Today, devices such as Marina pumping stations (Italy) are widely used for automatic water supply. They are common not only in industry, but are also very convenient for home use. Pumping units are used in drainage systems, for pumping water from fountains and swimming pools, for removing water from basements, etc.

It is difficult to find another device that copes with the tasks assigned to it as effectively as the Marina pumping station does. In this article you will learn about all the features and advantages of the design, and you will also be able to see real reviews from people who have installed this device.

What is the Marina pumping station?

This is a complex installation designed for automatic water supply, which allows for proper production and distribution of water in almost any area.

The design of the device is made in such a way that water can be pumped both from small reservoirs and from deep wells , tanks and wells. The production of such pumping stations has been going on for more than 60 years; during this period of time, the device has gained popularity among many consumers, including large enterprises and organizations.

The pumping station contributes to the uninterrupted supply of water to country cottages and summer cottages, and also allows you to increase the pressure in the main water pipelines.

In addition, the station can be used to irrigate summer cottages - the principle of operation is quite simple and does not require any special skills.

How to troubleshoot problems on your own?

Now we will consistently look at the most common malfunctions in pumping stations, the reasons for their occurrence and the methods used to eliminate them.

The pumping equipment rotates, but no water flows

If the owner turned on the station, the pump impeller began to rotate, but no water entered the pipeline, then this could happen due to certain factors.

To deal with this problem, you must first check how tight all connecting pipelines are. You also need to make sure there is really no water in the system. If there is no fluid, this may indicate poor operation of the check valve. It is located between the station inlet pipe and the well head

You should pay close attention to it. You need to check its condition

Failure of this element is possible if foreign objects get into it.

A special spring controls the operation of the check valve. Sometimes it breaks down, which leads to the failure of this element. In some cases the valve becomes dirty. To solve the problem, it must be removed and cleaned thoroughly. If the valve is faulty, then in this case it is necessary to replace it with a new one.

If the equipment has been idle for a long time, water may disappear in the area between the well and the pump. In this case, a special filling hole must be used to fill the inlet area.

Lack of water in the system may occur due to depletion of the well. In order to compensate for the seasonal decrease in water level, the owner can lower the input circuit of the pumping equipment deeper into the well shaft. However, this may create a risk of contamination. Therefore, to avoid this, it is necessary to equip the station inlet pipe with a filter.

If there is no water in the pipeline, but the station is working properly and the pump is rotating, then one of the reasons for this may be insufficient voltage in the electrical network. In this case, despite the rotation of the rotor, its rotation speed will not be enough to move the water coming from the well to the required distance. To check the voltage in the electrical network, you should use a special device - a power supply tester.

The station pump turns on frequently, and water is supplied in jerks

The reason may be improper operation of the automation unit. In pumping stations this is a pressure gauge. The main function of this device is to measure pressure. Working in jerks, you can observe how the pressure gauge readings can change, rising to large values, and then dropping sharply.

The reason for this deficiency may be damage that has occurred in the membrane in the accumulator. You can get to the membrane through the nipple, which is located on the back side of the accumulator housing. By pressing this part, air should flow out of it. If water comes out of it instead of air, this indicates that it is time to change the accumulator membrane. To perform this operation, it is necessary to disassemble the accumulator housing, for which the bolts are unscrewed, and then the membrane is replaced.

Another reason for the station to operate irregularly may be a drop in pressure in the air cushion located behind the membrane part of the accumulator. The manufacturer usually pumps air into this part of the device at a pressure of 1.8 atmospheres. If the seal is broken, air will escape and the accumulator will cease to perform its functions. The pressure can be increased by using the nipple located under the rear of the device.

If there are traces of rust or microcracks in the body of the device, then the only way out is to seal the seams. To perform this operation it is necessary to use cold welding. Or you can spend money and replace the housing or accumulator.

This malfunction can also occur due to a breakdown of the automatic adjustment unit. It cannot be repaired, so you will have to replace the faulty device with a new one.

The pumping station is working, but water flows into the system intermittently and intermittently

This problem can occur if air partially enters the pipeline. Such suction can occur in a segment that is located in the area from the suction pipe with the filter to the outlet pipe of the station. To eliminate this drawback, it is necessary to ensure the tightness of pipelines and their connections. In addition, it is necessary to achieve a deeper immersion of the suction pipe into the well.

Pumping station design

The body of the device is made of cast iron or steel, which are highly resistant to corrosion. Thanks to the good performance characteristics of the device, the station is capable of providing constant fluid pressure and supply, as well as maintaining the required pressure.

The pumping device is equipped with a reliable protective mechanism, which is needed to stop the device from operating under high electrical voltage.

The design operates according to the following principle:

- inside the ejector there is a special small tube;

- using this tube, the pump automatically sucks in water;

- one part of the water goes directly into the tank, the other part of the sucked liquid is recirculated and allows the self-priming process to occur.

