An automatic well pump is usually paired with a hydropneumatic or electronic water supply system. The automation takes the form of an external relay that is connected to the pump, or it can be an electrical unit installed in the pump itself.

There are two types of well pump: surface and submersible. The first ones in their design have a hydraulic accumulator and a pressure switch. Such models are distributed individually or as a whole unit, that is, a pumping station. Submersible devices, in turn, are distinguished by the presence of built-in sensors and electromechanical control.

When choosing a specific model, you should start from the technical characteristics of the specific model. We are talking about productivity, delivery height and maximum pressure.

You may also like

Choosing a submersible pump for watering from a barrel

Submersible water pump for the dacha: choosing the best

Screw deep-well pumps

A screw pump is a highly efficient device, the normal functionality of which does not depend on either the housing or environmental factors. In other words: this deep device can pump very dirty liquid in both vertical and horizontal positions. With the help of such a pump, you can organize the pumping out of any medium.

Features of this type: simplicity and ease of maintenance, ease of transportation, quick repair and installation.

conclusions

Submersible water pumps are very powerful devices for lifting water. They are used for various purposes, at different depths. This is a very important, and in some cases, irreplaceable unit in cases where it is necessary to ensure water supply in dachas and houses on the ground. In addition, pumps are used for irrigation or to get rid of accumulated sewage from flooded cellars and basements, ditches and pits.

The different types of existing submersible pumps allow users to choose exactly the device that will perform the important and necessary work , which requires the use of pumps.

Installing these units does not pose any particular difficulties, but this process cannot be taken lightly. A very important point is that it is necessary to approach the integrity and serviceability of the entire structure extremely carefully and responsibly. Each piece of equipment should be inspected before installation to avoid all the unpleasant consequences that may result from improper installation.

Submersible pumps are very useful mechanisms that bring real benefits in the absence of a centralized water supply , as well as in other situations requiring the intervention of pumps. Before purchasing such equipment, you should familiarize yourself in detail with all its characteristics specified in the instructions in order to select the right device. This must be done carefully, since there is always the possibility of purchasing a unit that will not meet the required work requirements.

There is a very wide range of such devices on the domestic market, so it will not be difficult for the user to choose the right pump for his needs. The price range can also be called relatively small, so a user with average earnings can purchase such equipment.

Rod pumps

Deep (well) rod pumps are the most common type, which are designed to lift oil from wells. They can often be seen at various oil wells around the world.

Rod pumps are:

- Non-insertable

- Plug-in

Non-insertable - the cylinder of this device is lowered into the oil well without a plunger.

Inserted - a cylinder with a plunger is lowered into an oil well on rods.

A plunger is a cylindrical displacer that is used in deep-well pumps of the rod type.

Types of hand pumps

Manual pumps, unlike electric pumps, are capable of lifting liquid from shallow depths and are significantly inferior to them in performance; collection requires physical effort and time - this is inconvenient for a large number of consumers.

Mechanical devices for water intake have several classes, differing in their operating principle, physical parameters and technical characteristics.

Fig. 3 Piston devices - operating principle and appearance

Piston pump

The simple principle of operation and the scope of application, suitable for most water intake work in the household, have led to the high popularity of this unit.

The standard design of a piston pump includes a cylindrical body within which a piston moves, the rod of which is fixed to a rocker arm.

There are elastic seals along the perimeter of the piston disc, ensuring its tight fit to the walls, and spherical check valves are located on its surface.

A hand pump for water from a well is installed on the top of the casing pipes in such a way that a check valve is located at the outlet of the water-lifting pipe immersed in the hole, without which the operation of the system is impossible.

Rice. 4 Making a piston hand pump

As the piston moves forward, the valve installed at the outlet of the well pipe lowers and prevents the reverse flow of water. Under pressure, the liquid opens the built-in valves in the disk and is placed above its surface. During the reverse stroke, the disk valves close, preventing water from draining, and it, rising along with the piston, pours out through the pump outlet drain tube.

Rodless deep well pumps

In recent years, we can conclude that rodless deep-well pumps have begun to be used more and more often in fields. In most cases, they are used to work with a well after a deep-rod pump has already worked with this well. And this happens because rodless types can pump oil from greater depths, thereby significantly increasing the level of production of this liquid. But the full operation of these devices has not yet been fully implemented, since they are complex in their design and internal composition of parts. There are two varieties of this type:

- Electrically immersed. This type is actively used for working with oil wells.

- Hydropiston.

