Polyethylene multilayer pipes (HDPE) are a complex structure created by the polymerization of ethylene without the use of high pressure. Thanks to their multilayer structure, these pipes are quite strong and at the same time flexible. Low cost, variety of types and unpretentiousness make it possible to use HDPE pipes for water supply in the country, the installation of which is easy to do with your own hands.

At your summer cottage, you can install a water supply using polyethylene pipes

What are HDPE pipes?

HDPE is polyethylene made under low pressure. HDPE is obtained by polymerization of the organic substance ethylene at temperatures up to 120 ͒ C under pressure up to 2 MPa in a solution of a special catalyst. The resulting material is also called high-density polyethylene (HDPE) because it is denser and stronger than other polymers.

Note! Modifications of HDPE are used in the creation of boats, body armor and the construction of hazardous waste processing sites, as well as for the manufacture of pipes. The variety of applications proves that low-density polyethylene is a very durable and airtight material.

Features of HDPE pipes

The abbreviation HDPE stands for low-density polyethylene. This is a polymer material made using special technology, when polymerization occurs without external pressure. The result is a strong, elastic polymer that is chemically inert and can be used for storing and transporting food products (including drinking water).

Positive qualities of HDPE communications:

- Chemically resistant. Polymer communications made from HDPE are not susceptible to aggressive liquids and can be used to transport drinking water.

- Do not corrode. The service life of communications is more than 50 years.

- They do not conduct electric current.

- Elastic. HDPE pipelines have proven themselves to be excellent in seismic zones and areas with high vibration. They do not lose their performance in such conditions, they are durable and reliable.

- The high elasticity of the material prevents pipes from cracking when they freeze with water inside. Where a steel pipeline bursts, polyethylene communications will maintain integrity and tightness.

- Resistant to water hammer.

- Lungs. Light weight makes it possible to: save on delivery, assemble communications without involving third-party labor.

- Easy to install. Ease of cutting, availability of special fittings makes it possible to assemble a pipeline without professional skills.

The disadvantages include the limited scope of application of HDPE pipes, since the material cannot withstand high temperatures. The maximum temperature for operation is 80 degrees.

Note! For long-term and trouble-free operation of HDPE pipelines, it is recommended not to use them for transporting liquids that are hotter than 40 degrees.

Manufacturers offer two types of HDPE pipes:

- for operation under pressure - water supply, gas pipeline;

- for operation without pressure inside the pipe - sewerage, storm drains, electrical communications.

The difference lies in the thickness of the walls and the method of joining the pipes.

Advantages and disadvantages of HDPE pipes

The advantages of HDPE pipes include:

- Immunity to any kind of solvents. At temperatures up to 80 ͒ C, HDPE pipes do not dissolve at all. When this temperature is reached - only in special solvents. Water is harmful only at temperatures above 180 ͒C.

- Do not corrode. This problem is known for all metal pipes, which, under the influence of water and air, begin to oxidize over time. HDPE pipes are not susceptible to corrosion because they contain no metals.

- Smooth inner surface. Roughness and unevenness lead to the accumulation of various types of contaminants. Over time, such dirt can almost completely block the lumen. HDPE pipes are smooth, so nothing interferes with the laminar flow of liquids through them.

- Durability. Manufacturers promise that their products can last up to 50 years. It is worth considering that this figure was obtained theoretically. High-density polyethylene was introduced into service about 60 years ago, so reliable data on such a service life have not yet been obtained.

- Flexibility. HDPE pipes are very flexible, they can even be rolled. This is an undeniable advantage if they are laid through uneven terrain.

- High strength. HDPE is a durable, airtight and at the same time elastic material. It does not leak, does not break or bend. Thanks to their flexibility and strength, they have proven themselves well even in seismically active areas.

A significant disadvantage is the instability of the material to ultraviolet rays.

HDPE pipes are laid only underground or indoors away from sunlight. When exposed to sunlight, high-density polyethylene becomes brittle and begins to deteriorate. The decay process occurs quickly, such pipes need to be replaced.

