The well is the main source of individual water supply for private houses; during its operation, it is necessary to take special measures for ease of use and repair of pumping equipment, protecting it and the wellhead from the external environment. The question of how to insulate a well for the winter with your own hands is especially pressing; various methods are used to solve it.

It should be taken into account that when constructing wells, various technologies are used - in addition to traditional caisson pits, a modern, economical method has appeared for connecting electric pumps using a special device (adapter) attached to the upper part of the casing below the freezing depth. Another technology widely used in everyday life is home-made drilling of a shallow and narrow Abyssinian well - in this case, insulation is also required, which is different from other options.

Rice. 1 Well construction - options

When to insulate a well

In deciding how to insulate a well for the winter with your own hands outside, not the least important is the relevance of the problem itself. Thermal insulation work must be carried out only in the following cases:

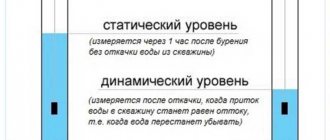

- The upper part of the casing is located in a caisson pit . Water, when passing through an open section of the water pipe (coming out of the head), will turn into ice and, as a result, it will expand with subsequent damage to the system.

- The upper water level is above the freezing point of the soil. With the onset of cold weather, the pipe system will simply freeze with ice and stop working.

- Water intake is carried out by means of an electric pump , the structure of which has a return valve to retain water in the pressure pipe. When exposed to negative temperatures, icing will occur at the inlet section.

- The equipment and pump can be located in a caisson pit at a shallow depth . When exposed to cold, equipment will deteriorate.

- Due to unforeseen circumstances, the well was left unattended . The water in the system will freeze and expand, which will lead to equipment and pipeline failure.

- The design does not have a caisson pit and the casing is located at or slightly above the edge of the ground . In this case, the entire mouth of the system needs thermal insulation.

Scheme of arrangement of a well in a private house Source ht16.ru

Note! Knowledge of the properties of the materials used and the design of the well helps to properly organize the thermal insulation of a private water intake system. So, in regions with a warm climate or when laying a water pipe deeply, it is enough to cover the head with natural insulation, for example, sawdust or peat.

Advantages and disadvantages

Among the advantages of Abyssinian wells are:

- Relatively cheap. You can do the work yourself.

- The necessary components are widely available.

- Fast production. Setting up a well with all the components in place will take literally a couple of hours.

- Ease of arrangement. A well requires limited space. Any area of the yard, as well as a basement or garage, is suitable.

- No special drilling equipment is required for the work. Such equipment usually requires special access roads and special transport.

- Long service life. However, this statement is only realistic for properly equipped wells.

Minuses:

- Construction of an Abyssinian well is not practical in areas where there are layers of clay and limestone. The work will not be economically viable.

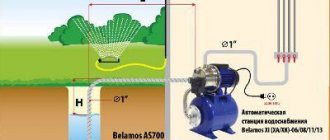

- It is impossible to install a submersible pump in a small diameter pipe that is installed for a well. Therefore, a pumping station is needed to raise water.

- Construction of a well becomes more complicated if the distance to the water surface is more than 8 meters. To set up a pumping station, you will need a pit with a caisson, which can also be installed in the basement of the house. The pumping station will not be able to lift water from deep aquifers.

Before starting work, you need to study the area. On the ground, you need to find out the depth of the aquifers. In addition to choosing a location, it is important to choose the time for work, since the water level changes from season to season.

Methods of insulation depending on seasonality of operation

Options for how to insulate a well for the winter depend primarily on how often it is used. There are 3 main types of use and corresponding methods of thermal insulation:

- Seasonal.

Typical for a country house. This implies the preservation of the system for the winter and the complete absence of any thermal insulation. Before the onset of the first cold weather, the pipes are drained and the equipment is disconnected from the power supply. In this case, the pump is turned off and all taps are opened.

- Periodic.

The water intake operates all year round, but not constantly, but in periods, for example, every other day, on weekends or holidays, etc. In this case, in addition to passive thermal materials, active heating technologies are used - heating wire. Since a long absence of flow in the pipes will lead to their rapid cooling and icing with subsequent damage.

