Until recently, choosing sewer pipes was easy. Their range was limited to products made of steel and cast iron. But technology is constantly evolving. Therefore, today, depending on the material of manufacture, other types of sewer pipes have appeared on the market - polypropylene, polyethylene, polyvinyl chloride, etc. Of course, without specialized knowledge, it is very difficult to make a choice.

Today, a variety of types of pipes are used for the installation of sewer systems, including polymer ones.

Sewage pipes in a private house and requirements for them

Having decided to install a wastewater disposal system in a country cottage or country house, it is necessary to take into account that all its elements must have high throughput capacity and also be characterized by:

- resistance to low temperatures (this applies to external sewerage pipes);

- long service life;

- smooth inner surface;

- high mechanical and chemical wear resistance (in this case we are talking about the surface of not only sewer pipes for external sewerage, but also for internal ones);

- increased strength.

All modern sewer systems are divided according to their location and purpose. Internal networks collect wastewater, which is then transported through external sewer pipes to external networks. The final point of delivery of human waste products is purification complexes. They are available in any locality. In these facilities, wastewater is treated to the required characteristics, after which it is sent to discharge points.

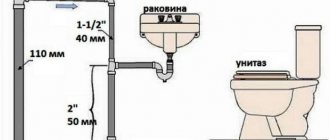

The installation of a sewer system in a private house requires compliance with the rules for laying pipes in the ground; the most important is their correct slope

The key indicator for classifying sewer pipes is the material of manufacture. As mentioned above, today there are not only rolled metal products on the market, but also polymer products. The latter will be discussed below, but now let’s talk about pipes made from materials traditional for this area.

According to this criterion, there are the following types of sewer pipes:

- asbestos-cement. They are distinguished by their low weight, chemical and thermal stability, resistance to corrosion and low cost. However, fragility makes it difficult to transport and install such external sewer pipes. In addition, their inner surface is not perfectly smooth;

- concrete and reinforced concrete pipes for external sewerage. There are no complaints about the environmental friendliness of such products. However, for their transportation and installation, due to their large weight, it is impossible to do without special equipment;

- cast iron pipes for sewerage. Their time-tested positive properties are offset by their heavy weight, which complicates installation work, as well as their susceptibility to corrosion. The rough surface of cast iron pipes for plumbing water supply and sewerage causes frequent clogging of these utilities

- ceramic. In the recent past, sewage systems in apartments were very often created on the basis of such products. Among their positive qualities, it is worth highlighting their resistance to most aggressive chemical compounds, absolute waterproofness and smoothness of the inner surface. The disadvantages of ceramic sewer pipes for indoor use include fragility and heavy weight. Another significant disadvantage is the high cost. The reason is a rather complex manufacturing technology. It requires the use of kaolin, fireclay, natural clay, as well as the mandatory procedure of high-temperature annealing.

Among all types of sewer pipes, plastic products are the most popular

Helpful information! Modern metallurgy even produces special cast iron finned pipes. Although they have not found application in sewer networks and water supply systems, they are in great demand when installing heating pipelines.

How to properly combine different materials

There are several methods for joining materials together:

- Bell method. This is the most common method, which is carried out with or without an O-ring, using glue or resistance welding.

- Sealing with cement. Pipes can be of different diameters and made of different materials. This method is used for cast iron pipes. The pipe elements are inserted into each other, the gap between them is sealed with a layer of flax or hemp, then filled with cement, asbestos, bitumen mastic or silicone sealant.

- Application of O-ring. Increases the reliability of socket joints of plastic pipes. The ring may have a plastic liner. When connecting, do not allow deformation of the sealing ring. The ring is lubricated with glycerin, soap or silicone.

To connect pipes made of different materials, adapters are used:

Connection using glue or contact welding.

Glue installation is quite simple, but you need to remember that glued connections cannot withstand lateral loads.

