Fum tape is currently the most effective sealing material for pipe joints; it is resistant to chemically aggressive environments, heat-resistant and durable. It is widely used as a sealant when connecting water and gas pipes. From our article you will learn how to properly wind fum tape to ensure the most reliable connection and avoid common mistakes.

What is fum tape

FUM tape is a sealant, which is a narrow thin unsintered film made of fluoroplastic. The abbreviation “FUM” stands for: fluoroplastic sealing material.

All manufacturers of this sanitary film offer two types: white (thick) and translucent (thin). Both of these materials have a similar list of characteristics. Namely:

- are characterized by heat resistance;

- elastic;

- resistant to chemicals;

- average tensile strength 1.5 MPa;

- elongation at break not less than 200%;

- thickness 0.075-0.2 mm.

The film is made by rolling a fluoroplastic rope and wound onto polypropylene reels equipped with a lid. The width of the tape can be different: from 10 to 60 mm. To prevent the thin elastic film from sticking together during winding, one side of the tape is coated with lubricant. Most often this is medical Vaseline oil. There are also sealing films without lubricant.

Fum tape or flax

Tow, or flax, began to be used as a sealant for threaded connections long before the advent of fum tape. This is a natural material that is a waste product from the primary processing of flax. As a rule, tow is used to seal threaded connections of metal pipes together with silicone sealants - this method has existed for quite a long time and has been tested by several generations of plumbers.

Currently, most experts consider linen to be an obsolete material. First of all, this is due to the fact that working with tow requires some experience, while fum tape can be easily mastered even by a non-specialist. So, to lay tow on a thread, you must first evenly divide the flax into fibers, and then carefully place it in the inter-thread grooves, trying to prevent overlaps through the turns. After this, you need to evenly apply a layer of sealant to the tow, smoothing it with a brush

The amount of sealant is also important, since its deficiency reduces the tightness of the connection, and the excess, cut off by metal pipes when twisting, leads to the creation of excess stress, which in turn can cause destruction of parts both during installation and during operation

Other seal options

Of course, FUM tape is not the only existing option for sealing joints. Among others, linen tow should be highlighted, along with which various types of sealants, as well as plumbing thread, are used to fasten pipe parts. Let's consider their advantages and disadvantages in comparison with FUM.

Flax tow

Linen is also one of the most popular materials. Just like FUM, it is customary to wrap tow in a dense layer.

It is important to wind the tow carefully and tightly, filling the thread completely along the turns. The outside of the fibers is additionally coated with paint or sealant. This leads to the main disadvantage of this material. It should be borne in mind that if paint is used, the connections cannot be dismantled and the pipes will be unsuitable for repair.

Flax tow Source ytimg.com

Also, the disadvantage of this material is its relative fragility. Unlike tape, flax is subject to gradual decomposition under the influence of moisture.

The main advantages of tow in comparison with FUM are:

- Adjustability. After winding and securing the connection, it is possible to unscrew it at a slight angle without loss of tightness and the need to replace the sealing material.

- Reliable sealing, high degree of tightness and ability to absorb liquid.

- High resistance to various types of physical influences.

- Easy to disassemble the connection.

If you have to choose what is better to use – ribbon or linen tow, then there is no definite answer. As a rule, it is recommended to use tow for intermediate pipeline connections. The tape is more suitable for securing taps, meters and mixers.

Sealants

When using flax tow, for a better fit and seal, the joint is additionally treated with a liquid sealant.

Liquid sealants Source ad-cd.net

What is fum tape and what is it used for?

FUM tape, or fluoroplastic sealing material, is a thin synthetic sealant produced in the form of a tape, usually having a translucent or matte white tint. Due to the fluorine content, fum tape has quite high mechanical and thermal stability. It does not age, does not tear when stretched and does not lose its properties under the influence of an aggressive chemical environment or high temperature.

Fum tape is made by rolling out a rope of fluoroplastic-4 and wound into rolls of various widths (from 10 to 16 mm). Depending on the brand, this product may also contain various types of lubricants. There are three main brands of fum tape:

FUM 1: Used for sealing general industrial pipelines or for systems operating in aggressive chemical environments. It contains up to 20% petroleum jelly as a lubricant;

Scope of application

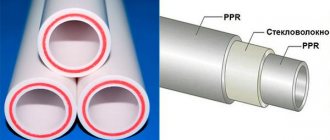

To manufacture the FUM seal, a synthetic polymer, polytetrafluoroethylene (fluoroplastic F-4), obtained by chemical synthesis, is used. Initially, fluoroplastic looks like white flakes, but during the process of thermal and chemical treatment, the raw material is sintered and pressed, forming an elastic fabric.