Summer well for home Source i2-ww.ru

- Permanent.

The movement of water in the pipes occurs constantly, with the exception of short periods of downtime - at night, during the day, when everyone is at work, etc. However, the icing process can begin during extreme cold snaps, and at the peak of the cold season, and with shallow communications, and superficial location of the pump and equipment. Therefore, the use of high-quality insulation with special materials is required.

Advice! Methods and means of insulation directly depend on the climatic characteristics of the region where the well is operated. If the temperature rarely drops below -12-15°C, communications need not be immersed in the ground to great depths, but sawdust, peat, expanded clay and other natural fillers can be used as thermal insulation materials. On the contrary, in places with more extreme climates, where temperature drops to -20-30°C and below are not uncommon, it is permissible to use only professional materials - polystyrene foam, penoizol, polyurethane foam, etc.

Insulating a well for the winter from the inside Source notperfect.ru

See also: Catalog of companies that specialize in water supply and sewerage

Insulation of a source at the dacha during the construction phase

Only the upper section of the trunk needs to be isolated. Various materials are used for this:

- liquid polyurethane foam;

- shrink film;

- sawdust;

- foam shavings;

- foam boards;

- upper layers of soil peat.

At the moment of drilling the hole, before lowering the uppermost sections of the pipe, they are insulated. For example, they cover it with heat-resistant adhesive tape at least 1.5 - 2.5 centimeters thick, then lower it into place.

Instead of adhesive tape, you can use the air heat protection method. It is known that air in a closed position conducts neither heat nor cold. Therefore, if a small air space is provided between the pipe wall and the ground, the mine will not freeze in winter.

Technology options

There are several technological methods for insulating a well on the street in a private house, differing in the types of materials used, system design and equipment. There are mainly 4 methods used:

- With insulation.

- With caisson.

- Without caisson.

- With heating cable.

Let's look at them in more detail.

With insulation

Thermal insulation is carried out using special materials. The method is primarily suitable for harsh climatic conditions. Its peculiarity is that the walls of the protective structure, and in some places the pipes themselves, are lined with thermal protection on the outside. The structure of the latter includes tiny isolated cavities. Thanks to them, the temperature of the internal environment is maintained at an acceptable level.

In this case, a number of requirements are imposed on the heat-insulating material:

- The structure should not absorb moisture and have a reliable water-repellent outer layer.

- The design of the insulation should not change the characteristics under pressure from soil, pipes and other objects.

- Thermal protection must be resistant to biological influences - rodents, insects, fungi and microorganisms.

External insulation of the caisson Source beton-house.com

Advice! In harsh climates, it is permissible to use only industrially produced foam materials as a heat insulator. In this case, the optimal thickness of the protective layer should be at least 0.35 m.

With caisson

The caisson is a special structure for protecting the ground part of the well. It can be either factory-made or home-made. In the first case, the product is made of reinforced concrete, plastic or metal, in the second, as a rule, it is made of boards, timber, bricks and other building materials. They can be rectangular, square, or cylindrical in shape.

Depending on the features, the caisson is insulated in two ways:

- Outside: used when it is necessary to preserve the internal usable volume, as well as protect the material of the product from external influences, for example, protect plastic from frost.

- From the inside: used when the caisson body itself is strong and completely sealed. The advantage of the method is the protection of the heat-insulating material from external influences.

Important! Passive insulation of the caisson using insulating material is not enough. For protection during periods of severe cold, a small heater is installed in it. For example, a 50 W incandescent lamp is enough to heat a standard room.

Well with plastic caisson Source plastik-da.ru

Using improvised means

Sawdust, straw, peat or even dry leaves are often used as insulation.

The pit around the source is reinforced with boards or sheets of metal. Waterproofing material is laid between the soil and the shield. Heaped sawdust is poured into the trench and allowed to settle for a couple of days. The depth of the warm chamber is up to 2 meters, and the width is 40 - 50 centimeters. Do not compact sawdust or straw. Air should remain in the insulation. You also need to ensure that the material at hand is dry and crumbly.

