Currently, water supply pipes are made of metal, but plastic pipes for water supply are becoming increasingly popular. They are distinguished by much higher manufacturability, durability and do not become clogged with plaque on the internal walls.

Today's building materials market is saturated with pipes made from various plastics.

PVC water lines

For manufacturing, polyvinyl chloride is used, the manufacturing method is extrusion. PVC plastic pipe has the following characteristics:

- service life – up to 50 years;

- density – 1.41 g/m3;

- ability to burn – non-flammable;

- elongation when heated – no more than 5%;

- The value of relative elongation at break is no more than 0.2%.

PVC plastic water pipes in the pressure version are equipped with a socket at one end to simplify installation. A rubber O-ring is installed in it. During assembly, no additional devices or equipment are used, which makes it possible to install the water supply system yourself.

The plastic material does not rot or corrode, so the water supplied through such a system is safe for use. The surface in contact with the liquid is smooth and always remains clean, since it does not deposit any substances of either organic or inorganic origin, which significantly increases the service life.

Their properties meet all the requirements of sanitary standards for the transportation of drinking water. At the same time, the equipment with additional elements for a wide variety of purposes allows you to create plastic pipeline networks of any degree of complexity.

PVC pipes are resistant to harsh ultraviolet radiation, which makes it possible to install open areas of external networks without additional insulation.

The disadvantages include low heat resistance, which allows their use at temperatures of no more than 65 degrees. Which prevents their use in networks with hot liquid. At the same time, when operating at temperatures below -10 degrees, the water supply system must be carefully insulated.

PVC markings and properties

Markings containing the following information are applied to the outer surface:

- PVC material type.

- A type of socket connection.

- Dimensions based on outer Ø and wall thickness.

- Intended use.

- Regulatory documentation (GOST or TU).

- Manufacturer's name and logo.

In addition, color design matters:

- Gray or corrugated black pipes are used for laying internal networks in free-flow or pressure form.

- Yellow or orange colors are used for external water supply or sewerage networks.

- White or blue colors of PVC pipes indicate the priority of use for casing water wells.

- Corrugated pipes have an inner surface of light gray or white. Their main area of application is deep highways, since these plastic products are characterized by increased strength in the radial direction.

Strength indicators of PVC pipes

According to the strength characteristics, polyvinyl chloride pipes are divided into three categories:

- light series, designated "L";

- middle series – “N”;

- heavy – “S”.

Belonging to the category indicated above prescribes the possibility of use for highways with different depths.

Spiral reinforced PVC pipes are produced by applying osneova to a spiral frame. This design allows them to be used on pipeline sections in the presence of vibration loads, for example, in a network adjacent to a pump, where it plays the role of a shock absorber.

Production is regulated by GOST 51613-2000, and the size range is specified in GOST 18599-2001.

The dimensions of plastic pipes are specified by GOST 28117-89 and represent a line of Ø (dia.) in the range from 5 to 630 mm with walls from 1 to 83 millimeters. In addition to being used in plumbing systems, they are used for laying electrical networks, transporting aggressive media, and also as a structural basis for the manufacture of various products.

We want to draw attention to the fact that a PVC plastic pipe is not suitable for hot water supply, it can only be used for cold liquids and when used at temperatures below 10 degrees it must be insulated.

Polypropylene

Currently, many types of plastic pipes made of polypropylene are used, differing in many factors, including technical characteristics, purpose, color and quality.

Labeling, advantages and disadvantages

Polypropylene pipes differ in consumer properties and are marked with the designation “PN”. There are several varieties of them:

- PN 10 . Designed for systems with pressure up to 10 atmospheres. In this case, the maximum permissible temperature of the circulating fluid is +45 degrees. Structurally endowed with thin walls, they do not have high strength. Therefore, their main area of application is water supply systems for cold water with pressure restrictions.

- PN 16 . As can be seen from the markings, they are able to withstand pressure up to 16 atmospheres. The permissible liquid temperature is +60 degrees. In this regard, we can conclude that they are also suitable only for cold water supply systems. It should be noted that polypropylene has the inherent ability of temperature deformation, which finally removes them from the list of materials for the installation of hot water supply and heating networks.

- PN 20 . They can easily withstand pressure up to 20 atmospheres at a temperature of +95 degrees. Such characteristics mean that they can be used for heating and hot water supply, but with certain restrictions. The high capacity for thermal deformation leads to the fact that at temperatures close to the limiting values, individual sections can sag and sag.