Due to their chemical and physical properties, fum strips are widely used in various household areas for hermetic insulation of threaded connections:

- Water supply and heating systems. Fluoroplastic tapes are used for connecting plumbing fixtures, heating radiators, and connecting pipes. Due to its water resistance, FUM is used when organizing external water supply from HDPE pipes and for hermetically sealing polymer fittings.

- Gas lines. Since fluoroplastic does not allow gases to pass through, it is used to provide reliable protection against leaks in gas lines. When connecting household gas appliances, cylinders and metering devices and other equipment, this tape seal is also used.

- Automotive technology. Due to its high degree of thermal and chemical resistance, fluoroplastic tape is used for repairs of any type of technical equipment. The tape sealant is also resistant to automotive fuel and oil.

As a rule, FUM tape is produced in white for water supply networks and in yellow for gas pipelines.

The product also differs by brand and grade, depending on its technical parameters and physical properties. A specific type of tape seal is designed for different conditions, where it will be most effective. Therefore, when choosing fum tape, you should pay attention to the color and technical characteristics in order to buy a product suitable for a specific type of installation work.

Properties and technical characteristics of fum tape

The main advantage of fum tape is its good performance characteristics, among which are plasticity, non-toxicity, high strength, chemical and thermal resistance, as well as high anti-corrosion qualities. In addition, it has a fairly wide range of operating conditions: pressure (under certain conditions) up to 41.2 MPa and operating temperature from - 60 to + 200 degrees Celsius.

Heat-resistant FUM tape is classified as a highly flammable and non-explosive material. The spontaneous combustion temperature of this product is +520 degrees Celsius. However, when the fum tape is heated to a temperature exceeding +260ºC, the fluoroplastic contained in it begins to release volatile fluoride compounds, which are highly toxic.

How to use

As mentioned above, in order to properly seal the connection of two pipes, you do not need to undergo special training. However, there are some nuances here, without which all efforts can be wasted; they will be discussed further.

To better ensure high-quality sealing, you first need to prepare the connection: remove all dirt and, if any, rust.

Next, wipe the joint with gasoline or any solvent and let it dry. After the pipes are prepared, the tape is wound onto the external thread, as we twist it, clockwise.

You don’t need to pull the tape hard, it just might break, just make sure that it doesn’t dangle, the tighter you screw it, the better the sealing will be. Then pull out the end of the tape so that it does not interfere with screwing another element onto the thread.

Please note: if it becomes necessary to unwind the connection after you have wound the FUM tape, then you will have to wind it again from the beginning, because in this case, the tightness is lost

So, if you are dealing with a metal-plastic or plastic pipe, feel free to use FUM tape. When sealing metal pipes, you need to use tow, taking into account the nuances of its winding.

The cost of the tape depends on the manufacturer and width, for example, 15 m of tape with a width of 19 mm will cost 65 rubles. It is widely represented in all construction stores and is affordable for everyone. Choose a tape according to our recommendations, use it correctly and then not a single extra drop of water will spoil the operation of your plumbing.

Cold and hot water

BUT wait, why use tape or thread then? Why were they created at all? It's simple - they are perfect for waterways. Where there is a constant temperature.

For example, for cold water. Where there is no thermal expansion and then cooling, there are no high temperatures. It seals just fine.

For hot water you need to think about it. It is clear that the pipes are almost always heated; they are hot in one position. No one will turn them down, the temperature is also constant - THIS IS A PLUS. BUT, the water may be turned off for a while, for example, during seasonal testing, then the pipes may also cool down and leaks may appear at the joints. Also, over time, FUM seals can dry out, as happened to me.

Now we are watching a useful video.

EVENTUALLY. Where there are no high temperatures, no expansion of metals, FUM can and even should be used, it’s an excellent means. For heating and hot water, I would advise you to use Paklya with sealing paste, it has been working for decades.

This is where I end, I think my materials were useful to you. Read our construction site.