Types of materials

There is a fail-safe way to insulate and improve a well in a country house without the use of additional heating equipment - this is to cover all its components and protective structures with thermal insulation material. For professional installation, the following 4 types are used:

- Expanded polystyrene and penoplex.

- It is characterized by low thermal conductivity, strength and moisture resistance. Suitable for lining both inside and outside caissons, as well as external and underground pipes.

- Foamed polyethylene.

- It is characterized by good thermal insulation and low load resistance. Therefore, it is used for lining internal walls of rooms and external pipelines.

External insulation of a well with foamed heat insulator Source pechiexpert.ru

Construction rules and preparation

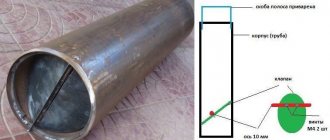

Preparation for work can be divided into conditional stages. Before you start drilling, it is worth taking a closer look at the design of the Abyssinian. It is extremely simple and includes a set of metal pipes, the length of which is 1-2 meters. The pipes are connected to each other by couplings. A filter pipe will be required for the lower part of the well through which water is drawn. The method of its manufacture was discussed above. A pump will need to be installed on the ground surface.

Experts advise choosing galvanized pipes for the well.

Stainless steel options are also suitable.

Copper pipes are not suitable for a well at all. On pipes that are suitable for installation on both sides, you need to cut an external thread.

The length of the perforated pipe (which will play the role of a filter) should be 70-100 cm. It is good if a tip is welded to the lower end of this part. A spear-shaped pipe will make driving easier. It is important that the diameter of the tip is slightly larger than the diameter of the pipe.

Sometimes there is a need to temporarily or completely stop the well. The reasons are very different, and there are two methods for stopping work - conservation and plugging. Conservation is a set of measures whose purpose is to temporarily protect an idle well. Backfilling is the elimination of an accident or the hydraulic structure itself. Both technologies are used to protect the aquifer from chemical and bacteriological contaminants. What is needed to preserve artesian wells and equip them for the winter? How to liquidate the structure if necessary?

Video description

For a clear overview of well insulation, watch this video:

In the standard case, the procedure consists of sequential thermal insulation of the following main elements:

Caisson

Stages of work:

- The required amount of polystyrene foam or other heat insulator is prepared.

- Next, the material is cut into the necessary fragments, based on the shape and size of the caisson.

- The outer part of the caisson is waterproofed with bitumen, unless it is made of plastic or iron.

- The prepared fragments are applied to the outer walls and secured with wire, stops, mesh or tape.

- The joints between the sheets are filled with polyurethane foam for sealing.

- Upon completion of fastening, the structure is covered with a layer of expanded clay.

Casing and cap

Subsequence:

- A box is made from pieces of chipboard, boards, plywood, sheets of metal or rigid insulation for the external closure of the casing and head.

- The box is installed on top of the casing and cap.

- Its internal space is filled with parts of mineral wool, glass wool or natural components (hay, straw, paper).

As an option, instead of a box, a cylinder is formed from a chain-link mesh with a diameter exceeding the head by 0.3 m.

Do-it-yourself well insulation Source kimberia.ru

Without caisson

Water supply equipment, filters and related electronics are located in the house or a separate room - this does not mean that the shaft does not need to be insulated. There are several ways to insulate a source without a caisson:

- Thermal protection of the mine shaft with wood chips or sawdust. The pipe is dug around its entire circumference to a depth of 2 - 2.5 meters. The width of the trench is 30 - 40 centimeters. Then a mesh with a large cell is wound to provide an air gap between the wall and the insulation. Next, the material (sawdust or peat) is gradually filled in. You cannot compact the insulation; it is better to let it stand for a while, and after shrinking, add more. A durable lid made of wood or metal is placed on top.

- Thermal insulation with mineral wool. They dig a trench in the same way and stretch the mesh. Then several layers of glass wool or mineral wool are wound onto the pipe. It is better to use a 5 cm thick mat. The final insulation layer is 35 cm.

- Insulation with liquid polyurethane foam is a little simpler. No need to wrap the mesh. A special device is simply lowered into the pit and polyurethane foam is sprayed layer by layer onto the surface of the pipe.

