For the uninterrupted operation of an independent water supply, automation devices are required. One of them is considered to be a water pressure switch for the pump. This device is a safety device and controls the operation of the water pump. When the pressure in the pipeline decreases, the switching element turns on the pumping unit, and when it increases, it turns it off. Fluid pressure thresholds can be adjusted.

Device and principle of operation

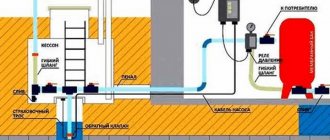

To ensure water supply to a private home, the relay is connected simultaneously to two systems: water supply and electrical network. It is advisable to connect the device via a separate line, then longer and uninterrupted operation of the equipment will be guaranteed. The main elements of an electromechanical water pressure device for a pump:

- plastic case;

- couplings for connecting cables;

- terminals for connecting the ground wire;

- contacts for connecting power wires;

- manual switch button;

- pressure adjustment nut and spring;

- base;

- fitting for connection to the system.

All control is carried out through a membrane that is in contact with the water supply and is a thin plate. If the pressure in the system reaches its maximum value, the membrane reacts instantly and the water pump is turned off.

A low pressure reading will not prevent the spring from bending the plate in the opposite direction, and the pump will turn on. The spring pressure switch block for the pump consists of two parts. The first includes a spring that controls the minimum pressure value and restrains the main water pressure.

The adjusting nut adjusts the minimum pressure. The other unit is a spring that controls the maximum value, and adjustment is carried out with a special nut. The principle of operation of the hydraulic relay is that the membrane, under the influence of water flow, closes and opens contacts that turn the pump on or off.

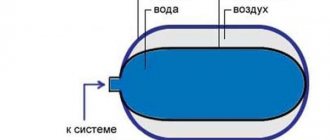

This happens due to the fact that the relay is in a circuit with a hydraulic accumulator, in which a membrane separates water and compressed air. When the pump operates, water presses on air through a membrane, creating some pressure, which decreases as the liquid flows. The adjustment is carried out based on the pressure gauge readings:

- upper pressure threshold - 2.8 kg/cm²;

- the lower value is 1.4 kg/cm².

If the setup is carried out correctly, the equipment will operate automatically without user intervention. From time to time it will be necessary to clean the contacts, since they oxidize during prolonged use.

Frequent malfunctions

Awareness of the main malfunctions that can occur with the water pressure switch will help to avoid long shutdowns and equally lengthy repairs.

The most common malfunctions include:

- A break in the supply wire requires finding the location of the circuit break and then eliminating it.

- Jamming of relay contacts - eliminated during equipment inspection;

- Oxidation of contacts or carbon deposits is also done by disassembling and cleaning the device;

- Failure of the sensitive element of the relay will require either replacement of only one membrane, or the entire device.

Operation of electronic devices

In addition to electromechanical equipment, consumers use electronic devices that have more precise settings and modern design. Each model has a built-in controller that controls the operation of the pump, depending on the water flow. Thanks to this device, the pump is protected from idling operation, that is, when there is no water in the pipe.

In addition, this device extends the life of pumping equipment. To prevent water hammer in the system, the water pressure relay-regulator for the pump is equipped with a small hydraulic tank. In addition to many advantages, there are also disadvantages in the operation of electronic devices.

The disadvantages include:

- high price;

- increased demands on water quality.

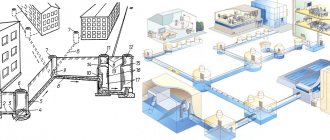

But consumers note that the device quickly pays for itself, thanks to reliable and durable operation, and installing additional filters improves water quality. The relay is considered a mandatory part in a deep water supply system or when operating a pump from a well.

It ensures filling of the hydraulic tank and stabilization of pressure in the pipeline system. In addition, the control device allows you to fully automate the water supply process.

Connection features

There are two schemes by which you can connect the relay-regulator to the water supply system. Which one to choose depends on the manufacturer’s recommendations and the technical capabilities of the system. An important feature of the connection is that the regulator is always first installed in the pipeline and then connected to the electrical network.

In the first case, the relay is installed in a tee connected to the adapter fitting. The second involves connecting it to a hydraulic accumulator using a fitting with five outlets. They are connected to:

- intake water supply;

- relay-regulator;

- pressure gauge;

- supply pipeline;

- hydraulic accumulator

In addition, the control device is connected to the pump and power supply. All threaded connections are sealed with flax or special tape. To connect to the electrical network, a cable is selected whose parameters must withstand the power of the pump. The relay contacts are connected according to the markings. The following are installed as additional equipment:

- coarse and fine filters;

- check valves;

- shut-off valves.