Resistance welding can be used for various materials: cast iron, steel, and plastic. It requires a special manual or mechanical welding machine, equipped with special devices for heating to a certain temperature.

Plastic pipes

In order to find the answer to the question of which pipes are best for sewerage, it is necessary to consider the properties of all types of rolled pipe products. Only then will it be possible to make the right choice.

So, despite the growing popularity of plastic pipes for sewerage, they cannot be used everywhere, so the design of such products needs to be modified. Modern industry keeps up with the times. Responding to the needs of consumers, it produces several modifications of polymer products.

PVC pipes. The abbreviation PVC stands for polyvinyl chloride material. Such pipes are used for gravity sewerage, that is, one in which wastewater moves due to the force of gravity and the slope of the pipeline. These products are characterized by strength and resistance to ultraviolet radiation. They have found application mainly in internal sewage disposal systems, since they do not tolerate the effects of aggressive environments and changes in street temperature. However, with the right approach, it is possible to install polyvinyl chloride products in external networks.

The classification of PVC polymer pipes for sewerage according to strength class is as follows:

- lungs. Class SN2. They are used when the drainage system does not pass under roads and lies at a shallow depth;

- average. Class SN4. The scope of application of plastic sewer pipes of this class is pipelines under small roads;

- heavy sewer pipes. Class SN8. They are laid under highways and industrial facilities.

PVC pipes are used for arranging sewage systems indoors, outdoors and even underground

Pipes made of unplasticized polyvinyl chloride (abbreviation UPVC) . They are used in drainage systems of any type: internal and external, free-flow and pressure. The downside of the PVC-U sewer pipe is its poor temperature resistance and flammability. This is due to the properties of the source material.

Good to know! The use of PVC-U sewer pipes, pressure and non-pressure, is allowed when filled for a long time with wastewater, the temperature of which does not exceed +60˚C. At the same time, PVC-U products are capable of briefly transporting sewage with a temperature of +100˚C.

Polypropylene pipes. These products are distinguished by a long service life – up to 100 (!) years – and resistance to high temperatures. The combination of these characteristics allows them to be used not only as a sewer pipe in a private house, but also in a hot water supply system.

Polypropylene pipe products have the following advantages:

- under the influence of high mechanical loads, PP products are deformed, but do not break;

- high diffusion resistance;

- environmental Safety;

- resistance to acids and alkalis;

- high temperature resistance. Withstands temperatures up to 100˚C.

Polypropylene pipes for sewerage have the following disadvantages:

- low resistance to ultraviolet radiation;

- increased elasticity. It is recommended to use a product of this type only as a pipe for internal sewerage. Due to its increased softness, it is easily deformed during use.

Polypropylene pipes are suitable only for a closed type system, since they are negatively affected by ultraviolet radiation

Polyethylene pipes for sewerage. Products made from this material are capable of operating in a wide temperature range. The disadvantages include insufficient heat resistance and a high coefficient of thermal linear expansion. Therefore, it is not recommended to use polyethylene pipes in a sewer system that discharges hot water.

HDPE sewer pipes. The abbreviation HDPE stands for low-density polyethylene material. Among the main advantages of products of this type, experts highlight:

- light weight;

- resistance to hydraulic shock;

- possibility of operation at very low temperatures – down to -70˚С;

- lack of thermal elongation and expansion;

- low thermal conductivity coefficient;

- no corrosion;

- long service life.

HDPE pipe for external sewerage must be laid exclusively underground, since it does not withstand exposure to ultraviolet radiation.

Corrugated pipes for sewerage. In this segment of the building materials market, such products appeared relatively recently. According to experts, this is practically an ideal option for an external sewer pipe. The consumer appreciates the following qualities of a corrugated plastic pipe in a wastewater disposal system;

- long (about half a century!) service life;

- ease of installation;

- impeccable smoothness of the inner surface of corrugated flexible pipes for sewerage;

- affordable price.

- ease of maintenance.