- Heating with electric cable. The principle is to use a special heating cable, which is tightly wound to the well pipe. A non-flammable film must be wrapped over the heating element and additional waterproofing is provided.

Briefly about the main thing

Depending on the frequency of operation, there are the following ways to insulate a well on the street:

- Seasonal, when the well is not operated, but is simply drained and turned off for the winter.

- Periodic, when water is collected on weekends or once every few days. To maintain performance, heat-insulating materials and heaters are used.

- Constant, when the well is practically never idle, so the flow never stops for long. However, in cold weather, icing may begin. Therefore, professional insulation is required.

At the same time, 4 technologies are used for thermal insulation - using insulation, with a coffered structure, without it and with the installation of a heating cable. In most cases, combined methods are used. Thermal insulating materials are polystyrene foam, penoplex, polyethylene foam, mineral or glass wool, as well as penoizol, polyurethane foam and expanded clay. You can do the thermal insulation yourself, but it is better to entrust the job to a professional team.

Ratings 0

Time for work and choice of location

When developing professional individual water supply projects, the question of choosing a work season is usually not raised. Here, even non-specialists understand that drilling is best done in the summer season. If the homeowner does not have the opportunity to carry out work in the summer, he has to choose another time. Experts sometimes associate the choice of time of year with the parameters of the future source. In this case, the physical characteristics of the aquifer are taken into account.

It is best to drill a well in summer or autumn. The work will be facilitated by:

- dry stable soil;

- low rainfall;

- positive air temperature.

The water level in the source will be at its lowest at this time. This will allow the Abyssinian well to be used during periods of drought. At any other time, high water levels will be present.

The advantage of performing work in the summer will be long daylight hours.

Dry soil will also be an advantage, as it will absorb more of the pumped out liquid. After installing a well, dirt will form. Usually it is pumped out for several hours or days.

If there is no rain in the autumn, work can also be carried out. In case of high humidity, it is better to avoid drilling.

The spring period is considered unsuitable for drilling. Changes in shallow aquifers during this period occur due to flooding. This may lead to an erroneous location. In addition, increased pollution will be observed in the drilled mine. Dirty impurities will have to be pumped for a long time and intensively.

In winter conditions, drilling will be difficult due to soil freezing.

It will be impossible to prepare the Abyssinian well using the driving method. However, when using a drill, there is an advantage - due to freezing, the soil in the hole will be more stable. The mine will be less polluted. In some cases, no initial bleeding is required in winter. During winter, shallow aquifers are at their lowest levels. The filter installation accuracy will be the best.

When constructing well sources, it is necessary to take into account the sanitary rules of the norm. SANPIN implies three types of established zones that are under sanitary protection. The rules are aimed at protecting surface and deep water sources from pollution.

The first belt of the security zone includes the area of underground communications. The boundaries of the first zone are located at a distance of no more than 30 meters from an underground source and 50 meters when exploiting an unprotected water layer. Therefore, in some cases, it will be necessary to coordinate the choice of location for the well with the relevant authorities.

The general requirements for choosing a location are as follows:

- Activities such as tree planting and construction should not be carried out at the well site. The use of chemicals is prohibited.

- Well owners must dispose of sewage waste to special treatment stations. When disposing of them, the surface of the sanitary area must not be contaminated.

- When operating a well, it must not be contaminated.

- The area where the well is located must be fenced.

It is easy to determine the volume of a sanitary zone. For a shallow Abyssinian well, this will be a 50-meter zone. For deep wells, the zone will be 30 meters.

Constant heating electric cable

In places with deep freezing of the ground and high ground water level, which freeze in winter, additional protection is required. Heating cord is divided into two categories:

- With installation inside the pipeline.

- Outer winding.

To lay the cable inside the pipe, a special tee is installed at different angles. It is completely sealed. After installing the line, a cord is inserted into it, which runs along the entire length of the thread and exits through a tee on both sides of the pipe. A prerequisite is subsequent thermal insulation of the pipe from the outside. The cable is reinforced with additional waterproofing and is safe. Mandatory installation of a thermostat is required to avoid excessive energy consumption.