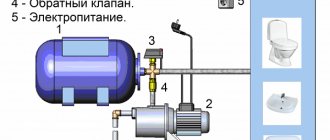

The main elements that make up the design of this Italian-made device:

- membrane tank;

- pressure gauge;

- a unit that allows for water suction;

- special pressure switch.

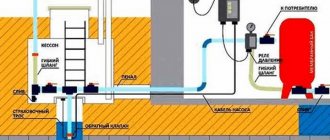

Installation on heating equipment

Sometimes a pumping station is also installed in those houses where a central water supply is connected. This is done to ensure that heating equipment operates without interruption due to too low pressure in the system. In this case, the order of work will be as follows:

- the water pipe is disconnected in the right place;

- the end of the pipe coming from the central line is connected to the storage tank;

- water from the tank goes to the pump inlet, and the end of the pipe that goes into the house is connected to its outlet;

- After this, you can install the wiring and configure the equipment.

- pour no more than two liters of water into the snail;

- we note the pressure at which the pump turns on and off, compare these indicators with those declared by the manufacturer (when turned on - from 2.5 to 3 bar, when turned off - from 1.5 to 1.8 bar);

- if the indicators differ from those indicated above, we find a special screw under the relay cover, marked with the letters DR, and rotate it in the desired direction (“+” or “-“).

Don’t forget to also install a filter to protect the suction device from harmful impurities contained in the water.

In order for the pumping station to serve for a long time, it must not only be installed strictly according to the instructions, it must also be operated correctly. For example, if you live in a country house only in the summer, then the automatic water supply station is mothballed for the winter. To do this, drain all the water from it. If the device continues to be used during the cold season, then it is better to install it in a heated basement or other building, and lay the pipes below the freezing level of the soil.

To prevent water from flowing out of the device when the pump is turned off, a check valve should be installed at its suction end.

turn off

As you can see, having a pumping station in your home does not guarantee a complete absence of problems. However, it is quite capable of reducing the frequency of their occurrence. The main thing is to make the right choice and connect the station, observing all the requirements that are in the instructions.

Comparison of technical characteristics and cost

To begin with, it is worth recalling which pumping stations are used today for autonomous water supply. Firstly, these are pumping units with a built-in ejector that lift water from a depth of up to 45 meters. They are distinguished by reliability and durability.

Most of these stations operate with increased noise, which does not allow placing the device near a residential building. Recent Entries

Chainsaw or electric saw - what to choose for the garden? 4 mistakes when growing tomatoes in pots that almost all housewives make Secrets of growing seedlings from the Japanese, who are very sensitive to the soil

Marina pumping stations operate almost silently, which is their main difference from other installations.

Devices with a remote ejector operate silently and consume a small amount of energy. Many models of such installations have a relatively low efficiency, which also puts them at a disadvantage compared to the Italian-made Marina device.

There are also stations that operate without the help of an ejector by sucking water using hydraulic components. Among the advantages, it is worth noting quiet operation and energy savings. Not all models have excellent performance.

Devices of this brand also differ from each other, mainly in their technical characteristics. The final cost of the device will largely depend on indicators such as:

- engine power;

- performance;

- voltage;

- pressure;

- suction lift;

- accumulator volume, etc.

The weight of the equipment also plays an important role. Average prices range from 700−1200 rubles.

“Vodomet” pump: do-it-yourself installation and repair

Water is lifted from a deep source - a well or a well - using a pump.

Depending on the type, the pump is lowered below the water level, or mounted on the surface of the earth, and a pipe or hose is lowered into the water. Accordingly, such pumps are called submersible or surface pumps.

The operating conditions of a submersible pump are much more difficult, since it is constantly located in water at great depths.

This also complicates the maintenance and repair of the pump, since the pump must be lifted to the surface instead of being carried out by a bundle of pipes, cables and cables.

For example, consider a popular one among many country homeowners.

water cannon pump

The pump does not turn on:

- check the power cable going to the pump. Check the presence of voltage in the network.

- The power supply protection is triggered too often. It is necessary to check the network for short circuits and current leakage. Call a professional electrician.

- The pump control panel is not functioning. Call the service department or take the unit to the manufacturer’s warranty department.

The pump turns on, but does not pump water:

- the pump turns on but does not pump water. The check valve may be incorrectly installed or blocked.

- air lock in the pump. The dynamic level may have decreased. Lower the pump to a greater depth.

check the pressure in the accumulator

The pump turns on and off frequently:

- check the tightness of the accumulator, pipes, hoses, connections and pump

- check the range of recommended operating pressure in the accumulator

- a well pump installed with too high a capacity

The pump works, but the pressure is weak:

- The filter mesh is clogged.

- reduction in pump efficiency due to the ingress of large amounts of sand.

- severe wear of the pump mechanism.