Specifications

FUM tape, the technical characteristics of which meet the requirements for the quality of work at a particular site, will serve flawlessly for at least 10 years. In order to accurately select the most suitable product, it is recommended to familiarize yourself with the characteristics of the 1st and 2nd grade films.

| Characteristics | FUM-1 | FUM-2 |

| Film thickness (mm) | 0,1-0,14 | 0,035-0,2 |

| Film Width (mm) | 10-60 | 5-60 |

| Elongation at break (%) | 100-200 | 100 |

| Availability of lubrication (%) | 20 | 0,3 |

| Maximum tensile stress (kg/cm2) | 40 | 60 |

It is difficult for a beginner in plumbing work to understand all the intricacies of choosing sealing films the first time. Therefore, you can rely on the recommendations of experienced craftsmen and use the same materials in your work.

Questions often arise about which films to use when installing household water pipes. These are the most popular plumbing jobs, during which mistakes made will be noticeable immediately after water is supplied or will be discovered in the near future.

The most suitable fulente for water is as follows:

- for small threaded connections - width 12 mm, thin (0.075-0.1 mm);

- for large threads - width 19 mm, thickness 0.12-0.2 mm.

We have prepared a detailed guide to choosing and using fum tape for novice craftsmen and those who are used to doing everything in the house with their own hands. Our advice may also be useful to experienced plumbers, because refreshing your knowledge is never a bad idea.

From our guide you will learn who and when invented fum tape for water, what does Apollo 11 have to do with it, how to properly wind fum on a thread and - most importantly - how to avoid leaks.

Go!

Just one tug: a brief history of fum tape

There is not much information on the Internet about the history of the invention of fum tape. There is only one source - Wikipedia. From there you will learn that the material on which the fum tape is made - polytetrafluoroethylene, PTFE or PTFE, was accidentally discovered by one of the employees of the chemical giant DuPont back in 1938. And registered under the trademark “Teflon”. You will learn that fluoroplastics came to the USSR on American ships during the Second World War, and their production in our country was mastered and brought to Union scale at the Kirovo-Chepetsk plant.

We went deeper. What can you do, the craving for interesting facts about the simplest and most common things is inextinguishable in the Santekhmaster Group team.

So. The PTFE material was actually invented by DuPont. Its extraordinary properties became interested in the talented chemist and experimenter Bill Gore, who had a master's degree in physical chemistry and led research at DuPont for 16 years. Bill was truly sick of chemistry; he managed to “infect” his entire family with this science. The company became cramped for him, he dreamed of his own business, and one day Bill Gore left DuPont to open his own company. He did this first in the basement of his house. And then he built one of the most successful American companies in the world, WL Gore & Associates, which is still led by his son, Bob Gore.

PTFE, in the hands of the Gore family, developed its miraculous properties and found application in medicine, heavy industry, and the space industry. PTFE cables were used during the Apollo 11 space mission. A Gore-brand cable connected the craft to a seismograph placed on the lunar surface.

It would seem that if your product has been in outer space, your homeland (including) is proud of it, and the whole world is not so jealous, you can calm down. Launched production and rested on your laurels. But it was not there. Just after the Apollo 11 flight, WL Gore & Associates received a very unusual order. The company's client, in order to develop a new market, needed a cheap, but at the same time durable plumbing tape. And since the Mountains could make cables “for the moon,” then let them make a tape for plumbing.

Bob Gore, who by that time, by the way, was still quite young, had become the head of research at his father’s company, took this order as a challenge. It took a long time to get a thin elastic tape out of a PTFE bundle. And although Bob had all the company’s power at his disposal, he felt that complex technology would not help him; the secret of PTFE lay in something else. The truth is somewhere nearby, as they will later say in one world-famous series.

What was Bob Gore doing? He heated the PTFE bundle and very slowly and carefully tried to stretch it. The tourniquet obediently stretched a couple of centimeters and then broke. When Bob was completely tired of all this - but he was not ready to give up the idea and the order - he decided to experiment. “If before we were slowly stretching the tourniquet,” thought Bob, sitting one night in the basement laboratory of his house, “now I’ll just make a jerk.”

And did. The PTFE harness not only did not break, but stretched - easily and simply - to the entire width of Bob's arms. This movement - the jerk - then formed the basis of the PTFE stretching process, which reaches 1000%.

The experiment, by the way, turned out to be not only revolutionary, but also fun. The next day, at the WL Gore & Associates production facility, everyone was pulling the harnesses in different directions. And Bob’s father, Bill Gore, could not contain his delight after his son’s report. He immediately understood the possibilities of the new form of PTFE and what things could be created based on it. Gore Jr.'s discovery was a turning point in both his career and the history of WL Gore and Associates. Thanks to him, all kinds of medical implants, ultra-durable waterproof fabric for clothes and shoes GORE-Tex and, of course, sanitary fum tape have appeared in the life of a modern person.