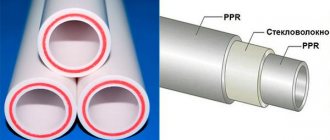

- PN 25 . Technical characteristics allow them to be used for heating without serious restrictions. The technology for manufacturing polypropylene pipes of this design involves the use of a reinforcing insert, which increases performance characteristics. For this purpose, nylon fibers are used, as well as aluminum foil inserts. In addition to imparting greater strength, reinforcement reduces susceptibility to deformation. This explains the widespread use of polypropylene pipes in high-pressure heating and hot water supply systems.

For successful installation, various additional elements are used.

Experts identify a number of parameters that distinguish them favorably:

- The life cycle of polypropylene is about 50 years. Manufacturers declare that the service life of plastic water pipes in cold water supply systems can be increased to 100 years.

- Pipes are not prone to the formation of limescale on the inner surface, and are also resistant to biological substances.

- Carriers made from this material have noise-absorbing properties. Therefore, they are used to install water pipelines operating under pressure, the passage of liquid through which is often accompanied by noise.

- Having low thermal conductivity, polypropylene pipes are not covered with condensate.

- Easy to install. Welding is used during assembly. One acquaintance with this procedure is enough to master this simple process.

- Polypropylene pipes do not require additional maintenance during operation.

However, like any product, polypropylene also has some disadvantages. To complete the picture, we suggest that you familiarize yourself with them as well:

- High linear expansion value. Therefore, polypropylene systems must be constructed using deformation compensators.

- Low heat resistance. Heating requires additional insulation.

- Low deformation during operation does not allow their use when installing complex communications without additional parts - fittings.

- Polypropylene is not resistant to ultraviolet radiation. Its use for open outdoor systems is not recommended.

- The presence of certain shortcomings in operational properties is compensated by low cost.

Depending on the design features of the system, the diameter of plastic pipes can be 20 or 25 millimeters for wiring. For the riser you need to take dimensions of 40 or 50 mm. Larger Ø (dia.) are used for intra-house and main wiring in the basement of a multi-storey building.

Watch the video

Polypropylene pipes for water supply and heating systems. Types and benefits // FORUMHOUSE

In addition to external text markings indicating the size, type and manufacturer, color markings are used. Polypropylene pipes are painted as follows:

- white - used together with gray ones for indoor and apartment plumbing and heating;

- black are used for non-pressure sewers operating without pressure;

- Green polypropylene pipes are so favorable in terms of strength characteristics and price that many summer residents simply do not look at other options.

A feature of white pipes is their poor temperature resistance to low temperatures. Already at zero degrees the material begins to crystallize and lose flexibility.

Standard solutions

As a general rule, pipes with a diameter of 10 or 15 mm are selected for water supply, while the diameter of the pipes for the riser should be 25 mm. When purchasing pipes of the specified diameter, be prepared for the fact that these products do not have pinpoint accuracy. That is, a 10 mm pipe can actually have a diameter of 10-12 mm.

Complex plumbing work requires the use of pipes of increased diameter. They are optimal for operating a system with numerous joints, turns and permanent changes in water pressure.

To summarize: when choosing, pay attention to the following points:

- The more complex the design of the water supply system, the larger the diameter of the pipes.

- Hot water pipes require pipes with reinforced walls.

- The higher the water consumption rate, the larger the diameter of the pipes.

It is impossible to install a modern plumbing system without understanding the size of the pipes. The cross-section of such pipe products is of utmost importance.

Water supply made from polyethylene pipes

It is ethylene gas polymerized at high pressure.

The process occurs in the presence of catalysts. It is noteworthy that the dependence of the mechanical properties of polyethylene on pressure during the production process is inverse. The higher the pressure in the container, the lower the properties of the final product. Plastic pipes made of high-density polyethylene are not used for the installation of main pipelines.

They can be used in pressure communications, increasing the wall thickness, which entails an increase in the cost of products. In turn, HDPE pipes are successfully used in main pipelines not only for liquids, but also for gas.

Cross-linked polyethylene

With a further increase in pressure in the chamber, the molecules, which are long chains, begin to form cross-links with each other. This leads to the formation of a spatial structure in the form of a network, which leads to a significant increase in mechanical properties.

