The problem of draining water from the roofs of houses appeared around the same time when people learned to build houses with more than one room. At first, the water simply flowed down the eaves, which was very impractical: the foundation was washed away, the walls of the house got wet, not to mention the real swamp that grew under the slopes in any rainy weather. Then they invented an external drainage system, which solved this problem for centuries. Until buildings with flat roofs, high-rise buildings and huge structures, such as factory workshops and shopping centers, appeared. Conventional gutters under the eaves coped very poorly with draining water from such roofs, so we had to urgently look for a new solution. It became an internal drain - a system with which you can provide effective and safe drainage from the roof of any building, regardless of its height and area.

Installation of internal drainage

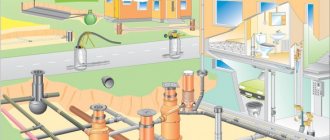

Let's start with the fact that this type of drainage system is used only on flat roofs. They consist of several elements connected to each other using a socket method, that is, when the end of one element fits into the end of another with tight pressure. And this ensures 100% sealing of the connection. True, craftsmen often add sealant to ensure the tightness of the joint.

So, the first element that is located on the roof plane is the funnel. Its purpose is the primary collection of rain and melt water. There is a huge variety of drainage funnels on the market. By design, they are flat and bell-shaped, according to the raw material from which they are made, plastic, stainless steel or copper alloys. It is the raw material that most often determines the price of the funnel.

Internal drainage funnel Source vellmart.net

And the third division is based on the dimensions of the internal section. This is an important parameter on which the efficiency of the entire drainage system depends. The diameter of the funnel is selected according to the diameter of the pipes used, which in turn are selected based on calculations. The latter is carried out taking into account the area of the roof from which water is collected.

Let us add that funnels can be equipped with all sorts of additional functions. For example, heated, with protective filters, with water flow stabilizers. It is clear that such models are priced higher than standard ones. And in each case, the cost of the option included in the funnel is taken into account.

The second element is pipes for the internal drainage, which are assembled into a riser. Essentially, this is a vertically located circuit that connects the funnel to the outlet pipe circuit. As mentioned above, the diameter of the pipes is chosen taking into account the area of the roofing plane. Usually the riser is laid during the construction of the house. And its location is inside the load-bearing wall, but not external. The thing is that pipes inside such a wall can freeze.

For internal drainage, plastic or asbestos-cement pipes are used Source vellmart.net

It is the location of the riser in the wall that determines the technology for its assembly. The thing is that any joint is a place for possible leaks. Therefore, riser pipes are mainly connected by welding. In this case, the welding process is carried out by a highly qualified master. Here quality comes first. At the same time, they try to assemble the riser with the least number of joints.

The third element of the internal drainage system is discharge pipes. Their purpose is to connect the riser to the storm sewer. Typically, two circuits are connected to each other by a tap. In this case, the discharge part of the drain should be located at a slight slope to the horizon to ensure gravity flow of the discharged water. It should be noted that there are different types of internal drainage systems, where drainage pipes can be located between the funnel and the riser. But more on that below.

So, the internal drain consists of three parts. But besides this, its package includes fasteners and inspection pipes (inspections). As for fasteners, these can be clamps or brackets, with the help of which all pipe products are attached to the load-bearing structures of the building.

Inspection for internal drainage Source dahbud.od.ua

As for the revision, it is a short pipe, the design of which has a hole that is closed with a lid. Note that inspections are a mandatory fixture of the drain, through which the circuits are cleaned (if necessary) and inspected for clogging or defects.

Speaking about the design of the internal drainage system, it should be noted that the roof plane is formed with the so-called slope. That is, when the funnel is lower than the rest of the roof plane. It is in this way that water is collected precisely in the area where the funnel is installed. That is, the liquid flows downhill towards it.

A flat roof is constructed with a slope towards the water intake funnels Source iv-proect.ru

See also: Catalog of companies that specialize in roof repair and design.

Drainage materials

The construction market offers drainage systems made of various materials.

When choosing drainage elements, the following recommendations must be taken into account:

- Drainage systems for multi-storey residential buildings with pitched roofs must be made of durable structures that meet safety standards. Galvanized steel systems with a polymer coating or stainless steel products equipped with reliable fasteners and connecting elements are suitable.

- Gutter structures made of copper are installed in luxury homes and country residences with an exclusive design. The material looks stylish and noble, indicating the high status of the home owner. Copper gutter systems can have a lifespan of over a hundred years.

Figure 4. Copper drainage systems.