It is important! When choosing HDPE pipes, you should pay attention to the markings. Each color means its area of application: blue - drinking water supply, yellow - gas supply, without marking - technical water supply.

Structure of HDPE pipes

Products made of low-density polyethylene consist of several layers:

- The inner layer of the pipe is the so-called “cross-linked” polyethylene. The tube-like structure is formed by stitching the edges of the workpiece together using a high-temperature method;

- the adhesive layer provides reinforcement for the HDPE pipe, this allows it to withstand water pressure quite sufficient for the implementation of a water supply system in the country;

- the oxygen barrier between the adhesive layers of the HDPE pipe prevents the penetration of oxygen molecules in the water into the structure of the country water supply. Polyethylene pipes without a protective barrier are short-lived, and two adhesive layers provide mechanical strength sufficient for the implementation of water supply in an open way;

- The outer polyethylene layer performs protective functions and bears the manufacturer's markings. Letter indices indicate the type of pipe and the type of stitching of polyethylene layers.

A country water supply system is an extensive system of supplying cold water from a source to consumers. Cold water is used to water garden beds at the dacha, or to supply water to the collector - storage tank for a summer shower. The most commonly used type of HDPE pipes for water supply to a dacha system are PE 80 pipes and PE 100 pipes. The temperature range of this type of pipe is from +15C to + 40C. Exceeding the maximum operating temperature threshold will result in a rupture of the water supply system.

Small-diameter pipes are quite suitable for country water supply.

In the case of system operation with high temperatures and pressure levels of up to 10 bar - for example, in “warm floor” systems - use pipes marked PE-S (also known as PE-X in the standards of the international classification of pipes).

Which polyethylene pipes are better?

For the production of water pipes, two grades of polyethylene are used - PE 80 and PE 100. The hundredth polyethylene is more dense and durable than the eightieth. For water supply systems in a private home, the strength of PE 80 is more than enough - they can withstand pressure up to 8 atm. If you like a large margin of safety, you can take them from PE100. They work normally at 10 atm.

First of all, you need to choose a manufacturer

What you should pay attention to is the country in which the product was produced. The leaders in quality are European manufacturers. High precision execution guarantees high system reliability. Average quality and prices are from Turkish companies, in the cheaper price segment are Chinese manufacturers. Their quality, as usual, is also much lower. It’s difficult to give advice here; everyone chooses at their own discretion (or what is available in the region).

How to choose

Manufacturers make several types of HDPE pipes to choose from. The first difference is what the water with different color stripes will be used for.

For use in drinking water supply systems from wells and boreholes, HDPE pipes with a blue stripe should be used.

To make gas pipes, additives are used that change the composition of water. Pipes with yellow markings can also be used for country water supply, but their cost is noticeably higher. These pipes are designed for high pressure gas and have increased strength and a higher price.

HDPE pipes without markings cannot be used for drinking water supply. These are technical products made from recycled polyethylene. They can release toxic substances into the water.

For underground installation, two types of polyethylene are used:

- HDPE PE 100 according to GOST 18599-2001. The diameter of the products is 20 to 1200 mm, the appearance is a black pipe with a longitudinal blue stripe along the entire length.

- HDPE PE PROSAFE is produced in accordance with GOST 18599-2001, TU 2248-012-54432486-2013, PAS 1075, they are provided with an additional mineral protective shell up to 2 mm thick.

A pipe with a diameter of 40 mm is suitable for connecting the house. For other consumers, 20 mm or 25 mm is sufficient.

Types of HDPE pipe connections

There are several types of connections for polyethylene pipes:

- detachable (on fittings or couplings);

- one-piece - by welding: using a special welding machine;

- electric couplings - a heater is built into such couplings; when electric current is applied to it, the polyethylene heats up and fuses.