- the pump consumes too much electricity

If the pump breaks

What to do if the pump fails?

- If the filter is clogged, it is necessary to disassemble the pump, clean or replace the strainer.

- The pump mechanism is jammed due to the ingress of solid particles. The pump must be cleaned, an additional filter must be installed to protect against solid particles, or the pump must be raised slightly, moving it away from the sand accumulation site at the bottom of the well.

steel mesh for filter

- increased energy consumption may be a consequence of increased friction between parts due to sand ingress.

- If the pump mechanisms are severely worn, it will require inspection and repair at a service center to replace individual components, or replace the entire pump.

How to prevent breakdown of pumping equipment?

Water lifting equipment for autonomous water supply contains complex mechanical and electronic components. In order for all equipment to work for a long time and without failures, it is necessary to comply with certain requirements, which the manufacturer usually indicates in the technical data sheet of the product.

Recommendations for high-quality operation of an autonomous water supply system:

- it is necessary to ground all equipment, ensure the pump is protected from power surges and other negative manifestations of the power supply.

- the pump must hang on a special steel cable, and not on an electrical supply cable or plastic pipe. If the pump comes off, complex and expensive work will be required to lift the equipment that has fallen into the well.

steel safety rope

- Inspect, disassemble and repair the pump, as well as other equipment, only when completely disconnected from the electrical network.

- protect the pump from dry running and overheating

- the maximum depth of lowering the pump is 1 m from the bottom of the well. Otherwise, the risk of sand getting into the pump mechanisms increases.

- Eliminate any possible routes for sand and other solid abrasives to enter the pump.

If all requirements for the operation of the Vodomet well pump and related equipment are met, the autonomous water supply system will serve you for a long time without failures.

Modifications of the Marina pumping station

There are several modifications of this equipment on the modern market. Each of these models is designed for use in specific conditions. Next, several installation options will be discussed in detail, based on which you can make the right choice when purchasing a station.

- Marina CAM models . They are made of stainless steel or cast iron. The weight of the installation can range from 12 to 29 kg. The power here also varies and can reach 1.5 kilowatts. The devices are distinguished by their ability to lift water from a depth of up to 8 m.

- The next model is APM . The developers equipped it with a cast iron body, power = 1.5 kilowatts, and weight is 27 kg. Such stations are characterized by high productivity, as a result of which they are much more expensive than other models.

- Another model is Marina KS . The equipment has a plastic case, which made it possible to create a compact model weighing only 14 kg. The installation helps provide water to an ordinary family of 3-4 people, and is also widely used for watering garden plots.

Advantages of the Marina pumping station

- high performance;

- relatively low cost combined with efficiency;

- high wear resistance and immunity to corrosion;

- light weight of most models;

- ease of operation of the equipment;

- easy pump power adjustment;

- energy saving;

- the presence of a check valve that prevents the occurrence of water hammer in the system.

It is noteworthy that Marina pumping stations practically do not require regular maintenance. Their working elements and the body itself are reliably protected from any mechanical damage.

In addition, the service life of such devices is significantly increased compared to the equipment of their closest competitors due to their increased strength. As you can see, purchasing a station is the most profitable decision you can make today.

The unit works, but does not pump water

If during operation the hydrophore turns on, but water does not flow from the tap, there may be several reasons for this. The choice of troubleshooting method depends on the cause of this situation.

If during operation the hydrophore turns on, but water does not flow from the tap, there may be several reasons for this. The choice of troubleshooting method depends on the cause of this situation. There may be several of them. To find the source of the problem, you need to check the following operating parameters:

- If the hydrophore does not pump water, evaluate the functionality and serviceability of the check valve. It is located on the pipeline inside the well or borehole. If this device is clogged with debris or sand, the valve will not open, and as a result the unit will not pump water.

- See if there is water in the section of pipeline running from the source to the pumping unit. Sometimes air collects there due to power outages or pump failure. The air pressure in this section will not allow the unit to pump water into the system. If this is the reason, then to eliminate them it is enough to pour water into this part of the pipeline through a special hole.

- A situation where the hydrophore turns on, but does not take in water, may arise due to the presence of a large amount of abrasive impurities in the liquid. Usually in this case you can notice a lot of wear between the impeller and the housing. Removing them may require expensive repairs. No matter which station you use, Marina or another brand, you may need to completely replace the pump or purchase a housing and impeller.

- If the unit turns on but does not pump water, the reason may lie in the lack of water in the well. To eliminate the cause, you can carefully immerse the supply pipeline or hose deeper into the well.

Operation of the Marina pumping station

The launch of this device should be carried out strictly according to the instructions that come with the sale of the product.

Any wrong step can lead to the station not working and you not being provided with water. The installation instructions will help you clearly fulfill all the conditions for further operation of the device. If you have never done such a thing and do not want to risk an expensive device, it is better to seek help from specialists.