How to choose fum tape for water?

Today, fum tape is produced by manufacturers around the world. Italian FADO and VALTEC tapes, Belgian HPX, and Russian BVB-Alliance are considered to be of decent quality. When choosing fum tape, pay attention first of all to these brands.

In general, fum tape is widely represented on the Russian sealing market. Its packaging is standard - a plastic reel with white tape inside. The tape itself - and this is important - differs in width, thickness and length. The length for choosing a beginner is not so relevant, the only question here is consumption, but the thickness and width play a role when winding on a certain type of thread and the scope of application of the tape.

Let's tell you in more detail.

Fum tape can be wide and narrow, thick and thin. A narrow tape is considered to be up to 12 mm, wide - up to 19 mm and more. A thin tape is one that is translucent, i.e. an object is visible through it. But it is not transparent, it does not look like tape. The thickness of the thin tape is the same for all manufacturers - 0.12; 0.75 mm. Thick tape is denser, its thickness is 0.1-0.2 mm.

Why would a beginner need to know this? Then, different threads are sealed with different tapes. For large 1-inch threads, it is better to use a wide, thick fum tape. It is easier to wind and costs less. But for small threads, for example, ¼ inch, a thin, narrow fum tape is suitable, which is first stretched to the state of a thread, placed in each thread, and then several layers of the entire width are made on top.

A good fum tape has the following characteristics:

• high elasticity and strength; • heat resistance (from -40˚C to +150˚C); • chemical resistance to solvents and acids; • environmental friendliness; • resistance to fungi and bacteria; • protection of the thread and the entire connection from corrosion; • unlimited service life.

How to find such a tape? For a beginner - only through experience. If you don’t find the manufacturers we listed above in your local store, buy several tapes of different thicknesses and widths to test them for strength and evaluate the result in advance. Let your tool suitcase at home have at least 4 fum tapes of different models. If you are going to seal the threads with tape for the first time, buy a few fittings as well. Assemble the connection empty to understand how many turns need to be made on the working connection, how to wind it correctly and whether it is convenient for you to use fum tape in general.

Scope of application and winding

Traditionally, fum tape is used to assemble home water supply and irrigation pipelines on the site. It also copes with other simple tasks:

— replacement of rubber gaskets;

— repair of mixers;

— plastic thread seal;

— minor household repairs (as a more aesthetic substitute for electrical tape).

We recommend that the home handyman seal with fum tape those connections in the water supply system in which leaks are easy to notice and fix. But it is wiser, at least at the beginning of your plumbing practice, to use fum tape in safe places - when assembling an irrigation pipeline or for repairing faucets and shower hoses. Get your hands on it first, and then start assembling critical systems.

Winding tactics:

For large threads (but not larger than 1 inch). Leaks when working with water tape occur due to improper winding. Follow these tactics and everything will work out.

- Take a tape 0.1-0.2 mm thick and 19 mm wide.

- Prepare the carving. If it is not new, clean it and wipe it dry.

- When winding the entire width, secure the beginning of the tape to the thread and press.

- Stretch the tape with force and lay it with tension along the thread so that it falls into the turns. Those. The first few layers of tape should fit the turns, they should be visible.

- You cannot wrap the tape without tension, as you would when wrapping an adhesive plaster around a cut finger. In this case, the tape will quickly slide off the thread and leakage is inevitable.

- Make approximately 5-6 turns, assemble and tighten the connection.

If you choose a thinner and narrower tape to seal large threads, it will take longer to wind. Approximately 13-14 revolutions.

For small carvings.

- Take a tape with a thickness of 0.12 or 0.75 mm and a width of 12 mm.

- Prepare the carving.

- Pull the ribbon out until it becomes a thread.

- Place the thread in each turn along the thread.

- Do this in several layers.

- Then wind the entire width of the thread and secure.

- It may turn out to be more than 20 revolutions.

- Assemble and tighten the connection.

The number of revolutions is impossible to predict. There is no universal advice on how to use fum tape for water. It all depends on the size, material, condition of the thread and the type of tape. High-quality fum will require less consumption. The one that breaks more often during winding will have to be reinforced with additional layers. In any case, fum tape cannot be called economical in consumption. Especially if you also take into account the expense for compaction training.

Other disadvantages of fum tape

Impossibility of adjustment.