Pipes for pressure and free-flow sewerage

When considering this issue, you need to know that pressure sewerage is a system in which wastewater moves through pipes under the influence of pressure created by pumps.

Corrugated pipes are one of the best options for a pressure sewer network

This technical solution imposes certain requirements on the pipeline design. First of all, pressure sewerage in a private house should be created on the basis of pipes with increased annular rigidity.

Good to know! The sewage system you create in an apartment with your own hands does not belong to the pressure category. The wastewater is transported by gravity to the central main, and there the pumps are put into operation.

Pressure sewer pipes must have the following properties:

- resistance to water hammer;

- versatility;

- non-susceptibility to electrocorrosion caused by stray currents;

- strength;

- ease of installation;

- tightness.

And, of course, pipes for pressure sewerage must be resistant to chemically aggressive environments. PVC-U products have all these properties. The tightness of the structure is ensured by connection using sockets: sealing gaskets are inserted into their grooves. Table No. 1 shows the maximum operating pressures and sizes of PVC-U pressure sewer pipes.

Table 1

| Average outer diameter, mm | SDR 13.6 | SDR 17.0 | SDR 21.0 | SDR 26.0 | SDR 33.0 | SDR 41.0 | |||||||||

| MOP 1.60 (MOP 2.00) | MOP 1.250 (MOP 1.60) | MOP 1.00 (MOP 1.250) | MOP 0.80 (MOP 1.0) | MOP 0.630 (MOP 0.80) | MOP 0.50 (UPVC 100), MOP 0.630 (UPVC 125) | ||||||||||

| Wall thickness | |||||||||||||||

| denomination | off | nom | off | nom | off | nom | off | nom | off | nom | off | nom | off | ||

| 315 | +1 | 23,2 | +2,6 | 18,7 | +2,1 | 15 | +1,8 | 12,1 | +1,5 | 9,7 | +1,2 | 7,7 | +1 | ||

| 280 | +0,9 | 20,6 | +2,3 | 16,6 | +1,9 | 13,4 | +1,6 | 10,6 | +1,3 | 8,6 | +1,1 | 6,9 | +0,9 | ||

| 250 | +0,8 | 18,4 | +2,1 | 14,8 | +1,7 | 11,9 | +1,4 | 9,6 | +1,1 | 7,7 | +1, | 6,2 | +0,9 | ||

| 225 | +0,7 | 16,6 | 1,9 | 13,4 | +1,6 | 10,8 | +1,3 | 8,6 | +1,1 | 7 | +0,9 | 5,5 | +0,8 | ||

| 200 | +0,6 | 14,7 | 1,7 | 11,9 | +1,4 | 9,6 | +1,2 | 7,7 | +1 | 6,2 | +0,9 | 4,9 | +0,7 | ||

| 180 | +0,6 | 13,3 | 1,6 | 10,7 | +1,3 | 8,6 | +1,1 | 6,9 | +0,9 | 5,5 | +0,8 | 4,4 | +0,7 | ||

| 160 | +0,5 | 11,8 | 1,4 | 9,5 | +1,2 | 7,7 | +1 | 6,2 | +0,9 | 5 | +0,7 | 4 | +0,7 | ||

| 140 | +0,5 | 10,3 | 1,3 | 8,3 | +1,1 | 6,7 | +0,9 | 5,4 | +0.8 | 4,3 | +0,7 | 3,5 | +0,6 | ||

| 125 | +0,4 | 9,2 | 1,2 | 7,4 | +1 | 6 | +0,8 | 4,8 | +0,7 | 3,9 | +0,6 | 3,1 | +0,6 | ||

| 110 | +0,4 | 8,1 | 1,1 | 6,6 | +0,9 | 5,3 | +0,8 | 4,2 | +0,7 | 3,4 | +0,6 | 2,7 | +0,5 | ||

MOP is the maximum pressure of the working medium (MPa) at its temperature of 20˚C. In parentheses, the dimensions of PVC-U pipes for sewerage pressure type 100, corresponding to the maximum operating pressure, are indicated.