The external heating cord is attached to the pipe along its entire length with tape or plastic clamps. We glue the entire cable with tape, then lay the thermal insulation. The cord should not sag or come off; only its tight contact with the pipeline will ensure good heating. The well can also be insulated with a cable, but due to the fact that the diameter of the casing is much larger, the cord is wrapped around it. Steps of five centimeters.

Recommended insulation for a well made of concrete rings

| Type of insulation | Features of the material | Installation technology |

| Styrofoam | Inexpensive, has good thermal conductivity, does not deform, and does not absorb water. Not resistant to rodents and insects. Sold in the form of ready-made elements corresponding to the sizes of reinforced concrete rings. | The walls of the well are cleaned of debris, façade glue is applied tightly, without gaps. Styrofoam is attached. If the foam does not adhere well, you can secure it with concrete dowel nails. Any barrier insulation material is laid on the foam. The trench is filled with earth and compacted. |

| Extruded polystyrene foam | Resistant to low temperatures, aggressive environments, and withstands loads well. Approximately 20% more expensive than polystyrene foam, produced in the form of slabs. | Installation is no different from installing foam plastic. The joints are sealed with polyurethane foam. The insulation is wrapped with rolled waterproofing material. |

We invite you to see how a member of our portal with the nickname pdp000 insulated his well

The insulation of the blind area is made of EPS, the walls of the ring are insulated with expanded clay. An insulated lid-liner is also made.

You can insulate a well with a little blood. Here are a few methods tested on FORUMHOUSE.

- Our user with the nickname Accurate covers the concrete ring of the ring with plastic film. Since then, the water supply pipe has not frozen even once - it was heated by well water, and the water did not freeze because the film did not allow the cold to pass through.

- Our participant with the nickname Hodok has been insulating a well from the inside for 40 years. Attach two frames made of thick wire in the form of inverted letters P to the last ring at a distance of 25 cm from each other. They descend to ground level. On them, Walker places two semicircles cut out of iron - this creates a flooring on which a plastic film is placed. He covers all the cracks with the same film, puts old clothes inside and leaves the well until spring. But this needs to be done when stable frosts arrive, so that the improvised insulation does not get wet from the fumes from the well.

How to drain water from a pump for the winter

The next important part of the system is the pumping station. If it is installed in the house, be sure to empty the water from it. If it’s in a well or borehole, then, theoretically, you don’t have to do anything at all - the freezing depth in the Moscow region is 1.5 meters, and pumps are installed deeper.

Sanych1415 Member FORUMHOUSE

The main thing is that the hose can withstand temperature changes. If it holds up, then there is no problem.

But in practice, when using a well or well seasonally, FORUMHOUSE participants, at the end of the summer season, pull out the pumps and take them to the city so that the equipment can winter in a warm room.

Andrey 203 FORUMHOUSE Administrator

At the end of the season I sort everything out. The pump and automation are stored at home at positive temperatures.

To drain water from the pumping station, you need to turn off the power and unscrew the drain plug, which is located in the lower part of the pump housing. The pump should be tilted towards draining the water, and to ensure complete drainage, turn it upside down.

How to drain water from a washing machine and dishwasher

If a washing machine and dishwasher are left to spend the winter at the dacha, then they will also need to be dehydrated. There can be difficulties with dishwashers, as our users say, “they have real labyrinths for water inside.” Therefore, if the manufacturer’s instructions do not directly indicate that the device can be wintered in an unheated room, and the preparation steps for such wintering are not outlined, it is better not to take risks.

With washing machines everything is simpler. To drain the water from the washing machine, you need to:

- Disconnect the machine from the water supply and sewerage. Place the ends of both hoses into a low basin. Turn on the "drain" mode. Wait for the work to finish.

- Disconnect the machine from electricity. Place a flat container like a cat litter box and unscrew the drain pump cover.

- To be completely sure, you can turn the washing machine upside down and leave it to winter in this position.

But some models of washing machines have containers inside in which water may remain, and if not, access to them is possible only through partial disassembly.