- PVC drainage systems are suitable for private houses and country houses. Lightweight structures are quickly installed, easy to maintain, and retain an attractive appearance for a long time.

Owners of modern houses with external drainage are increasingly choosing drainage structures made of modified PVC from European manufacturers, presented in a wide range in.

PVC roof gutters have many advantages;

- strength exceeding that of cast iron;

- resistance to temperature changes;

- good noise absorption;

- molecular memory, which allows, in case of deformation, to return to its original shape.

The service life of thermoplastic PVC products exceeds 50 years.

Funnel ACO Spin for flat roofs made of cast iron with vertical outlet DN100 with thermal insulation and…

RUB 35,949

Order

Funnel ACO Spin for flat roofs made of stainless steel with horizontal outlet DN100 with…

RUB 44,235

Order

Funnel ACO Spin for flat roofs made of stainless steel with vertical outlet DN100 with…

RUB 22,443

Order

Funnel ACO Spin for flat roofs made of stainless steel with vertical outlet DN100 with…

Price on request

Order

Types of internal drainage system

There are two types of internal drainage:

- Gravity system . This is the simplest design, inexpensive, but low-performance . Even the most accurate calculation cannot give a 100% guarantee that rainwater from a heavy downpour will be effectively removed from a flat roof. And this is its only minus . Of course, you can increase the diameters of the drainage elements, but you won’t know for sure.

Schemes of two types of internal drainage system Source ppt-online.org

- Siphon system . Firstly, this variety differs from gravity flow in the funnels . Bell-shaped devices with flow stabilizers are installed here. It turns out that the entire drainage system from the funnel to the drain into the sewer is completely filled with water . That is, a water column . As soon as the water level inside the drain begins to fall, a vacuum zone is created in the funnel, in other words a vacuum, or a low pressure zone. And this is the reason that the funnel begins to suck in water located on the surface of the flat roof with greater force. That is, the physical law of pressure difference works when the material tends from a high-pressure zone to a low-pressure zone. At the same time, the speed of water movement in such a drainage system is much higher than in a gravity system . This means that such a drain cleans itself well.

Advantages of the design

Gravity and siphon-vacuum systems differ in throughput. In comparison, a gravity-flow system is inferior to a more complex analogue and requires the installation of a larger number of risers on equal roofing areas, increasing the cost of purchasing materials. At the same time, the two types of systems are characterized by common advantages. Thus, the advantages of internal drainage compared to its external counterpart are:

- maintaining the ideal appearance of the building facades;

- efficient operation of the system regardless of weather conditions, including in winter;

- high system throughput;

- drainage of wastewater directly into the sewer system, which eliminates erosion of the soil near the foundation of the building and destruction of sidewalk coverings.

Due to its numerous advantages, the internal drainage system is widely used not only in apartment buildings, but also in private construction.

Rules and nuances of the installation process

It should be noted that internal drainage will work for a long time and efficiently if it is done correctly. You can carry out the calculations correctly, use the best and highest quality materials for its construction, but even the smallest mistake during assembly or installation will lead to big problems. Therefore, you should be very particular about following fairly simple rules.

- If the flat roof of the house is small two water intake funnels on it . If the area is large , then it is necessary to calculate the required number of water intake elements and distribute them evenly over the entire roof plane. The set of rules and regulations states that one funnel should be installed per area of 20 m² .

- Funnels must not than 1 m from the walls of the building.

- The distance between adjacent funnels connected to the same pipe riser should not be less than 20 m.

- of the metals was chosen as the material for the elements of the drainage system , then the entire drainage system must be equipped with a heating cable . This is a necessary measure that will protect the entire system from deformation and rapid failure.

How to properly install internal drains Source bta.ru

Additional rules when installing storm drains

Specialists carrying out installation work on installing gutters on the roof of buildings must take into account some rules:

Installation of gutters

- one storm drain riser serves no more than 250 m² of roof;

- all sewerage elements are sealed in the most thorough manner;

- fasteners should not “squeeze” the material of the main elements of the storm drain;

- the riser pipes must have inspections for their maintenance;

- The introduction of a storm sewer into operation should be carried out after its performance test.

Installation of sewerage systems and their maintenance are carried out only by certified specialists.

Video description

The video shows how to correctly install an internal drainage funnel on a flat roof:

Let us add that funnels consisting of two parts are one hundred percent justified. They easily compensate for movements of the insulation when the air temperature changes.

There is one more point that concerns the effective operation of internal drainage. This is a connection of funnels to one riser. Usually, for this purpose, outlet pipe sections are used, which are laid under the ceiling of the building, but above the ceiling. Since the drainage system is a gravity flow system, these sections must be laid at a slight inclination of 1-2°. They must be insulated with noise-absorbing materials.