The sewage system of apartment buildings is considered free-flow, but you still need to choose durable pipes, for example, PVC

There is a misconception that there are no special requirements for pipelines through which the working fluid is transported without pressure. All of them should have the same properties that are characteristic of pressure types of sewer pipes, with the exception of increased ring rigidity. However, it won't hurt either. Let's consider some features of a free-flow sewer system created on the basis of polyethylene pipes. Such products with a diameter of 125 to 4000 mm have no worthy competitors in this area, even in the form of uPVC sewer pipes.

First of all, this concerns ease of installation. The installation of internal sewerage systems using PE pipes does not require the use of special equipment. And the installation process itself is facilitated by a wide range of shaped parts produced by modern industry.

Perhaps the only drawback of this sewer pipe material is its exposure to direct sunlight. Therefore, plastic products should be stored in a dark place.

Important! Despite its name - non-pressure - liquid in utility networks is transported under an average pressure of 5 bar or 4.93 atmospheres. This gives the wastewater a certain flow speed.

Among the operating features, it is worth noting that the degree of filling of polyethylene sewer pipes for internal sewerage should not exceed 0.8. This indicator is the result of dividing the height of the transported wastewater by the diameter of the utility line. There are different situations in life. But polyethylene pipes for sewerage, being 100% filled at the time of peak load, will continue to do their job. And without any accidents!

One of the disadvantages of using PE pipes for sewage is the specific way they are connected

Procedure for creating an external sewer system

The laying of sewerage pipes begins with the project. It is recommended to make a trench with a minimum number of bends; the optimal solution is a completely straight pipe without any turns.

If you can’t do without them, and the length of the system is more than 12 meters, inspection wells are installed in such places, since this is where blockages and breakdowns most often occur.

Note! Even ideally straight sewers must be equipped with inspection wells every 25 meters.

It is important to correctly determine the depth of the sewer pipe. When determining it, the depth of soil freezing and the level of the entrance of the sewer pipe into the septic tank or pipe of the centralized sewer system are taken into account.

In addition, the required sewerage slope should be ensured, which is 2 cm for each linear meter of the structure.

Often, creating a sufficiently deep trench turns out to be too labor-intensive, and sometimes impossible. In this case, it is necessary to carry out thermal insulation work to protect the drains from freezing in winter.

According to the rules for laying sewer pipes, the minimum trench width is defined as the diameter of the pipe plus 20 mm on each side for pipes.

If the pipe is wider than 200 mm, the free space should be increased, otherwise it will be difficult to correctly install the structure. Once the plan has been drawn up and all factors have been taken into account, the work begins.

To install external sewerage you should:

- Dig a trench of suitable size. Place a sand cushion approximately 50 mm thick on the bottom. Carefully compact the bottom of the trench.

- Lay and connect sewer pipes. Connect them to the internal sewerage system and to the septic tank.

- Check the operation of the system and make sure it is tight.

- Fill the space on the sides of the pipes with sand, compacting it layer by layer. Backfill the sewer from above.

Note! The layer of sand or soil laid on top of sewer pipes does not need to be compacted.

When figuring out how to properly lay sewer pipes, you should take into account the recommendations of experts:

the number of joints and turns should be minimal; all pipes must be directed towards the flow of waste; sockets and shaped elements cannot be shortened; The pipes should be secured to ensure the correct slope of the sewer.

To maintain the slope, use a marking cord that is pulled along the bottom of the trench.

Pipe color: what does it mean?

Arriving at a hardware store, on the racks you can see several types of sewer pipes, differing in color, but made of the same material. Thus, manufacturers have made life easier for consumers by giving products appropriate colors depending on the scope of application. Thus, in order to purchase, for example, pipes for internal sewerage, it is enough to pay attention to gray products. There are other colors too. Let's take a quick look at what they mean to the consumer.