The result is a material that can withstand temperatures up to 95 degrees, which allows them to be used for hot water supply, while at the same time, a plastic pipe made of HDPE is resistant only up to 45 degrees, that is, it is only suitable for transporting cold liquid.

To further improve the mechanical properties, reinforced pipes are produced. Glass fiber threads are used as a reinforcing layer. Such pipes are already suitable for transporting liquefied gas under high pressure, or they are used in particularly critical areas.

The main regulatory document used in the production of polyethylene pipes is GOST 18599-2002.

Marking

The marking is applied to the outer surface and includes the following information:

- brand of polyethylene;

- the value of the dimensional ratio (ratio of Ø (dia.) to wall thickness – sdr);

- indication of nominal Ø (dia.);

- wall thickness;

- purposes for drinking or technical liquids;

- designation of the technical document used in production (GOST or TU).

Metal polymers

In the process of improving the production of materials using polymers, traditional metal pipes are increasingly being replaced. One of the obvious and successful competitors for water supply installations are products of a combined design, consisting of five layers.

The inner working layer is made of cross-linked polyethylene, usually PEX, which has high strength. An adhesive layer is applied to it, securing the reinforcing layer of aluminum. For it, a tape of this metal with a thickness of 0.2 - 0.5 millimeters is used.

In the process of spiral winding, laser welding of the joints is performed. Thus, a strong aluminum pipe is formed. A second adhesive layer is applied to it.

The outer surface is also made from cross-linked polyethylene of the same brand. The manufacturing technology used on automated equipment allows us to produce such products in coils up to 600 meters long. A scale in centimeters is applied to the outer surface, which makes it easier for both the seller and the buyer.

Manufacturers also produce special tools for cutting and installing them. In addition, they have developed a full line of fittings, with which it is possible to create networks of any degree of complexity. Various adapters are also provided for connection with pipes made of other materials.

Plastic pipes and their components are almost ideal for installing water pipes in private housing construction.

Advantages and disadvantages

The advantages of metal-plastic include the following qualities:

- The ability to retain its shape after deforming influences, which greatly simplifies installation.

- Ability to withstand loads up to 10 bar at temperatures up to 95 degrees. Those. These plastic pipes are ideal for hot water mains.

- Suitable for drinking water supply.

- Completely impermeable to any gases.

- Resistance to the formation of biological or lime deposits on the internal walls.

- High quality internal surface, ensuring the passage of liquid with minimal hydraulic losses. This allows the use of pipes with a smaller bore Ø (dia.).

- Reduced thermal conductivity, preventing the formation of condensation on the outer surface of the pipe.

- Elasticity that prevents damage to the system from water hammer.

- Long service life if installation rules are followed.

- Accelerated and simple installation due to the use of a wide range of fittings.

All the positive qualities of metal-plastic pipes are ensured by a successful combination of the properties of two components: aluminum and cross-linked polyethylene. The relative cheapness of the final product allows the use of high-quality equipment for the production.

However, there is no good without a bad thing, there are also some negative properties:

- A high coefficient of thermal linear expansion and low resistance to temperature changes reduce the service life of heating and water supply lines.

- In DHW systems it is necessary to use U-shaped compensators.

- The need to arrange sliding fasteners during installation, ensuring linear displacement.

- Use of special tools for making press connections.

In Russia, only products of well-known brands are certified, and the seller is obliged to provide all certificates for the following items:

- confirmation of compliance with Gosstandart;

- hygiene certificate;

- certificate confirming fire safety.

In addition to the listed items, plastic pipe materials for heating and hot water supply must have confirmation of compliance with oxygen protection requirements. The penetration of this gas into the coolant leads to premature failure of the heating due to accelerated corrosion.

The absence of any of these documents may indicate that the product does not meet the requirements for it, as well as a counterfeit.

Watch the video

Pipes for heating and water supply. Types of pipes. Pipe installation

Marking of metal-plastic pipes

Marking of metal-plastic products is carried out to the same extent as for other plastic pipes, including the application of a size scale on the coils.

During production, compliance with several regulatory documents is mandatory, the main one of which is GOST 18599-2002.

The main diameters of plastic pipes for water supply inside an apartment or private house are 20 or 25 millimeters, and for a riser – 40-50 mm.

Features of the use of metal-polymer pipe products

Any products made from this material find their application in the following areas:

- High-pressure polyethylene pipes are most often used in non-pressure sewerage and drainage systems. Connections are made into a socket with a cuff.