After assembly, the connection sometimes needs to be “tightened” and adjusted. This is impossible with fum tape. When the thread is untwisted, the tape inside breaks and the connection loses its tightness.

Thread requirements.

Fum tape loves clean new threads. Preferably with notches so that the tape does not slip. For worn threads, regardless of size, it is recommended to use a thicker tape. For large-diameter threads, fum tape is not economical in consumption.

Quality.

You won't know until you buy it. A reel of fum tape can easily be called a surprise box. To determine whether the material can be worked with, stretch the tape slightly before winding. Does it tear quickly? Get a new coil. It’s not for nothing that we advised buying a lot at once.

Price.

Fum tape is considered one of the cheapest materials. This is what attracts newcomers. However, not everything is so simple. The price range for fum is very wide - from 20 rubles to 120. Taking into account the uneconomical consumption, the cost of one connection with a fum tape will be equal to the cost of a connection with sanitary thread, which is a more modern material and is more expensive.

Stock up on various sealing materials. Replenish your collection with modern sealants: winding, anaerobic sealants, threads. Don't rely on one remedy, nothing is universal. And try to keep up with market news.

Which is better linen or fum tape for water?

A professional plumber always has different types of seals on hand:

- fum tape;

- flax and sanitary paste;

- threads (type “Tangit”);

- anaerobic sealant.

The craftsmen know that all seals, when installed correctly, perform their task 100%. But to do this you need to know how to use it, what to use and under what circumstances. The abundance of modern sealing materials has displaced flax from its leading position. But not all masters agree with this.

The fact is that in past decades flax was used together with red lead or oil paint. Today – with Unipak plumbing sealing paste. Its main task is to prevent the flax from drying out and rotting. Connections made using these materials can be adjusted (axially shifted) by 45° without loss of tightness.

Benefits of flax:

- inexpensive price;

- suitable for sealing threads of any diameter;

- the connection will be good regardless of whether the base surface is wet or dirty.

The disadvantage is that any connection made with flax subsequently requires additional twisting and tightening. Another “minus” of flax is that it is not very convenient to work with: the fibers delaminate and cling to clothing and the tools and materials used.

Rules for working with fum tape

The first rule of working with fluoroplastic seals is the correct choice of material. For high-quality connections, only those films that stretch well are suitable. All the rest will eventually begin to crack and turn into crumbs.

In order to avoid installation errors, you need to know how to wind fum tape onto a thread. Masters advise you to remember a few simple rules and adhere to them in your work.

There are no recommendations for the number of turns to be wound. You need to look at the parameters of the tape: its thickness and width

You also need to pay attention to what kind of thread it is. When winding the film, it is slightly stretched. The tape should fit into the grooves of the thread and fit tightly around them. If the film breaks during winding and stretching, place the free end on the thread and continue working. Winding is carried out until all the threads are hidden under the tape.

Its ribbing should look smoothed, but visible through the seal.

Masters claim that the skill of using fum tape comes quickly. It is enough to practice several times and understand the principle of working with this material.

Basic properties

Fluoroplast-4 is the basis for FUM tape. Strips of this material are rolled out under a press and then wound to form rolls. Roll width is from 1 cm to 1.6 cm.

There are 3 main types of FUM tape:

- FUM 1 – using Vaseline lubricant (20%). For industrial pipelines, as well as in aggressive environments;

- FUM 2 – without lubrication. Where there are strong oxidizing agents in the system;

- FUM 3 – for systems with a non-aggressive environment.

Main properties of FUM tape:

- Non-toxic;

- Durable;

- Plastic;

- Chemically resistant;

- Thermally stable;

- Corrosion resistant.

Application temperature – up to 200°С, minimum temperature – from 60°С.

The following characteristics are used for the FUM-1 tape:

- Thickness – 0.1-0.14 mm

- Width 10 mm, 15 mm, 20 mm, 60 mm.

- Breaking stress 40 kgf/cm2

- Elongation at break 100%

- The percentage of Vaseline lubricant is 17-20%

FUM-2 is characterized by:

- Large range of thickness – 0.035 – 0.2 mm

- High tensile stress – 60 kgf/cm2

- Lubrication rate less than 0.3%.

FUM-3 represents average indicators, because These are the cut edges from the first two brands.

Flax paste effectiveness of the old method

Plumbing flax (or tow) was actively used in the Soviet years, but has not lost its popularity today, despite the wide variety of modern seals. To seal threaded connections, strands of flax were used in combination with red lead on drying oil or special oil paint. The main active ingredient of both formulations is lead. It is rarely found in modern analogues, and the sealant itself is not able to fully combat corrosion.