Orange pipe. This product is used as a pipe for external sewerage. Its walls are very rigid and can withstand high pressure, including external pressure. Orange pipes are also suitable for laying sewerage in the ground, and you don’t have to worry about having to change them in a few years.

Green pipe. The drainage pipes are painted this color. They can be flexible and rigid. Their surface is perforated, allowing water to penetrate inside the product. The strength of the walls allows them to withstand a considerable layer of soil. In addition, the green drainage flexible sewer pipe has a high degree of resistance to temperature changes.

Gray pipe. As mentioned above, choosing a sulfur sewer pipe is the best solution for arranging the internal part of the wastewater disposal system of a country cottage or summer house. It is easy to work with, it is not afraid of corrosion and is very durable. Due to its low resistance to mechanical loads, the gray pipe is unsuitable for organizing an external pipeline.

White pipe. In terms of frequency of use, it cannot even be compared with a black sewer pipe. This type of product is preferred by people who want not to spoil the aesthetics of their home.

White pipes are used for indoor sewerage; these are one of the few types of products that can be glued together

Black pipe. Such products can be found much less frequently than orange and gray plumbing sewer pipes. They are made from low-density polyethylene. The scope of application of sewer black pipes is the laying of both internal and external pipelines. However, it must be taken into account that there is a certain range of pressure and temperature that they can withstand.

These products are used extremely rarely on their own. They are most widely used as protection for communication cables. Some modifications of black pipes can be used as drainage pipes. They can be distinguished by the presence of many holes on the surface.

Good to know! Gray color can be discordant with the interior of a kitchen or bathroom. Therefore, a white pipe is an excellent alternative to a gray pipe.

Dimensions of polymer sewer and drainage pipes. GOST

PVC pipes. The dimensions of polyvinyl chloride products are specified in the state standard R 51613-2000 (geometric characteristics of pressure sewer pipelines) and in the construction standards VSN 48-96 (dimensions of elements of non-pressure networks). The product range contained in the latest document contains only 3 standard diameter sizes: 110.90 and 50 mm. The first two values of this parameter are classified as “sewer classics”. Pipes (including uPVC) with this diameter are used for vertical risers in apartments.

The cross-sections of pressure pipes (13 standard sizes in total) range from 63...315 mm. In this case, the basis for the riser of industrial sewer systems is usually products of 250 and 300 mm.

PE pipes. According to GOST 22689.2-89, there are only 4 standard sizes of these products. These are diameters 40, 50, 90 or 110 mm.

When choosing pipes for sewerage, their diameter and wall thickness are important.

PPR pipes. The range of polypropylene products is specified in two standards: GOST R 51613-2000 and GOST 22689.2-89. But besides them, there are larger external sewerage pipes. These include the well-known brands Korsis and Pragma. Their cross section reaches 1.2 meters. Of course, it is impractical to organize a riser of such a diameter. And in general, these pipes are not suitable for internal sewerage. OST 4926-002-88742502-00 requires the use of polypropylene products with a cross-section of 150, 100 or 50 mm for this purpose.

Flexible drainage pipes. The most popular polymer products are HDPE and PVC. Modern industry produces corrugated single-layer drainage pipes of the following sizes:

- length 40, 50 meters;

- diameter 63, 90, 110, 160 and 200 mm.

The standard hole cross-section is 5-15 mm. The interval between them is 50...70 cm.

The upper shell of two-layer flexible corrugated drainage pipes has good characteristics of resistance to external mechanical influences. And the inner surface has excellent sliding properties. Such flexible polymer pipes are produced using the extrusion method.

Central sewer riser

Do-it-yourself sewerage in a private house, as a rule, is created on the basis of one riser. However, if the wiring system is large, there may be several of them. But, one way or another, the wastewater must be discharged through the lowest point.