- The second typical application is the protection of power electrical networks from moisture and mechanical damage. The connection is made by butt welding or installing a heat-shrinkable sleeve.

- Installation of such products in the ground is carried out below the depth of its freezing. In this case, there is no need to install trays, since the flexible pipe easily withstands soil movements.

- Tubes made of cross-linked polyethylene can be used for water heated floors. In this case, the tightness of the connections is ensured by a movable sleeve, which allows you to take not only a solid pipe for this.

Features of choosing other equipment

Pipe diameters can also be selected according to the conditions of hydraulic resistance for atypically long pipeline lengths, at which the technical characteristics of the pumps may be exceeded.

But this can happen for production workshops, but practically never occurs in private construction.

For a house up to 150 sq. m., according to the conditions of the hydraulic resistance of the heating and radiator system, a pump of type 25 - 40 (pressure 0.4 atm) is always suitable; it can also be suitable up to 250 sq. m. in some cases, and for houses up to 300 sq. m. . – 25 – 60 (pressure up to 0.6 atm).

The pipeline is designed for maximum capacity. But the system, if it ever operates in this mode, will not last for a long time. When designing a heating pipeline, you can take parameters such that at maximum load, the coolant speed is 0.7 m/s.

In practice, the speed of water in heating pipes is set by a pump that has 3 rotor speeds.

In addition, the supplied power is regulated by the temperature of the coolant and the duration of operation of the system, and in each room it can be adjusted by disconnecting the radiator from the system using a thermal head with a push valve.

Thus, with the diameter of the pipeline we ensure that the speed is within the range of up to 0.7 m at maximum power, but the system will generally operate with a lower fluid speed.

Source: teplodom1.ru/radiattopl/114-kakoy-diametr-trub-iz-polipropilena-dlya-otopleniya.html

Prices and sizes of different types of pipes

Now let’s look at the price categories and optimal sizes of various types of pipe materials.

PVC

Manufacturers offer a choice of finished products with an outer thickness from 1.4 cm to 1 m. The length varies from 0.56 to 6 m.

The cost depends on the parameters and scope of application. If we take into account average prices, the minimum option will cost about 100 rubles, pipes with a parameter of 10-15 cm and a length of 300 cm will cost 500 rubles. The most expensive 6 meter products cost 2 times more per piece.

Polypropylene

Standard outer diameters range from 20 mm to 12.5 cm. Wall thickness varies from 2.3 to 20.8 mm. You can purchase 1 meter or a 100 meter bay at once.

The cost of a linear meter of pipe with a width of 20 mm can cost 40 rubles. The reinforced analogue costs 15-30 rubles more. For a reinforced version with a thickness of 25 mm and a length of 4 m, you will have to spend 10 times more money.

Polyethylene

In accordance with GOST, the outer Ø (dia.) can be in the range of 0.1-120 cm. At the same time, the wall thickness ranges from 0.2 to 6 cm. The length of the coil reaches 1000 meters.

The cost per linear meter, depending on the diameter, varies from 20 to 350 rubles. per linear meter.

Cross-linked polyethylene (PEX)

The outer diameter ranges from 1.6 to 3.2 cm. The wall thickness ranges from 2.2 to 4.4 mm. Sold in coils of 100 m.

The cost of a pipe with an oxygen layer 100 m long and 16 mm wide is about 6,500 rubles. A similar product with a diameter of 20 mm will cost 11,000 rubles.

Low pressure polyethylene (HDPE)

The value relative to the outer diameter ranges from 10 to 160 mm. The minimum wall thickness is 2 mm. As for the length, you can purchase ready-made sections from 3 to 12 m, or a coil from 100 to 500 m.

A pipe with a diameter of 20 mm per linear meter will cost approximately 22 rubles. If we consider the 4 cm option for cold water supply, then a 100 meter bay will cost 6,500 rubles.

Metal-plastic

The outer diameter of the finished product ranges from 1.6 to 5 cm. The wall thickness varies from 2-4 mm. It goes on sale in coils from 20 to 200 m.

At cost per linear meter, 1.6 cm costs from 21 rubles, 2 cm from 55 rubles.

Regulatory technical documents

The design, production and use of polymer products must be carried out in accordance with regulatory documents. In Russia this is GOST R 52134-2003.

The technical conditions apply to pressure water pipes and connecting elements made of synthetic materials. They regulate technical parameters that affect the service life of products. The standard defines the duration of hydrostatic strength of materials, operating conditions measured by a set of temperatures and the time of their influence, as well as pressure parameters.