Installation of a submersible pump

Once the user has decided on the choice of the device he needs, then after purchase he will need to install the pump. In principle, you can involve specialists, but it is quite possible to carry out the installation yourself.

Before installing the equipment, a thorough check of all elements of the equipment's current insulation . It is imperative to check the entire length of the electrical cable, as well as the location of its connection to the device.

To install a submersible pump, you will need a hose (this is if the pump will later be used for watering and irrigation activities), a cable, a pipe, couplings, brackets and a safety rope. Then installation is carried out according to the following instructions:

- First, attach a pressure pipe or hose to the pump. Couplings are used for this.

- Next, to the pipe, which was previously secured with couplings to the device, you need to fix the cable using the existing brackets. Please remember that the pump must never be lifted by the cable. For this, another structural element is already used, called a safety cable.

- After the above operations and checking all fastenings, you now need to lower the pump to the desired depth.

- After immersing the device, you need to check the grounding and insulation

The engine must be started for the first time without any load. Then you should wait an hour. This is done in order to identify the presence of possible deficiencies and malfunctions in the operation of the engine. If, after idling, no shortcomings were found in the engine, then you can already connect the load and start using it.

Pros and cons of using deep-well pumps

Pros:

- These deep mechanisms are resistant to various contaminants.

- Suitable for use in any type of soil.

- Quite a small cost.

Minuses:

- They may vibrate significantly during operation.

- It cannot be said that these devices are more reliable and durable; the service life of a conventional pump is no different.

- Low throughput.

From all this we can conclude that absolutely ideal pumps do not exist. Everywhere has its pros and cons, and you have to come to terms with the latter. But there are a number of cases when all the advantages can cover even a large number of disadvantages.

Distinctive features and parameters of screw electric pumps

A typical screw pump for wells used in individual water supply has the following technical parameters:

- Power supply voltage: AC 220V ± 10%, frequency 50 Hz.

- Temperature range of the pumped liquid: from 0 to 35 °C.

- pH of pumped water: 6.5 - 8.5.

- Operating ambient temperature range: from 0 to +40 °C.

- Minimum depth of immersion under the water surface: 0.5 m.

- Permissible volume of mechanical particles in pumped water: - no more than 500 g/m3, the content of fibrous materials in the liquid is not allowed.

- Permissible diameter of mechanical fractions: - 1 mm.

- Maximum pressure: 3 m3/h, for most models it does not exceed the threshold of 1.5 m3/h.

- Maximum pressure: up to 200 m, this indicator is a rare exception; most modifications create a pressure pressure of no more than 100 m.

Rice.

8 Main characteristics of Chinese Oasis Main advantages of screw electric pumps:

- Low cost, the price of the cheapest models is about 80 USD, in general all models are cheaper than centrifugal types.

- Simplicity of design. The working part consists of a screw and a rubber cage; they are easy to maintain and, if necessary, simply replaced, which makes repairing screw units very simple.

- Due to its operating principle, a screw pump for a well can transport liquid with large fractions of sand and clay deposits - this is its main advantage. A submersible screw pump is preferable to use for water intake from well sources on sand, which often have a high content of suspended particles of clay and sand. Although their parts are subject to mechanical stress from solid particles, the service life of a screw pump in turbid sources will be longer than that of centrifugal models.

The disadvantages of screw units include the mediocre quality of many products (chrome-plated screw, quickly abraded holder) and not very high technical characteristics, noticeably inferior to centrifugal types, as well as low efficiency, not exceeding 45%.

How to choose a deep-well pump yourself

Of course, choosing a deep-well pump for your site is a serious matter that requires care and concentration. It’s safest to entrust this matter to specialists who can easily select the right device based on the customer’s preferences and be able to install it correctly. But if you choose such a pump yourself, then you should take into account all the features, all the pros and cons of each type, compare prices and calculate which type would be more appropriate to buy from a financial point of view. You can contact consultants directly in the store itself, or you can buy this device, guided and relying only on yourself and your preferences. In this matter, you should not listen to neighbors, friends and comrades, since this device is selected completely individually for each site.

What influences the cost?

Installation diagram of the deep-well pump ECV.

The design of the pump has a certain impact on the cost:

- Technical characteristics, water supply, performance and power. For deep-water equipment, it is important exactly how water will be supplied and under what pressure this will happen.

- The type and power of the engine have always been one of the most important values. The more powerful the equipment, the greater the depth it will be able to lift water, but its cost will be higher.

- With an increase in power, the price increases by 4 thousand rubles for a difference of 0.75-1.5 kW.