As an alternative, gray sealing pastes are used. Dry winding is strictly prohibited. The paste prevents flax from rotting and drying out, and plays an important role in water. Without its use on threaded connections with hot water and heating, the flax strand dries out, crumbles, and leaks appear. A black coating with traces of corrosion will form on the surface of the cold water pipeline and a leak will occur.

In direct contact with water temperatures above 90°C, tow shrinks and loses its properties, which is why it is so important to cover it with paste in order to increase the temperature barrier and the service life of the seal.

When choosing a high-quality material for sealing threaded connections, experts recommend choosing Unigarn flax and Unipak sealing paste. This seal can be easily dismantled and replaced if necessary.

Here are the main advantages of using sanitary flax with paste for hot water taps:

- 1. Possibility of winding on pipes of any design and diameter.

- 2. Winding on dirty, wet and old surfaces.

- 3. Adjustment (regulation) of connections at 45° and higher.

- 4. Ability to withstand temperatures up to 140°C, used for heating systems.

- 5. Long service life if the correct winding technique is followed.

- 6. Cheap material. The price of 100 g of flax does not exceed 100 rubles, a good paste costs 200–250 rubles. For home use, such a kit is enough for a large number of connections.

It is also necessary to remember that flax is a natural material, it does not contain harmful impurities, and is suitable for connecting threaded connections with drinking water.

The material also has its disadvantages:

- the paste stains your hands and leaves marks on white propylene pipes;

- inconvenient for winding on plastic and small threads;

- flax fibers get tangled and create inconvenience when working.

Working with plumbing flax requires skill and knowledge. The main thing is to attract the tow well, hide the ends of the strands, ensure complete closure of the threaded connection and do not skimp on the sealing paste.

Where is it used?

Due to its properties and characteristics, FUM tape is used in most situations where sealing treatment is required.

- Water pipes . The most important thing that FUM tape is used for is sealing water connections. The material is water-repellent, which makes it almost indispensable for fastening water pipes and parts during the assembly and installation of equipment.

- Gas pipeline . The film can be made gas-tight, and it can be used to install gas appliances and meters. However, not every FUM tape is suitable for this purpose; you need to purchase a specialized tape for gas.

- Technique . The material is characterized by resistance to various types of influences, therefore it is actively used to repair internal mechanisms of cars and various technical devices.

Heating pipes fastened with tape Source re-st.ru

Purpose of the FUM tape

We have already described what fum tape is and where it is used in previous articles. An interesting question - how to wind the fum tape hermetically - still remained open. In fact, there are just a few things to keep in mind. For example, you need to start winding the tape clockwise, that is, the way an external thread is twisted. At the same time, try to pull the fum slightly so that the winding fits tightly to the thread. Wrap in several layers, depending on the diameter of the pipe: for pipes up to 40 mm, 6-7 layers of durable fum tape are needed, but if the pipe diameter is less than 25 mm, 4-5 layers will be enough.

The following video explains in more detail what FUM tape is and how to use it.

Winding tape onto pipe threads

This operation is always performed using an external thread. If repairs are made by replacing the fitting, the pipe threads must be thoroughly cleaned of dirt and rust, degreased using acetone or white spirit, and dried in air for about 10 - 12 minutes. How to use a pipe burner to ensure its effectiveness:

- the seal must be wound onto the thread from its rear end;

- the FUM tape is applied in the direction of its descent, that is, its end should be located in the direction of screwing on the fitting;

- winding is carried out with tension, ensuring a tight fit of the pipe thread profile; it is better to allow the tape to break than to perform loose winding;

Important! The threads are notched in the axial direction to prevent rotation of the sealing material when screwing on the fitting.

If there are no such notches, you need to do them yourself.

FUM tape for pipes is a modern and most commonly used means for sealing joints in pipelines for various purposes. FUM cord products that have appeared in recent years do not provide any special advantages either in application technology or in efficiency.

To understand how to use FUM tape for gas pipes, you need to take into account the characteristics of the material and apply it in the appropriate way.

Watch the video

Alternative materials – linen tow

Various seals are used, which include bast fibers in the form of strands and various sealants.

One of the first sealing materials to find widespread use in pipeline installation is tow. This is still the name given to flax fibers in the form of strands wound on the external thread of a pipe.

In this case, it is important to wind it carefully in turns, filling out the full cutting profile. For more reliable sealing, the winding of tow is covered with additional materials, from thickly rubbed paint to specially developed sealants.