Good to know! In order for the sewerage system to work normally, it must be connected through two points: a higher one (a drain riser is installed there to release gases) and a lower one (here the sewerage pipe is provided to exit from the house into the public main).

Improper arrangement of the lowest point of the sewer pipe exit from the house will cause blockages in the system, preventing the normal drainage of sewage. In the absence of a vent riser, the removal of unpleasant odors will not be ensured, and the formation of gases (methane and ammonia) will create pressure in the instrument valves. This also applies to the sewerage system in a multi-storey apartment, and not just a private house.

All sewage pipes in the apartment are connected to a central riser, which must be equipped according to all the rules

According to SNiP, combining a conventional ventilation riser with a gas exhaust riser, and even more so with a fan riser, is strictly prohibited. It is also prohibited to arrange a joint outlet of risers into one ventilation shaft. The regulatory documents contain another important requirement. It sounds like this: it is necessary to install the riser according to a previously developed and approved project. In addition, all drains must be discharged to a single point where the sewer pipe exits from the base of the house.

Apartment

In the process of renovating an apartment, you will only be faced with the need to re-plan the water supply distribution. The heating is central, its wiring was designed by the builders. The most you can do is to slightly move the radiators that are bothering you.

So, plumbing.

The wiring can be:

Collector. Each plumbing fixture has a separate pair of pipes, which are assembled on a common comb - a manifold.

Looks scary

Consistent. One pair of valves; all devices are connected to a common pipe through tees. This does not prevent you from installing your own valves on each of them, but they will be located directly next to the device.

Typical representative

Mixed. For example, the wiring to the faucets is made independent, through a comb, but the toilet tank and washing machine are powered in series.

Mixed type of water supply: some consumers are supplied directly from the collector, others through tees

Typical apartments traditionally use sequential wiring. It is easier to perform and requires less material.

It is also important that in this case the wall is decorated with only two pipes, and not six or ten

A typical wiring diagram today is as follows:

- In the bathroom or closet there are water supply risers, the outlets of which are decorated with a pair of valves;

- Immediately after the valve there is a tee from which the toilet tank is powered;

- Next, a welded connection is used to make an outlet to the faucet in the bathroom, which is attached directly to the pipes. The pipes are fixed to the wall with a welded bracket.

- In the kitchen, the faucet is mounted on the sink and connected to the water supply with flexible hoses.

Possible variations are:

- In dormitories for small families, there are often two sets of water supply risers per apartment. In the kitchen, only the kitchen faucet is powered from the risers; The pipe layout in the bathroom corresponds exactly to that described above.

- Coil - The bathroom heater in new homes is simply a coil of water supply riser. However, in the Khrushchev you can see a heated towel rail through which hot water flows into the mixer. It warms up only from water intake. Our ancestors also left us more exotic options - heated towel rails can be powered from a separate riser or even represent a kind of “short circuit” between the water supply and heating systems that operates in winter.

In Stalin buildings built in the 1930s you can also see heated towel rails like this. The battery, by the way, clearly changed after the house was built: in the thirties, the fins on the cast iron sections looked different

The tank in old houses often has a separate connection to the cold water supply riser. Considering the growth of steel water pipes, this seems like a great idea.

How to do it better?

If you have a small apartment in which all the plumbing fixtures are located on one side of the risers, there is no need to reinvent the wheel. Sequential connection diagram, ball valves at the entrance to the apartment, mandatory coarse filters.

If possible, it is better to feed the tank from the riser via a separate connection. Then flushing the water won’t scald anyone in the shower.

Don't complicate your life unnecessarily

When the bathroom and kitchen are located on opposite sides of the water supply risers, the collector wiring ceases to look redundant. Valves concentrated at one point are very convenient, but costs will not increase significantly.

Nobody bothers you to use a mixed type of wiring: make your own valve for the toilet, bidet and washing machine, and then dilute the water with tees.