Making water pipes from plastic pipes

You can carry out the installation yourself. To do this you will need a special device called a soldering iron. The unit is expensive for one-time use, so you can rent it. To understand how the elements are connected, it is recommended to practice on cheap fittings.

Step 1 . The exact locations of cold and hot water consumers are determined. The necessary markings of the future water supply system are applied to the walls. In this case, the length of the flexible line is taken into account. It should connect easily to the pipes.

Step 2 . Determining the installation method. Serial or tee connection in Fig. a) will save on the purchase of materials, but more than 2 devices can be provided with water with insufficient pressure when several points are opened at the same time.

Parallel (in Fig. b) water supply wiring is more expensive due to the larger pipe footage and the need to purchase a collector. But the pressure along the entire length of the line is the same and in case of repairs it is not necessary to turn off all devices.

Step 3. Assembling the counters. It is recommended to entrust this issue to a specialist. Step 4. Installation of clips with an average step of 1.5 m. Horizontal pipes will be attached to them. If hidden wiring is provided, then grooves are formed. It is taken into account that installation is carried out along walls or floors, so most often the connections are straight and at an angle of 90 degrees. Cold water treatment is recommended to be carried out over hot water supply.

Step 5. Cold and hot water supply lines are assembled. To do this you will need a soldering iron, a pipe cutter, a tape measure with a pencil or marker and a level.

At this stage several actions occur:

- Tubular products are cut taking into account up to 1.5 cm, which are included in the connecting fitting. You can check the depth by inserting a pipe into it without heating. The cutting angle must be strictly perpendicular to the base of the pipe.

- The ends are cleaned of burrs and degreased.

- The depth of insertion of the pipe into the fitting is noted.

- The soldering iron is equipped with nozzles of the appropriate diameter.

- The tool heats up to 260 degrees Celsius.

- The elements are put on the soldering iron sleeve to the specified limit. Fittings that do not meet the specified parameters are immediately rejected, since a monolithic connection will not be ensured in this case. Heating of suitable parts must be carried out simultaneously. The melting, holding and cooling times may vary depending on the diameter of the plastic pipe and the depth of welding. The table below shows the required information.

- During the connection process, using small forces, rotation of the elements relative to their axis is prohibited. This indicates that the connecting elements are fixed immediately at the proper angle. Corrections are allowed only in the first seconds.

Step 6 . Threaded fittings. They are installed in places where devices and flexible connections are connected.

Step 7 . Counters are taken into account separately. All connections are recommended to be made using flax, paste or sealing tape.

Step 8 . Checking the water supply. The first launch is allowed no earlier than an hour after assembly of the structure. It’s worth starting with what is less dangerous if there are gaps at the junction of the elements.

Step 9 . Elimination of all problems and errors during the assembly of the water supply system. To do this, the elements are separated or replaced completely between the nearest fittings or connections. You can cut out a section and add a couple more connecting elements. The second option is more economical, but there are more risks. Therefore, it is recommended to prefer a complete replacement.

Step 10 . Connecting all equipment.

Step 11 . Calling a service company representative to take meter readings and install seals. After this, you can proceed to full operation.

Choosing the diameter for your heating

Do not expect that you will immediately be able to select the correct pipe diameter for heating your home. The fact is that you can achieve the desired efficiency in different ways.

Now in more detail. What is most important in a proper heating system? The most important thing is uniform heating and delivery of liquid to all heating elements (radiators).

In our case, this process is constantly supported by the pump, thanks to which, over a specific time period, the liquid moves through the system. Therefore, we can only choose from two options:

- buy pipes with a large cross-section and, as a result, a low flow rate of coolant;

- or a pipe with a small cross-section, naturally the pressure and speed of the fluid will increase.

Logically, of course, it is better to choose the second option for the diameter of the pipes for heating the house, and for these reasons:

- when laying pipes externally, they will be less noticeable;

- when laying internally (for example, in a wall or under the floor), the grooves in the concrete will be more accurate and easier to chisel;

- the smaller the diameter of the product, the cheaper it is, naturally, which is also important;

- with a smaller pipe cross-section, the total volume of coolant also decreases, thanks to which we save fuel (electricity) and reduce the inertia of the entire system.

And working with a thin pipe is much easier and simpler than with a thick one.