And one last thing. Equally important is the heating system of the internal drainage system. The most important thing is to prevent pieces of ice from getting inside the system, which will block the cross-section, leading to clogging. Therefore, it is near the water intake funnels that the heating cable is laid. There are many different layout options, one of them is in the photo below.

How to lay a heating cable near a water inlet Source stranapap.ru

General requirements of SNiP

When developing a sewer system project in an apartment building, all contractors are guided by state standards, building codes and regulations. They are the ones who can guarantee the installation of reliable and safe sewage systems. Indeed, if the rules are violated, problems such as blockages, flooding and unpleasant odors may appear in an apartment building.

Otherwise, blockages will form at the bends of the pipeline, which will complicate the operation of the system. According to SNiP, the drainage slope must be at least 3% for pipes with a diameter of 4-5 cm. For a pipeline with a diameter of 8.5-10 cm, the slope must be 2%. The outlet of the network should be connected to the external sewerage system at a right angle.

It is forbidden to change sewer pipes without the appropriate permission.

In addition, the following requirements are put forward for the installation of sewage systems in an apartment building:

- Taking into account strength, corrosion and load, cast iron, asbestos-cement, concrete or plastic pipes should be used for drainage in multi-storey buildings.

- The installation of internal communication networks should be carried out in a hidden way in installation grooves, shafts, channels and boxes.

- The pipeline should be protected with waterproofing roll material.

It is not allowed to lay sewer pipelines under ceilings in kitchens, in the floors and walls of living rooms. To ensure ventilation of the system, exhaust ducts should be installed at least 4 m above the roof level. In this case, the connection of the exhaust sewer and chimney ducts is not allowed!

Do-it-yourself storm drain

Installation

Drainage gutters are installed on the roof. Using special brackets

Please note that the tray must extend only 1/3 under the roof, otherwise water from the roof will not get into it. After installing the roof trays, drainpipes are installed. Whether there will be 2 or more is up to you

The pipes are attached to the wall with clamps.

Having finished with the drainage main on the house, you should install point storm inlets.

A pit slightly larger than a storm inlet is dug under the drainpipe, and a trench with pipes is laid from each storm inlet.

The first rainwater inlet is installed at the highest point of the site, the rest are lower. The slope of the pipes is made from the first to the next. In this way, gravity flow is organized.

For better fixation, the rainwater inlet is installed on a concrete solution or a cushion of crushed stone and sand. The trenches for the pipes are filled with gravel and sand.

After the pipes are connected to the water receiver, it is covered with a grill.

For your information. Point rainwater inlets are used not only to drain water from the roof, but also as an independent element. It is installed in a parking lot or playground at the lowest point.

Water drainage

It is carried out through drains that are connected to a general storm sewer:

In the vast majority, one common pipe is created that goes to the inspection well; such a line reduces the number of turns and pipes, which is quite important, since the system must be cleaned periodically. A pipe goes from the well to a reservoir or storage tank. Inspection (drainage) well

It is installed at the intersection of pipes. This is a hollow pipe with a bottom and a hatch. Stepping back from the bottom, holes are made for drains. The connection is made using rubber gaskets and sealant. The well itself is mounted on a concrete screed or a bed of sand and crushed stone. From the drainage well, the pipe goes to a storage tank, reservoir or drainage field. The reservoir collects all the liquid, produces a sediment where the debris settles, after which the water can be used for irrigation or discharged into a nearby reservoir; if there is none, then drainage fields are created that drain the water into the ground. External storm drainage can be installed in two ways.

Storm drains are part of the sewer drainage system or act as an independent structure.

In the first option, water is drained into laid pipes. Which involves creating holes and connections to the system. Installation is more complicated

It doesn't matter what type of drain you choose. The highway itself is laid according to one scheme

All trays are laid on a slope, like pipes. To install the trays, you will need to organize a trench larger than the gutter.

Laying starts from the highest point

The trays are connected to each other, the seams are treated with sealant.

It is advisable to install drainage trays with cement mortar to avoid them being squeezed out during the cold season and being washed away with large amounts of precipitation.

If drainage products are made of plastic, then after pouring the solution, you should immediately install a grate to correct distortions.

A plug is installed on the first tray. To the last sand trap. In the case of discharge into drainage pipes, sand traps are installed at each drain.

Water from surface storm drains is discharged into a reservoir or storage tank.

In the case when a surface outlet is connected to a hidden outlet, no outlet arrangement is required; a plug is placed on the last tray.