We have already noted that with fairly high efficiency, connections using paint become practically permanent, and pipeline systems are of little use for repair.

Types of fum tape

There are three types of sanitary fum tape. Each brand is intended for use at sites with different work requirements. The numbers indicate the grade of the product. 1 – first grade, 2 – second grade, etc.

- Brand "FUM-1". Designed to perform plumbing work on utility lines for domestic and industrial purposes. Resistant to aggressive environments, heat-resistant (begins to melt at temperatures from 520°C). Contains lubricant: petroleum jelly.

- Brand "FUM-2". Sealing films of this type are intended for use on objects that interact with oxygen and oxidizing agents. Does not contain lubricant.

- Brand "FUM-3" are narrow strips, which are sections of the edge parts of films of the first two types. It is often used to seal threaded connections when installing domestic lines.

Using FUM for a gas pipeline

To fasten gas pipeline parts and install gas equipment, you should use only special FUM tape for gas. It must be supplied with a certificate of conformity confirming its suitability for use on gas pipes.

The special film for gas is yellow. It is made wider - up to two centimeters in width.

Yellow FUM tape for gas Source megastroy.com

The use of the material is possible only when sealing can only be achieved using a sealant. In the case of rubber hoses, as well as metal hoses, the sealing function is provided by a special gasket. In this case, the additional seal will not add tightness to the connection, and may even break it, as it will interfere with the tight fit of the gasket.

Advantages and disadvantages of fum tape

PTFE fum tape is sold in any building or household materials store. Therefore, one of the main advantages of sealing film is accessibility. One can also note the low cost of this material. It is cheaper than various types of plumbing threads.

Craftsmen also note such advantages of using films as speed and ease of installation. But to achieve these results, you will need to practice winding the tape on threads of different calibers. After acquiring the skill, working with this material will be easy, simple and pleasant.

The most important advantage of fum films is that connections made using these materials can be quickly and easily disassembled. Including several years after completion of installation work.

Flaws:

- low aesthetics of the joints (the film partially protrudes beyond the outer boundaries of the fittings, which gives the pipeline an untidy appearance);

- when tightening the connections, the tape may “move out” and partially enter the internal cavity of the pipeline;

- high risk of leakage.

Due to the fact that not everyone knows how to properly handle sealing films, it is not recommended to use these materials when installing complex pipelines. However, even in the absence of winding skills, fluoroplastic seals can be safely used on open structures, the distinctive feature of which is free access to joints. These can be garden water supply systems, temporary water supply lines.

Advantages:

- hands do not get dirty during work;

- optimal for working with thin-walled fittings;

- Can be wound on dirty and wet surfaces;

- Excellent for sealing small threads;

- ideal for sealing plastic threads when installing polyethylene pipelines.

Pros and cons of using

The main advantage of choosing tape is its availability. FUM is sold at a low price, cheaper than flax tow and most other sealants used in plumbing.

The material is characterized by ease of installation. With proper skill, winding the tape occurs in a matter of seconds, but for this you should practice winding it on connections of different diameters for some time.

An important advantage of using tape is that the parts fastened with it can be easily disassembled. The connections do not freeze tightly; they can be disassembled even years after installation.

The main disadvantage of the material is that it is not the most reliable of seals, therefore, as a rule, it is not used for industrial installation. However, for household repairs the hermetic properties of FUM are quite sufficient.

Another disadvantage is that the tape often protrudes outward from the joints, so the pipes may look sloppy because of this.

Threaded tapeSource sdelairukami.ru

How to wind FUM tape correctly

To make a threaded connection airtight, you do not need to have any special skills. However, this matter still has its own nuances that you definitely need to know about.

So, to begin with, the fum tape is wound onto the external thread clockwise, that is, in the direction of its twisting. While winding, you need to slightly stretch the tape so that the resulting winding is tight enough and does not dangle. The more the tape is stretched, the better the connection will be, but do not forget that if the tension is strong, the fum tape may break. In addition, the end of the tape must be brought out in such a way as not to interfere with the process of winding the connecting element.

When working with fum tape, you should also take into account a number of its physical features. Firstly, it is quite slippery, so it can cause some inconvenience during installation. Secondly, after packing the tape and tightening the thread to the end, it can no longer be turned back without losing the tightness. Therefore, if it becomes necessary to loosen a connection assembled using fum tape, it can no longer be tightened back - such a connection will need to be disassembled and repacked again.