Typically, the pressure-regulating device is installed in the same block with the pump, and with a waterproof connection, the relay is located together with the pump in the well. When installing this way, it should be remembered that most models are operated at temperatures not lower than 4 ° C and humidity not higher than 70%.

Setting methods

After installing the relay regulator, you should configure it. The efficiency of the device and the uninterrupted supply of well or borehole water will depend on the correct adjustment. First you should turn on the device and wait for it to turn off automatically.

Then remove the cover on the large spring and loosen the nut. At the first stage, the minimum pressure value is set. To do this, rotate the nut counterclockwise until the minimum pressure value at which the pump turns on is established. The maximum value is set with the expectation that it will be 10% less than the pressure in an empty hydraulic tank.

Otherwise, strong pressure will be applied to the accumulator membrane, and it will quickly fail. Having opened the valve, you should empty the system and use a pressure gauge to record at what value the automation will operate. At the final stage, the pressure gauge is used to set the pressure at which the pump will turn off.

Sometimes, for a particular water supply, adjustment according to the attached instructions is not suitable; in this case, the adjustment is performed according to actual readings. It should be remembered that when adjusting there should be a difference of 1.2 to 1.6 bar between the minimum and maximum pressure.

Electronic devices are adjusted with special screws located on the housing. These devices do not start immediately, but after 15 seconds, since during this time the relay performs self-tuning. The pump also does not turn off immediately, but after a certain period of time.

Is it possible, in principle, to use your pressure switch with your pump?

The pressure switch connects not only to electricity, but also to water. For water connection there is a nut that is rigidly attached to the relay. This means that when screwing the pressure switch to the pump, you will have to twist the relay itself. Thus, first of all, figure out whether you have the ability to turn this relay clockwise on the pump? Will it fit? Will it hit other pipes or the pump housing itself?

We will assume that this issue has been resolved positively, since otherwise you need to look on the spot and, for example, take care of some kind of extension cord or something similar.

The pressure switch has a water inlet that is not quite standard in diameter. For most household relays this is a quarter inch. For professional relays, the connection diameter may be larger. You should definitely take care of this issue and, if necessary, buy a brass adapter for the required diameter.

Previously, in the production of automatic pumping stations, a special and completely standard part was used, popularly called a herringbone. This is such a nice piece of brass pipe, 10 or 12 centimeters long and 1 inch in diameter. The herringbone is screwed at one end onto the outlet pipe of the pump and has standard “outputs” for connecting a pressure gauge, pressure switch, accumulator tank and the water line itself. Now everything has become much more complicated. There are pumps where the pressure switch is screwed directly onto the pump or into very inappropriate, at first glance, places. This variety makes my job of writing detailed instructions quite difficult.

Some models

Now there is quite a large selection of pressure switches on the domestic market. Here you can find models from both Russian and foreign manufacturers. These include:

- PROMA-IDM is a universal regulator with which you can adjust the pressure of gas, air and liquid. The device body is made of plastic and is installed in a 48×96 mm hole. The converter has: four fixed ranges, improved metrological parameters, excellent interference protection, the ability to mount directly on a pipe, ambient temperature control, and so on.

- Grundfos FF is a pressure switch from German manufacturers designed for automated water supply systems at home, cottages and other facilities. The maximum setting range is from 0.5 to 8 atm, the minimum is from 0.2 to 7.5 atm. The relay can be installed in any convenient position. The device operates from a 220 V electrical network.

- SMS-PC F ¼ is an inexpensive relay regulator from a Russian manufacturer. The device is designed for operation in a pressure range from 1 to 6 bar. The electric pump starts at 1.4 bar and switches off when it reaches 2.8 bar.

- PC-58 - electronic relay is installed on the pressure water supply. The device turns off the pump in the following cases: there is no water in the system, the liquid supply stops as a result of a blockage, when water collection stops. The system can install a pump with a maximum power of 2.2 kW, the adjustment range is from 0.5 to 6 bar.

Before purchasing a device, there are several important points to consider. If you buy a relay for an autonomous system, then in this case a household device is better suited. This is due to the same indicators of key parameters of systems where the operating pressure is in the range from 1.4 to 2.8 atm. In this case, the reserve must be at least 2 atm, as this will prevent rapid wear of the membrane and extend the service life of the device.

Recommendations

So, if we subtract from the upper threshold (pump shutdown) the lower mark at which activation occurs, we obtain the pressure difference set by the smaller spring. If the resulting pressure level is insufficient, you can increase the upper limit by tightening the spring.

If the value is excessively high, then the spiral responsible for the upper mark is weakened. The optimal level difference (range width) is 1.4–1.5 atm. If it is less, then the supply will be more uniform, but the equipment will be activated more often, which will wear it out faster.