Welding is used more often on larger diameters

They mainly weld large-diameter pipes, which are used to create main pipelines. Pipes of small diameters - up to 110 mm, used in private construction, are mostly connected using fittings. Couplings are used more often during repair work, since their installation takes longer.

Fittings for polyethylene pipes are shaped parts (tees, crosses, angles, adapters, couplings) with the help of which the required system configuration is created. Since independent connection of polyethylene pipes is carried out more often with the help of fittings, let’s talk about them in more detail.

An approximate set of fittings for polyethylene water pipes

Chemical and electronic methods of cross-linking polyethylene

Various options for “cross-linking” layers of polyethylene ensure their performance characteristics. Initially in the manufacturing process, the stitching method is used, due to its low cost. The low strength of the polyethylene layer obtained in this way made the technology irrational.

Adding peroxides to heated polyethylene at the stage of “cross-linking” the pipe layer during its manufacture makes it possible to create a fairly strong structure. The method is common for creating pipes used in low-pressure water supply systems to supply cold water.

Cross-linking at the molecular level with an interpenetration quality of at least 65% is ensured by a chemical method. A mixture of catalysts and silane is added to the polyethylene layer; in this way, PE-S pipes are made.

Markings containing data on the purpose and technical characteristics of the product are applied to the outer surface of the pipe.

“Bombardment” of a polyethylene layer with electrons allows molecules to be stitched into a three-dimensional network with almost 100% interpenetration. The method is the most effective and quite complex, and therefore expensive. This is the best option for a polyethylene pipe for water supply. Do-it-yourself installation of such products can be done as easily as other types of plastic pipes.

Important! International indices indicating the crosslinking option are indicated in capital letters in the index: PE-Ha or PE-Xb. For a country water supply system assembled with your own hands, it is quite enough to use low-pressure HDPE pipes. If pipes that can withstand high temperatures are used, the cost of the project increases significantly.

Types of installation

Each method has its pros and cons.

Surface - for summer water supply

Connection using a detachable fitting

Ground installation is intended directly for summer cottages in order to promptly water your garden, shrubs and trees. There is also an option for supplying water to auxiliary buildings: a sauna, a utility room, or a summer house.

The layout of the summer water supply system at the dacha repeats the layout of the underground one, but is as convenient as possible for repair, disassembly, and alteration if necessary. It can be dismantled for the winter or in case of redevelopment of your summer cottage.

If necessary, within half an hour you can easily change the junction and the location of the water supply on the site.

To avoid accidental damage to pipes located on the surface, it is necessary to provide stands or supports.

Many people install summer or, as they say, temporary water supply according to the principle of how they assembled it or cobbled it together from what was there, directly at the location.

It is preferable to draw up a diagram of the house’s water supply system in advance if the site is planned into zones. On the drawing, the first thing to note is the main consumers of water: the house, shower, trees, hedges, and the points where the taps will be located.

The pipes must be placed at an angle directed towards the consumer, since a drain valve is installed at the lowest point.

Capital system

Underground installation

A system designed for a house with year-round use will require much more time to think through the project and carry out excavation work. In this case, the principle of assembling a country water supply system from HDPE pipes must be changed, since additional compressor equipment, a hydraulic accumulator and a closed arrangement will be installed.

Insulation of the water supply system

The depth of freezing is different in all regions, so it is necessary to proceed from the climate conditions. To prevent rupture of HDPE pipes during fluctuations in external temperatures, it is recommended to take care of insulation.

HDPE pipe in a “shell” of insulation

For insulation use:

- Basalt insulation is sold in the form of cylindrical modules of a certain length.

- Fiberglass in rolls. Additional waterproofing is necessary; roofing felt is most often used.

- Expanded polystyrene. Folding cylindrical modules consisting of two halves that can be used repeatedly.

Water under high pressure does not freeze. If a receiver is built into the system, there is no need for additional thermal insulation. Most perform this procedure simply for their peace of mind.

When the work is carried out efficiently, a heating cable is laid at a shallow depth along with the pipe. But it’s better not to do this, since an additional heater will not be able to protect you from burst pipes.