What brands of tape are found in stores?

The tape is divided into classes:

- 1 class. This type of product belongs to professional materials;

- 2nd grade. It is designed to work with strong oxidizing agents;

- 3rd grade. This type is created for industrial use.

The first type of tape contains medical vaseline oil GOST 3164-78 from 17 to 20%. The second type of product does not contain such lubricant. But the third type is the components of classes 1 and 2.

But there is also 4 more types of tape, this is a simple tape, it is often bought by consumers, it naturally cannot withstand any aggressive environments, alkalis and solvents, but it is ideal for sealing taps.

How to use FUM tape correctly

First you need to prepare the surface for the tape. If the pipes are new, they still need to be treated with gasoline or solvent. If the pipes are old, then you need to thoroughly clean the threads and treat them with a solvent.

Once the threads are clean, start winding the tape. Make the twist along the thread. But do not twist the material, make a rope out of it, try to twist it so that the product fits into the grooves of the thread. And every second turn overlapped the first, that is, wind without gaps.

Wrapping must be done directly from the reel; do not cut off pieces of tape, otherwise the work will not be done well. Only by winding from a reel can you create the necessary tension in the material and wind it tightly. Then take the second part and start screwing it onto the resulting thread section. You will have a part that turns tightly, but make an effort. The tighter it is twisted, the more securely it will hold.

What actions should be taken when the tape is wound, instructions

First make sure that the part is tightened firmly. If you notice that it was easy for you, then you need to apply another layer of tape. Then tighten it and tighten it with a wrench. Now the spin has happened efficiently. Next, you need to turn on the tap and carefully check for any leaks.

Why is FUM tape so popular?

It's very simple: you wind the elastic material. When you start twisting the parts, the tape begins to fall apart and penetrate into all the hidden corners of the second thread, that is, the internal thread. As a result, it tightly seals all the cracks and there is simply nowhere for water to flow. This is an ideal material, easy to use.

Tags:

how many layers of fum tape to wind, in which direction to wind the fum tape, in which direction to wind the fum tape, in which direction to wind the fum tape, in which direction the fum tape is wound

https://remstroyvopros.ru

What to choose FUM or LEN

Linen, or tow as it is called, is an outdated material for sealing.

The process of its application is quite labor-intensive and takes place in several stages. At the first stage of winding the connection of tow, you need to divide it into fibers and lay it in furrows, making sure that there are no overlaps.

In the second stage, apply the sealant using a brush.

Experts do not recommend using tow without experience working with this material, and here’s why. The use of this material requires some features:

- If there is not enough tow, the connection will depressurize

- And if there is an excess amount, during twisting it is cut off by pipes, and excess stress is created - hence various deformations of parts during operation.

The only case where it is better to use tow is when working with metal pipes, which are often found in old houses.

Santehgel and anaerobic gel sealants

Plumbing gel sealant is a modern means for high-quality and reliable sealing of threads on pipes. The polymers included in this material provide a reliable one-piece seal. The substance hardens after application and does not shrink or expand.

Santehgel has a high level of stability and is able to withstand sudden temperature changes. Does not collapse under high pressure. Thanks to these properties, sanitary gel is used for any connections on gas and water pipes.

Three types of sanitary gel are produced:

- In green tubes - intended for subsequent easy dismantling.

- In blue tubes - provides for medium dismantling.

- In red (Stop Master Gel) - for such material it is necessary to carry out dismantling with heating.

Installation using sanitary gel

This sealant is very practical and easy to use. Shake the tube well before use. Then the sanitary gel is applied over the entire circumference of the joint. This is done using a small brush. The applied layer of gel sealant must be thick and uniform.

After application, the structure is assembled. Any remaining gel on the outside is immediately removed. The hardening and polymerization time of the sealing material is 20 minutes. However, experts recommend keeping it for at least half an hour.

Important! Sanitary gel should only be applied to a thoroughly cleaned and degreased surface. This product is better and more practical than fum tape and can be used for connections in various systems - gas or water supply.

What is the best way to seal threaded connections: fum tape, flax or gel sealant - Video

In conclusion, I would like to note that working with modern seals requires certain skills. Various factors must be taken into account to make a quality connection. Therefore, it is better to consult before starting work and entrust it to specialists. They will select the appropriate material and be able to correctly wind the FUM or tow. Only in this case will the joints on pipes for hot water or gas be reliably sealed and unexpected leaks will not occur.

Share with friends

Similar articles