- Resistant to dirt and sand. It is important to use a pump that will not break if there is sand in the water. No pump can move clean sand, but there must be protection against it, especially for sand wells. For limestone springs this is not a big deal, but it is important to keep it in mind when choosing. Sand protection is provided by a special built-in filtration system.

- Performance affects cost as the pump design is more complex.

Average prices of deep-well pumps

- The price of centrifugal deep-well pumps varies from 9 thousand rubles to 13 thousand rubles. This is explained by the fact that this type is intended for summer cottages, and there is no point in putting a high price on this product, since it will not be in demand, which already causes damage directly to the manufacturer.

- Screw deep-well pumps can be purchased at an average price of 3 thousand rubles to 12 thousand rubles.

- The price of rod pumps starts from 6 thousand rubles and reaches quite high prices.

- Rodless deep-well pumps have a price approximately the same as sucker-rod pumps.

Of course, these prices are written in average values; the price for each device depends on many indicators, namely: the type, cable length, the company that manufactures the device, suppliers, the country where the purchase is made, the mechanism and many others.

Overview of borehole pumps for water supply

Deep well pumps must be selected based on a combination of parameters. This equipment is purchased for many years, so the main requirement is its high quality. The performance characteristics of the best models of borehole pumps for water supply are presented in the following table.

| Table of characteristics of deep-well pumps | |||||

| Pump name | Diameter, inches | Productivity, m³/hour | Head up to, m | Price, % | Country of manufacture |

| Rucheek-1 | 4 | 1,0 | 60 | 100 | Belarus |

| Unipump | 4 | 1,8-4,8 | 52 | 400 | China, Russia |

| Belamos TF | 3 | 1-3,3 | 60 | 720 | |

| Aquario | 3 | 1,5 | 60 | 1120 | Italy, Russia |

| ESPA | 4 | 4,2 | 60 | 1240 | Spain |

| Pedrollo | 9,0 | 135 | 1400 | Italy | |

| TWU | 3 | 3,8 | 70 | 1400 | Germany |

| Lowara | 4 | 1,4 | 105 | 1440 | Italy |

| Gardena | 4 | 1,5 | 60 | 1560 | Germany |

| Grundfos | 3 | 1,5 | 80 | 2000 | Denmark |

| Wilo | 3 | 2,6 | 88 | 2000 | Germany |

We hope that the recommendations outlined above will help you purchase the necessary equipment for pumping water. The following video clearly demonstrates the rules for selecting and installing a well pump.

Where is the easiest place to buy a deep well pump?

Firstly, these are cities in Russia, such as Moscow, Kazan, St. Petersburg, Ryazan, Ufa and many others.

You can also order a deep-well pump online. In the world of high technology, there are a huge number of Internet resources on which the buyer is provided with an endless assortment of this product. You can find sites where prices are lower, you can find free delivery, or quite the opposite, everyone decides for themselves.

Classification

These devices are classified according to technical characteristics and features of use into normal-priming and self-priming. They can be with either single-stage or multi-stage equipment.

Self-priming devices can be used in liquids with a high content of gases. Their main feature is the ability to start working without liquid, while normal-absorbing ones can only work when the suction pipe is filled with water.

More common types of device data include:

- Horizontal single-stage : for liquid substances with a chemical composition similar to water;

- Horizontal multi-stage : the ability to create high pressure with a small water supply;

- Fecal : for pumping water containing polluting particles;

- Sand dredger or dredger ; works with industrial waste liquid.

Pumping station vs. deep well pump

A pumping station is a kind of mechanism in which there is a storage tank. And the most important task of this structure is to fill the tank to a certain level, and only then supply water to the house’s pipeline. Often this is not entirely convenient, since this device is used in country houses, and water is needed there quite often, and there is no desire to wait until the tank is filled. In principle, the operation of a deep-well pump and a pumping station does not have any special differences, it’s just that everyone must choose for themselves what suits them best for use. Among the advantages of the pumping station is a long service life, but among the disadvantages are large dimensions. In a deep-well pump it is quite the opposite. It is impossible to say with certainty what is better and what is worse.

Other types of mechanical pumps

Manual mechanical water supply devices have been used since ancient times and have now been replaced by industrially produced models. In some cases, in the absence of electricity, the use of mechanical factory units is ineffective, and craftsmen come up with their own diagrams and drawings on how to make a hand pump for a well with their own hands.

If in the above case (water intake from a well) the principle of operation of industrial units can be used, then for water intake from open reservoirs they use their own developments based on ancient technologies.