How to connect HDPE pipes

There are also two types of connections: permanent and detachable. Both methods allow you to create reliable adhesion, but each of them has its own pros and cons, which are important to consider when installing pipelines.

Welding connection

Welding joints of polyethylene pipes are made end-to-end using the diffuse welding method. The joining principle is based on the ability of polymers to mix when heated. Diffusion (mutual penetration) of part materials occurs at the molecular level. The result is a monolithic connection, which is not inferior in strength to the pipe body.

Note! Butt welding is possible if the wall is thick enough. This technology is used for pipe diameters from 50 mm with a wall thickness of 5 mm.

To work you will need:

- special welding machine;

- clamps for pipe alignment;

- trimmer

Work algorithm:

- The material is cut strictly perpendicular to the guide. The cuts must be smooth and clean.

- The material is fixed rigidly with clamps (positioner).

- Clean the cuts using a trimmer.

- The sections are simultaneously heated using a welding machine. The heating time depends on the thickness of the pipe wall and is indicated in special tables.

- Connect the heated edges end to end, pressing them with physical force. Allow the connection to cool.

Note! Pipe material from different manufacturers may not produce a high-quality weld, since the material may vary slightly in composition.

Electrofusion welding

Welding using electrical fittings is a simpler process. It does not require special skills, but you can’t do it without a welding machine. Requirements for section preparation remain high.

Electrofusion welding is used for pipeline installation in hard-to-reach places.

The essence of the process is that the fitting has built-in heating elements and contacts that are brought out. When connecting an electrical fitting to a welding machine, the parts melt and are connected. This method can also be called diffuse welding, since the differences here are only in technology.

Note! Electrofusion welding allows you to obtain a seamless connection on pipes with different diameters. However, it should not diverge by more than 10%.

The process looks like this:

- The pipes are cut to size, taking into account the coupling.

- The cuts must be at an angle of 90 degrees. They should be cleaned of burrs and degreased.

- The prepared edges are inserted into the sleeve.

- Connect the built-in electrodes to the electric welding machine.

- The welding time is determined by the fitting barcode.

Connection using fittings

For independent installation of water supply or sewerage in the house, connections using compression fittings will be sufficiently reliable. Manufacturers offer a lot of variations that allow you to assemble any pipeline configuration.

Schematically, the process of connecting HDPE materials using fittings can be described as follows:

- We prepare the pipe by making a strictly perpendicular cut. It should be cleaned of burrs and dirt.

- Unscrew the fitting by removing the blue nut.

- Sequentially, starting with the nut, we put all the parts on the pipe.

- We insert the end of the pipe into the fitting, pushing it to the middle.

- Use a nut to secure the connection. For reliability, tighten with a wrench.

- We repeat the operation with the second pipe.

Note! If you remove only the nut from the fitting and try to push the pipe inside with the internal parts assembled, the joint will become leaky. The mistake is that the pipe will not go deep enough to be properly fixed.

Types of detachable fittings for HDPE pipelines

Manufacturers offer a full range of possible connections.

Detachable fittings are:

- for connecting straight sections - couplings;

- for wiring - tees;

- for contours - corners:

- shut-off valves – valves;

- for transition to metal pipes - compression fittings with threads (internal, external);

- to change to another diameter.

Socket connection

Before couplings and fittings became available in the construction markets, the socket connection method was widely used in pipeline laying. The technology consists of assembling pipes of different diameters: one pipe is inserted into another and the joint is sealed. For sealing, a rubberized coupling is used, previously placed on a wide section of the pipe.

Which way is better

For underground water supply it is better to use the butt welding method. This connection guarantees long-term operation of the system without leaks. The pipe welding process is quick and one person can handle the job.

Advantages of polymers

Pipes and connectors are made from durable, thick material.

Its popularity lies in its low cost and ease of installation compared to others. To manufacture systems you do not need to have special education, knowledge or skills. The connection of the pipe with the fitting is done manually, since there is a factory thread, you need to be careful and follow the assembly sequence.

Advantages of HDPE pipes:

- not subject to rotting and external influences;

- environmentally friendly;

- light;

- resistant to deformation;

- resistant to changes in water pressure;

- high maintainability;

- little heat dissipation.

Possible difficulties and problems during installation

Before digging a trench, find the underlying communication networks on the technical documentation drawings of the land plot: gas pipeline, telephone, heating, electrical cables. If there is no such documentation, please contact the administration. They have equipment at their disposal that can find an existing utility network at any depth. This will allow you to avoid damaging another network during the process of digging a trench for the water supply.

If the water supply is from a well on the site, no permitting documents are required. But if you are connecting to an existing network or laying a pipe through a neighbor's property, you will need official permission from the local authorities in writing. Otherwise, you may create an emergency situation, which could lead to legal action. It is necessary to agree with neighbors in advance and obtain approval for excavation work.

The problem may be the soil: hard, soft, waterlogged, rocky or unstable. Laying a water pipeline in such conditions will be more expensive, since additional protection and fastening of the entire system will be required.

Step-by-step instructions for doing the installation yourself

When the plan and estimate are ready, the material has been purchased and the connection method has been selected, you can begin laying HDPE in the ground.

Required Tools

If you decide to do everything yourself, then you will need:

- shovels for excavation work;

- two gas keys;

- grinder or hacksaw;

- pipe cutters;

- construction level;

- pegs, cord, tape measure.

If you have a special soldering tool, the above will not be needed, only compression fittings.

Step 1

At the first stage, they dig a trench according to a previously developed scheme. The shape of the excavation depends on the type of soil and the depth of groundwater. Simple and less labor-intensive - rectangular shape. This option should be chosen when the trench depth is no more than 1.5 meters, since this method does not provide for strengthening the walls.

A popular shape is trapezoidal. It is allowed for laying water pipes from HDPE to a depth of 1.5 meters and below, which is relevant for most of Russia. In this case, there is no need to additionally strengthen the walls.

In places where groundwater lies close, it is recommended to choose a mixed form with reinforcement. The width is determined based on the data of the SNiP 2.04.02-84 collection. On average, it varies from 0.5 to 0.8 meters.

If the water supply route is located in a place that is difficult for equipment to reach or the length is short - 5–10 meters, you can dig a trench manually. In other cases, it is better to contact an excavator, especially if the water source is located outside the site and runs into an existing water supply.

Along the route, pegs are driven in on both sides of the future trench, and a rope is pulled. In the future, this will become a guideline for excavation. The land is dumped.

Step 2

The next step is to assemble the HDPE pipes into a complete water supply system. Water is supplied under pressure to check the seal. If the water supply is long and it is inconvenient to install it on the surface, sections of pipes are laid directly in the trench. In this case, it is better to weld using the coupling method. Next, you need to insulate the pipeline along its entire length.

Before laying, the bottom of the trench is covered with a 15 centimeter layer of sand. You should also fill the laid HDPE pipe with sand, this will facilitate access to the system in case of an emergency.

Step 3

The last step is cutting into the house, installing shut-off valves. The soil from the dump is poured back into the trench and leveled.

Work order

Before installation, the length of the water supply pipeline from HDPE pipes to be laid is checked directly on site. To do this, it is necessary to transfer the diagram to the ground by marking with the placement of control pegs and pulling a cord that follows the contour of the future pipeline.

Only after this the excavation work begins. They measure the length again and begin shopping based on the measurements and calculations made.

The algorithm for performing the work is extremely simple:

- The trenches are dug at a slope at the connection point; the angle should not be large for its further exit into the horizontal plane.

- The bottom of the trench must be equipped with a sand cushion with additional waterproofing. This is done to smooth out any unevenness that will inevitably appear.

- HDPE pipes are cut directly when they are laid in a trench. Docking to the water intake point first, then laying along the site. We insulate pipes with pre-selected material. After completion of the work, connect the pumping station.