Archimedes screw

Rice. 9 Archimedes screw and its use

The design was invented by a Greek thinker in 250 BC and consists of a cylindrical pipe, inside of which there is a screw; the system is lowered into an open body of water at a slight angle. During operation, the rotating blades capture water and move it up the pipe, at the end of which it is poured into the prepared container.

An analogue of this installation is an electric screw pump designed for constant water intake from deep water sources.

Hydraulic ram

Rice. 10 Hydraulic ram

Mechanic Montgolfier is the creator of a hydraulic pump that raises water using its kinetic energy. Its principle of operation is to shut off the fast flow with a valve, after which water under pressure enters the hydraulic tank located above and is then delivered to the consumer through a floor hose. The device operates in repeating cycles; some manufacturers produce hydraulic pumps using artisanal methods.

Airlift

Rice. 11 Aerolift - operating principle

The German engineer Karl Loscher developed this method in 1797; its essence consists of pushing out liquid from a hollow pipe lowered into a source with air. To operate the airlift, air is pumped into the lower part of the pipe through the inlet pipe using a hand pump; its bubbles dissolve in water and, due to their light weight, rise to the surface along with the liquid.

To prevent liquid from entering the pressure air hose, inflation is carried out through the nipple.

This design can be used in the presence of electricity by connecting a compressor instead of a mechanical pump.

Homemade piston pump

Some craftsmen make piston pumps themselves. The usual design consists of a working chamber made of a welded pipe; a metal or plastic disk with a rubber sealing ring along the diameter is used as a piston. To ensure water supply using a homemade design, holes are drilled in plastic or metal piston discs to install a check valve system.

Rice. 12 Construction of a homemade piston pump

Most modern mechanical units, like surface electric pumps, are capable of lifting liquid from wells up to 10 meters deep.

The highest delivery height is provided by a rod pump, which operates in a similar way to electric submersible types. Its body and operating valve can be lowered into a source up to 30 meters deep, providing intake at a similar distance to the water surface. Among all types in everyday life, the most common are piston hand pumps, which are mounted directly above the outlet of the casing well pipe, with suction occurring through a pipe lowered into the hole with a check valve.

Advantages and disadvantages

Each type of submersible pump has its own advantages and disadvantages. For example, centrifugal pumps are very sensitive to the purity of the pumped liquid. Their disadvantage is their high cost compared to all other types. The rodless centrifugal unit is silent in operation, since its body is in the liquid. The service life depends on the number of on and off cycles, so a hydraulic accumulator is most often connected to it to extend the operating time.

Disadvantages of vibration pumps:

- React to sand in water.

- Lack of automation elements.

- The well silts up faster, as it creates waves that lift dirt from the bottom.

- High noise level.

- Low power and pressure.

- Short service life.

The advantages of screw equipment include:

- high pressure;

- low noise level;

- the ability to pump out dirty liquid without damaging the housing.

The efficiency of the screw mechanism is low, the productivity is low. Frequent replacement of parts is required, since there are many rubbing elements inside the case.

Optional equipment

Automation for downhole devices allows you to forget about the operation of the pump. Let's look at some types of equipment and connect it according to the diagram.

Automation

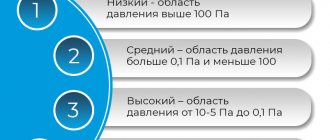

Divided into 3 generations:

- 1st generation: pressure switch, dry run blocker, float switch;

- 2nd generation: an electronic device that has several sensors installed in the pipeline, on the pump and other places. Thanks to it, the following work is performed: water level recording, dry running blocking, emergency shutdown, engine temperature control;

- 3rd generation: has advanced functions, with precise control of operation.

Popular models for home and garden

Let's compare the most famous:

- DAB IDEA 75M. Household vortex unit. Delivers liquid from 10 m. Easy to use. Ideally combined in energy consumption and technical requirements. characteristics. The rotation of the brass wheel may become stuck.

- Aquario ASP 1E-30-90. Centrifugal submersible unit, the ideal solution for the dacha. Lifts liquid from 20 m. Silent operation. An obvious disadvantage is damage to the motor after several years of operation.

- VORTEX CH-50N. The body of the submersible apparatus is made of high-quality stainless steel. A thermal relay is provided. Designed for up to 50 m of immersion. After a certain time, the impeller key changes shape, oil leaks, and the engine burns out.

- Wilo TWU 3-0501-HS-E-CP. This is a high pressure pump for source depths up to 150 m. Best for artesian water. Creates a pressure of up to 26 m. Has many levels of protection. There are practically no disadvantages.