Compression connectors are installed in the following sequence:

- The couplings are disassembled, the clamping part and the gasket are removed.

- The gasket and clamp are installed in the reverse order on the tabs.

- The nodes are joined, the fitting is screwed on manually, without much effort.

If the elements are connected by soldering, then the following rules must be followed:

- The joints are cleaned, degreased, and dried.

- Work is allowed to be carried out at temperatures greater than +5C.

- Pipes with a diameter of 50 mm or more must be chamfered.

Trial run

The development of the land plot and the digging of trenches is carried out only after a trial run. Water is released into the laid pipeline; do not forget to open the taps, since the filling should occur gradually and the air will be forced out of the system. Start the pump and check for leaks and no leaks at the connections. If there is leakage, damaged areas must be replaced.

If you want to install a year-round water supply with your own hands, you will have to spend a lot of effort and time to provide for all the nuances. The assembly process in the presence of dug trenches should not take more than 1 day. The main thing is not to bury the laid pipes right away; it is necessary to conduct a test run to inspect for leaks. Do not forget about the complete tightness of the system. If the pressure is unstable, this will lead to water leakage and rapid failure of the pumping station. Be careful when carrying out work.

Video about the construction of a summer water supply system at a dacha using pipes. Why did I have to change PVC pipes to HDPE?

Conclusion

In conclusion, it is worth adding. Laying stationary pipework in the country, no matter in the house or in the garden, is always done at a slight inclination. This will allow you to drain the water from the system when preparing it for winter.

Wiring in the house with polypropylene pipes.

Did you like the article? Subscribe to our Yandex.Zen channel

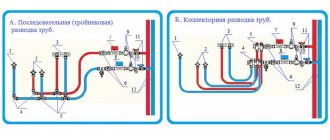

Plumbing diagram

Let us give an example of a capital (stationary) pipeline running from a well to a house. The diagram includes the following elements:

- The intake pipe through which water is supplied from the well to the system.

- Coarse filter, iron remover, softener - the type depends on the chemical composition of groundwater.

- Check valve to prevent water from flowing in the opposite direction.

- Pump - diaphragm or centrifugal, submersible or surface.

- Measuring equipment – pressure switch, pressure gauge, water meter.

- Drain valve.

- Hydraulic accumulator.

- Pipes with triple adapters for sequential connection of the pipeline to the house, to the site, to the bathhouse - depending on the flow rate of the well and the personal needs of the user.

- Valves for each water supply branch that shut off the water.

It is necessary to take care of high-quality fittings and couplings for connecting pipes, especially in areas where plastic pipes enter metal threaded adapters. The operation of the system depends on their quality.

Important! A separate trench is made for the electrical cable for the pump. The socket for connecting the pump must be grounded. It is forbidden to lay cables near pipes underground.

Sources

- https://InfoTruby.ru/polietilenovye/soedinenie-pnd

- https://InfoTruby.ru/polietilenovye/4-sposoba-dlya-montazha-pnd-trub

- https://TrubaMaster.ru/vodoprovodnye/truby-pnd-dlya-vodoprovoda-na-dache-montazh.html

- https://kak-sdelano.ru/vodosnabzhenie/soedinenie-polietilenovyix-trub

- https://kanalizaciyalite.ru/vodoprovod/vodoprovod-na-dache-iz-trub-pnd

- https://vseotrube.ru/vodosnabzhenie/prokladka-vodoprovoda-iz-pnd-truby-v-zemle

- https://InfoTruby.ru/polietilenovye/vodoprovod-iz-pnd-trub

[collapse]

Similar posts:

- Transition from HDPE to metal: connection methods...

- Do-it-yourself plumbing in the country: how to choose pipes,…

- Which pipes are better for plumbing in an apartment: types,…

- How to choose a pipe for a heated floor - recommendations...

- GOST 9573-2012 Mineral wool slabs on…

- How to paint polypropylene pipes: choice...